Cadmium tellude preparation method

A technology of cadmium telluride and cadmium particles, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problems of cadmium powder easy oxidation, dangerous synthesis process, human injury, etc., to reduce the probability of oxidation, reduce production costs, and improve safety performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

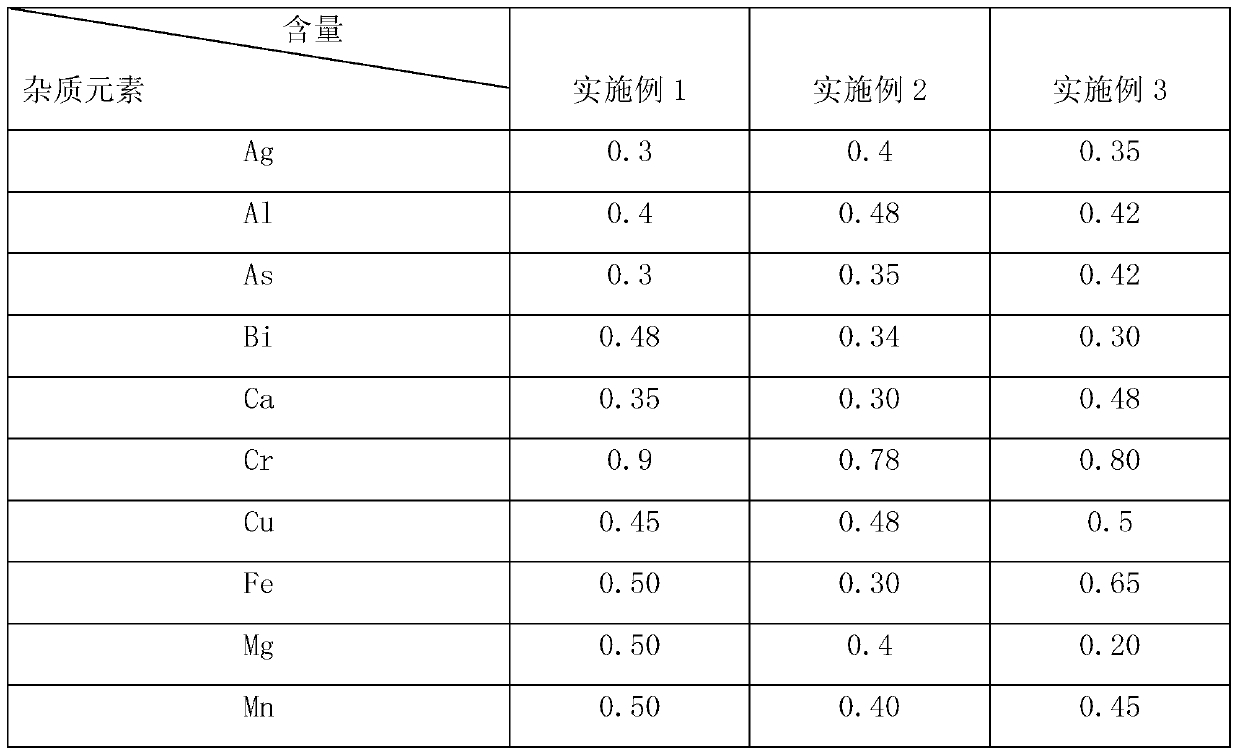

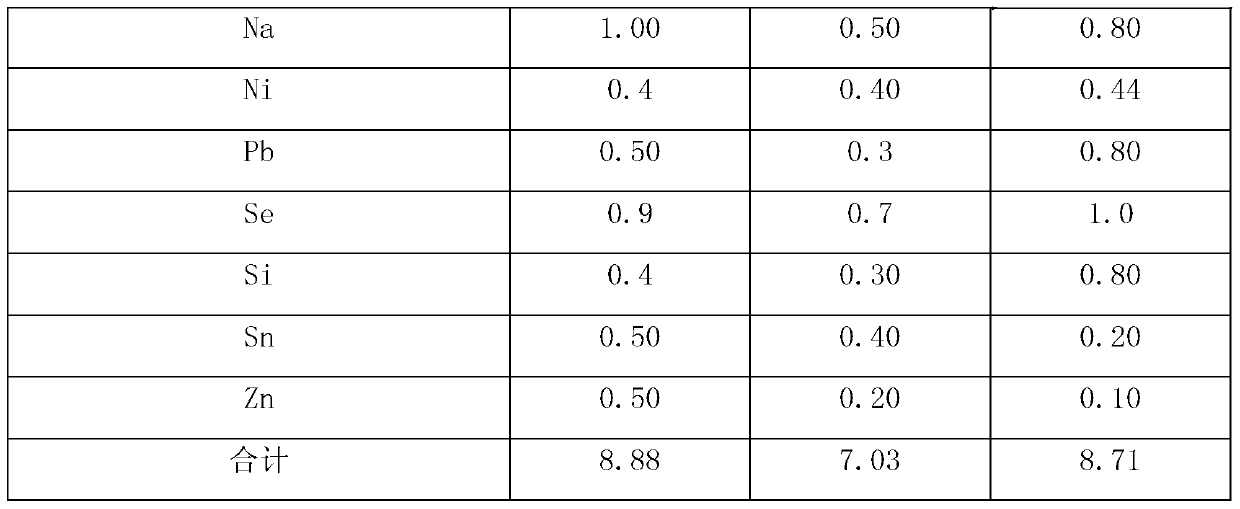

Embodiment 1

[0028] A: One synthesis step

[0029] Divide the cadmium particles with a size of 1mm5N and the tellurium particles with a size of 1mm5N into 5 parts and 5 parts respectively according to the molar ratio of 1:1;

[0030] Place 5N cadmium grains and 5N tellurium grains in the first graphite boat in sequence, the first portion of cadmium grains with relatively low melting point is placed at the bottom layer, and the first portion of tellurium grains with relatively high melting point is placed at the first On the cadmium grain, then place the second cadmium grain, the second tellurium grain, the third cadmium grain, the fourth tellurium grain, and so on, staggered layered charging; the first graphite boat is loaded before Carry out water quenching treatment;

[0031] Place the loaded first graphite boat in the first quartz tube, place the first graphite boat in the middle of the first quartz tube as much as possible;

[0032] Place the first quartz tube with the first graphite...

Embodiment 2

[0048] A: One synthesis step

[0049] Divide the cadmium particles with a size of 10mm5N and the tellurium particles with a size of 10mm5N into 12 parts and 12 parts respectively according to the molar ratio of 1:1;

[0050] Place 5N cadmium grains and 5N tellurium grains in the first graphite boat in sequence, the first portion of cadmium grains with relatively low melting point is placed at the bottom layer, and the first portion of tellurium grains with relatively high melting point is placed at the first On the cadmium grain, then place the second cadmium grain, the second tellurium grain, the third cadmium grain, the fourth tellurium grain, and so on, staggered layered charging; the first graphite boat is loaded before Carry out water quenching treatment;

[0051] Place the loaded first graphite boat in the first quartz tube, place the first graphite boat in the middle of the first quartz tube as much as possible;

[0052] Place the first quartz tube with the first grap...

Embodiment 3

[0068] A: One synthesis step

[0069] Divide the cadmium particles with a size of 5mm5N and the tellurium particles with a size of 7mm5N into 8 and 8 parts respectively according to the molar ratio of 1:1;

[0070] Place 5N cadmium grains and 5N tellurium grains in the first graphite boat in sequence, the first portion of cadmium grains with relatively low melting point is placed at the bottom layer, and the first portion of tellurium grains with relatively high melting point is placed at the first On the cadmium grain, then place the second cadmium grain, the second tellurium grain, the third cadmium grain, the fourth tellurium grain, and so on, staggered layered charging; the first graphite boat is loaded before Carry out water quenching treatment;

[0071] Place the loaded first graphite boat in the first quartz tube, place the first graphite boat in the middle of the first quartz tube as much as possible;

[0072] Place the first quartz tube with the first graphite boat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com