Method and device for drying and processing of porphyra haitanensis

A processing method, altar seaweed technology, applied in food processing, food drying, dry preservation of meat/fish, etc., can solve the problems of high cost, achieve low moisture content, large heat loss, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

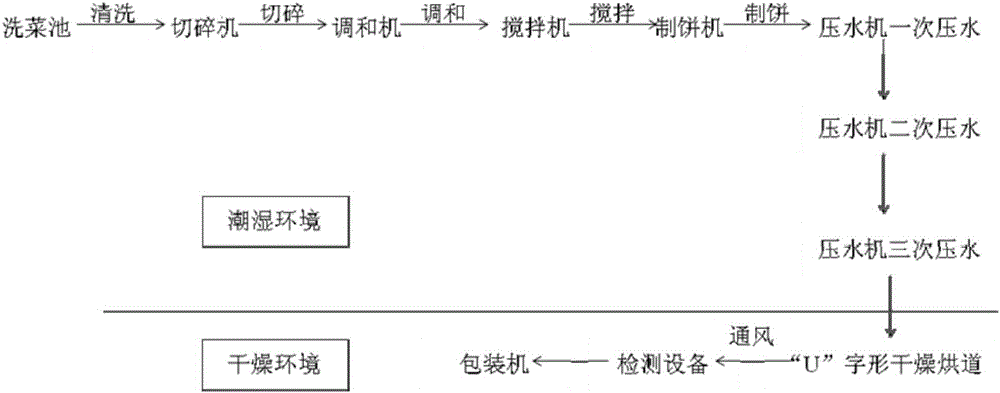

[0062] A drying and processing method of laver, comprising the following steps:

[0063] (1) Preprocessing:

[0064] According to the conventional drying process of laver, the laver is sent to the vegetable washing pool for cleaning, chopping in the chopper, blending in the blender, stirring in the mixer, and cake making in the cake maker. The moisture content of laver dish is 86-88%;

[0065] (2) External force dehydration in humid environment:

[0066] Send the laver plate of altar laver obtained in step (1) to a pressurized water machine for a pressurized water, the pressure is 1.5-2.0KPa, and the water content of the pressed laver plate is 79-80%; and then obtained through a pressurized water The laver plate is then sent to the press water machine for secondary water pressure, the pressure is 1.5-2.0KPa, and the moisture content of the pressed laver plate is 75-78%; then the laver plate obtained by the second press water is sent to the press water machine Press water th...

Embodiment 2

[0072] A drying and processing method of laver, comprising the following steps:

[0073] (1) Preprocessing:

[0074] According to the conventional drying process of laver, the laver is sent to the vegetable washing pool for cleaning, chopping in the chopper, blending in the blender, stirring in the mixer, and cake making in the cake maker. The moisture content of laver dish is 89-91%;

[0075] (2) External force dehydration in humid environment:

[0076] Send the laver plate of altar laver obtained in step (1) to a pressurized water machine for a water press, the pressure is 1.5-2.0KPa, and the water content of the laver plate after pressing is 79-85%; The laver plate is then sent to the press water machine for secondary water pressure, the pressure is 1.5-2.0KPa, and the moisture content of the pressed laver plate is 75-78%; then the laver plate obtained by the second press water is sent to the press water machine Press water three times in the middle, the pressure is 1.5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com