Belt type fluidized drying machine

A technology of fluidized drying and mesh belt, which is applied in the direction of dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of low drying efficiency and poor uniformity, increase utilization rate, prevent material splashing, improve The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

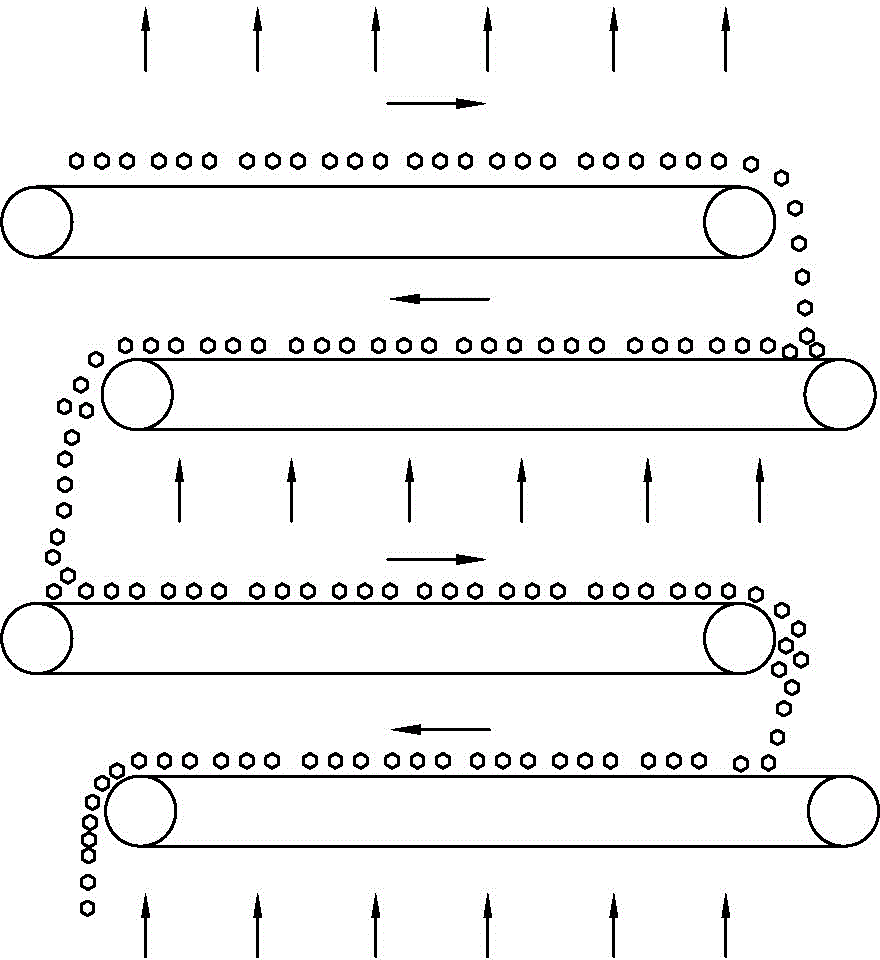

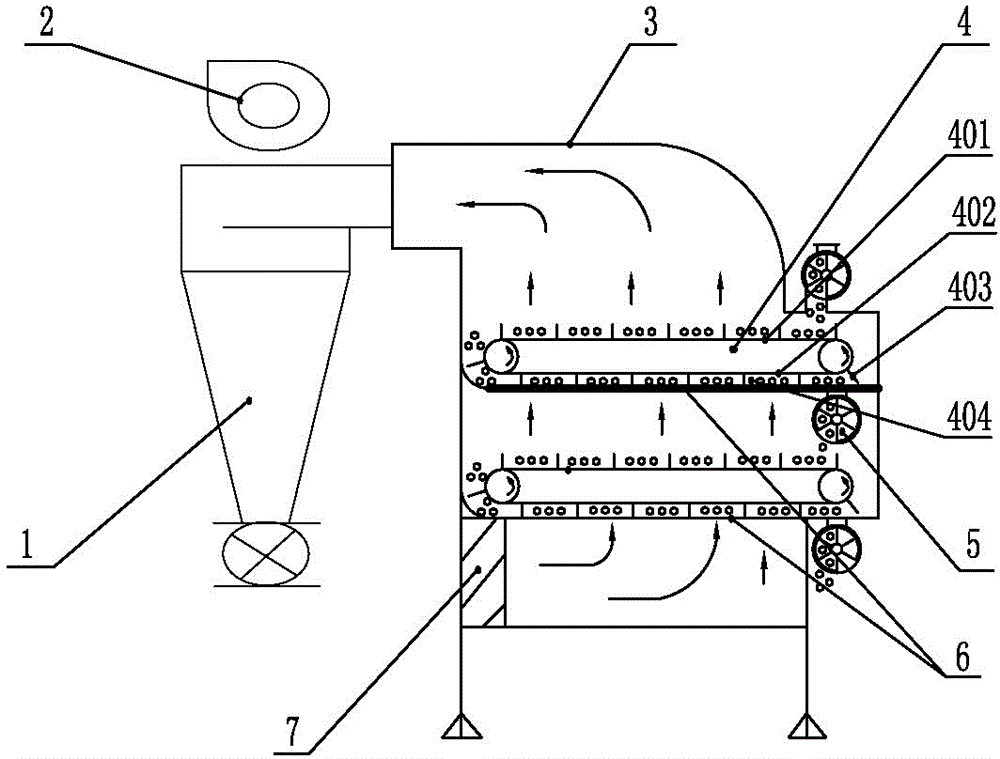

[0016] Such as figure 2 Shown is an embodiment of the belt fluidized dryer of the present invention, comprising a housing 3, a hot air conveying device 7 is provided at the bottom of the housing 3, a dust collecting device 1 and an induced draft fan 2 are provided at the top of the housing 3, and the housing 3 The body 3 is horizontally equipped with a mesh belt conveying unit 4 for conveying materials. The top end of the housing 3 above the mesh belt conveying unit 4 is provided with a feeding port, and the end of the mesh belt conveying unit 4 at the bottom of the housing 3 is provided with a discharge port. Mouth, wherein, the mesh belt conveying unit 4 comprises the upper layer mesh belt 401 and the lower mesh belt 402 of continuous circulation rotation, this mesh belt can adopt stainless steel mesh belt or polyester mesh belt, the upper layer mesh belt 401 and the lower layer mesh belt 402 length direction The surface of the surface is evenly and equidistantly fixed with...

Embodiment 2

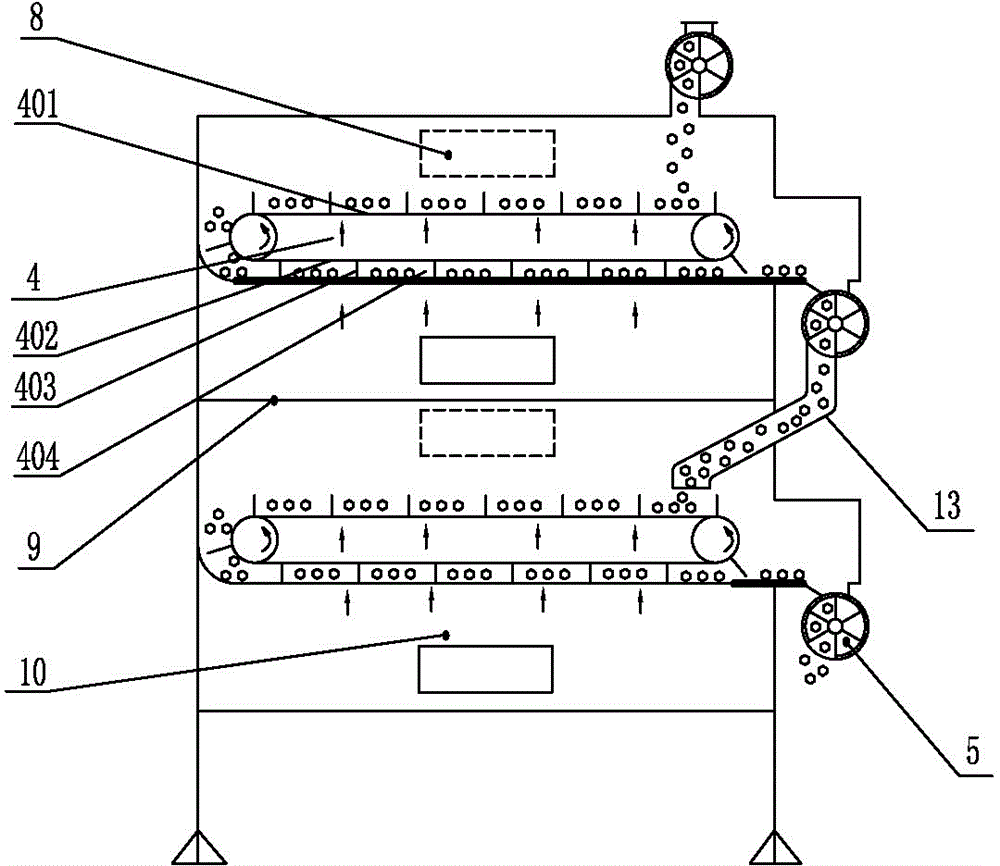

[0019] Such as image 3 and Figure 4 As shown, the present embodiment differs from Embodiment 1 in that a partition 9 for separating each mesh belt conveying unit 4 into independent hot air circulation units is provided between each layer of mesh belt conveying units 4, and the mesh belt conveying One side of unit 4 width direction is provided with hot blast air inlet channel 12, and the other side is provided with air outlet channel 11, and air inlet channel 12 communicates with the air supply port of hot blast conveying device 7, and air outlet channel 11 communicates with induced draft fan 2, each The bottom of the lower floor mesh belt 402 on one side of the mesh width direction of the mesh belt conveying unit 4 is provided with an air inlet 10 communicating with the air inlet passage 12, and the top of the upper floor mesh belt 401 on the other side of the mesh width direction is provided with an air outlet passage. 11 connected air outlets 8 . In order to facilitate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com