Sea tangle airing sunlight room and construction method and purpose thereof

A construction method and sun room technology, applied in the direction of building structure, application, construction, etc., can solve the problems of kelp polluting the environment, high labor intensity, waste of output, etc., and achieve the effects of less salt loss, reduced labor intensity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

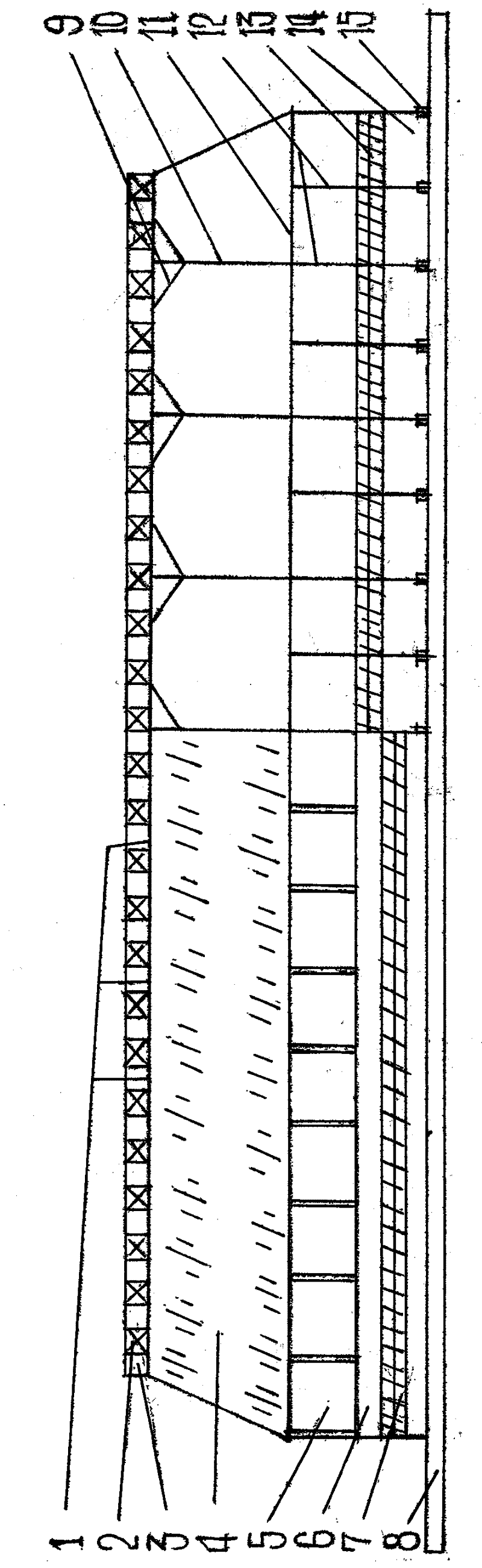

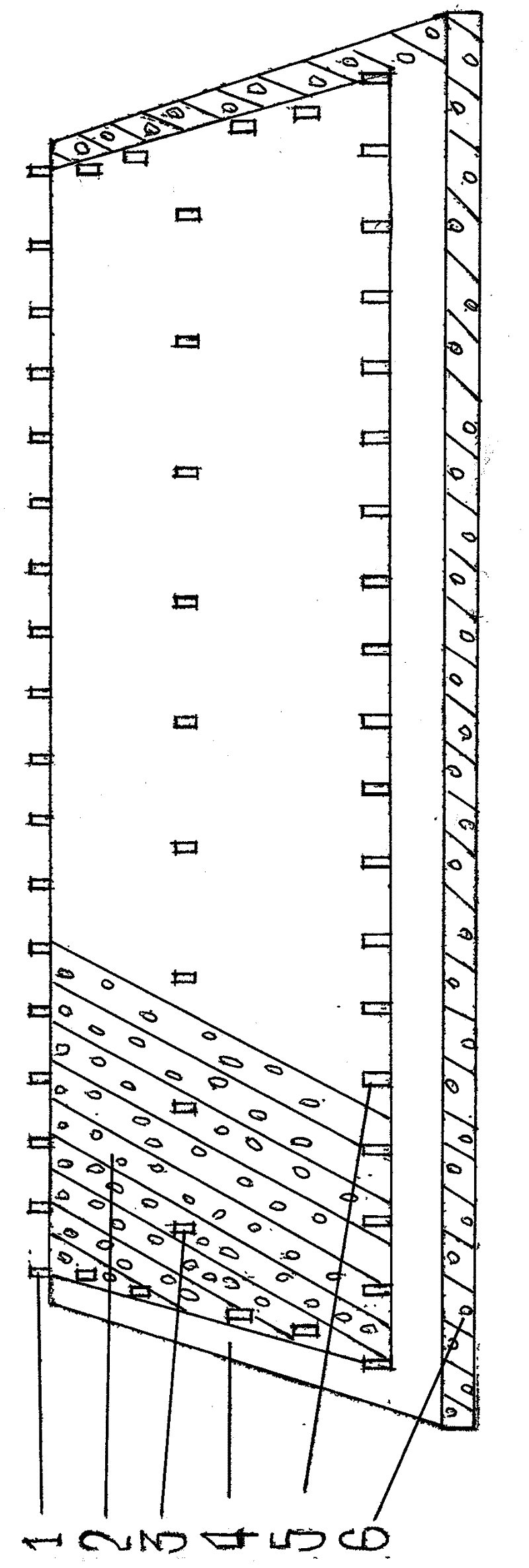

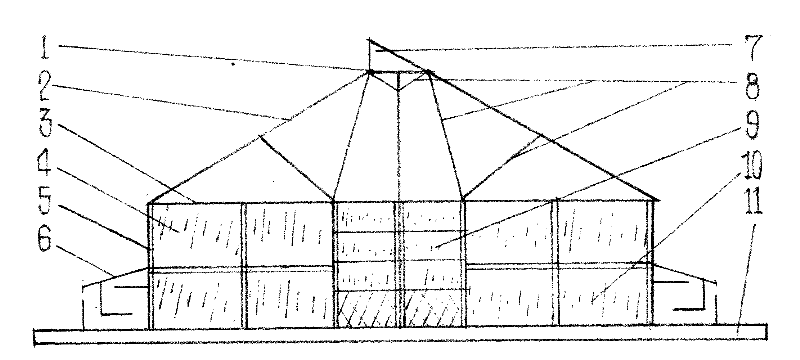

[0036] 1. Combined construction of plane foundation and column tube: the front of the sun room is built to be 5 to 10 degrees southeast, and the ground to be built is leveled and compacted with a machine, and the column tube ( Figure 5 ) combined with cement concrete to form a flat foundation ( figure 2 ). The total length of the cylinder should be less than 100cm, the bottom of the foundation should be less than 40cm, and the upper part should be less than 60cm ( Figure 5 ), the inner diameter of the column is within 60cm, the upper ends of all the columns are on the unified standard line, the front and back of the plane foundation, the left and the right, the multi-column and the foundation construction form a symmetrical body ( figure 2 ). The distance between the cylinder and the cylinder is within 6m ( figure 2 Among them 5), the middle cylinder is set at the center of the foundation ( figure 2 3). The cement concrete construction becomes a smooth plane at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com