Making method for cherry fruit wine

A cherry and fruit wine technology, applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of low acidity, thin taste, and easy oxidation of cherry fruit, and improve the richness of fruit aroma and fineness, bright and attractive color, and the effect of preventing excessive oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

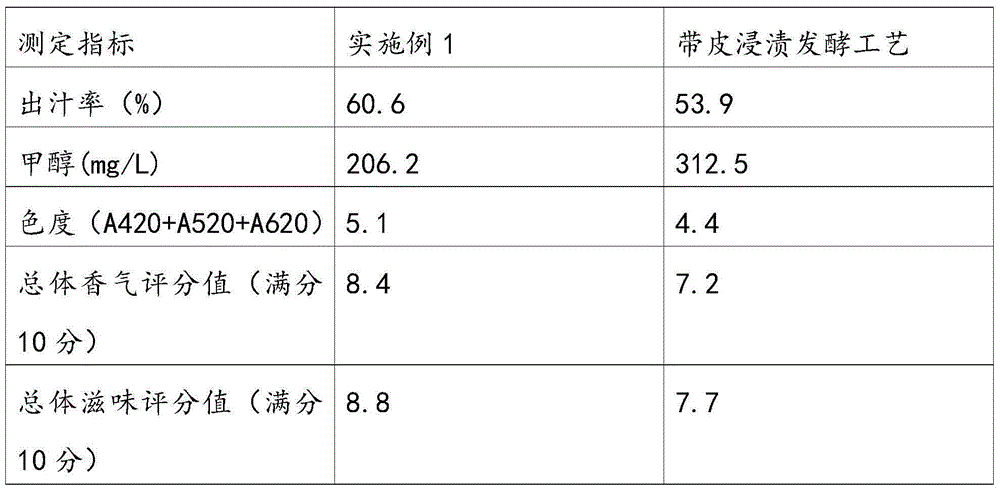

Embodiment 1

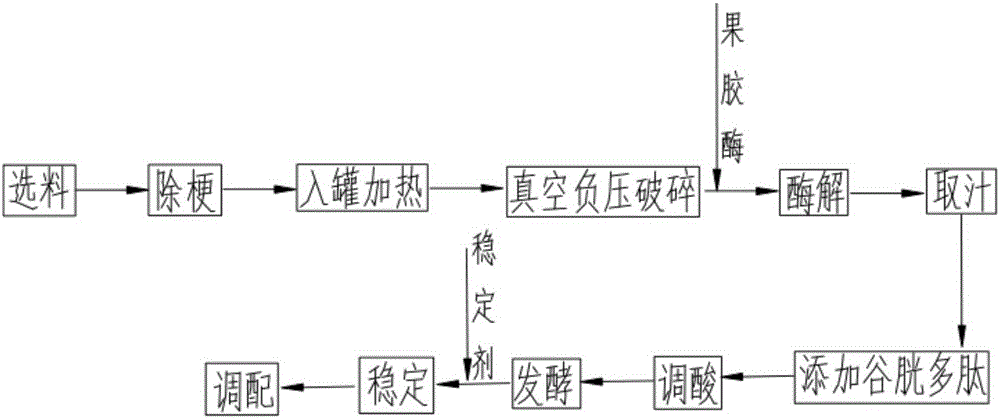

[0030] A brewing method of cherry wine, comprising the steps of:

[0031] 1) Material selection: choose the red light with a clean and tidy appearance as the raw material. After testing, the sugar content of the fruit is 155g / L, and the acidity is 6.5g / L;

[0032] 2) Destemming: remove the fruit stems of the cherries flexibly, keeping the fruit grains intact and undamaged;

[0033] 3) Heating: Place the fruit grains obtained in step 2) into a fermenter, and under the protection of nitrogen, heat up to 90 degrees within 2 minutes, while stirring, and keep for 5 minutes;

[0034] 4) Fragmentation: pump the cherry mash obtained in step 3) into a vacuum tank, keep the pressure at 50 Pa, the mash expands rapidly after entering the vacuum tank, and the pericarp cell tissue ruptures, keep for 30 minutes and after the pericarp expands, the mash Cool to 35 degrees;

[0035] 5) Enzymolysis: Add 30 mg / L of compound pectinase to the mash obtained in step 4), the enzymolysis process is c...

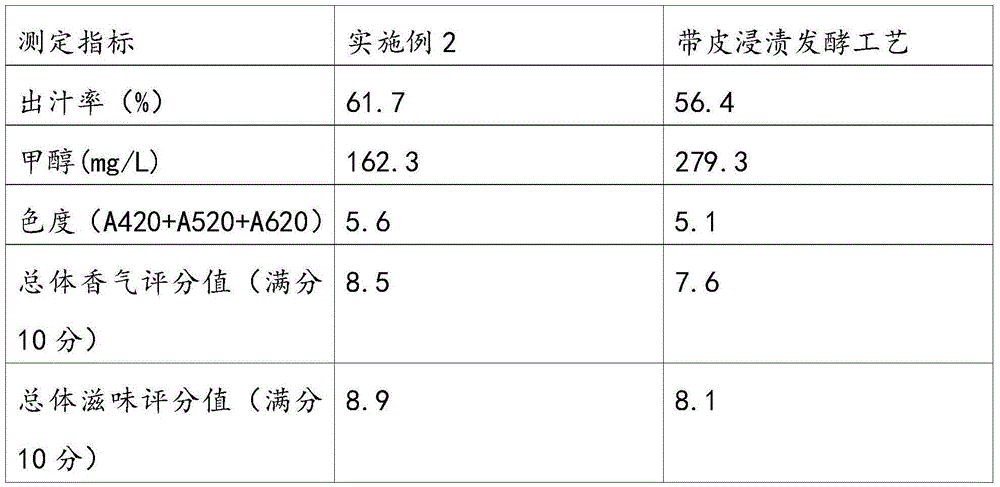

Embodiment 2

[0045] A brewing method of cherry wine, comprising the steps of:

[0046] 1) Material selection: choose Van, whose fruit is ripe and not rotted, and its appearance is clean and tidy. After testing, the sugar content of the fruit is 200g / L, and the acidity is 5.5g / L;

[0047] 2) Destemming: remove the fruit stems of the cherries flexibly, keeping the fruit grains intact and undamaged;

[0048] 3) Heating: put the fruit grains obtained in step 2) into a fermenter, and raise the temperature to 80 degrees within 1 minute under the protection of carbon dioxide, and stir at the same time for 5 minutes;

[0049] 4) Fragmentation: pump the cherry mash obtained in step 3) into a vacuum tank, keep the pressure at 100 Pa, the mash expands rapidly after entering the vacuum tank, and the pericarp cell tissue ruptures, keep for 30 minutes and after the pericarp expands, the mash Cool to 35 degrees;

[0050] 5) Enzymolysis: Add 40 mg / L of compound pectinase to the mash obtained in step 4),...

Embodiment 3

[0060] A brewing method of cherry wine, comprising the steps of:

[0061] 1) Material selection: choose Lapins (Lapins) whose fruit is ripe and not rotted and has a clean appearance as a raw material. After testing, the sugar content of the fruit is 152g / L, and the acidity is 7.0g / L;

[0062] 2) Destemming: remove the fruit stems of the cherries flexibly, keeping the fruit grains intact and undamaged;

[0063] 3) Heating: Place the fruit grains obtained in step 2) into a fermenter, heat up to 95 degrees within 3 minutes under the protection of helium, and keep stirring for 5 minutes;

[0064] 4) Fragmentation: pump the cherry mash obtained in step 3) into a vacuum tank, keep the pressure at 10Pa, the mash expands rapidly after entering the vacuum tank, and the pericarp cell tissue ruptures, keep for 30min and after the expansion of the pericarp is completed, the mash Cool to 40 degrees;

[0065] 5) Enzymolysis: Add 20 mg / L of compound pectinase to the mash obtained in step 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com