Sludge superheated steam triple-effect combined drying device

A technology of superheated steam and combined drying, applied in dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low efficiency, high energy consumption, secondary pollution and drying time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

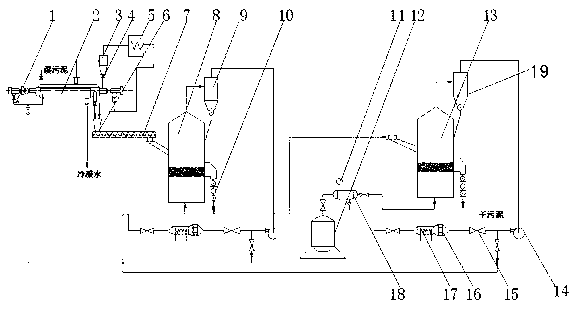

[0020] like figure 1 As shown, the present invention is achieved in that one end of the first effect dryer 2 is connected to the steam pipe 1, and the other end of the first effect dryer 2 is connected to the separator I3 through the discharger 4, and the separator I3 is connected to the condenser 5, The condenser 5 is connected to the first effect dryer 2, and the bottom of the first effect dryer 2 is provided with a stocker 6, and the stocker 6 is connected to one end of the charging forming device 7, and the other end of the charging forming device 7 is connected to the second effect Dryer 8, the upper side of the second effect dryer 8 is connected to the separator II9 through a steam pipe, the storage hopper 10 of the second effect dryer 8 is connected to the third effect dryer 13 through a pipeline, and the third effect The upper side of the dryer 13 is connected to the separator III 19 through a steam pipe, and the steam generator 12 is connected to the third effect dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com