Novel air medium type sludge drying system

A new type of sludge drying technology, used in dewatering/drying/concentrating sludge treatment, incinerators, combustion types, etc., can solve the problems of low safety, single function, complicated operation, etc., achieve low drying efficiency, Scientific and reasonable structure and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

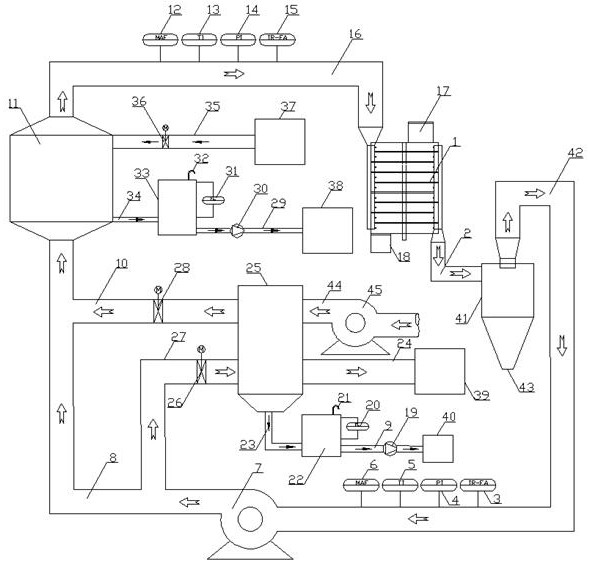

[0032] Example: such as figure 1 As shown, the present invention provides a technical solution, a novel wind-driven sludge drying system, including a sludge drying machine 1, for normal feeding and discharging, a wet sludge inlet 17 is provided at the top of the sludge drying machine 1, The bottom of the sludge dryer 1 is located on the opposite side of the wet sludge inlet 17, and a dry sludge outlet 18 is provided. The bottom of the sludge dryer 1 is connected with an air outlet duct 2, which is connected to the cyclone dust collector 41 is connected to the inlet, the top of the cyclone dust collector 41 is connected to a circulation return duct 42, the bottom end of the cyclone dust collector 41 is connected to an ash discharge port 43, and the circulation return duct 42 is connected to the inlet of the circulation fan 7;

[0033] The outlet of the circulating fan 7 is connected in parallel with the circulating air supply channel 8 and the heat exhausting air channel 27;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com