Method for preparing bismuth telluride-based thermoelectric material

A thermoelectric material, bismuth telluride-based technology, applied in chemical instruments and methods, polycrystalline material growth, self-regional melting method, etc., can solve the problem of reducing material conductivity, increasing material oxidation, increasing material production cost and production cycle, etc. problems, to achieve the effect of reducing the probability of oxidation, shortening the cycle, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

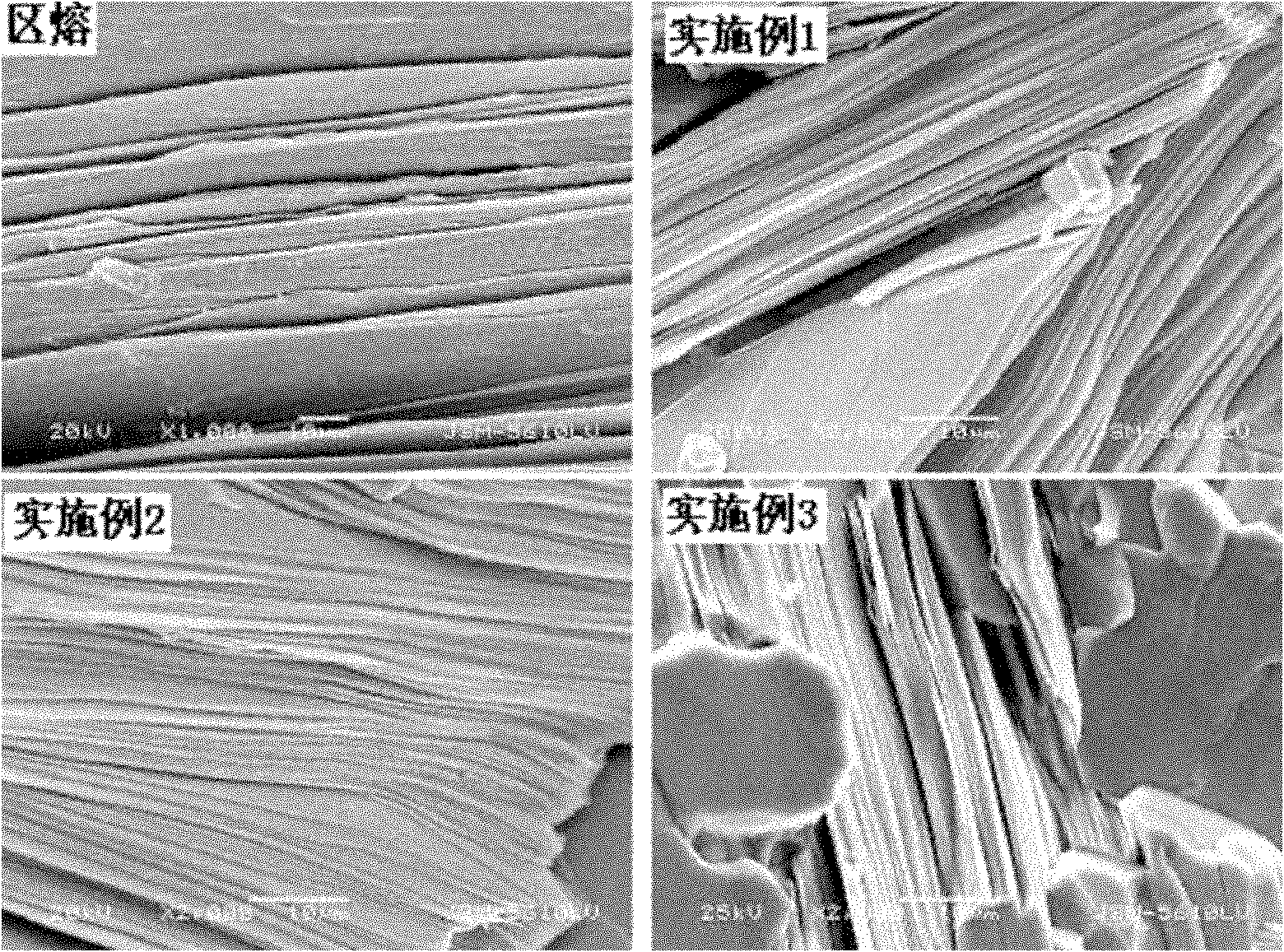

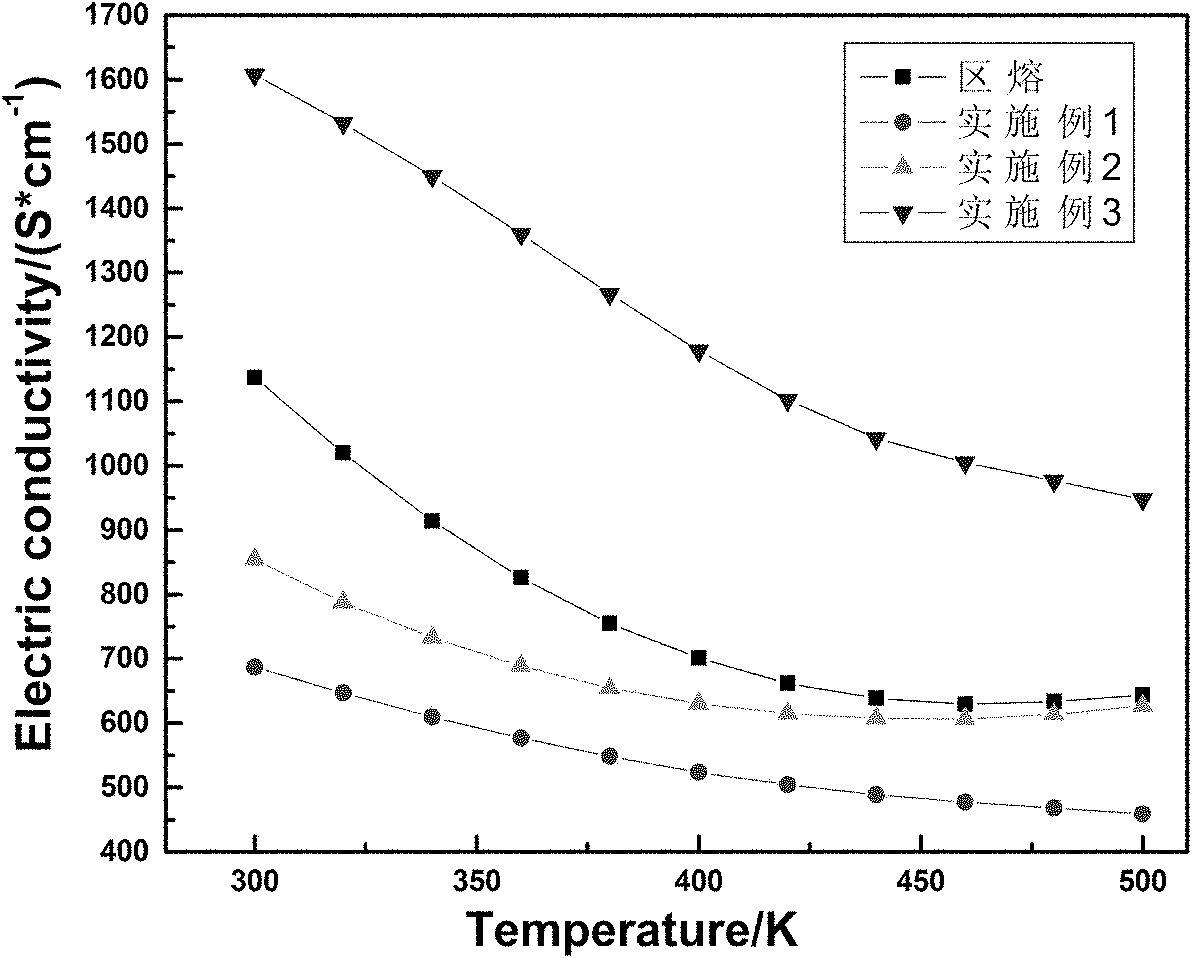

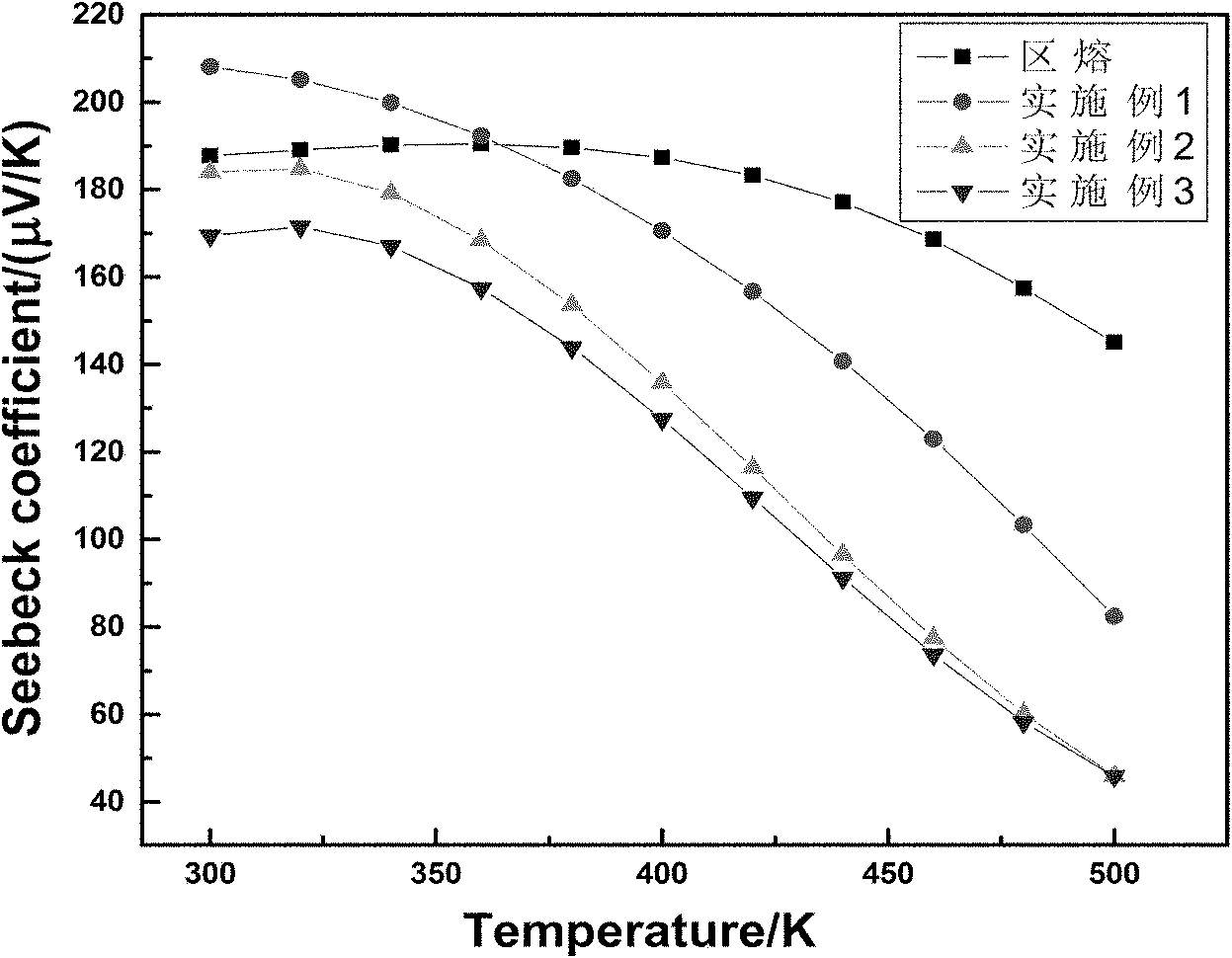

[0030] Example 1 (preparation of 350°C extrusion sample):

[0031] A preparation method for a bismuth telluride-based thermoelectric material, comprising the steps of:

[0032] 1) Prepare bismuth telluride-based thermoelectric material ingots (rod-shaped, zone-melted samples, and this preparation method is the prior art) by zone melting method. The diameter of the rod-shaped bismuth telluride-based thermoelectric material ingots is 30 mm. 50mm long, spare;

[0033] 2) Put the bismuth telluride-based thermoelectric material ingot with a length of 50mm and a diameter of 30mm and rod shape directly into the extrusion mold, and then put the ingot of the bismuth telluride-based thermoelectric material together with the extrusion mold into the hot extrusion furnace In vacuum (vacuum degree: 1.0Pa), hot extrusion is carried out to obtain bismuth telluride-based thermoelectric material (sample of Φ10mm×20mm); the hot extrusion conditions are: the temperature of hot extrusion is 350°C...

Embodiment 2

[0038] Embodiment 2 (preparation of 400 ℃ extrusion sample):

[0039] A preparation method for a bismuth telluride-based thermoelectric material, comprising the steps of:

[0040] 1) Prepare bismuth telluride-based thermoelectric material ingots (rod-shaped, zone-melted samples, and this preparation method is the prior art) by zone melting method. The diameter of the rod-shaped bismuth telluride-based thermoelectric material ingots is 30 mm. 50mm long, spare;

[0041] 2) Put the bismuth telluride-based thermoelectric material ingot with a length of 50mm and a diameter of 30mm and rod shape directly into the extrusion mold, and then put the ingot of the bismuth telluride-based thermoelectric material together with the extrusion mold into the hot extrusion furnace Hot extrusion was carried out under vacuum (vacuum degree of 1.0Pa) to obtain bismuth telluride-based thermoelectric materials (sample of Φ10mm×20mm); hot extrusion conditions were: hot extrusion temperature 400°C, he...

Embodiment 3

[0046] Embodiment 3 (preparation of 450 ℃ extrusion sample):

[0047] A preparation method for a bismuth telluride-based thermoelectric material, comprising the steps of:

[0048] 1) Prepare bismuth telluride-based thermoelectric material ingots (rod-shaped, zone-melted samples, and this preparation method is the prior art) by zone melting method as raw material, and the diameter of the rod-shaped bismuth telluride-based thermoelectric material ingots is 30mm , intercept 50mm long, spare;

[0049] 2) Put the bismuth telluride-based thermoelectric material ingot with a length of 50mm and a diameter of 30mm and rod shape directly into the extrusion mold, and then put the ingot of the bismuth telluride-based thermoelectric material together with the extrusion mold into the hot extrusion furnace Hot extrusion was carried out under an inert gas (argon) to obtain a bismuth telluride-based thermoelectric material (a sample of Φ10mm×20mm); the hot extrusion conditions were: the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com