Sludge ultrasonic roller drier

A drum drying and ultrasonic technology, applied in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low drying efficiency, poor solid-liquid separation performance, high operating cost, achieve uniform and sufficient effect, improve energy utilization, The effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

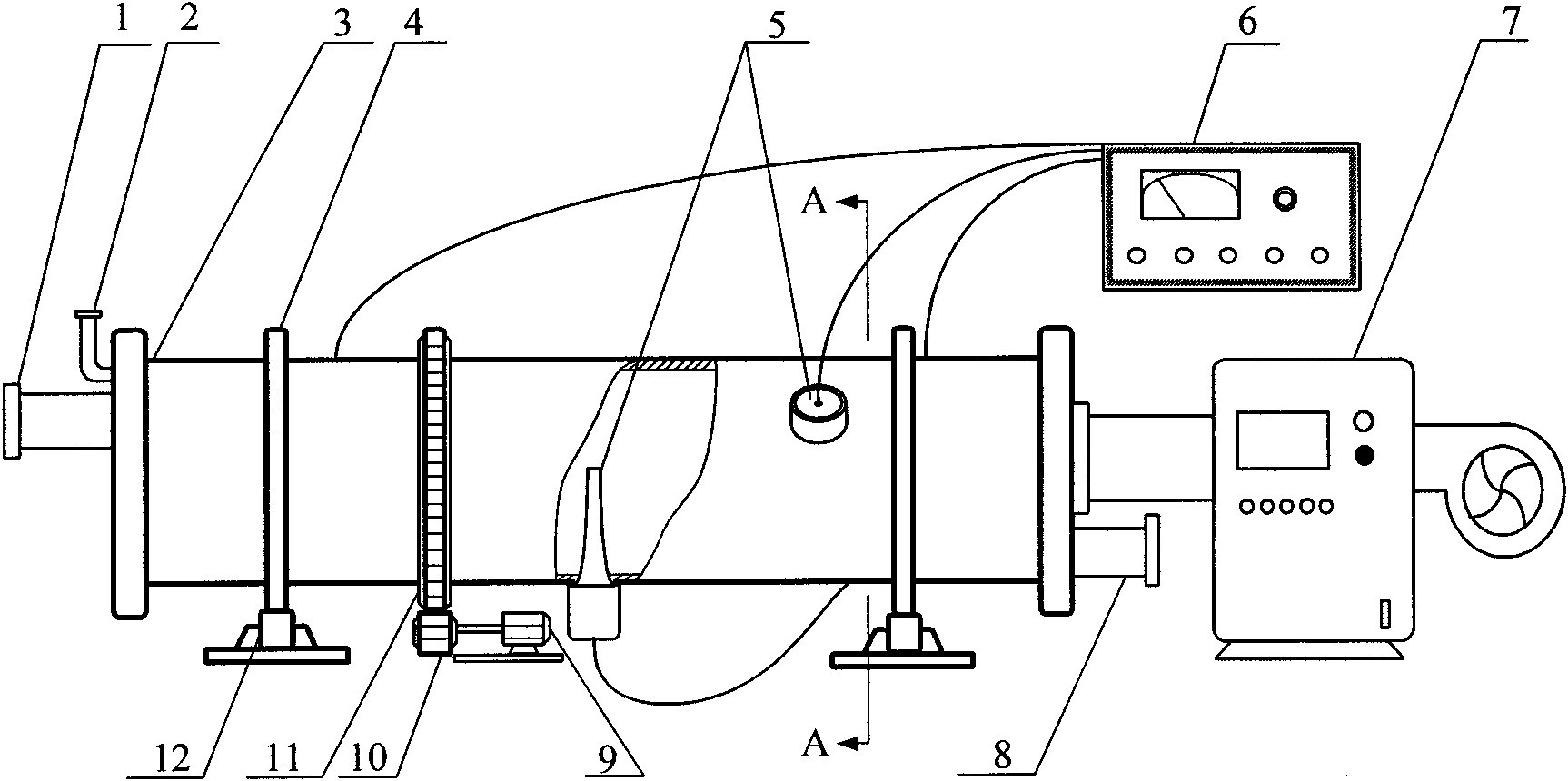

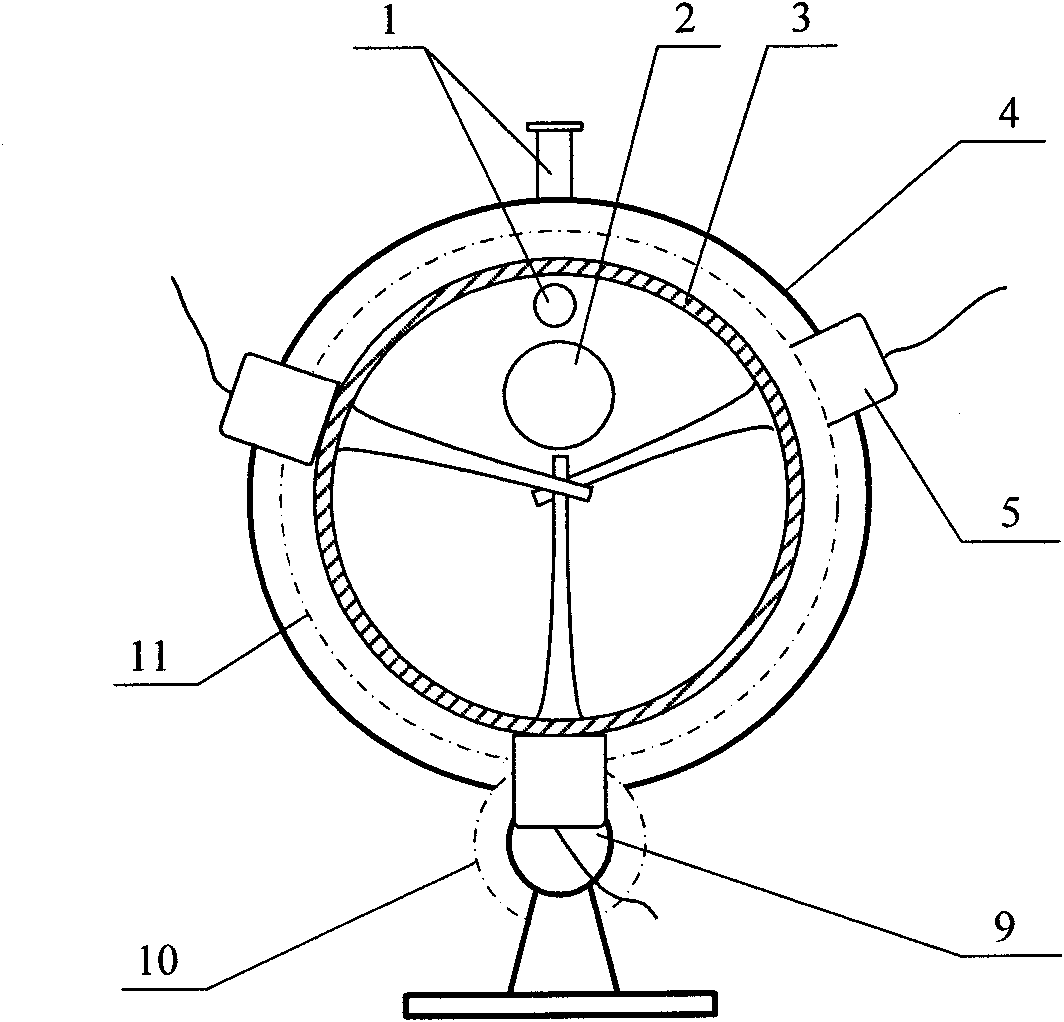

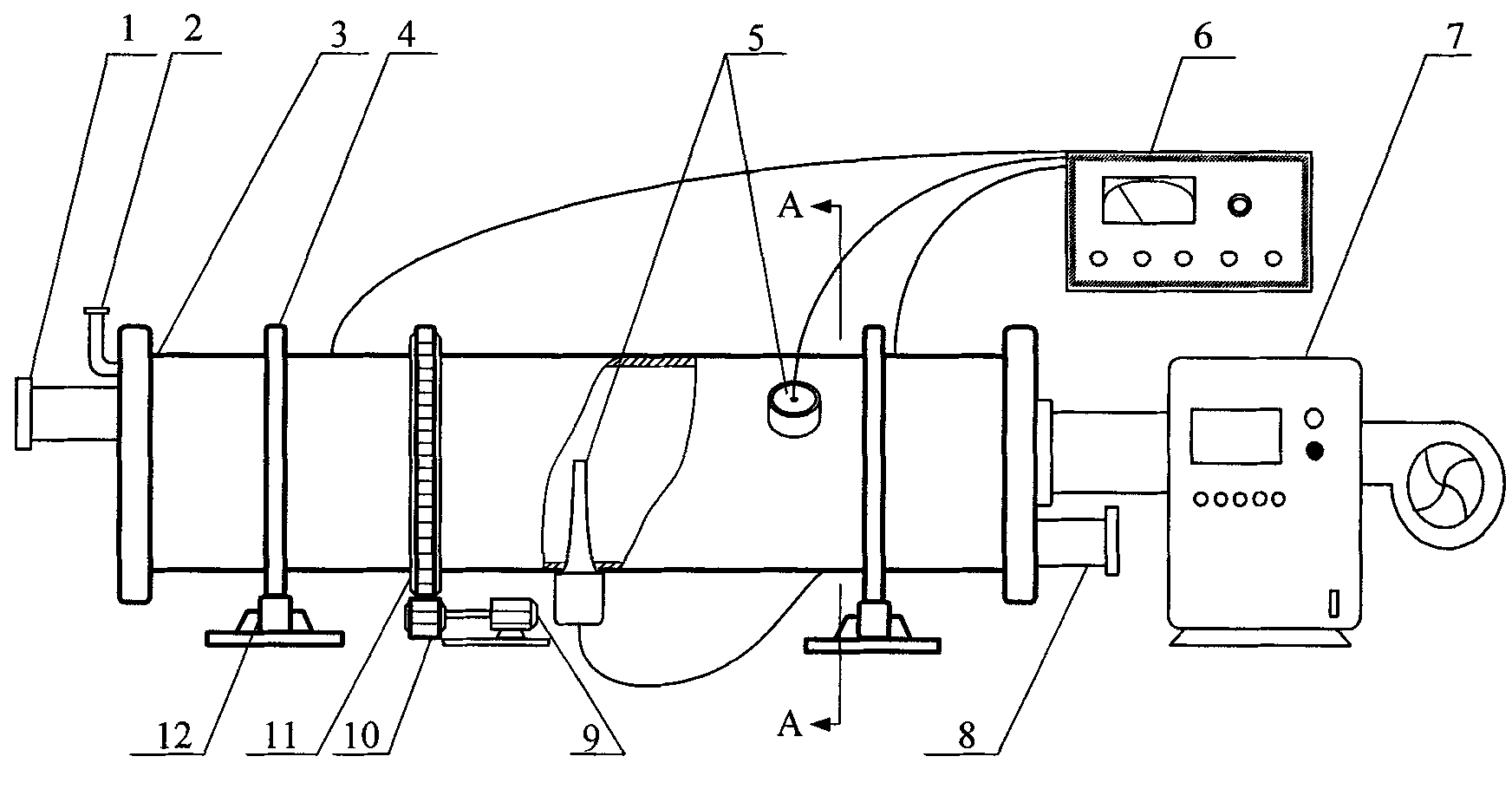

[0015] Below with reference to the accompanying drawings, specific embodiments of the present invention are described in more detail:

[0016] like figure 1 , figure 2 As shown, a sludge ultrasonic drum dryer is provided with a feed port 1, an exhaust port 2, an ultrasonic probe 5 and a discharge port 8 on the drying cylinder 3, and the ultrasonic probe 5 is inserted into the drying cylinder 3 and The ultrasonic probe 5 is connected to the ultrasonic generator 6, the hot air generator 7 is connected to the drying cylinder 3, a gear ring 11 and a rolling ring 4 are sleeved on the drying cylinder 3, and the rolling ring 4 is set on the supporting wheel 12 and is supported by the supporting wheel 12. The wheel 12 is supported, and the dryer also includes a speed regulating motor 9 , a gear 10 is arranged on the output shaft of the speed regulating motor 9 , and the gear 10 meshes with the ring gear 11 .

[0017] like figure 1 , figure 2 As shown, the number of ultrasonic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com