Full-automatic vacuum squeezing device for producing high-strength corrugated base paper

A corrugated base paper, fully automatic technology, applied in the field of corrugated paper processing, can solve the problems of general water absorption effect, affecting the cleanliness of the external environment of the press water, and achieve the effect of avoiding cleaning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

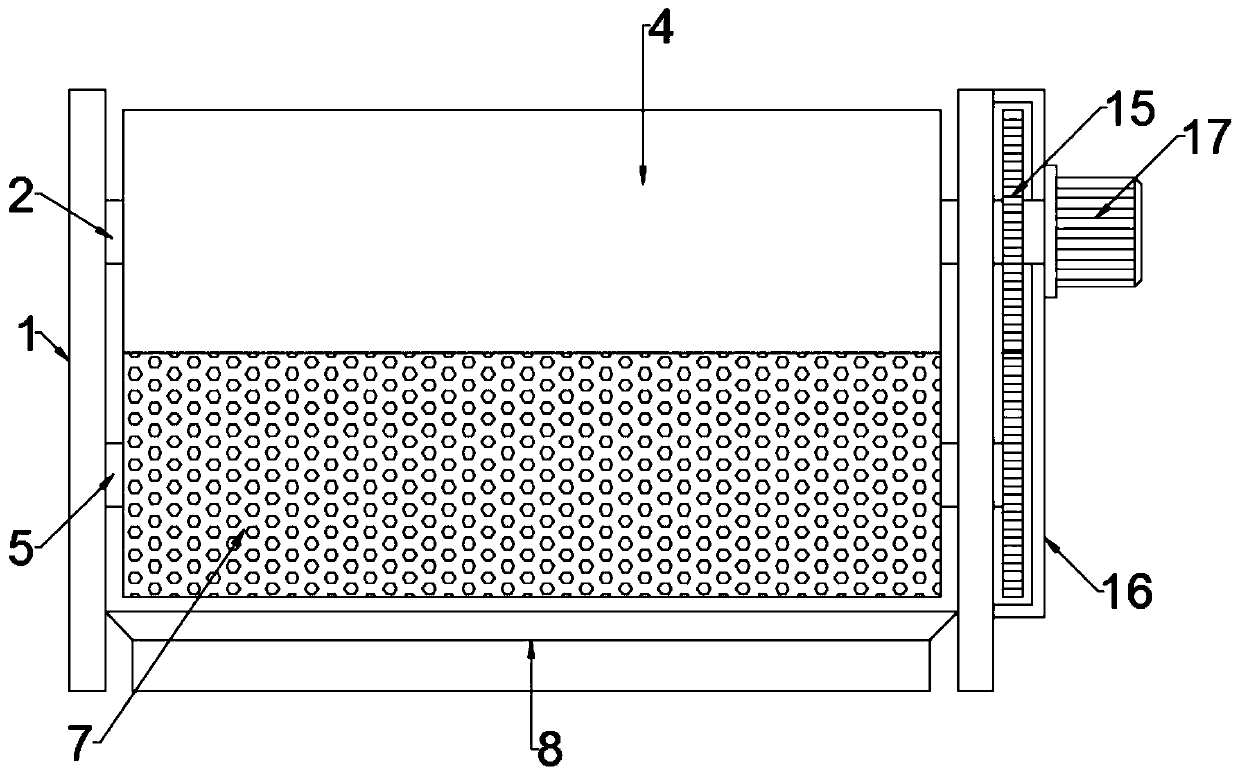

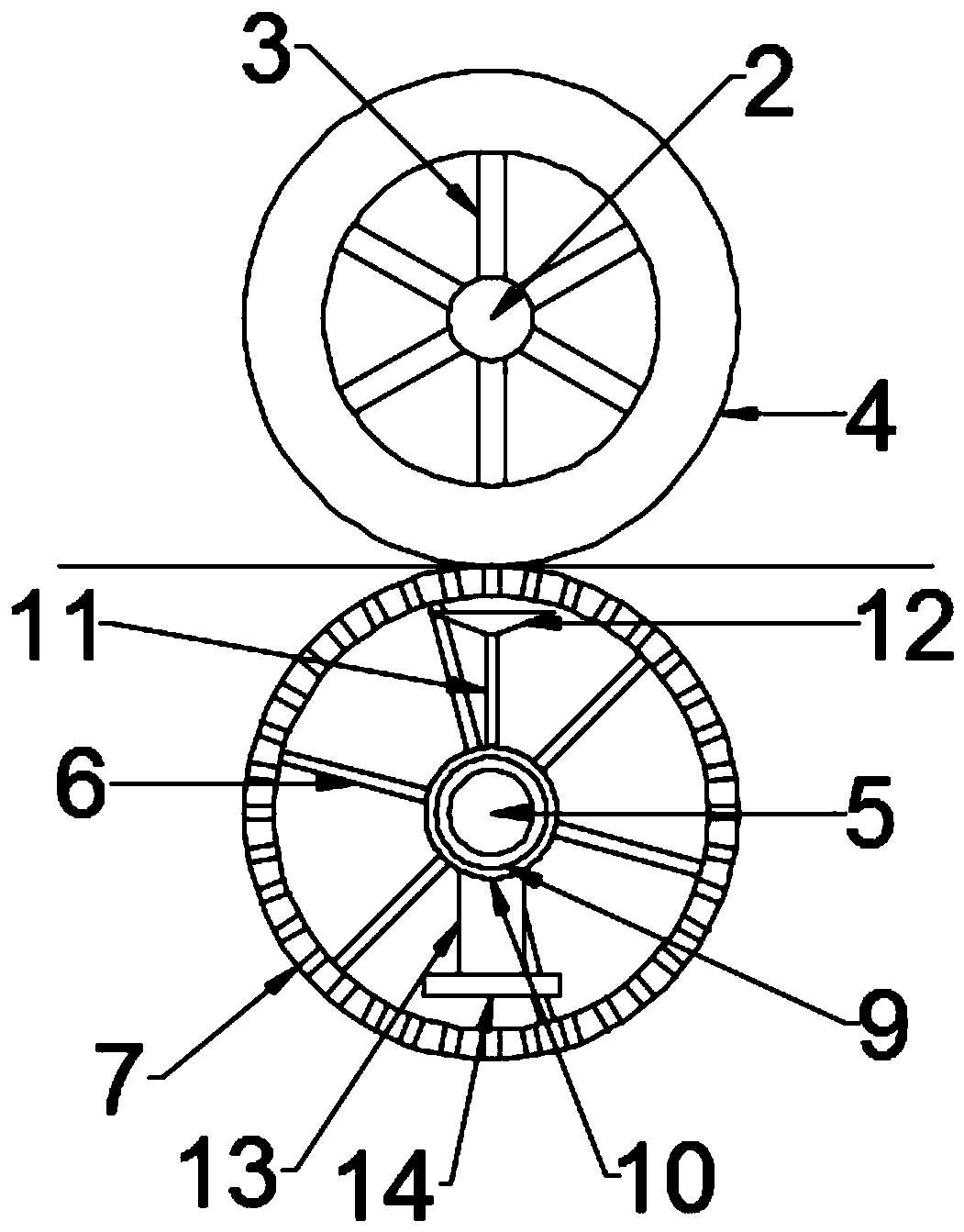

[0019] see Figure 1~2 , in an embodiment of the present invention, a fully automatic vacuum press device for producing high-strength corrugated base paper, including a heated press roll 4 and a negative press roll 7 that are movable and bonded, and the heated press roll 4 is coaxially provided with a first Rotating shaft 2, and the periphery of the first rotating shaft 2 is connected to the inner wall of the heating press roller 4 through the first support rod 3, the cavity of the heating pressing roller 4 is set and the two ends form a rotational connection with the first rotating shaft 2, and the heating pressing roller 4 is embedded A heating resistance wire is provided, and the negative pressure squeeze roller 7 is a net cylinder structure with both ends closed, and the middle part of the negative pressure squeeze roller 7 is coaxially rotated with a second rotating shaft 5, and the two sides of the second rotating shaft 5 are respectively A plurality of sets of second su...

Embodiment 2

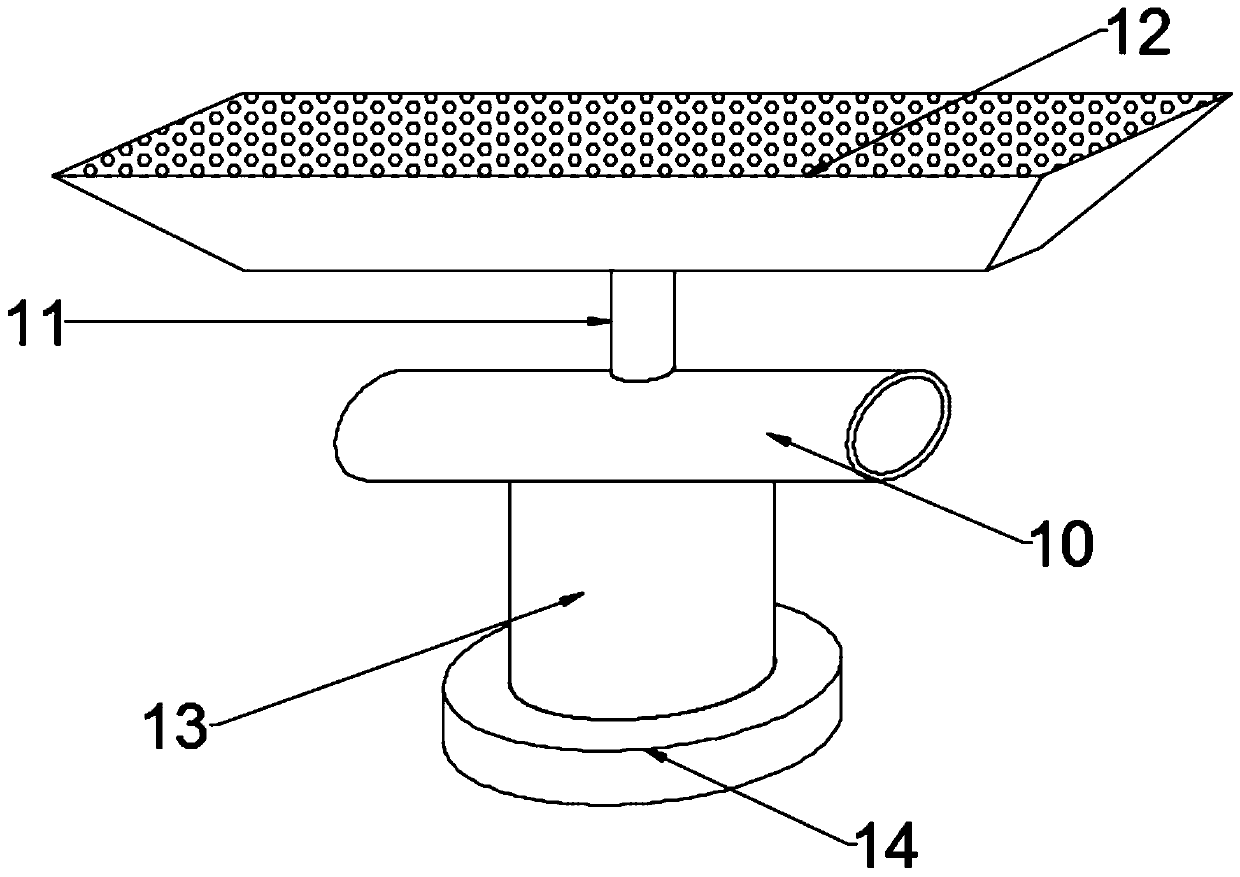

[0024] see image 3 , in an embodiment of the present invention, a fully automatic vacuum press device for producing high-strength corrugated base paper, on the basis of Embodiment 1, the vacuum negative pressure adsorption mechanism includes a vacuum pump 13, and the input end of the vacuum pump 13 is connected to a The pipe sleeve 10, the pipe sleeve 10 is a cylindrical structure, and the cylinder wall is arranged as a closed cavity, the pipe sleeve 10 is connected to the periphery of the second rotating shaft 5 through the bearing 9, and the vacuum pump 13 is far away from the pipe sleeve 10 A counterweight ring 14 is provided on the peripheral fixed sleeve at one end, and the output end of the vacuum pump 13 can be continuously kept downward through the counterweight of the counterweight ring 14. The side of the pipe sleeve 10 away from the vacuum pump 13 is communicated with a conduit 11, The end of the conduit 11 away from the sleeve 10 is connected with a water collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com