Preparation method of silicon composite negative electrode material with gradient coating layer on the surface

A gradient change, negative electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as poor solvent compatibility, potential safety hazards, and no tight coating yet found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Weighing magnesium powder and mesoporous silica according to the molar ratio Mg:Si=2:1, performing ball milling and mixing treatment in a ball mill, and placing the obtained precursor in an atmosphere protection furnace at 650 degrees for heat preservation for 5 hours, The atmosphere condition is an argon-hydrogen mixed gas containing 5% hydrogen by volume, and the heating rate is 2° C. / min.

[0019] 2) The obtained powder material was added into 1M hydrochloric acid solution and stirred for 10 hours, washed repeatedly with deionized water and ethanol, and then vacuum-dried at 80 degrees for 10 hours.

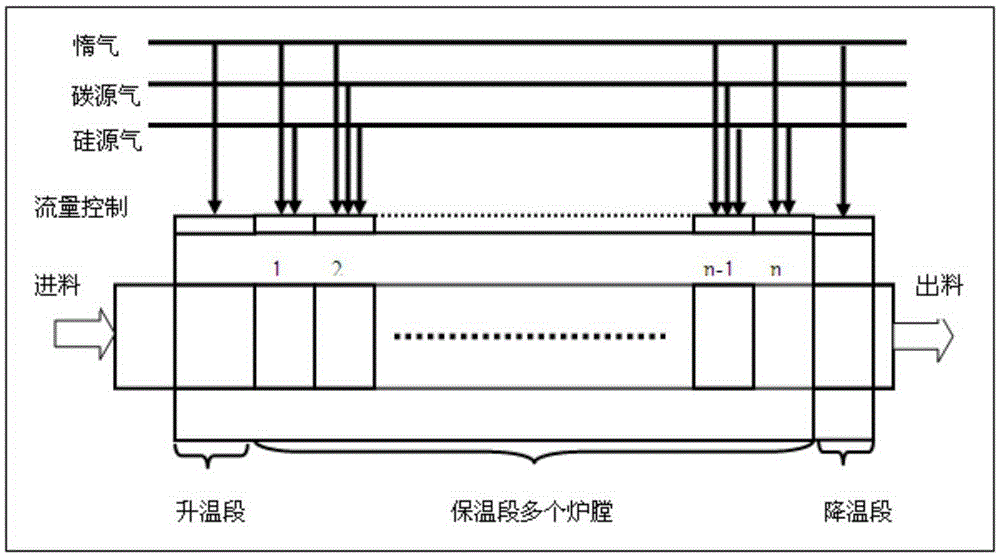

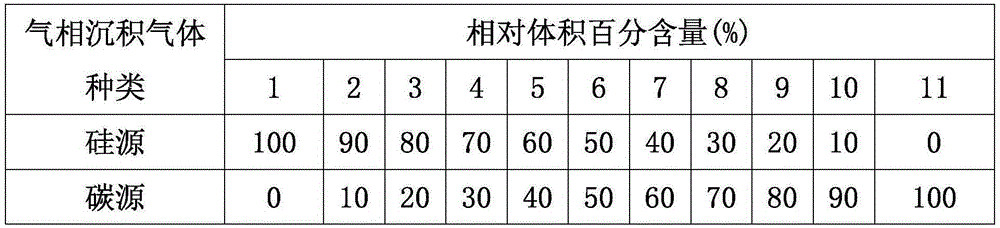

[0020] 3) The powder obtained in step 2) is placed in a multi-stage vapor deposition reaction furnace for vapor deposition coating treatment. like figure 1 As shown, the holding section of the multi-stage vapor deposition reaction furnace has 11 independently controllable furnaces, and the atmosphere condition is a mixed gas of nitrogen, monosilane, and methane. Mon...

Embodiment 2

[0024] 1) Weigh magnesium powder and mesoporous silica according to the molar ratio Mg:Si=3:1, and perform ball milling and mixing treatment in a ball mill. The obtained precursor is placed in an atmosphere protection furnace at 700 degrees for heat preservation for 4 hours, The atmosphere condition is an argon-hydrogen mixed gas containing 5% hydrogen by volume, and the heating rate is 6° C. / min.

[0025] 2) The obtained powder material was added into 1M hydrochloric acid solution and stirred for 10 hours, washed repeatedly with deionized water and ethanol, and then vacuum-dried at 80 degrees for 10 hours.

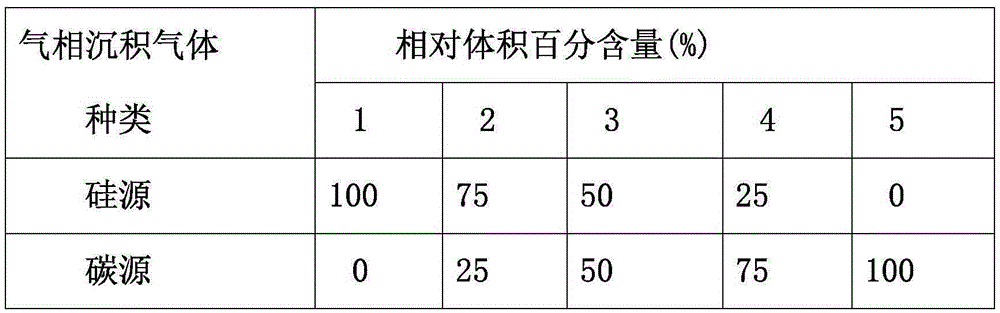

[0026] 3) The powder obtained in step 2) is placed in a multi-stage vapor deposition reaction furnace for vapor deposition coating treatment. The insulation section of the multi-stage vapor deposition reaction furnace has 5 independently controllable furnaces, and the atmosphere condition is a mixture of argon, disilane and ethane. Disilane and ethane are vapor depositio...

Embodiment 3

[0030] 1) Weigh magnesium powder and mesoporous silica according to the molar ratio of Mg:Si=4:1, and perform ball milling and mixing treatment in a ball mill. The obtained precursor is placed in an atmosphere protection furnace at 750 degrees for heat preservation for 3 hours, The atmosphere condition is an argon-hydrogen mixed gas containing 5% hydrogen by volume, and the heating rate is 8°C / min.

[0031] 2) The obtained powder material was added into 1M hydrochloric acid solution and stirred for 10 hours, washed repeatedly with deionized water and ethanol, and then vacuum-dried at 80 degrees for 10 hours.

[0032] 3) The powder obtained in step 2) is placed in a multi-stage vapor deposition reaction furnace for vapor deposition coating treatment. The insulation section of the multi-stage vapor deposition reaction furnace has three independently controllable furnaces, and the atmosphere condition is a mixed gas of helium, silicon tetrafluoride, and acetylene. Silicon tetraf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com