Preparation method of silicon composite anode material provided with gradient change coating layer on surface

A gradient change, negative electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as capacity fading, poor solvent compatibility, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Weigh magnesium powder and mesoporous silica according to the molar ratio Mg:Si=2:1, and perform ball milling and mixing treatment in a ball mill. The obtained precursor is placed in an atmosphere protection furnace at 650 degrees for 5 hours. The atmosphere condition is an argon-hydrogen mixed gas containing 5% hydrogen by volume, and the heating rate is 2°C / min.

[0020] 2) The obtained powder material was added to 1M hydrochloric acid solution and stirred for 10 hours, washed repeatedly with deionized water and ethanol, and then vacuum-dried at 80 degrees for 10 hours.

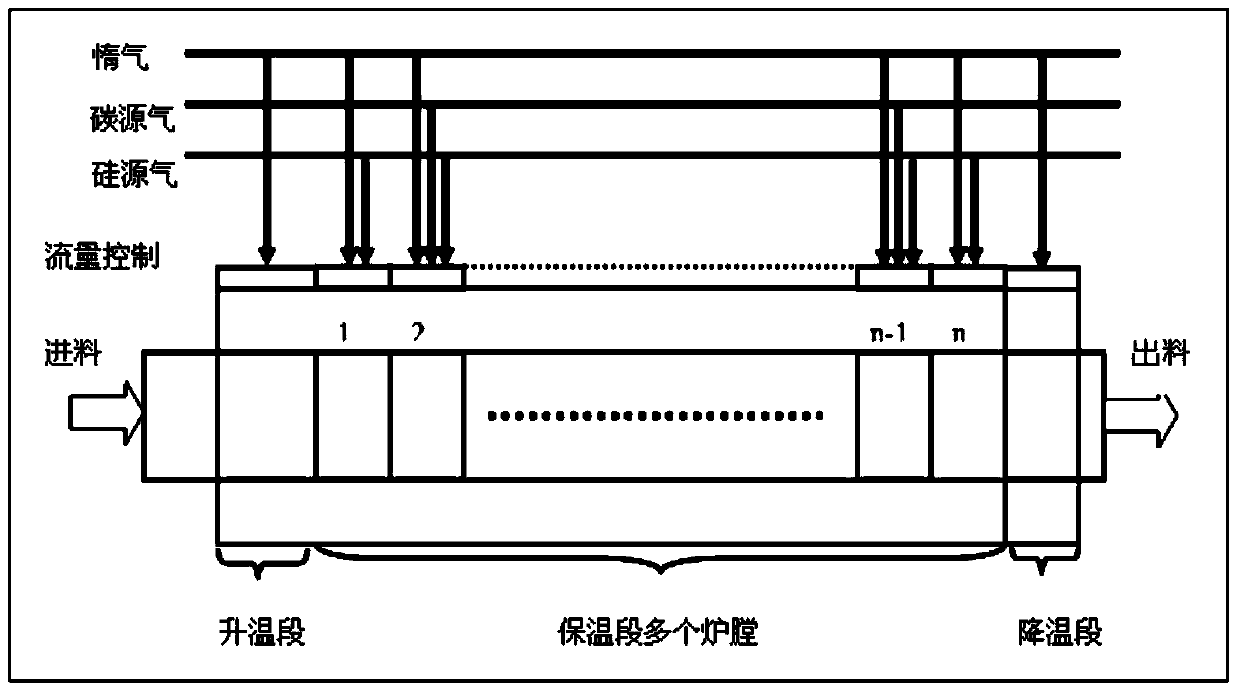

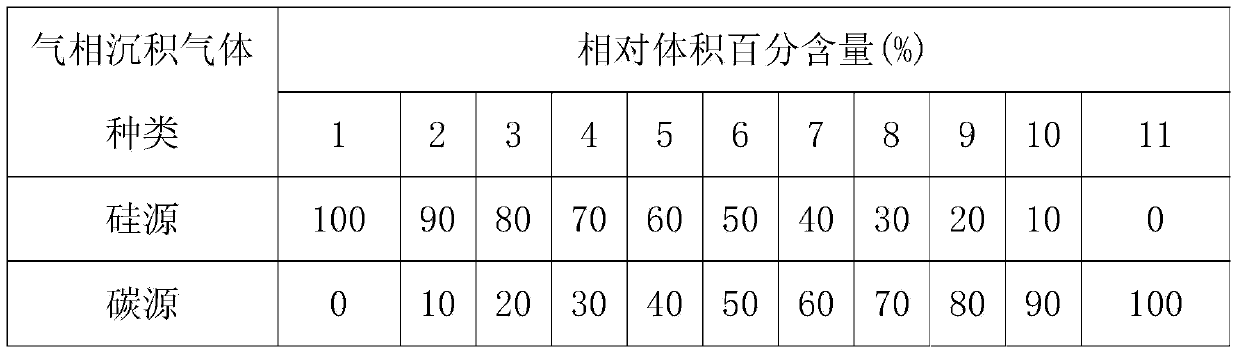

[0021] 3) The powder obtained in step 2) is placed in a multi-stage vapor deposition reaction furnace for vapor deposition coating treatment. Such as figure 1 As shown, the holding section of the multi-stage vapor deposition reaction furnace has 11 independently controllable furnaces, and the atmosphere condition is a mixture of nitrogen, monosilane and methane. Monosilane and methane are vapor ...

Embodiment 2

[0025] 1) Weigh magnesium powder and mesoporous silica according to the molar ratio Mg:Si=3:1, and perform ball milling and mixing treatment in a ball mill. The obtained precursor is placed in an atmosphere protection furnace at 700 degrees for 4 hours. The atmosphere condition is an argon-hydrogen mixed gas containing 5% hydrogen by volume, and the heating rate is 6°C / min.

[0026] 2) The obtained powder material was added to 1M hydrochloric acid solution and stirred for 10 hours, washed repeatedly with deionized water and ethanol, and then vacuum-dried at 80 degrees for 10 hours.

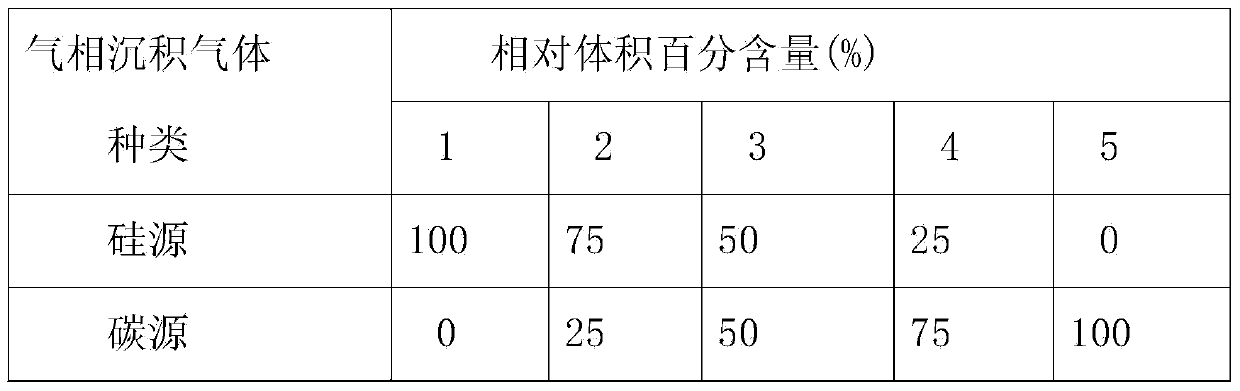

[0027] 3) The powder obtained in step 2) is placed in a multi-stage vapor deposition reaction furnace for vapor deposition coating treatment. The holding section of the multi-stage vapor deposition reaction furnace has 5 independently controllable furnaces, and the atmosphere condition is a mixed gas of argon, disilane and ethane. Disilane and ethane are vapor deposition gases, and their total vo...

Embodiment 3

[0031] 1) Weigh magnesium powder and mesoporous silica according to the molar ratio Mg:Si=4:1, and perform ball milling and mixing treatment in a ball mill. The obtained precursor is placed in an atmosphere protection furnace at 750 degrees for 3 hours. The atmosphere condition is an argon-hydrogen mixed gas containing 5% hydrogen by volume, and the heating rate is 8°C / min.

[0032] 2) The obtained powder material was added to 1M hydrochloric acid solution and stirred for 10 hours, washed repeatedly with deionized water and ethanol, and then vacuum-dried at 80 degrees for 10 hours.

[0033] 3) The powder obtained in step 2) is placed in a multi-stage vapor deposition reaction furnace for vapor deposition coating treatment. The holding section of the multi-stage vapor deposition reaction furnace has three independently controllable furnaces, and the atmosphere condition is a mixed gas of helium, silicon tetrafluoride and acetylene. Silicon tetrafluoride and acetylene are vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com