Nano-silicon composite negative electrode material and manufacturing method thereof

A negative electrode material, nano-silicon technology, applied in negative electrodes, nanotechnology, nanotechnology, etc., can solve the problems of battery capacity attenuation, affecting battery electrochemical performance, battery energy density reduction, etc., to inhibit volume expansion and contraction, improve Cycle and rate performance, the effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

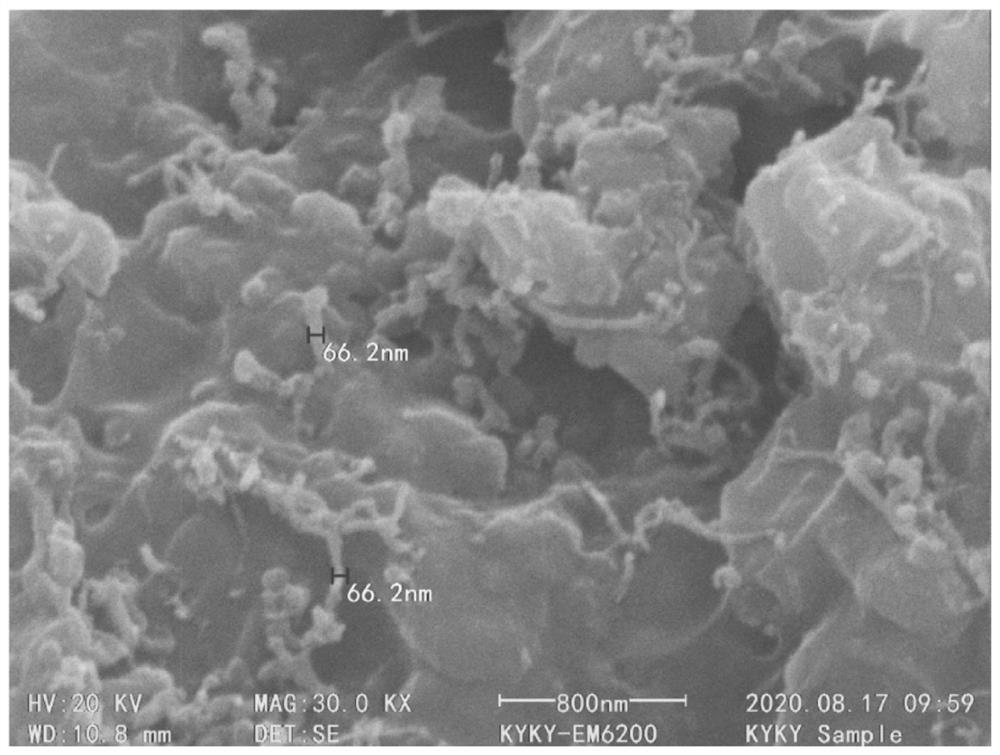

[0053] Take 200 g of N-methylpyrrolidone, add 45 g of phenolic resin, 37.5 g of butyl titanate, 12 g of carboxymethyl cellulose, and 150 g of nano-silica powder. The primary particle size of the silicon powder body is 110 nm. Ф5 zirconia ball stirring mill wet grinding for 10 minutes, vacuum rotary drying, add 30 grams of ferrocene, Ф10 vibrating ball mill dry vibration grinding for 15 minutes. Then put the powder into a 310S stainless steel airtight container, and seal it strictly with a brass sealing ring after vacuuming. Put it in a muffle furnace, heat up from room temperature to 600°C for 3 hours, keep at 600°C for 36 hours, then cool down to 300°C with the furnace, take it out, pour water and cool it down to room temperature rapidly. Open the sealing cap and take out the composite material sample. The scanning electron micrograph of the in-situ growth carbon nanotube / multi-coated nano-silicon composite negative electrode material prepared in embodiment 1 is as follows ...

Embodiment 2

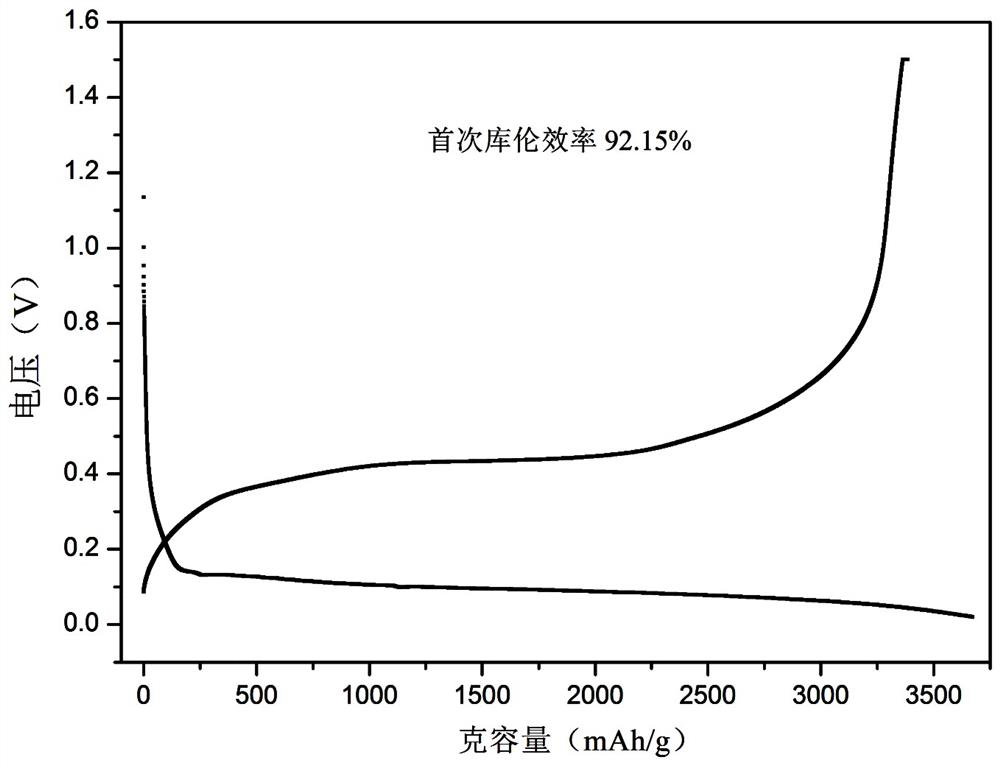

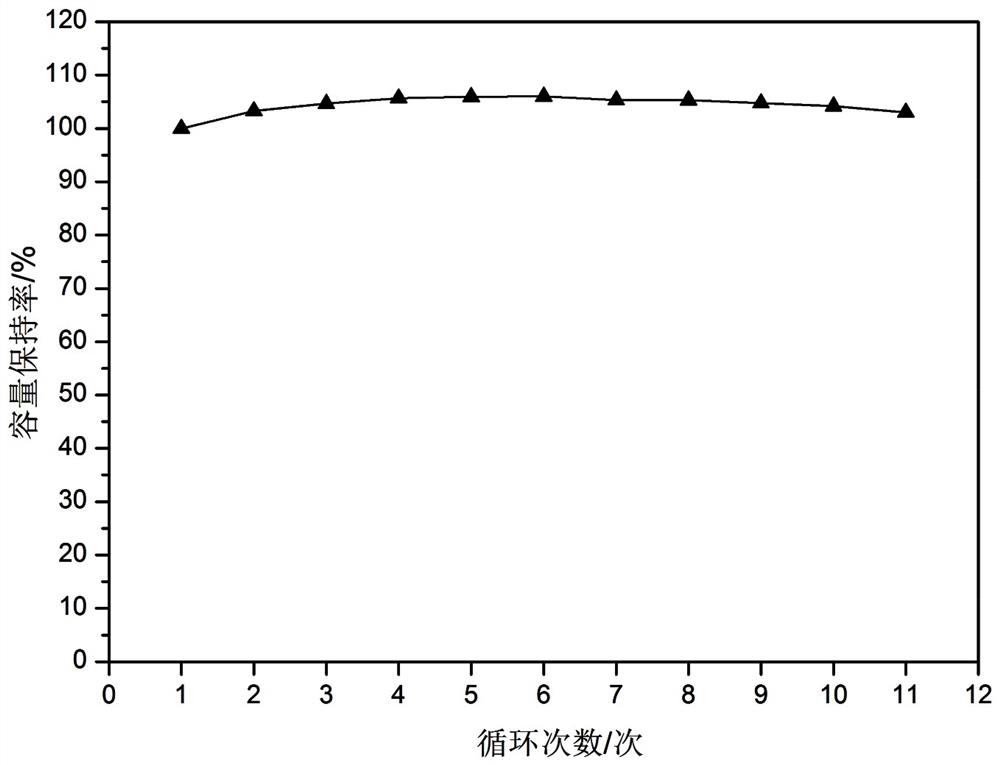

[0056] Take 300g of cyclohexane, add 30g of phenolic resin, 30g of propyl titanate, 10g of starch, 150g of nano-silicon powder, wet grinding with Ф5 zirconia ball stirring mill for 10 minutes, vacuum rotary drying, add ferrocene 25 grams, Ф10 vibrating ball mill dry vibration grinding for 15 minutes. Then put the powder into a 310S stainless steel airtight container, and seal it strictly with a brass sealing ring after vacuuming. Put it in a muffle furnace, heat up from room temperature to 650°C for 3 hours, keep at 650°C for 30 hours, then cool down to 300°C with the furnace, take it out, pour water and cool it down to room temperature rapidly. Open the sealing cap and take out the composite material sample. Take 1.7 grams of conductive carbon black SuperP, add 40 grams of N-methylpyrrolidone, grind, add 15 grams of self-made polyamic acid binder, and grind. Add 15 grams of the silicon-based composite powder material prepared above, stir evenly, and obtain a slurry with a v...

Embodiment 3

[0058] Take 250g of xylene, add 25g of phenolic resin, 45g of butyl zirconate, 15g of glucose, 150g of nano-silicon powder, wet grinding with Ф5 zirconia ball stirring mill for 10 minutes, vacuum rotary drying, and then add 20g of ferrocene , Ф10 vibration ball mill dry vibration grinding for 15 minutes. Then put the powder into a 310S stainless steel airtight container, and seal it strictly with a brass sealing ring after vacuuming. Put it in a muffle furnace, heat up from room temperature to 700°C for 3 hours, keep it at 700°C for 25 hours, then cool to 300°C with the furnace, take it out, pour water and cool it down to room temperature rapidly. Open the sealing cap and take out the composite material sample. Take 1.8 grams of conductive carbon black SuperP, add 40 grams of N-methylpyrrolidone, grind, add 15 grams of self-made polyamic acid binder, and grind. Add 15 grams of the silicon-based composite powder material prepared above, stir evenly, and obtain a slurry with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com