A drying method and mobile drying system for inorganic fine-grained sludge

An inorganic, mobile technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high cost and huge equipment, and achieve the effects of improving efficiency, reducing drying energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

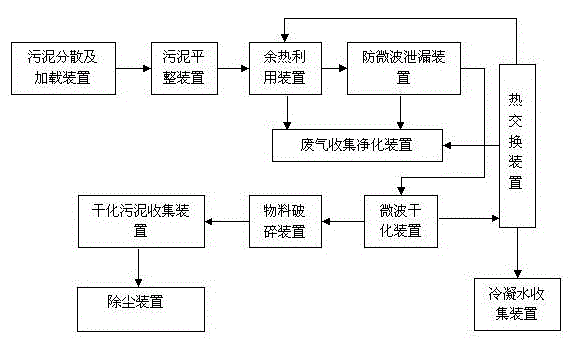

[0037] Inorganic fine-grained sludge mobile drying system, including sludge dispersion and loading device, sludge leveling device, waste heat utilization device, microwave drying device, microwave leakage prevention device, exhaust gas collection and purification device, heat exchange device, condensed water The outlet of the collecting device, the sludge dispersing and loading device is connected to the sludge leveling device, the outlet of the sludge leveling device is connected to the waste heat utilization device, and the exit of the waste heat utilization device is connected to the anti-microwave leakage device, and the waste heat utilization device and the anti-microwave leakage device are respectively connected to The waste gas collection and purification device is connected to exhaust the waste gas; the microwave leakage prevention device is installed at the entrance and exit of the microwave drying device; The collection and purification device is connected, the heat o...

Embodiment 2

[0051] The difference from Example 1 is that the waterworks sludge with a water content of 65% is selected, and a 2450MHz microwave source is used to work continuously, and the sludge is 12.2 cm thick (approximately equal to 3 × 10 8 / 2450MHz) cake shape, microwave power 1.0 kg water / electricity conversion, can be dried to 35% water content.

Embodiment 3

[0053] The difference from Example 1 is that electroplating sludge with a moisture content of 65% is selected, and a 915MHz microwave source is used for continuous operation. The sludge is 32.8 cm thick (approximately equal to 3×10 8 / 915MHz), the microwave power is 1.2 kg of water / electricity conversion, and can be dried to 30% water content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com