Vacuum vitrescence drying machine

A glassy drying and vacuum technology, applied in the fields of food science, food preservation, application, etc., can solve the problems of uneven heating of materials, slow heating speed, expensive drying, etc., to ensure the integrity and avoid the effect of puncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

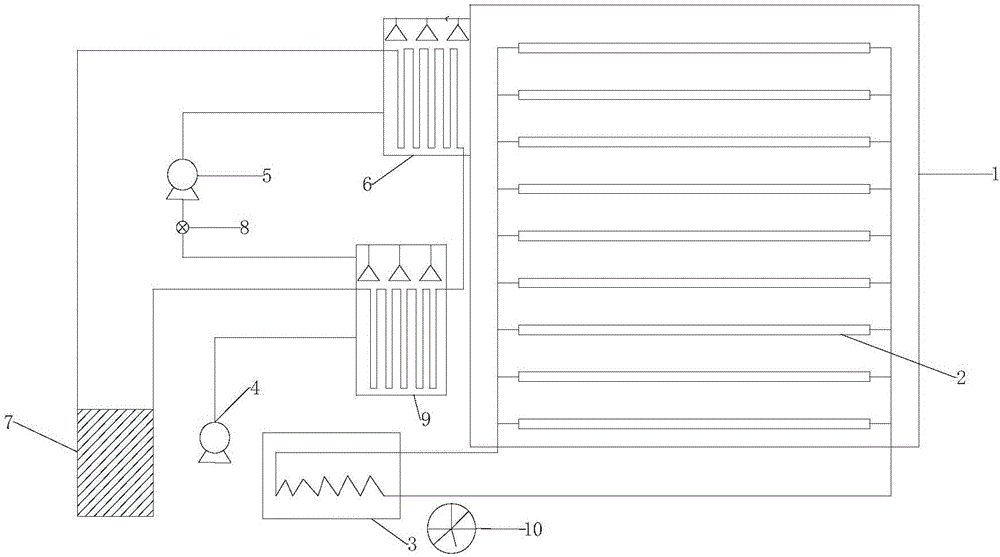

[0020] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in conjunction with the accompanying drawings and embodiments:

[0021] figure 1 A vacuum glass dryer is shown, comprising a material box 1, a heating unit, a vacuum unit and a condensation unit; the heating unit includes a heating plate 2 arranged in the material box for placing materials and a The heater 3 that provides heat for the heating plate outside the material box; the vacuum unit includes a Roots pump 5 and a rotary vane pump 4; the condensation unit includes a main cold trap 6 and an auxiliary cold trap 9 And a refrigeration unit 7 for cooling the main cold trap and the auxiliary cold trap; a pressure gauge 8 is provided between the Roots pump and the auxiliary cold trap 9 . The main cold trap is arranged between the Roots pump and the material box, and the auxiliary cold trap is arranged between the rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com