Simultaneous nitrogen blowing extraction device and essential oil fidelity extraction method

An extraction device and nitrogen blowing technology, applied in the directions of essential oil/spice, liquid solution solvent extraction, and fat generation, can solve the problems of large difference in aroma style of tea essential oil and reduced fidelity effect, and reduce high temperature and moisture. effect, avoid aroma distortion, and improve extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

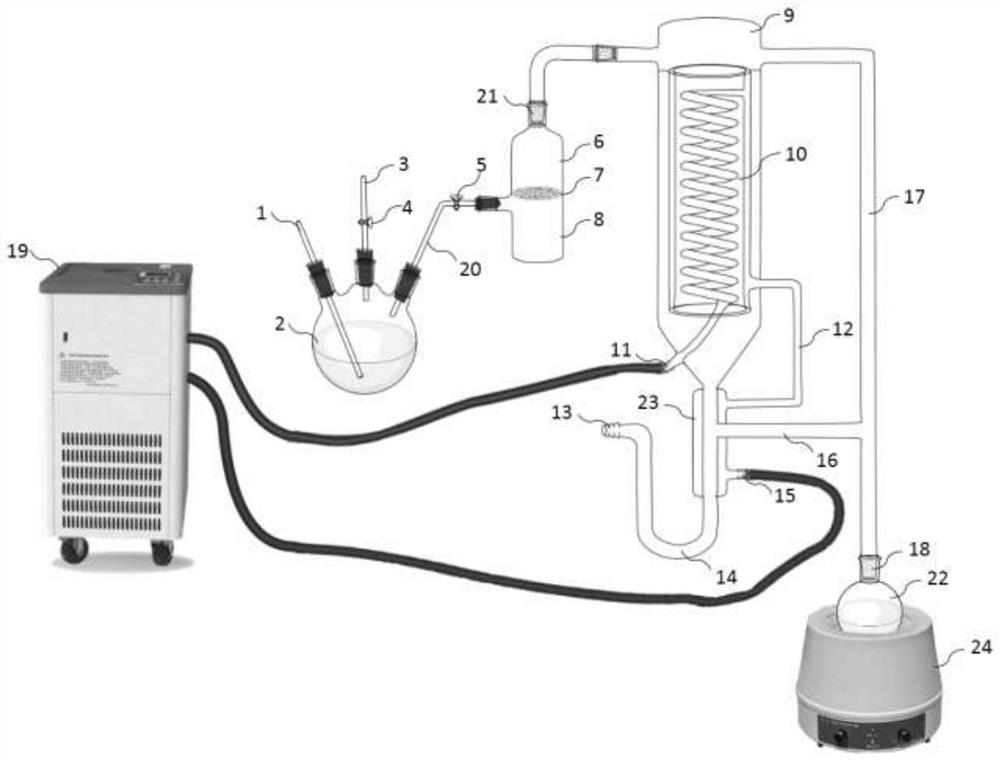

[0056] Embodiment 1, a kind of simultaneous nitrogen blowing extraction device, as figure 1 As shown, it includes a safety bottle 2, a sample placement chamber, a low-temperature condensation circulation pump 19, and an extraction chamber 9; The valve 5 and the safety conduit 3 are provided with a safety gas valve 4, and the nitrogen interface conduit 1, the safety conduit 3, and the nitrogen conduit 20 are all connected to the safety bottle 2 through their own corks. The safety air valve 4 is used to prevent possible bursting due to excessive pressure in the device.

[0057] A condenser 10 with a condenser tube is located in the extraction chamber 9 .

[0058] The sample placement bin is provided with a porous partition 7, thereby separating the sample placement bin into a solid sample placement bin 6 above the porous partition 7 and a liquid sample placement bin 8 below the porous partition 7; the porous partition 7 The aperture is set to ≤ 3mm, generally set to 1 ~ 2.5mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com