A drying device for mechanical parts with a central hole

A technology for mechanical parts and drying devices, which is applied in the field of mechanical parts processing, can solve the problems of taking a lot of time to disassemble the block, increasing the range of motion of the parts to be taken and dried, and achieve the effect of convenient taking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

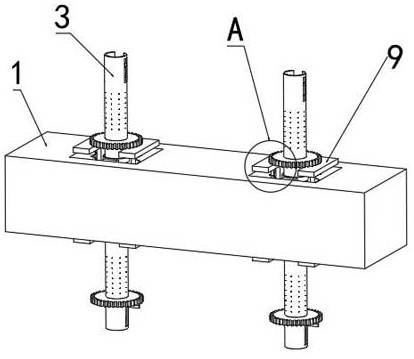

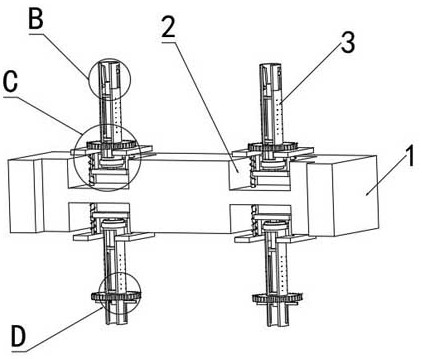

[0029] refer to Figure 1-7 , a drying device for mechanical parts with a central hole, comprising:

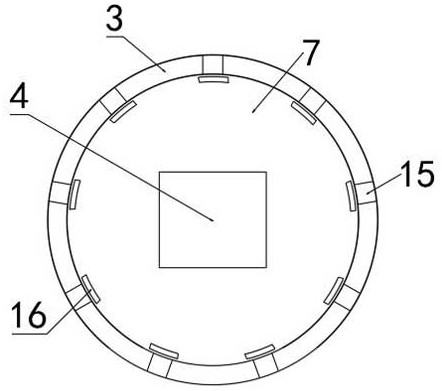

[0030] Turning plate 1, the upper and lower surfaces of turning plate 1 are symmetrically provided with a plurality of installation grooves 2, and in the installation groove 2, a stop rod 3 for mechanical parts sleeve is vertically fixed and installed through a snap ring 14;

[0031] The blocking mechanism consists of multiple groups, and the multiple groups of blocking mechanisms are respectively used to prevent the mechanical parts from sliding down from the plurality of limit rods 3 under the action of their own gravity. The blocking mechanism includes a pull rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com