Electrolyte applicable to silicon carbon negative and lithium ion battery comprising electrolyte

An electrolyte and negative electrode technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of SEI film instability, battery capacity decay, SEI damage, etc., to inhibit reduction and decomposition, and improve discharge capacity. , the effect of reducing the interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

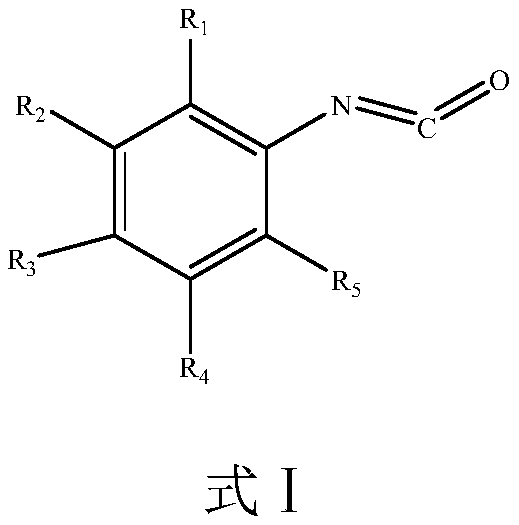

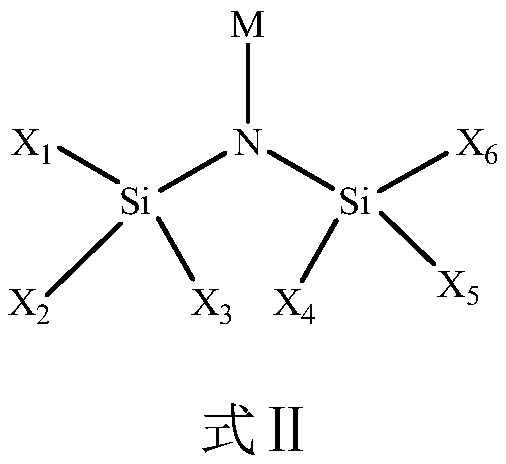

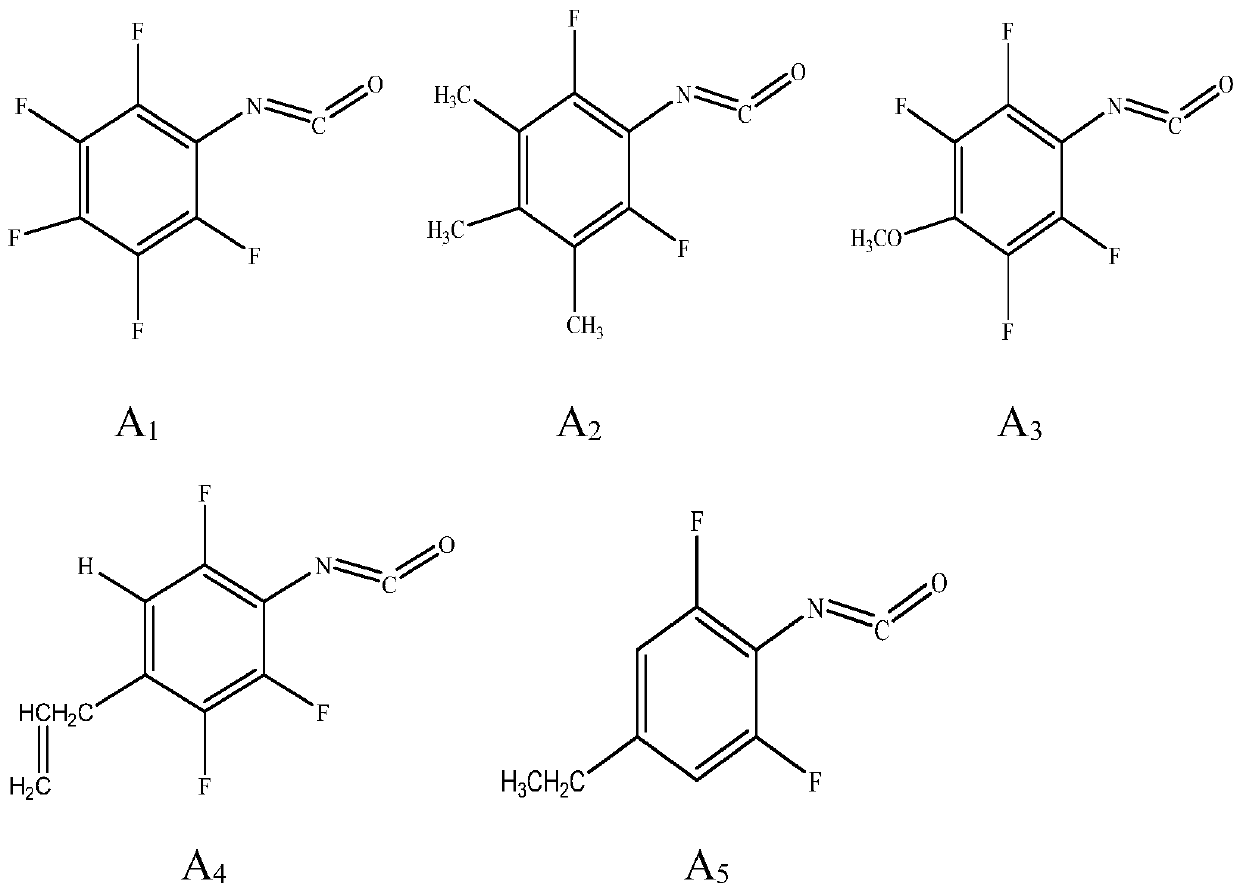

[0041] Preparation of electrolyte: In a glove box filled with argon, mix ethylene carbonate, diethyl carbonate and ethyl methyl carbonate according to the mass ratio of EC:DEC:EMC=2:3:3, and then add to the mixed solution Slowly add 12.5wt% lithium hexafluorophosphate (LiPF 6 ), based on 0.5wt% lithium bisoxalate borate (LiBOB) based on the total mass of the electrolyte and 2.5wt% lithium difluorooxalate borate (LiDFOB) based on the total mass of the electrolyte, and finally add 2.0wt% based on the total mass of the electrolyte Fluorophenylisocyanate compounds having the structure shown in formula I, 0.5wt% disilazide-based compounds having the structure shown in formula II, 5.0wt% fluoroethylene carbonate (FEC) and 0.5wt% 1, 3-propanediol cyclic sulfate (PCS), after being stirred uniformly, obtains the lithium-ion battery electrolyte of embodiment 1.

[0042] Preparation of soft-pack battery: stack the prepared positive electrode sheet, separator, and negative electrode shee...

Embodiment 2-12 and comparative example 1-8

[0044] In Examples 2-12 and Comparative Examples 1-8, except that the composition ratio of the components of the electrolyte is in accordance with the additives shown in Table 1, the others are the same as in Example 1.

[0045] Table 1 embodiment 1-12 and the composition ratio of each component of the electrolyte of comparative example 1-8

[0046]

[0047]

[0048]

[0049] The following performance tests were carried out on the full batteries prepared in Examples 1-12 and Comparative Examples 1-8:

[0050] 1) Cycling performance test at room temperature: At 25°C, charge the divided battery to 4.2V at 1C constant current and constant voltage, with a cut-off current of 0.05C, then discharge at 1C constant current to 3.0V, and cycle accordingly, charge / Calculate the capacity retention rate of the 1000th cycle after discharging 1000 cycles, the calculation formula is as follows:

[0051] 1000th cycle capacity retention rate (%)=(1000th cycle discharge capacity / first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com