A method for mass cleaning and drying carbon fiber composite parts

A composite material and carbon fiber technology, applied in cleaning methods and appliances, cleaning methods using liquids, dry gas arrangement, etc., can solve problems such as unstable operation, scratches on the surface of parts, and complicated operations of pendants, and achieve high production efficiency , avoid scratches, and operate safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

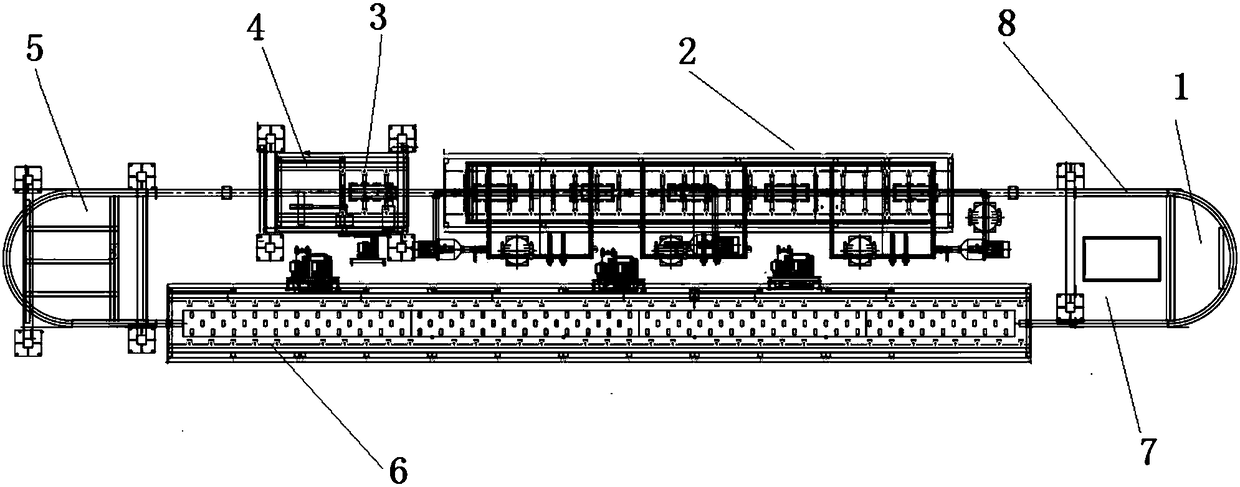

[0033] A method for cleaning and drying carbon fiber composite parts in large quantities, which is carried out according to the following steps:

[0034] 1) Manually transport the carbon fiber composite material to the loading area, which is located at the turning of the line body, equipped with emergency stop switch, start button and operation panel;

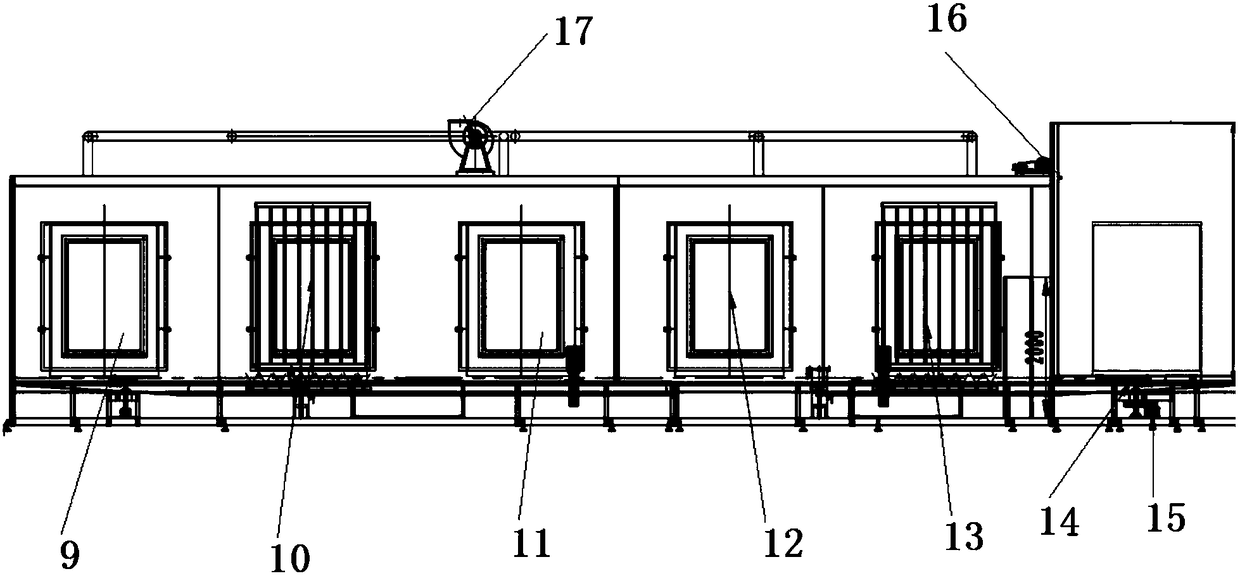

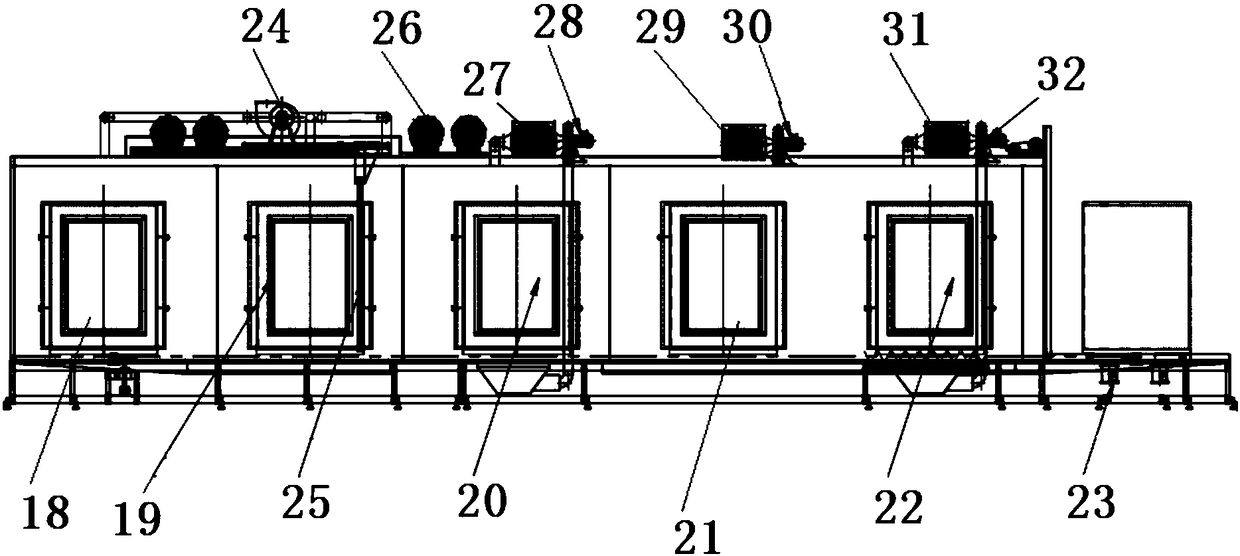

[0035] 2) Start the start button, transport the carbon fiber composite material to the spray cleaning area, perform the first water washing, heat the water washing tank to 40°C, use water curtain cleaning, and wash for 30 seconds. The liquid length is 3 meters; a coarse filter device is set in the washing tank to prevent large particles from entering the pump body, and the volume is 1200L;

[0036] 3) Spray rinsing is carried out by spraying components. There are nozzles on the left, right, and upper sides of the carbon fiber composite material. The spraying pressure is 0.5Mpa, and the spraying time is 30s. After cleaning, the ...

Embodiment 2

[0043]A method for cleaning and drying carbon fiber composite parts in large quantities, which is carried out according to the following steps:

[0044] 1) Manually transport the carbon fiber composite material to the loading area, which is located at the turning of the line body, equipped with emergency stop switch, start button and operation panel;

[0045] 2) Start the start button, transport the carbon fiber composite material to the spray cleaning area, perform the first water washing, heat the water washing tank to 38°C, use water curtain cleaning, and wash for 20s. The liquid length is 2 meters; a coarse filter device is set in the washing tank to prevent large particles from entering the pump body, and the volume is 1000L;

[0046] 3) Spray rinsing is carried out by spraying components. There are nozzles on the left, right, and upper sides of the carbon fiber composite material. The spray pressure is 0.3Mpa, and the spray time is 20ss. After cleaning, the empty station...

Embodiment 3

[0053] A method for cleaning and drying carbon fiber composite parts in large quantities, which is carried out according to the following steps:

[0054] 1) Manually transport the carbon fiber composite material to the loading area, which is located at the turning of the line body, equipped with emergency stop switch, start button and operation panel;

[0055] 2) Start the start button, transport the carbon fiber composite material to the spray cleaning area, perform the first water washing, heat the water washing tank to 42°C, use water curtain cleaning, and wash for 40 seconds. The liquid length is 4 meters; a coarse filter device is set in the washing tank to prevent large particles from entering the pump body, and the volume is 1500L;

[0056] 3) Spray rinsing is carried out by spraying components. There are nozzles on the left, right, and upper sides of the carbon fiber composite material. The spray pressure is 0.6Mpa, and the spray time is 40s. After cleaning, the empty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com