Treatment system for harmless and reduction of solid waste and solid waste treatment method

A solid waste and treatment system technology, applied in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of high unit treatment cost, large landfill volume, and high thermal energy consumption, achieve high cost performance and avoid secondary pollution. , the effect of cleaning the incineration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

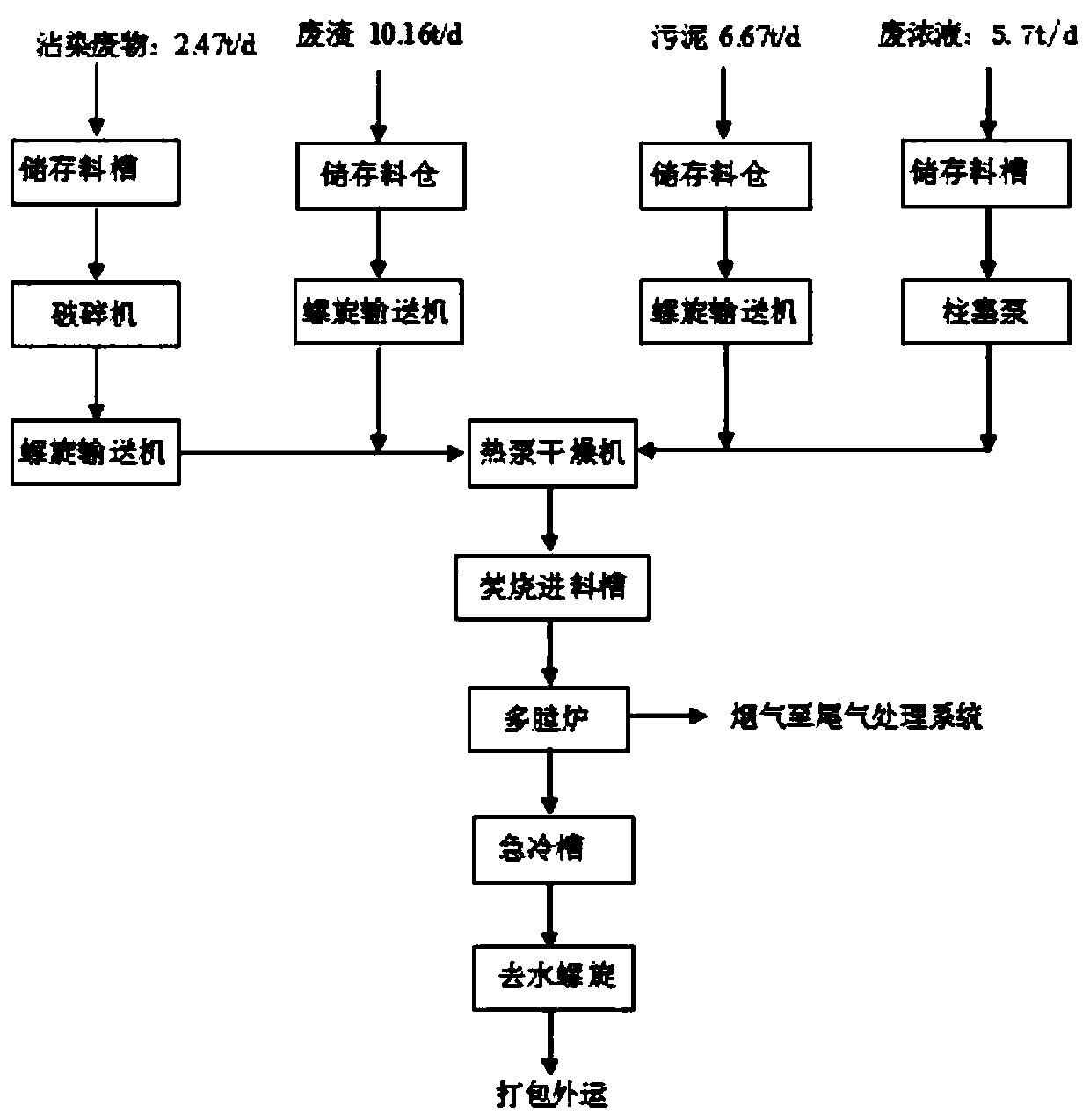

[0052] In Example 1, the solid waste treatment of Tianjin FAW Toyota is taken as an example.

[0053] The existing solid waste of Tianjin FAW Toyota Motor Co., Ltd. includes waste paint slag generated during the painting process and wastewater treatment sludge generated during the metal surface treatment process, all of which are hazardous waste. Both the waste paint slag and the sludge are stored in the silo. Since the organic components in the solid components of the waste paint slag account for more than 90%, the calorific value is very high, while the inorganic components in the solid components of the sludge account for about 50%. , lower calorific value.

[0054] Step 1: importing solid waste residue and sludge into different storage cavities in the waste storage bin;

[0055] Step 2: The daily processing capacity of the waste residue and sludge stored in the storage chamber is transported to the dryer at a ratio of 10:7 for mixing and shaping to form a mixture; in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com