Isothermal conversion device, and syngas complete-conversion reaction system comprising same

A technology of isothermal shift and shift reaction, applied in the field of coal chemical industry, can solve the problems of high temperature of shift reactor, low catalyst efficiency, long process route, etc., and achieve the effect of reducing system resistance, improving service life and activity, and shortening process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

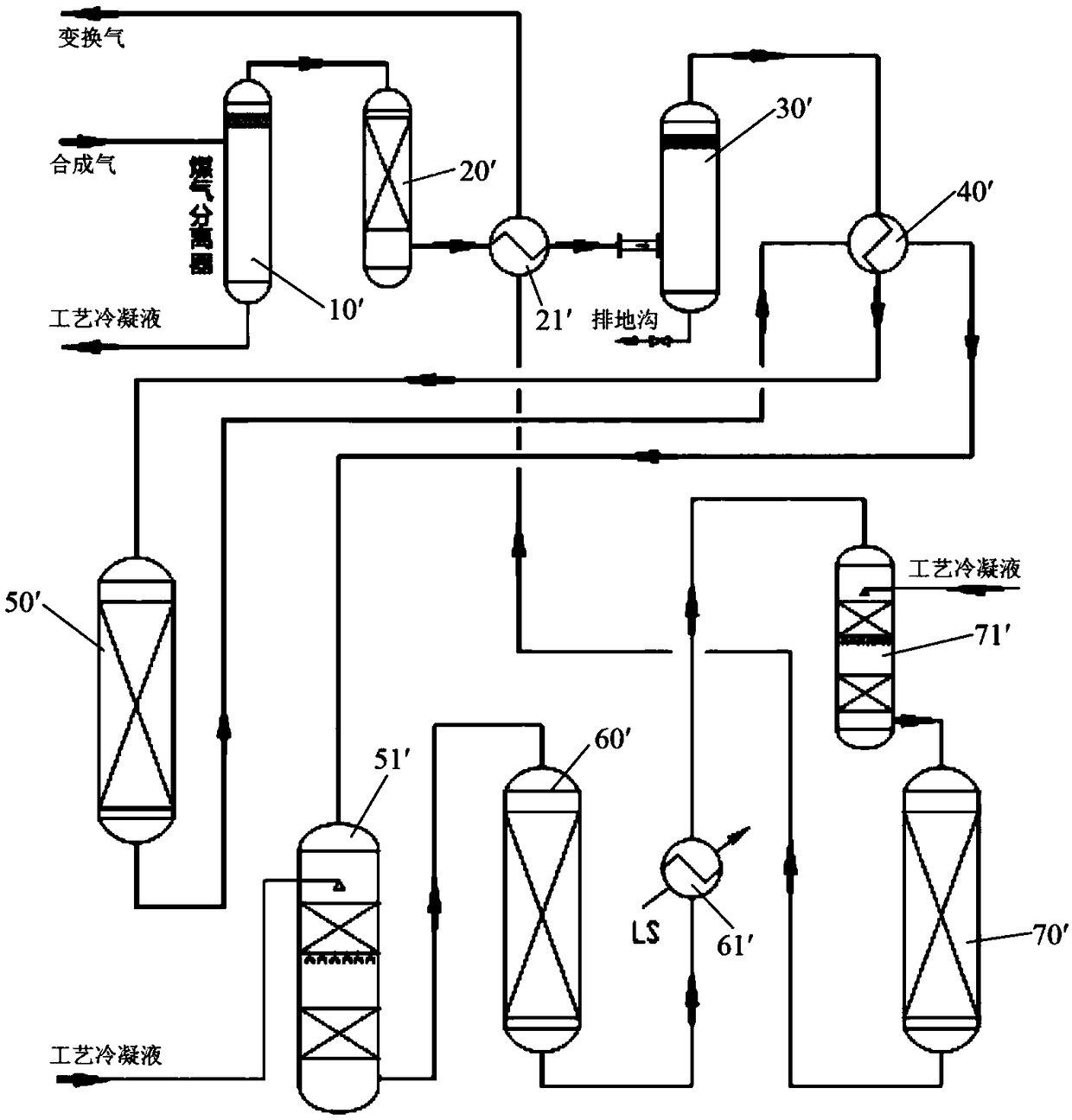

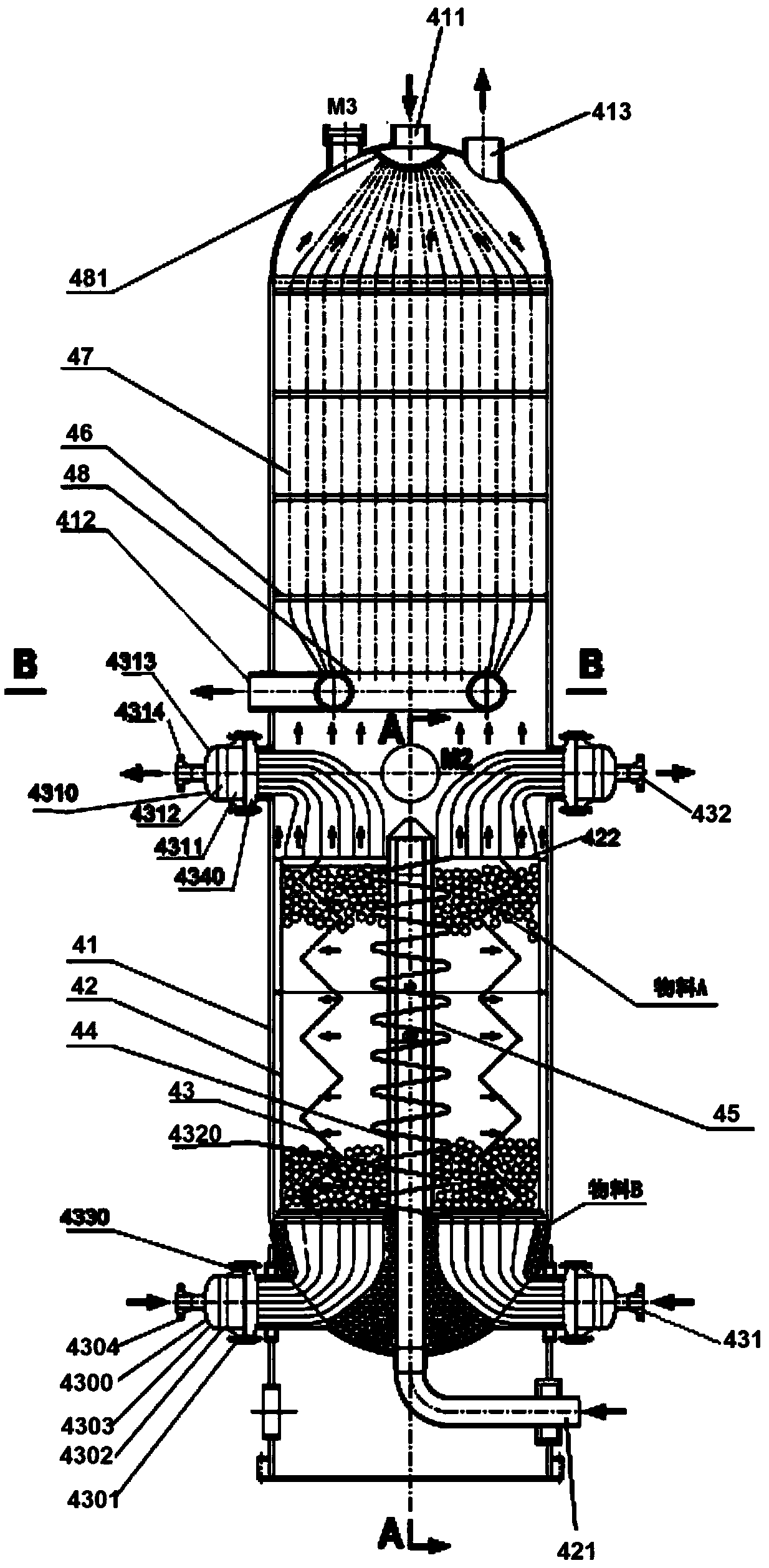

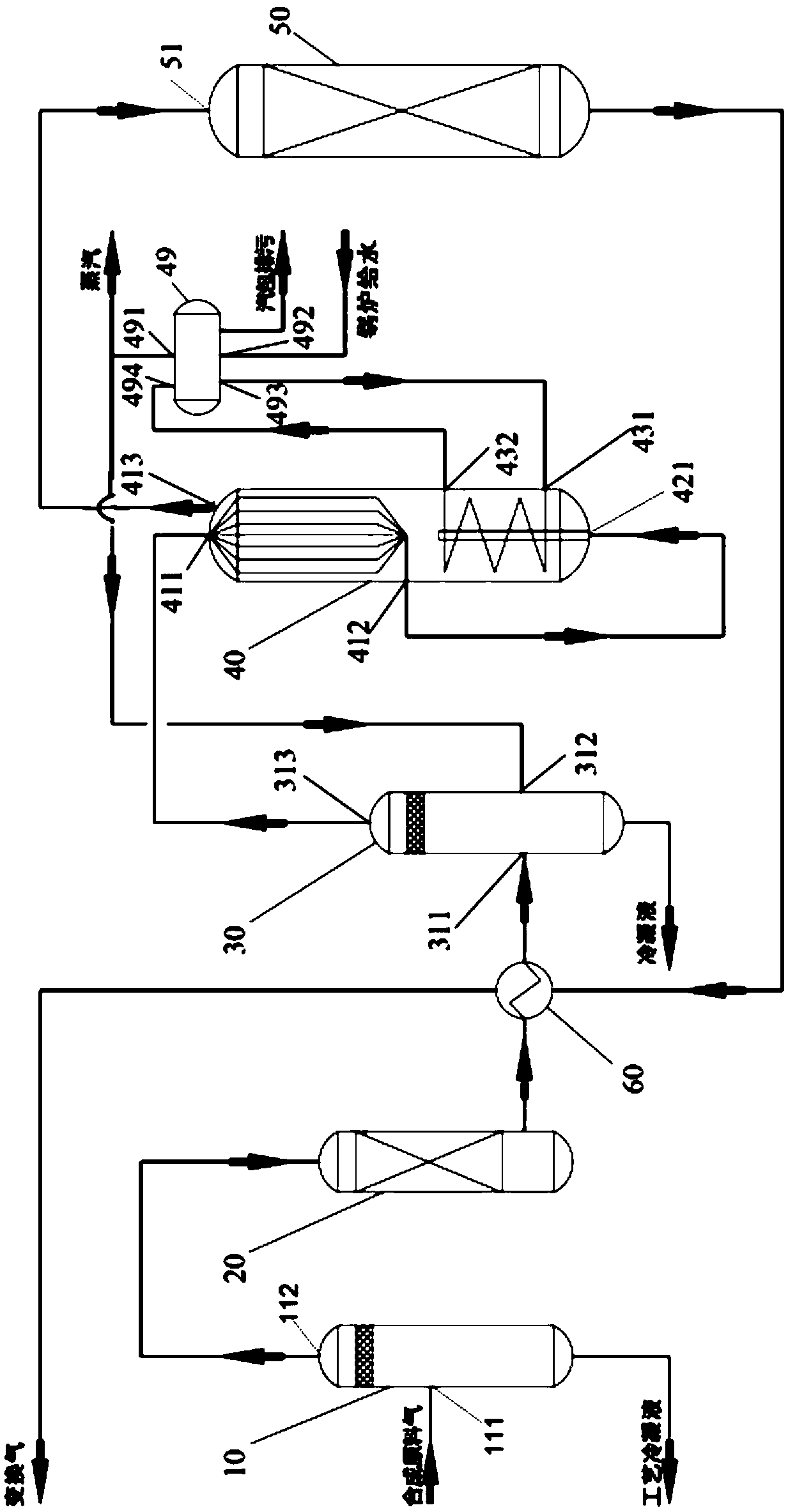

[0035] As described in the background art, the existing syngas shift device has the problems of long process route, large system resistance, large floor area, high temperature of the shift reactor, and low catalyst efficiency. In order to solve the above technical problems, the application provides an isothermal conversion device, such as figure 2 As shown, the isothermal conversion device includes: a housing 41 , a gas collection device 42 and at least one first heat exchange unit 43 . The first heat exchange unit 43 is located inside the gas collection device 42. The gas collection device 42 is provided with an inlet 421 for the gas to be converted and an outlet for the converted gas (the outlet for the converted gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com