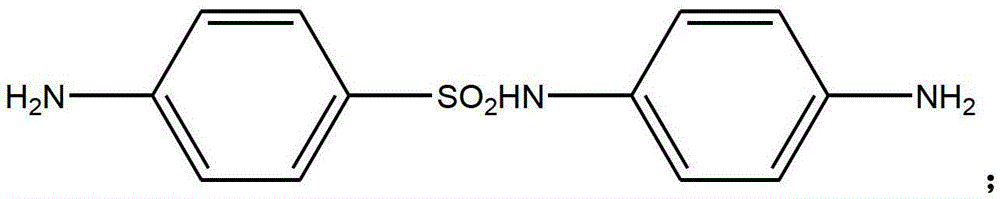

Preparation method of 4,4'-diaminobenzenesulphonamide

A technology of diaminobenzenesulfonyl anilide and acetanilide, which is applied in 4 fields, can solve problems such as immaturity, and achieve the effects of reducing content, avoiding the generation of carbon dioxide, and reducing product accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

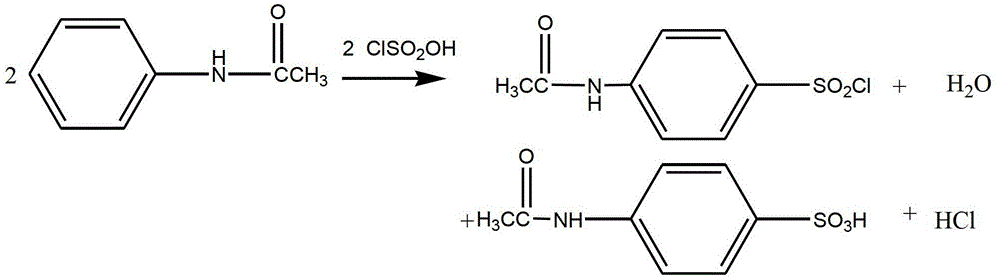

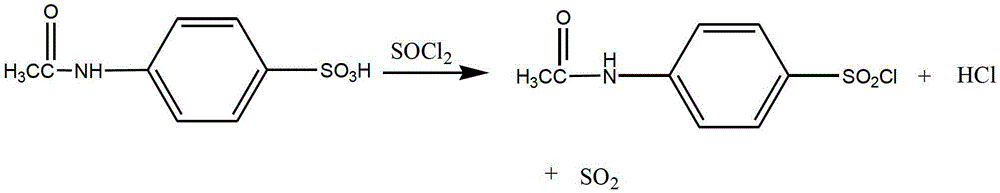

[0059] Add 2,500 kg of chlorosulfonic acid to a 5,000-liter enamel reaction kettle, and slowly add 900 kg of acetanilide, during which the temperature is controlled at 35°C. After the addition, the temperature is raised to 45°C for 3 hours, and then 600 kg of thionyl chloride is slowly added. After the addition, react at 40-45°C for 2 hours. After the end of the reaction, slowly add the sulfonated material to 5000 kg of ice-water mixture, during which the temperature is controlled not to be higher than 20°C. , The resulting filter cake was added to 4000 kg of water evenly and then used.

[0060] Add 750 kg of p-phenylenediamine to 6000 liters of water and heat up to 60°C to dissolve. After dissolving, use ice cubes and open frozen brine to cool down to 15°C. Slowly add the ice precipitated material, and adjust the pH to 8.0 with 15% sodium hydroxide solution during the process. -8.5, keep the temperature at 15-20°C, add the condensation material, after 3 hours of reaction, tes...

Embodiment 2

[0065] Add 3000 kg of chlorosulfonic acid to a 5000 liter enamel reaction kettle, then slowly add 900 kg of acetanilide, open the jacket cooling water during the adding process to control the temperature in the kettle not to exceed 40 ° C, after adding chlorosulfonic acid, adjust the temperature at 50 Incubate at -55°C for 3 hours, then slowly add 700 kg of thionyl chloride dropwise, control the temperature at 55-60°C during the addition, keep the reaction for 3 hours after adding, cool down to 25°C to prepare for ice crystallization.

[0066] Put 4000 kg of water in the dilution tank, open the coil tube to cool the frozen brine to 0 °C, then add 1000 kg of ice, slowly add the sulfonated material, control the temperature in the tank not higher than 10 °C, and beat the sulfonated material after adding the sulfonated material Into the filter press filter. The filter cake is ready for condensation.

[0067] Put 8,000 kg of water in the condensation kettle, raise the temperature ...

Embodiment 3

[0072] Except that the chlorosulfonic acid consumption of sulfonation becomes 3000 kilograms by 2500 kilograms, sulfur oxychloride becomes 500 kilograms by 600 kilograms, and all the other are identical with embodiment 1 except that neutralization reductive agent changes hydrosulfite into. The product yield is 92%, the content is 98.2%, the purity is 98.7%, and the product is light in color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com