Patents

Literature

116results about How to "Achieve antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

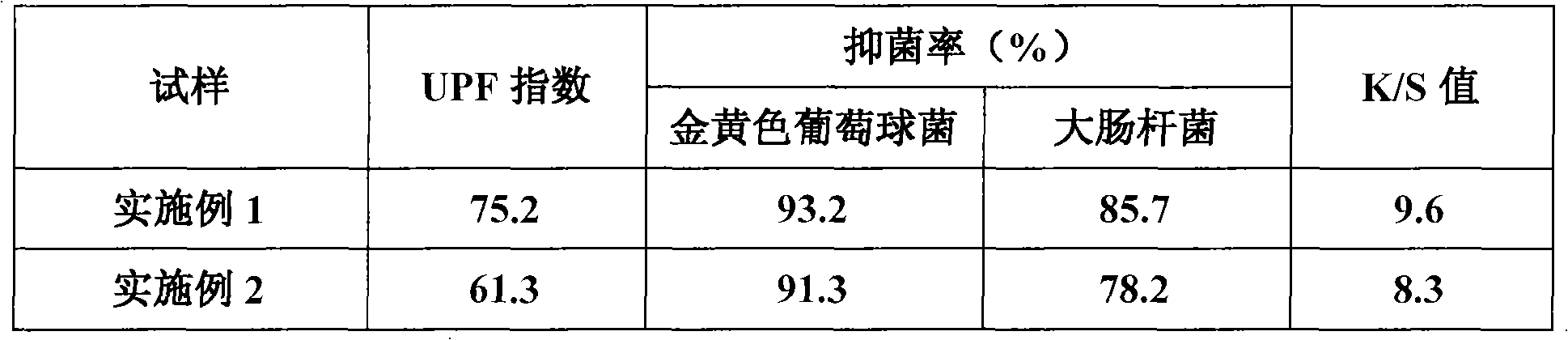

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

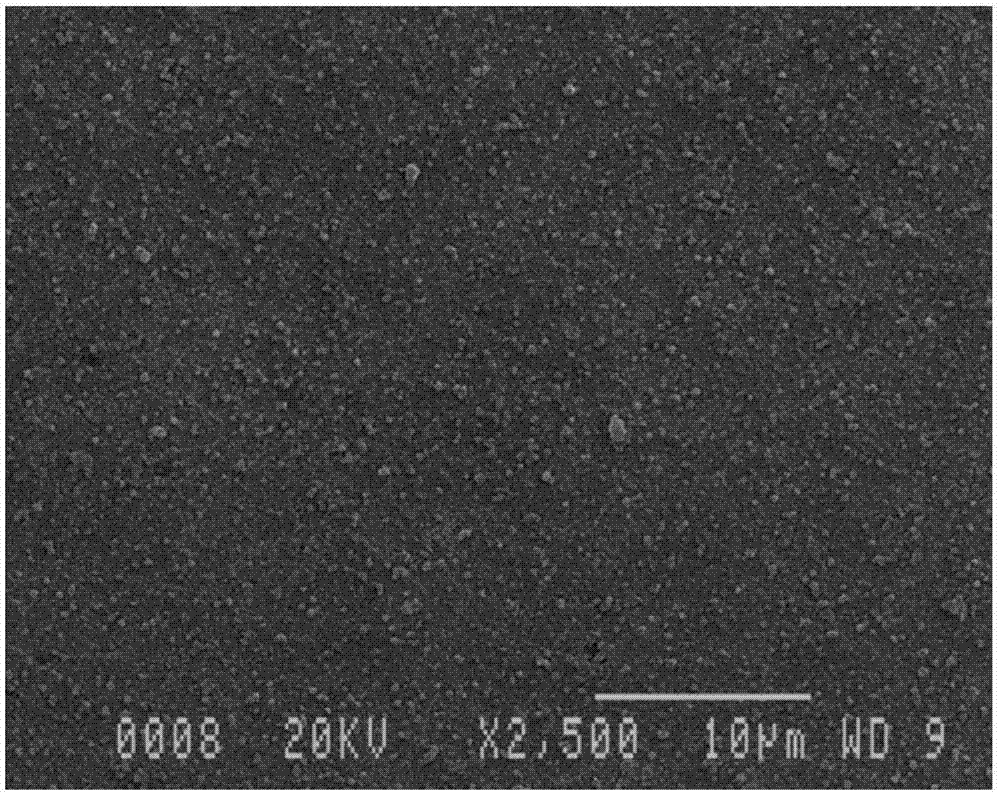

Nanometer inorganic powder modified water emulsion wall paint and its prepn

The present invention relates to one kind of nanometer inorganic powder modified water emulsion as multifunctional wall paint and its preparation process. The water emulsion as wall paint features containing nanometer inorganic composite powder in 0.5-5 wt%, and the nanometer inorganic composite powder consists of nanometer zinc oxide 1-5 wt%, other nanometer oxide 1-5 wt% and tourmaline powder 90-98 wt% and is produced through surface treatment. The water emulsion as wall paint is prepared through conventional latex preparing process including mixing, high speed dispersing, regulating and other steps. The water emulsion as wall paint has excellent physical performance, can release negative ion to purify air and kill bacteria to provide people with excellent living environment.

Owner:SUN YAT SEN UNIV

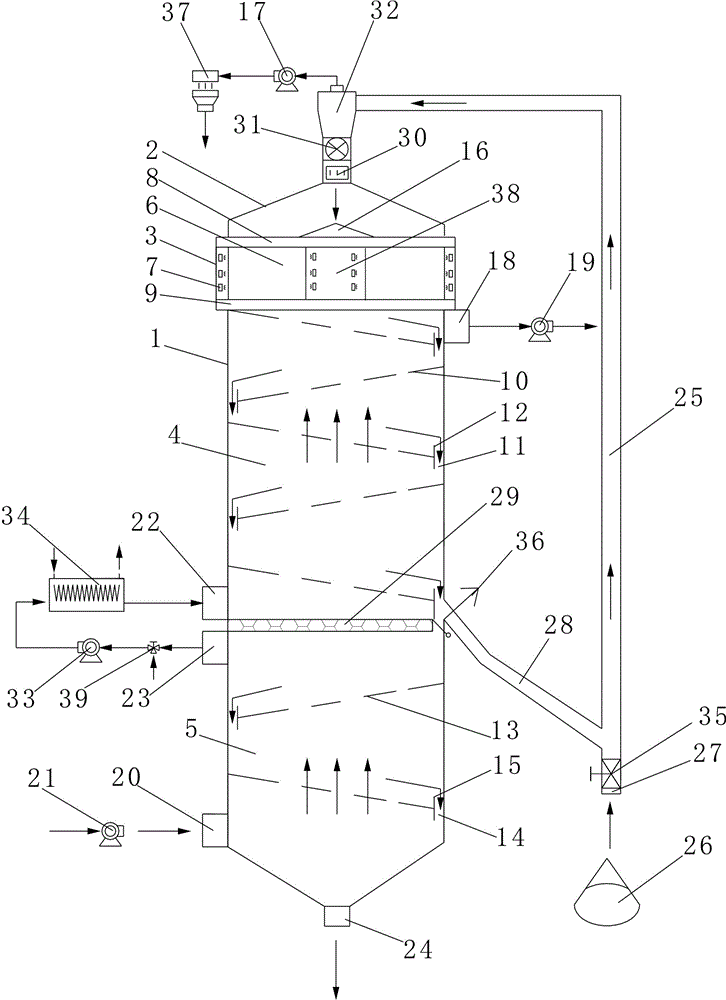

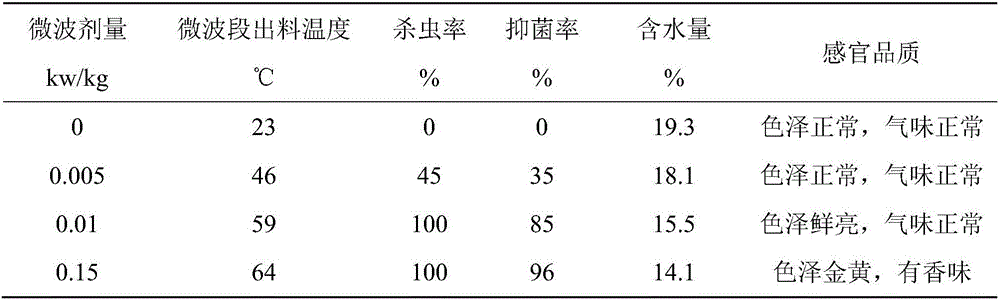

Grain microwave and fluidization combined drying equipment, drying method and application

ActiveCN105928323AReach killEfficient killingDrying solid materials with heatDrying gas arrangementsMicrowaveEngineering

The invention discloses grain microwave and fluidization combined drying equipment, a drying method and application. The equipment comprises a tower body; and the tower body is provided with a buffer bin, a microwave section, a drying section and a cooling section in sequence from top to bottom. The drying section and the cooling section respectively include multiple fluidization plates staggered on upper and lower layers; one ends of the fluidization plates are fixedly connected with the tower body, and baffle plates are mounted at the other ends; and overflow channels are formed between the baffle plates and the tower body. An exhaust port of the cooling section communicates with a hot air intake ports of the drying section via a hot air fan and a heat exchanger; hot air exhausted by the cooling section is leaded into the drying section; and afterheat thereof is fully used to save the energy. The drying method comprises three steps of microwave preheating, fluidization drying and fluidization cooling. The drying equipment and the drying method use the microwave and fluidization combined drying, have the characteristics of high drying efficiency and uniform drying, can realize functions of insecticide and bacteriostasis, and can be used for drying such grains with good fluidity as paddy, wheat and corn.

Owner:HUAZHONG AGRI UNIV

Multifunctional electrostatic spinning fiber dressing and preparation method thereof

The invention provides a multifunctional electrostatic spinning fiber dressing and a preparation method thereof, and belongs to the technical field of polymer medical materials. The fiber dressing isof a micro-nano structure, the electrostatic spinning method is adopted for spinning polymer materials with grafted functional groups into fiber, then, crosslinking is performed to obtain the fiber dressing, and the polymer materials have the function of stimulating macrophage transition. The invention further provides the preparation method of the multifunctional electrostatic spinning fiber dressing. The electrostatic spinning fiber dressing is obtained by grafting functional groups to polymer materials capable of promoting macrophage transition and then performing electrostatic spinning andcrosslinking, the fiber is soft and easy to fold and can well fit a superficial wound, a deep wound can also be filled with the fiber, and the fiber can achieve the multiple functions of stopping bleeding, resisting oxidation, resisting inflammation, resisting bacteria, promoting healing and reducing scars.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Multifunctional super-hydrophobic textile finishing agent, and preparation method and applications thereof

ActiveCN107326651AReduce usageSimple manufacturing processStain/soil resistant fibresBiochemical fibre treatmentHydrolysisSkin protection

The invention discloses a multifunctional super-hydrophobic textile finishing agent, and a preparation method and applications thereof. The preparation method comprises following steps: a precursor of an oxide sol and a graphite oxide aqueous dispersion are dispersed in deionized water, an anionic surfactant is added, a catalyst is added for hydrolysis and condensation reaction after uniform dispersion so as to obtain a mixed reaction system, and the mixed reaction system is heated to 30 to 50 DEG C for 3 to 12h of reaction so as to obtain a hydrosol; a functional agent is added into the hydrosol so as to obtain the multifunctional super-hydrophobic textile finishing agent. The multifunctional super-hydrophobic textile finishing agent is safe, is friendly to the environment, is excellent in effect, is used for super hydrophobic and multifunctional finishing of textile, is capable of providing textile with six functions including super-hydrophobic property, flame resistance, antibacterial property, stain resistance, ultraviolet resistance, and skin protection performance, is capable of eliminating adverse effect of the plurality of functions, improving the synergistic effect; the preparation method is simple and convenient, is easy to control, and is suitable for large scale production.

Owner:石狮市杰立纺织科技有限公司

Tourmaline/titanium dioxide composite collosol containing rare earth and its preparation method and uses

InactiveCN1669934ABroaden the response rangePromote degradationTitanium dioxideSilicon compoundsTitanium oxideRaw material

The invention relates to a method for preparing a tourmaline / titanium oxide composite sol and its purposes. The mass percentage of raw materials and feeds is listed: titanate with 5-15%, anhydrous alcohol with 60-90%, organic acid with 3-13%, inorganic acid with 2-15%, deionized water with 0.5-1.5%, tourmaline with 0.001-3%, tombarthite with 0.0004-0.0008%, the total is 100%. The said titanate is one of the kinds such as methyl titanate, ethyl titanate, butyl titanate, titanic chloride and titanoxy sulfate. The said organic acid is one of the kinds such as acetic acid, oxalic acid, formic acid and monosulfonic acid. The said inorganic acid is one of the kinds such as concentrated sulfuric acid, concentrated nitric acid and concentrated chlorhydric acid. The said tourmaline is one or more of the kinds such as iron-tourmaline, elbaite and dravite. The said tombarthite is one of the kinds such as lanthanum, europium nitrate, erbium nitrate, cerous nitrate and neodymium nitrate. The invention also provides the method for preparation of the said sol and its main purposes.

Owner:HEBEI UNIV OF TECH

UHMWPE (Ultra High Molecular Weight Poly Ethylene) fiber composite summer sleeping mat and manufacturing method thereof

InactiveCN104287537AImprove thermal conductivityLightweight is obviousSynthetic resin layered productsWoven fabricsFiberSurface layer

The invention discloses a UHMWPE (Ultra High Molecular Weight Poly Ethylene) fiber composite summer sleeping mat and a manufacturing method thereof. The summer sleeping mat comprises a mat surface layer, a sweat absorption layer and a mat bottom coating layer, wherein the mat surface layer is prepared from UHMWPE, or is prepared by arranging the UHMWPE and higher-water-absorption common textile materials at intervals or is prepared by using the UHMWPE and higher-water-absorption fiber composite yarns as warp and weft yarns, and is subjected to anti-bacterial and insect-preventing treatment; the sweat absorption layer is made of a high-water-absorption fabric and is arranged between the mat surface layer and the mat bottom coating layer; the mat bottom coating layer is a common hydrophilic fabric with certain abrasion resistance, is sewn in an edge coating manner, covers the sweat absorption layer and the mat surface layer and is sewn around the mat surface layer. The mat has an obvious and ensuring contact feeling of coolness, is easy to fold and carry, is light in weight, and has the anti-bacterial and insect-preventing functions; the mat surface is dry and comfortable for a long time.

Owner:PAP LOGISTICS EQUIP RES INST +1

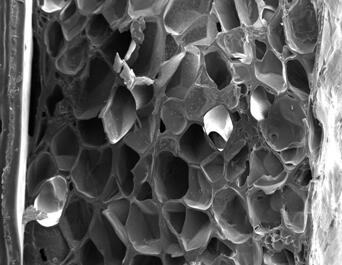

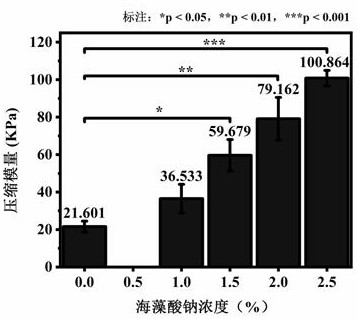

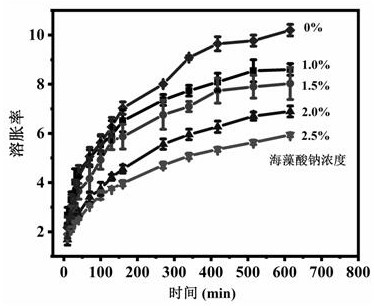

Preparation method of drug-loaded sodium alginate/gelatin composite hydrogel band-aid

InactiveCN111803697ASoft natureHas a swelling ratePharmaceutical delivery mechanismAbsorbent padsDrug ModelingGlutamine

The invention discloses a preparation method of a drug-loaded sodium alginate / gelatin composite hydrogel band-aid. The method comprises the following steps: (1) mixing sodium alginate and a gelatin solution, and preparing sodium alginate / gelatin composite hydrogel by utilizing the characteristics of cross-linking between calcium ions and sodium alginate and cross-linking between glutamine transferase and gelatin; and (2) preparing the drug-loaded sodium alginate / gelatin composite hydrogel band-aid: loading a drug into the composite hydrogel, so that the finally prepared band-aid has the effects of resisting bacteria, diminishing inflammation and promoting wound healing. The drug-loaded sodium alginate / gelatin composite hydrogel band-aid is successfully prepared, the raw materials adopted in the preparation process are all non-toxic compounds, the preparation process is simple, and the cost is low. Experimental tests show that the composite hydrogel is of a porous structure and is beneficial to gas exchange; the swelling property is beneficial to absorption of exudate of the wound; and berberine serving as a drug model is successfully loaded into the composite hydrogel and can be slowly released, so that the composite hydrogel has an antibacterial effect.

Owner:TAIYUAN UNIV OF TECH

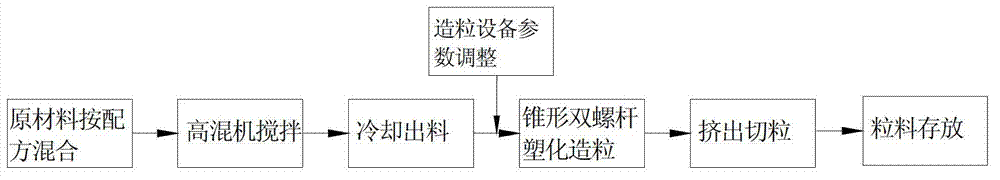

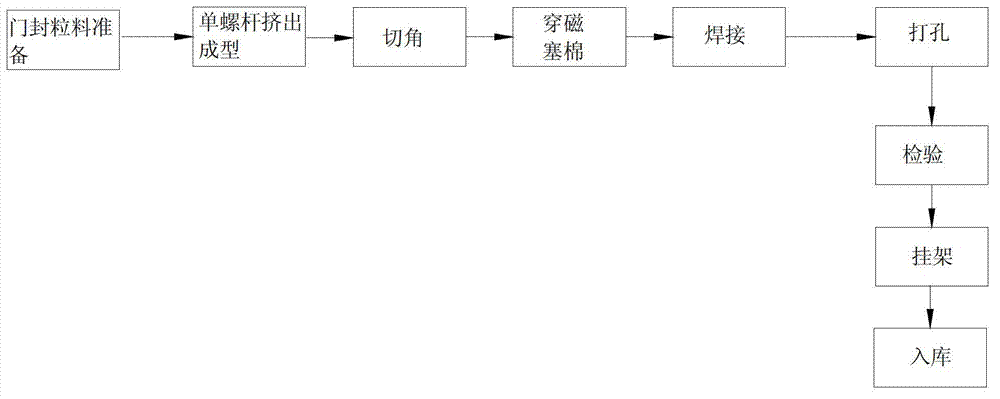

Door seal and preparation method thereof as well as refrigeration equipment

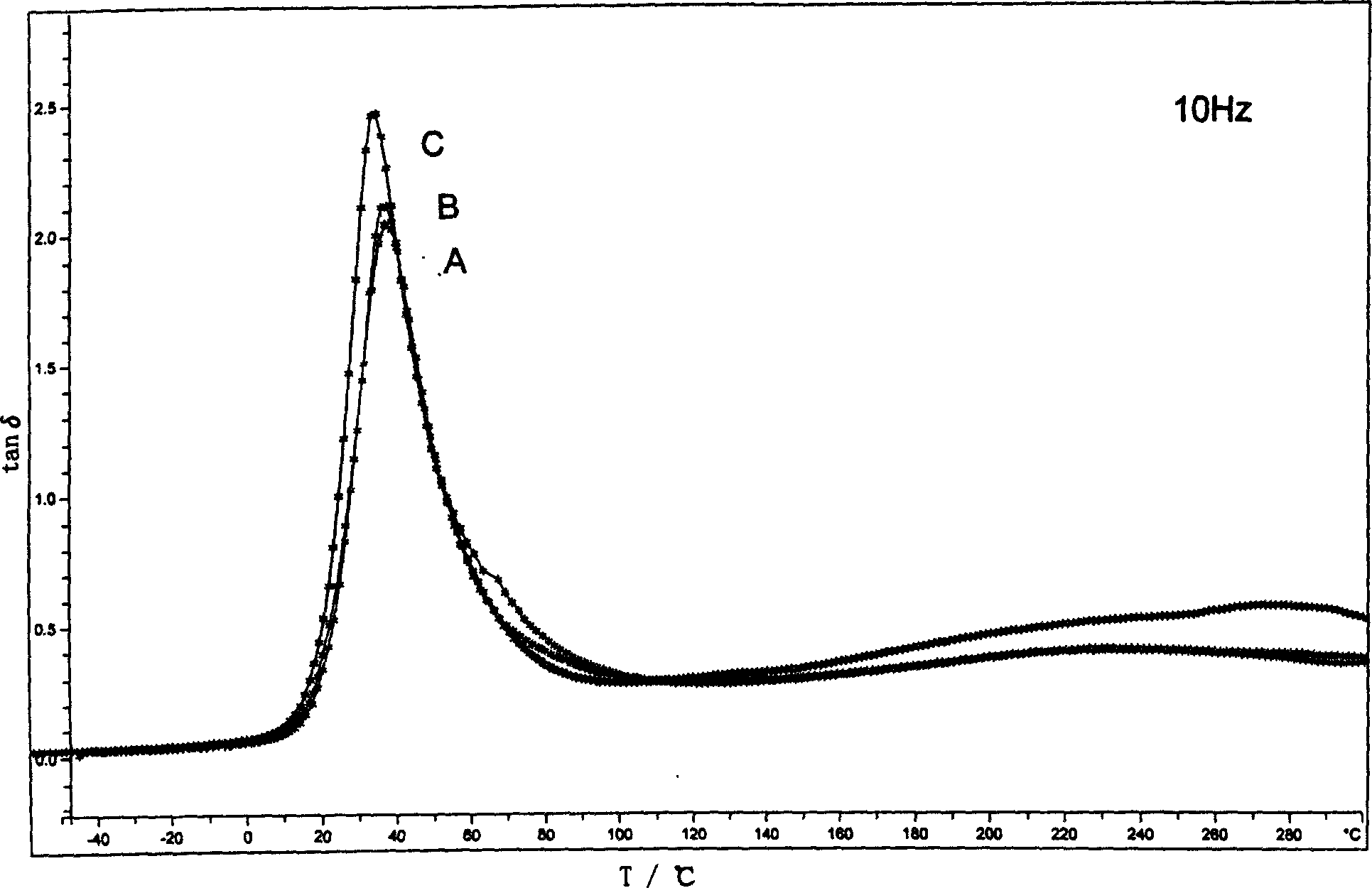

ActiveCN103087446AImprove thermal insulationReduce energy consumptionDomestic cooling apparatusLighting and heating apparatusElastomerFoaming agent

The invention discloses a door seal and a preparation method thereof as well as refrigeration equipment, wherein the door seal comprises the following components in parts by weight: 35-50 parts of PVC (polyvinyl chloride) resins, 5-15 parts of elastomer, 20-40 parts of plasticizer, 0-20 parts of inorganic filler, 1-3 parts of heat stabilizer, 0.5-2 parts of lubricating agent and 0.1-2 parts of foaming agent. The door seal disclosed by the invention has a micro-foaming structure, and has the advantages of better elasticity and tenacity, low mobility, less possibility of being adhered to side plates and a door body, low corrosivity for the side plates and the door body, and the like.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

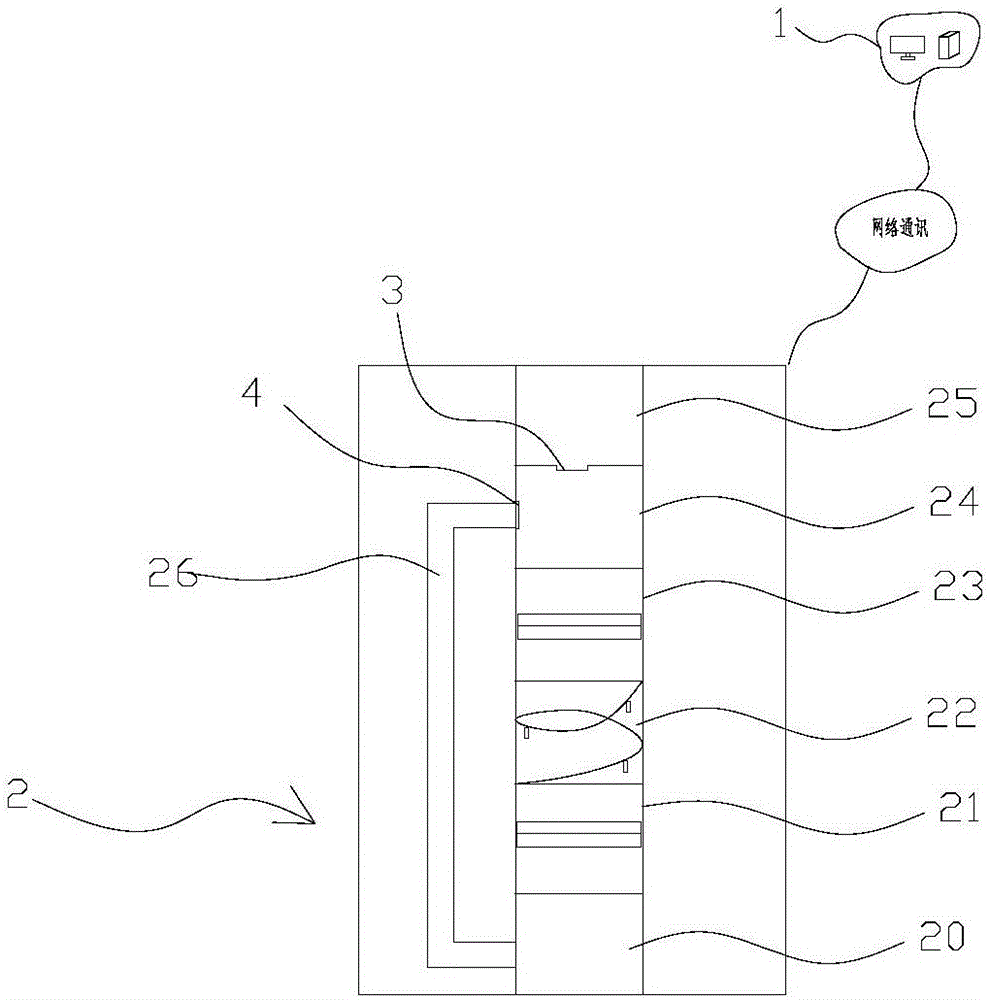

Highly efficient intelligent purification system

InactiveCN106288257APurify thoroughlyPurification process is stableMechanical apparatusSpace heating and ventilation safety systemsElectricityEngineering

The invention relates to a highly efficient intelligent purification system including a server, a communication network, a purification area and a mobile control terminal. The server includes a gas content information database, a judgment module, an information interaction module and a gas control module. The purifying pipeline comprises an inlet section, a filtering section, a spraying section, a gas-liquid separating section, a detecting section, an outlet section and a circulating section. A first electromagnetic valve and a second electromagnetic valve are arranged in the outlet section and the circulating section and results detected by a harmful gas-detecting sensor are transmitted to the server. The server then compares the detected hazardous gas content with the allowable content range in the database, and controls the closing of the first electromagnetic valve and the second electromagnetic valve by the comparison result, thereby controlling the current gas to be discharged out of the room or again into for purification. The invention has the advantages of good reliability, high purification efficiency, complete and stable air purification, continuous operation, and air humidification and antibacterial effect.

Owner:苏州市克拉思科文化传播有限公司

Luminescent panel and manufacturing method thereof

InactiveCN101776214AImprove luminous brightnessLong glow timeLuminescenceCeriumUltraviolet protection

The invention discloses a luminescent panel and a manufacturing method thereof. The luminescent panel is provided with a luminescent layer. The luminescent layer is prepared from the following components in percentage by weight: 10-50% of luminescent powder, 0.5-2% of nanometer titanium oxide, 0.05-2% of nanometer cerium, 0.05-0.2% of curing agent, 5-20% of flame retardant, 0.05-0.2% of accelerator, and the balance of transparent resin. The luminescent panel has the advantages of high luminescent brightness, long luminescent time, ultraviolet protection, good strength and long service life.

Owner:HEBEI NAMING NEW MATERIAL SCI & TECH CO

Wool/crotalaria sp./mulberry silk/cotton/polyester fiber blended fabric and preparation method thereof

The invention relates to a wool / crotalaria sp. / mulberry silk / cotton / polyester fiber blended fabric. The fabric comprises the following material components in percentage by weight: 28% of wool fiber, 35% of crotalaria sp. fiber, 17% of polyester fiber, 18% of cotton fiber and 3% of mulberry silk. The method includes the steps of: 1, top dying process of the cotton fiber and the crotalaria sp. Fiber; 2, dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber; 3, spinning process; 4 weaving process; 5, dying and finishing process; the spinning process includes: mixing and performing primary gilling, secondary gilling, third gilling and fourth gilling on products prepared by the dying and re-combing process of the wool fiber, the polyester fiber and the mulberry silk fiber, then being subjected to primary roving, secondary roving and spinning processes together with yarn prepared by the top dying process of the cotton fiber and the crotalaria sp. Fiber, when a double-steel wire hook is adopted in the spinning process. The fabric achieves the purpose of being breathable, antibacterial and health-care, and meanwhile meets the requirements on various technical indexes of spring and summer fabrics.

Owner:江苏华西村纺织服装有限公司

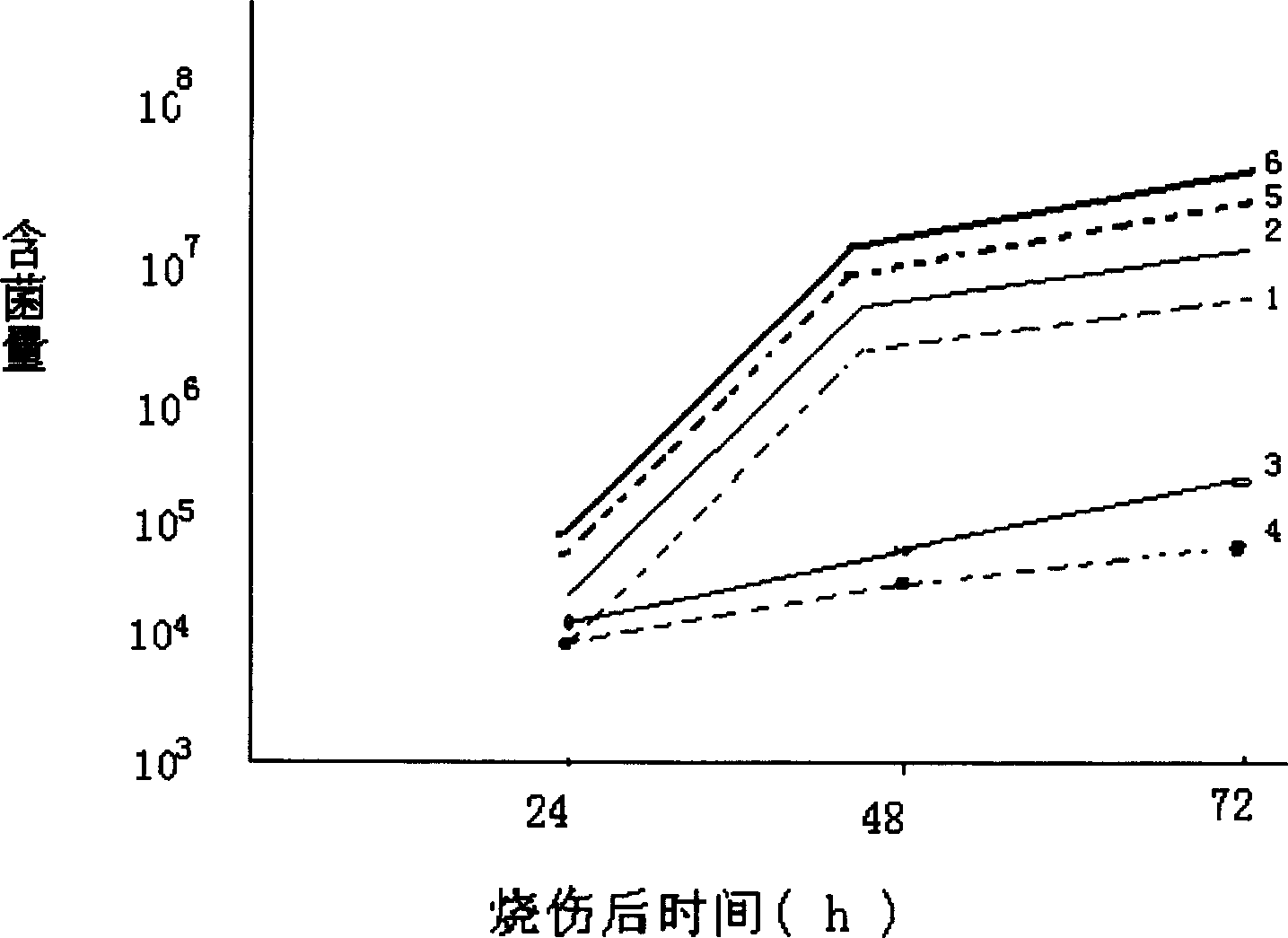

Compound silver zinc sulfapyrimidine ointment, and its prepn. method

InactiveCN1513458ASynergisticPromote in-depthOrganic active ingredientsAerosol deliveryEthyl hydroxybenzoateSulfanilamide

A compound sulfapyrimidine silver zinc ointment for treating burn is prepared from sulfapyrimidine silver, sulfapyrimidine zinc, osmotic aid medical auxiliary, ethyl p-hydroxybenzoate, glycerine and distilled water through heating oil phase to 75 deg.C, heating water phase to 75 deg.C, slowly adding oil phase to water phase while stirring, cooling, adding sulfapyrimidine silver and sulfapyrimidine zinc, grinding, and examining. Its advantage is strong antibacterial function.

Owner:YOULIKAI BIOLOGICAL TECH BEIJING

Polyurethane coating material for shoe coating and preparation method of polyurethane coating material

ActiveCN109762456AReduce coefficient of frictionGel fastAntifouling/underwater paintsPaints with biocidesALUMINUM POTASSIUM SULFATEIsocyanate

The invention provides a polyurethane coating material for shoe coating and a preparation method of the polyurethane coating material. The preparation method comprises the following steps that step (1) isocyanate, polyester polyol, a moisture scavenger and a diluent are added into a reaction kettle in proportion and mixed evenly, reaction is carried out for 6-8 hours under the condition of 80-120DEG C, vacuum bubble removal is carried out, and cooling is performed to obtain a component A; step (2) polyester polyol, a chain extender, a catalytic agent and a glycerin solution of dehydrated aluminum potassium sulfate dodecahydrate are added into the reaction kettle in proportion and mixed evenly and vacuumized for 2-3 hours to remove bubbles, and a component B is obtained; and step (3) the component A and the component B are evenly mixed in proportion, vacuum bubble removal is carried out for 30s, and the polyurethane coating material is obtained. The prepared polyurethane coating material is used for coating the surface of a shoe, once-forming can be achieved, and the problem that bubbles generated in the coating due to the fact that a known spraying polyurethane elastomer reacts with moisture is further solved.

Owner:FOSHAN NANHAI QIHONG SHOES MATERIAL CO LTD

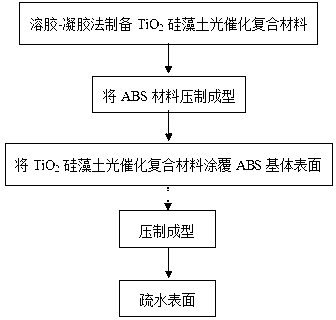

ABS hydrophobic and oleophobic material with surface loaded by TiO2/diatomite, and preparation method thereof

InactiveCN103275456AEasy to useOleophobicOrganic-compounds/hydrides/coordination-complexes catalystsFungicidesCompression moldingPollution

The invention provides an ABS hydrophobic and oleophobic material with surface loaded by TiO2 / diatomite, and a preparation method thereof. The ABS hydrophobic and oleophobic material is composed by the following raw materials by mass: 98-99.9% of an ABS resin and 0.1-2% of a TiO2 / diatomite composite photocatalytic material. The ABS hydrophobic and oleophobic material with the surface loaded by TiO2 / diatomite is obtained by the steps of A. firstly preparing the TiO2 / diatomite composite photocatalytic material, B. dispersing the TiO2 / diatomite composite photocatalytic material in ethanol to form a suspension liquid, and C. coating the suspension liquid on the surface of a mold, then keeping ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, and compression molding at the temperature of 150-180 DEG C; or keeping the ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, compression molding at the temperature of 150-180 DEG C, then coating the suspension liquid obtained by the step B on the surface of the compression molded ABS resin material, and then compression molding at the temperature of 150-180 DEG C. The ABS hydrophobic and oleophobic material has the characteristics of super-hydrophobic surface self-cleaning effect and self-cleaning capacity. The preparation method is simple in process, simple in operations, small in investment, low in operation cost and no pollution to environment.

Owner:KUNMING UNIV OF SCI & TECH

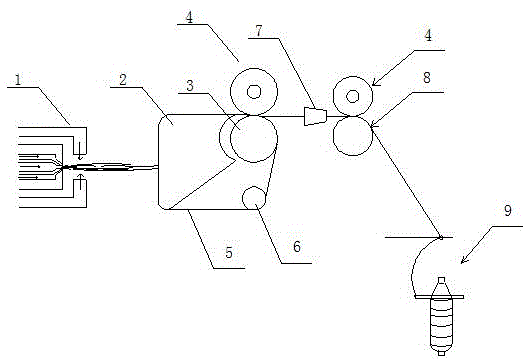

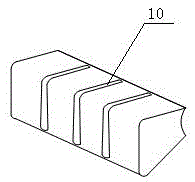

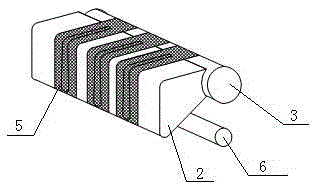

Novel micro-nano fiber yarn spinning device and technology

InactiveCN105568446AWith heat insulationImprove insulation effectDrafting machinesContinuous wound-up machinesYarnFiber

The invention discloses a novel micro-nano fiber yarn spinning device and technology. The device comprises a spinning nozzle, a fiber polymerization mechanism, a drafting mechanism and a twisting mechanism. The fiber polymerization mechanism is composed of an irregularly-shaped exhaust pipe, a grid ring and a tension frame. The drafting mechanism is composed of a first roller, a second roller, a leather roller and a cotton collector, wherein the leather roller and the cotton collector are matched with the first roller and the second roller. The novel micro-nano fiber yarn spinning technology comprises the steps that micro-nano fibers are formed at first, then reach the receiving device irregularly-shaped exhaust pipe along with airflow, are drafted finally and enter the twisting area to be twisted to form a micro-nano fiber yarn. The structure and technology design is reasonable, actual operation is convenient, super fine micro-nanoscale fibers formed through melt-blown spinning can be spun into the yarn under high fitting rate and high production efficiency, the produced yarn has the advantages of excellent heat insulation, heat preservation, adsorption, filtration, sound absorption and the like, and production of the micro-nano fiber yarn with the features and functions of bacteria resistance and ultraviolet resistance is achieved through melt component design.

Owner:SHENZHEN ZHONGSHENG LIDA TRADE CO LTD

High-biocompatibility fiber

ActiveCN106943627AAchieve growthAchieve antibacterialSurgeryVacuum evaporation coatingFiberGas phase

The invention provides a high-biocompatibility fiber including a fiber base material and a plating layer. The plating layer includes a titanium plating layer formed on the fiber base material and a tantalum-containing plating layer formed on the titanium plating layer. The tantalum-containing plating layer may also include silver, zinc, strontium or like. The titanium plating layer is formed by plating titanium on the fiber base material through a plasma chemical vapor deposition method. The tantalum-containing plating layer is formed by plating a tantalum-containing material on the titanium film layer through a physical vapor deposition method. The high-biocompatibility fiber has antibacterial, healing promoting and tissue growth inducing functions.

Owner:北京华钽生物科技开发有限公司

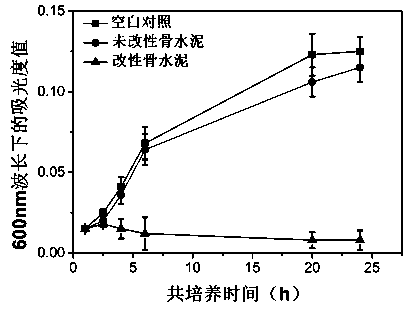

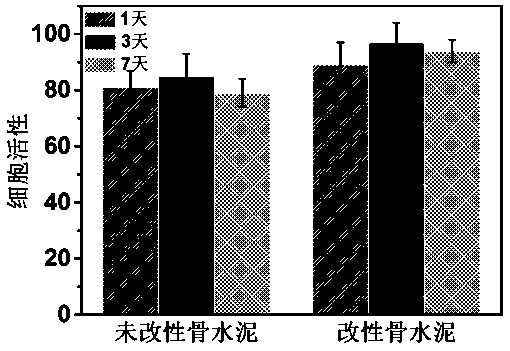

Bone cement with biological activity and antibacterial function and preparation method thereof

ActiveCN109464698ASolve the problem of prone to drug resistanceAvoid the problem of cumulative toxicityTissue regenerationProsthesisChemical treatmentCvd risk

The invention discloses bone cement with biological activity and antibacterial function and a preparation method thereof and belongs to the field of material science and medicine. After modification treatment, biological glass is mixed with an acrylate bone cement matrix material, so that the bone cement is endowed with the biological activity and the antibacterial function. The surface of the biological glass is rich in amino through chemical treatment, and further silver, copper and other ions are compounded, so that the biological glass with the antibacterial metal ions on the surface is formed. The biological glass not only has the antibacterial function, but also can avoid the risks of circulation and accumulation of the metal ions in a human body. The antibacterial biological glass is added in the acrylate bone cement and can realize a long-term antibacterial effect in an implantation position. The bone cement prepared by the preparation method can reduce the risk of revision caused by infection after the bone cement is implanted in a patient, solve the problem of human body drug resistance caused by the current clinical application of antibiotic bone cement and can be used in the orthopaedic field such as joint and spine repair, thereby having a broad clinical application prospect.

Owner:上海朗迈医疗器械科技有限公司

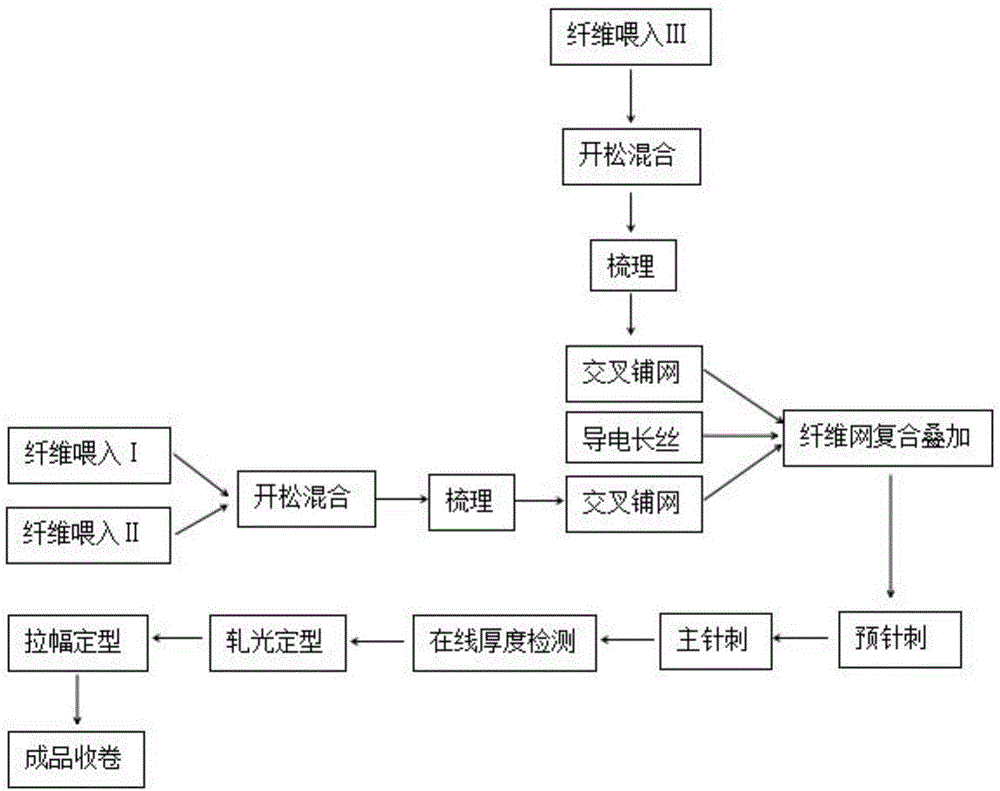

Antibacterial, fire-resistant and anti-static non-woven fabric and weaving method thereof

ActiveCN106757773AAvoid keeping time limitedAchieve antibacterialNon-woven fabricsWoven fabricConductive filament

The invention relates to an antibacterial, fire-resistant and anti-static non-woven fabric and a weaving method thereof. The non-woven fabric comprises, by weight, 30-40 parts of antibacterial deodorant fiber and 60-70 parts of polypropylene fiber. The method comprises the steps that the antibacterial deodorant fiber and the polypropylene fiber are mixed and then subjected to carding and cross lapping to form a blend fiber net; fire resistant fiber is subjected to carding and cross lapping to form a fire resistant fiber net; the blend fiber net and the fire resistant fiber net are arranged on the upper and lower faces of a conductive filament, the blend fiber net, the conductive filament and the fire-resistant fiber net are composited and stacked on a delivery apron to form a composite fiber net, and the composite fiber net forms the needling non-woven fabric through needling reinforcing. The non-woven fabric is manufactured through simple technological processes, and is easy to manufacture and good in anti-static and deodorant effect.

Owner:TIANDINGFENG NONWOVENS CO LTD

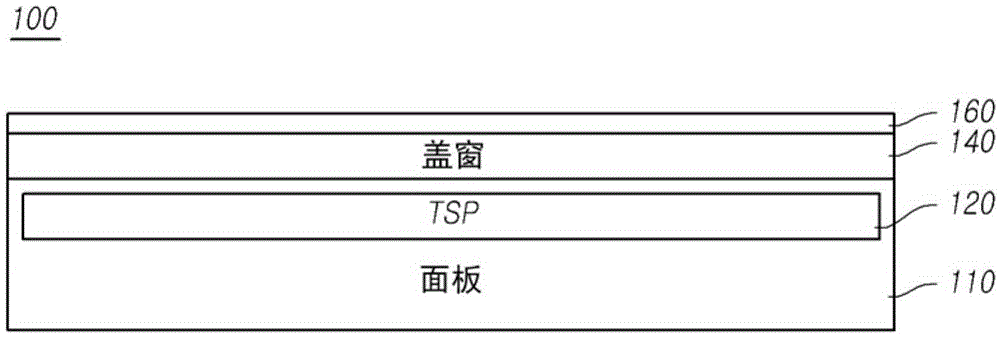

Functional single-layer film and display device having the same

ActiveCN105549128AHigh strengthAnti-reflection improvementDigital data processing detailsPaints with biocidesDisplay deviceMaterials science

Disclosed are a functional single-layer film and a display device including the same. The functional single-layer film is positioned on a cover window of the display device. The functional single-layer film includes a matrix material and carbon-containing flakes contained in the matrix material. The content of the carbon-containing flakes ranges from 0.01% to 0.1% by weight.

Owner:LG DISPLAY CO LTD

Active packing material, preparation method and application thereof

The invention discloses an active packing material, a preparation method and application thereof, and belongs to the field of packing materials. The active packing material is prepared mainly through mixing main materials with an adhesive, and carrying out molding, wherein the main materials comprise the following components by mass percent: 30% to 60% of orange peel residues, 5% to 35% of indocalamus leaves, 5% to 30% of phyllostachys edulis and 5% to 25% of licorice extract; and the mass ratio of the main materials to the adhesive is 1 to (0.15 to 5). The preparation method comprises the steps of mixing the orange peel residues, the indocalamus leaves, the phyllostachys edulis and the licorice extract according to the mass percent to obtain the main materials, adding water into the main materials, pulping, and carrying out finish grinding to obtain main material slurry; adding the adhesive into the main material slurry, and stirring till uniform dissolution to obtain a mixture; and carrying out molding on the mixture to obtain the active packing material. The active packing material has antibacterial property, oxidation resistance, water absorption and water-retaining property, is easily decomposed after being discarded, and can be used for storing cold fresh meat.

Owner:HUNAN AGRI PRODS PROCESSING INST

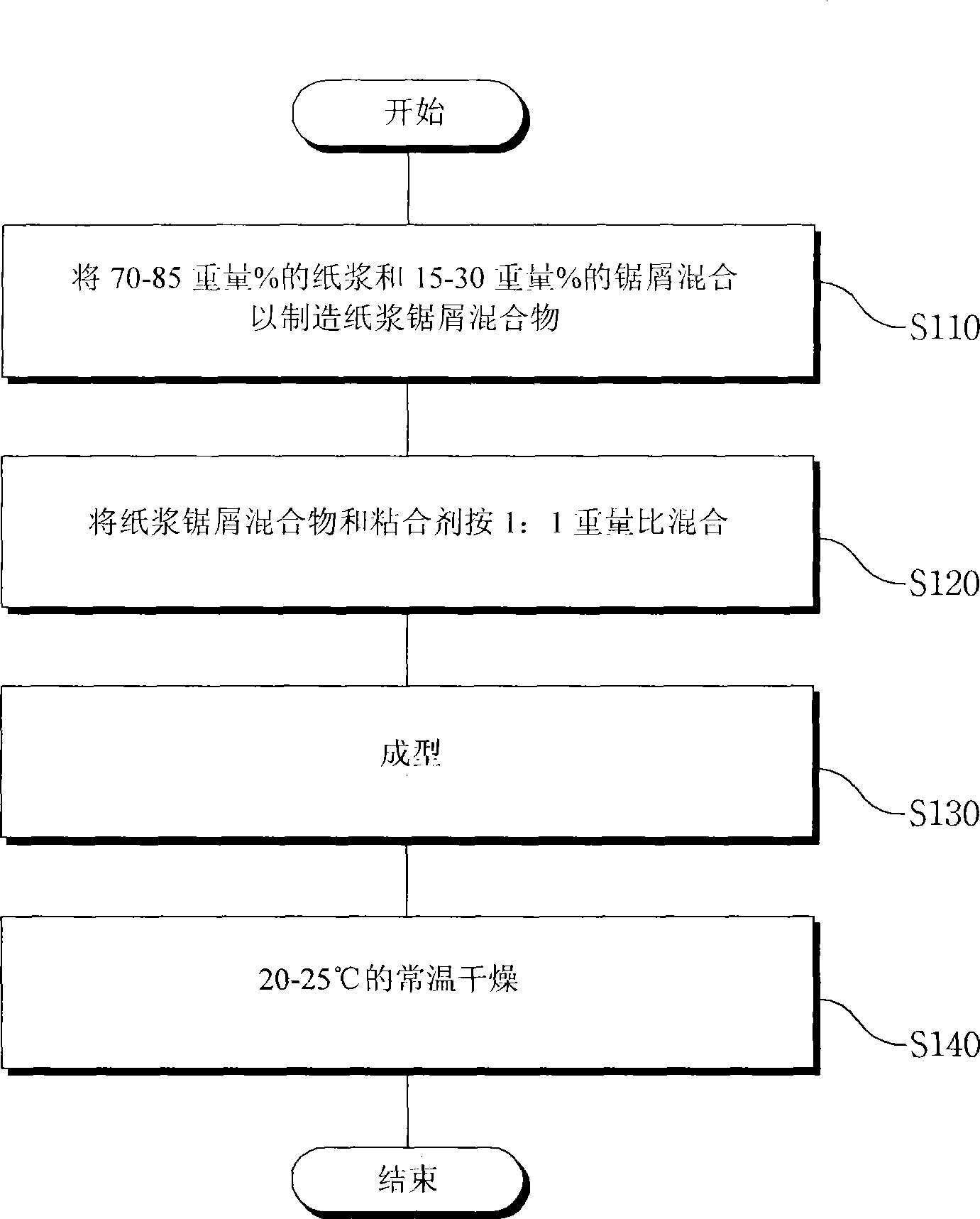

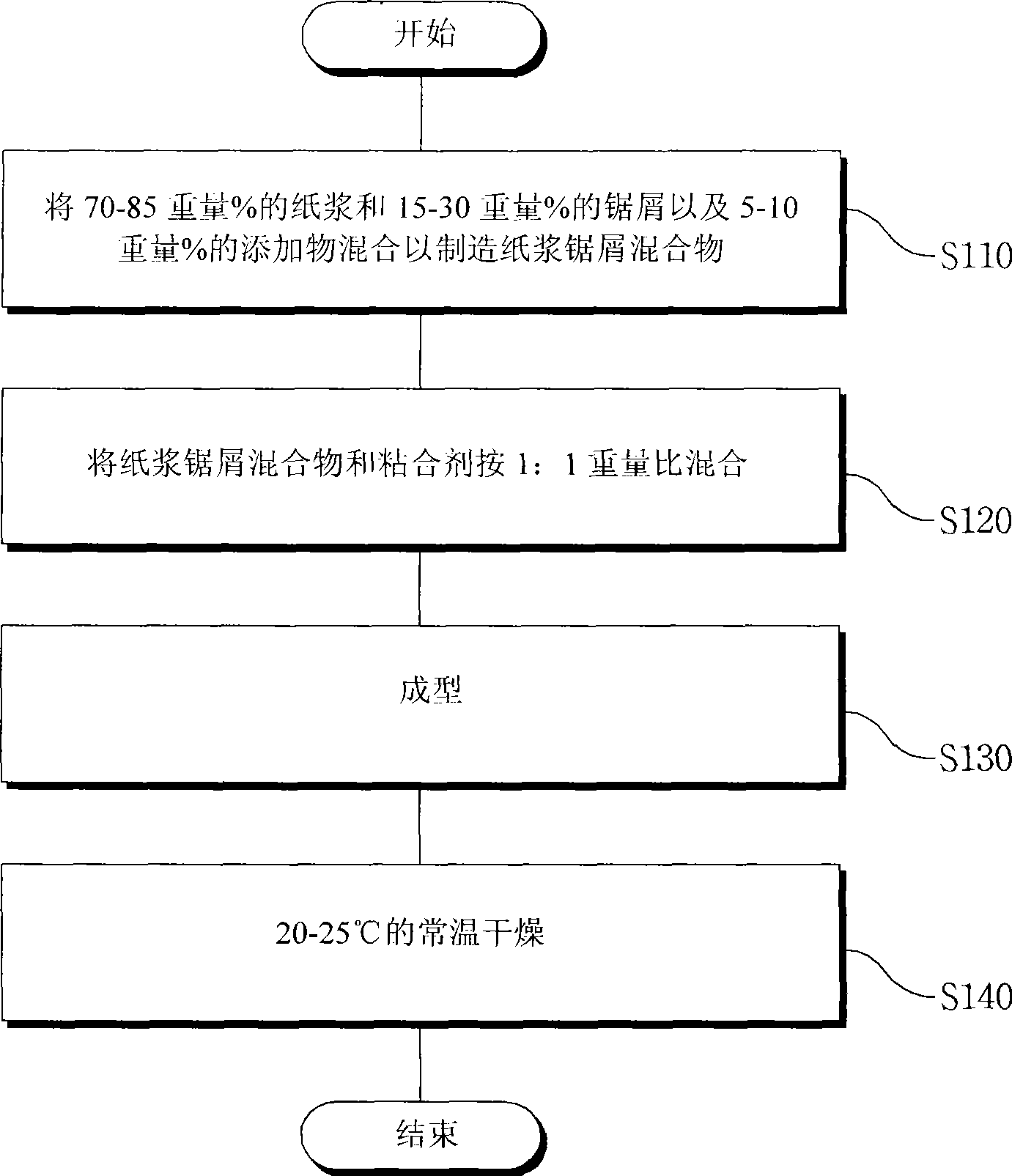

Strengthening pulp house decorative material mixed with saw powder and method for producing the same

InactiveCN101451329AAchieve releaseHigh strengthFibreboardSecondary cellulose fibresGlass fiberAdhesive

The invention relates to an enhanced pulp interior decoration material mixed with sawdust and a manufacturing method thereof. Particularly the manufacturing method for the pulp interior decoration material is characterized in that the method comprises the steps of: a paper pulp-sawdust mixture formation stage, in which 70 to 85 weight percent of paper pulp produced by recycled waste paper and 15 to 30 weight percent of sawdust are mixed to form a paper pulp-sawdust mixture; an adhesive mixing stage, in which an adhesive and the paper pulp-sawdust mixture are mixed according to the weight proportion of 1:1; a molding stage, in which the paper pulp-sawdust mixture mixed with the adhesive is placed into a mould for molding to produce the enhanced pulp interior decoration material; and a drying stage, in which the molded enhanced pulp interior decoration material is naturally dried at a normal temperature of between 20 and 25 DEG C to finish a product. The pulp interior decoration material produced by mixing the sawdust and the paper pulp or the sawdust and the paper pulp as well as a mixture (carbon, yellow earth, glass fiber, ceramic, and silver) according to the method has the improved strength and moistureproof effect, and realizes the deodorization, the antibacterium and the release of infrared rays, thereby semi-permanently prolonging the service life of the product, and enlarging the use range to soundproof materials or ceiling boards, transportation protection materials with strength requirement and so on.

Owner:ELITE ENTERPRISES INC +1

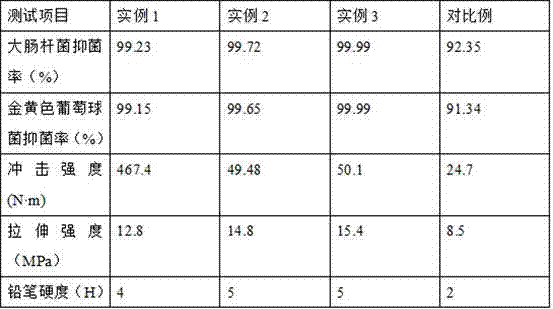

Preparation method of antibacterial paperboard high in bonding strength

InactiveCN107881846AHigh bonding strengthImprove operating conditionsPaper/cardboardInorganic compound additionCrosslinked chitosanPaperboard

The invention discloses a preparation method of antibacterial paperboard high in bonding strength, and belongs to the technical field of board preparation. An amphoteric polyacrylamide emulsion servesas a bridge and is combined and linked with silver-loaded zeolite and paper pulp, gaps between layers are filled with cationic starch and modified chitosan, and the antibacterial paperboard high in bonding strength is obtained; zeolite of a porous structure is modified through a silver nitrate solution, a catalytic reaction is utilized for sterilization, water molecules and oxygen in the air areactivated with nanometer particles, and then the antibacterial effect of the paperboard is improved, the very good retention effect is achieved for the starch, and the bonding strength, between the layers, of the paperboard is further improved; crosslinked chitosan resin is prepared by mixing the chitosan with epichlorohydrin, formalin and acetic acid, the crosslinked chitosan resin can control loss of the chitosan and enhance adsorptive selectivity of the chitosan, and then the effect of killing bacteria is achieved; the bacterial effect of the paperboard is further improved, and a wide application prospect is achieved.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

Furniture board paint process for removal of formaldehyde and solution for removal of formaldehyde

InactiveCN102488998AAchieve antibacterialAchieve mildew resistancePretreated surfacesDeodrantsSodium phosphatesManganese

The invention relates to a board paint process, in particular to a furniture board paint process for removal of formaldehyde and a solution for removal of the formaldehyde. The solution contains the following raw components in percentage by mass: 13 percent to 15 percent of titanium dioxide, 0.5 percent to 0.54 percent of sodium phosphate powder; 3.1 percent to 3.3 percent of calcium carbonate powder, 0.02 percent to 0.04 percent of dimethylbenzene powder, 0.04 percent to 0.06 percent of brown sugar, 2.0 percent to 2.4 percent of manganese metal powder, and 76 percent to 84 percent of thinner. The solution for removal of the formaldehyde can catalyze water and oxygen in air to have redox reaction under the condition with or without light to generate hydroxyl radical with strong oxidizing force, and the hydroxyl radical plays a role in decomposing formaldehyde, benzene, ammonia, TVOC (Total Volatile Organic Compound) and other organic compounds, so that the effects of antibiosis, mould proof, deodorization, stain repellent, hydrophile, self-cleanness and the like are simultaneously achieved.

Owner:好来屋厨柜(厦门)有限公司

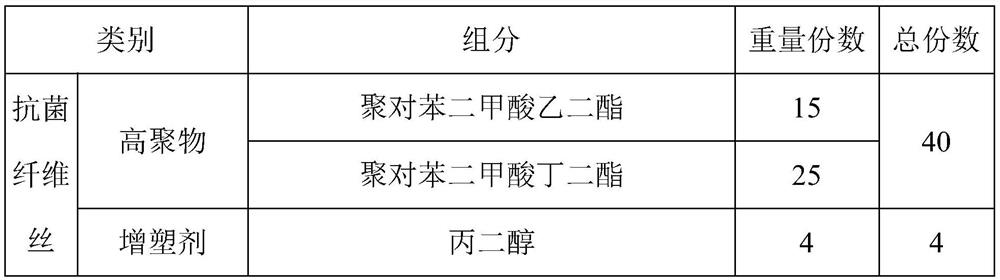

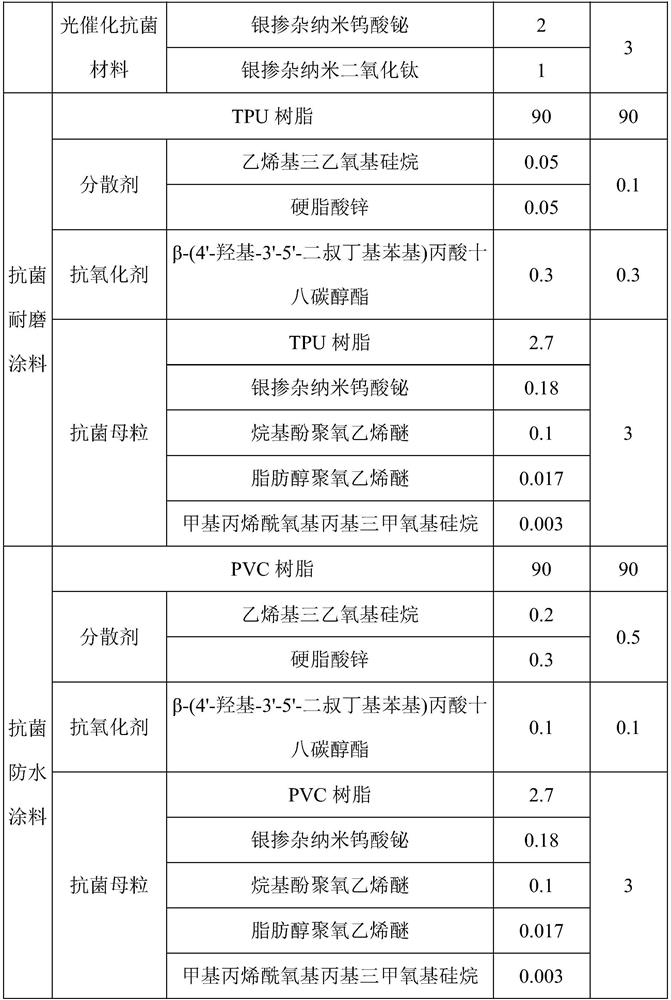

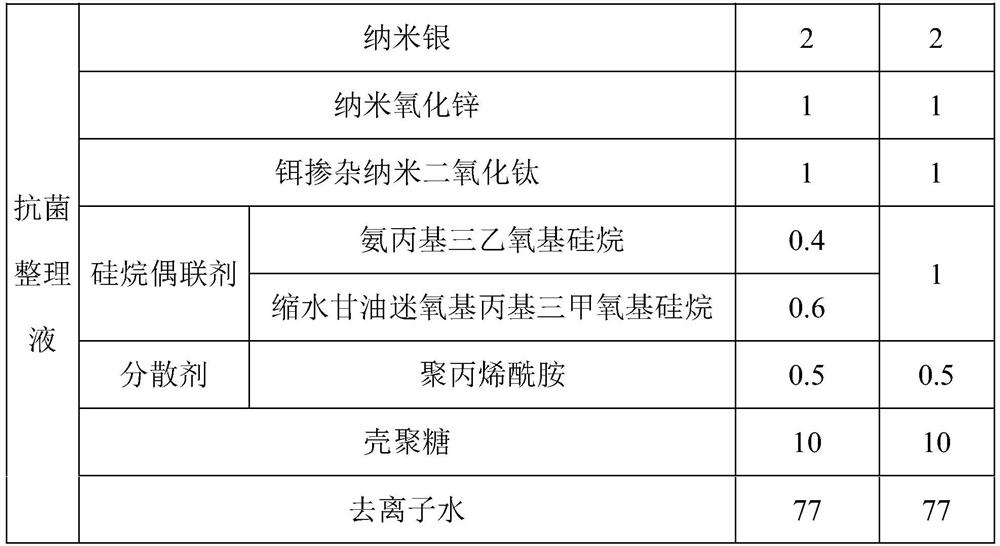

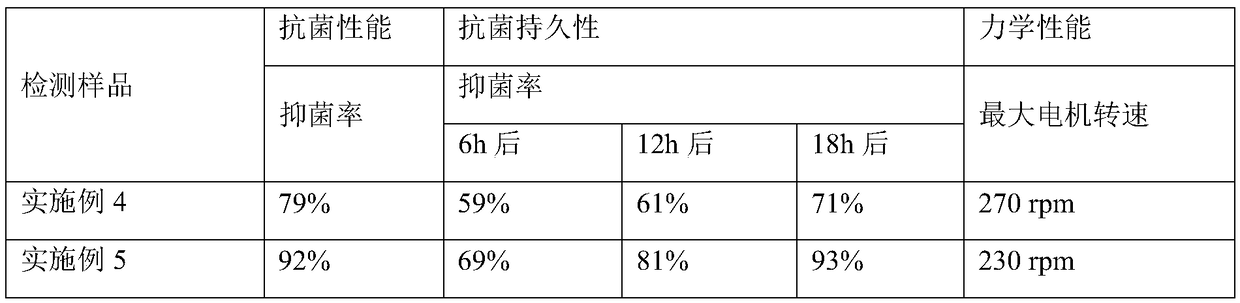

Antibacterial fabric as well as preparation method and application thereof

ActiveCN112680970AOvercoming Technical Shortcomings of Antimicrobial EfficacyAchieve antibacterialFibre typesYarnFiber

The invention provides an antibacterial fabric as well as a preparation method and application thereof. The antibacterial fabric comprises an antibacterial and wear-resistant layer, antibacterial base cloth and an antibacterial and waterproof layer which are sequentially laminated. The preparation method comprises the following steps of spinning antibacterial fiber yarns into base cloth, putting the base cloth into an antibacterial mixed solution containing antibacterial finishing liquid and fabric finishing liquid, and performing padding and drying to obtain the antibacterial base cloth; and preparing antibacterial and wear-resistant paint from raw materials of the antibacterial and wear-resistant layer, preparing antibacterial and waterproof paint from preparation raw materials of the antibacterial and waterproof layer, and spraying the antibacterial and wear-resistant paint and the antibacterial and waterproof paint to two sides of the antibacterial base cloth respectively to obtain the antibacterial fabric. The three layers of structures of the antibacterial fabric all have the antibacterial effects, the overall antibacterial performance of the fabric is achieved, the waterproof and self-cleaning functions are achieved, and the strength of the fabric is relatively high, so that the fabric is suitable for preparation of luggage fabrics; and the preparation process is scientific and efficient, and the application value is extremely high.

Owner:同曦集团有限公司

Fluorescent degradable polyester fiber

InactiveCN101701382AEffective reflectionGood warningFlame-proof filament manufactureMelt spinning methodsFluorescenceChemistry

The invention relates to a fluorescent degradable polyester fiber which is characterized in that first, nano titanium dioxide, silver oxide, strontium aluminate and nickel powder are added into the synthesis of degradable polyester, and modified nano degradable polyester can be obtained; and the polyester is directly processed by melt spinning technique, so that the fluorescent degradable polyester fiber is obtained.

Owner:JIANGSU YINGXIANG FIBER

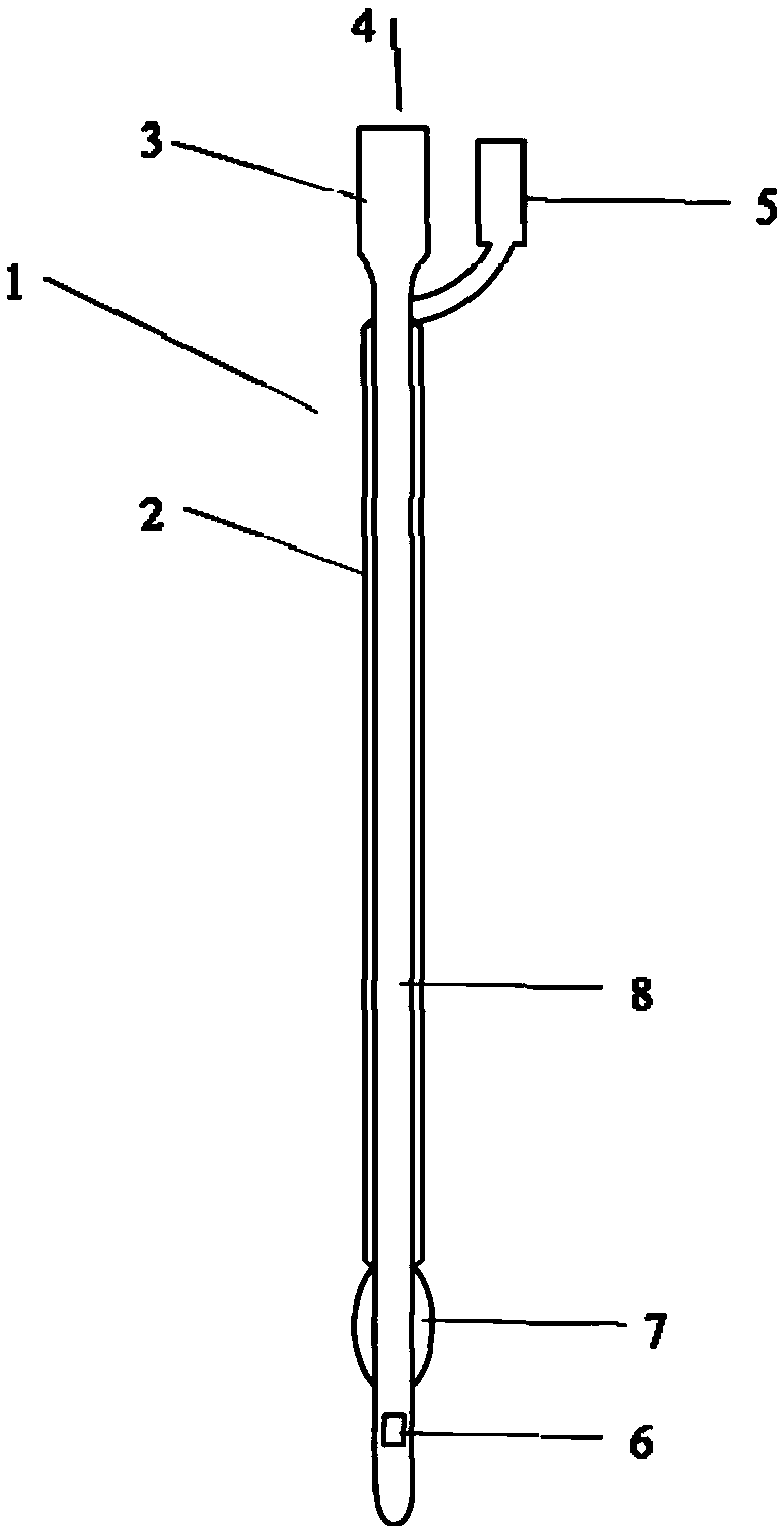

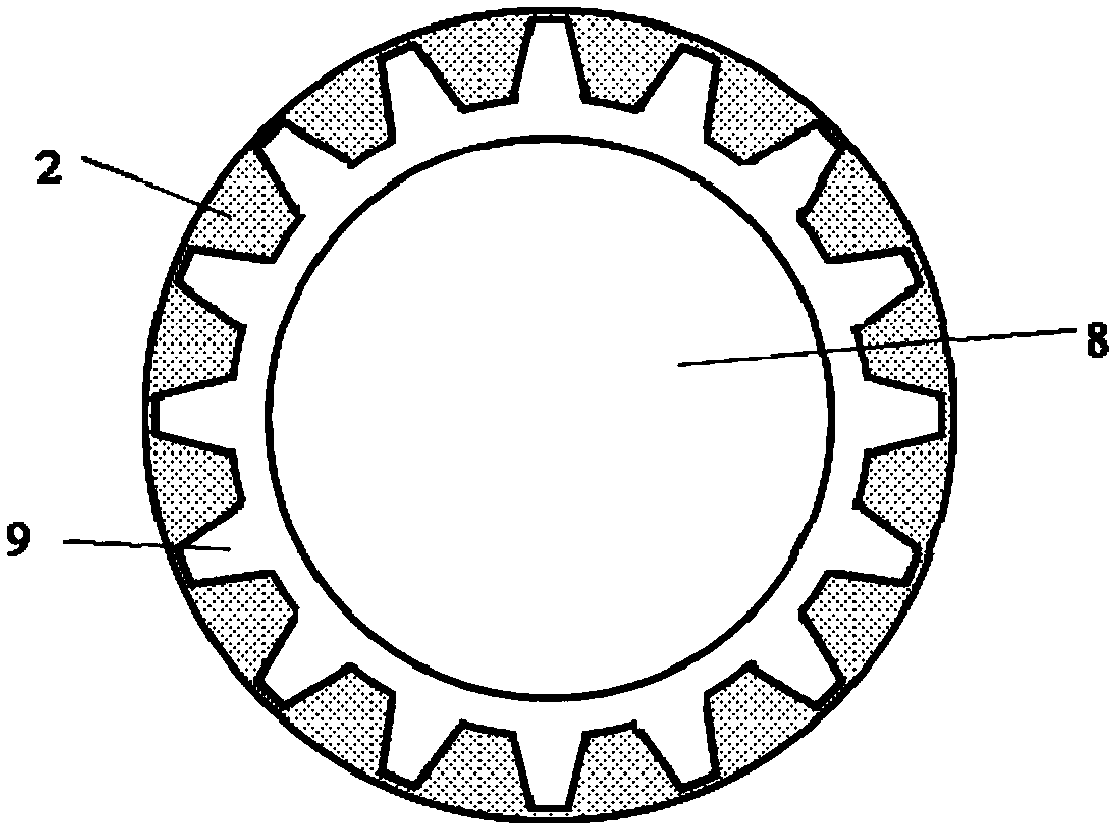

Catheter capable of preventing urinary tract infection

PendingCN109107021AImprove solubilityElasticBalloon catheterCoatingsUpper urinary tract infectionAntibiotic Y

The invention discloses a catheter capable of preventing urinary tract infection, belonging to the technical field of medical instruments. The catheter of the invention comprises a catheter main bodyand a hydrogel layer containing antibiotics. The upper end of the catheter main body comprises a catheter outlet and an inflation valve with a standard joint, and the lower end comprises a catheter inlet and an inflation balloon. The catheter inlet and the catheter outlet are connected by a catheter cavity, and the inflation balloon and the inflation valve are connected by an inflation pipe. The hydrogel layer covers a portion of the catheter body located between the balloon and the catheter outlet. As that hydrogel coat with antibiotics is added on the outside of the conventional catheter tube, the antibacterial of the catheter is effectively realized; at the same time, the hydrogel has a certain sustained-release effect, which delays the release of antibiotics and prolongs the time thatthe catheter can be used. Further, a protrusion is arranged on the outside of the catheter so as to prevent the hydrogel from falling off in the process of use, and the safety of use is ensured.

Owner:AFFILIATED HOSPITAL OF JIANGNAN UNIV

Novel environmentally-friendly nanometer antibacterial latex paint

InactiveCN102649881AAchieve antibacterialAchieve waterproof effectAntifouling/underwater paintsPaints with biocidesMilk paintAnatase

The invention discloses a novel environmentally-friendly nanometer antibacterial latex paint. A process formula comprises 0.5-1 percent by weight of anatase TiO2, 0.5-1 percent by weight of antibacterial powder and 0.2-0.4 percent of nanometer calcium carbonate besides components including water, an emulsion, a pigment, a filler and various aids in the conventional latex paint. A production process comprises the following steps of: adding water into a stirrer; adding a dispersant, a wetting agent, diatomite, a pigment-filler, attapulgite and a part of antifoaming agent in sequence in a stirring process; stirring uniformly, and injecting into a sand mill for milling to certain fineness; pouring into a thinning tank; adding an emulsion and the remaining antifoaming agent, and stirring uniformly; slowly adding a film forming aid, a dry film mold preventive, a preservative and super absorbent resin, and fully stirring; adding anatase TiO2 and antibacterial powder; adjusting the latex paint to appropriate viscosity; and stirring uniformly, filtering and packaging. The latex paint has the functions of resisting bacteria, purifying air, and the like.

Owner:李艳 +1

A method for TiO2 nano polymerization synergistic modification of natural pearls

InactiveCN101006881ADecreased reflection spectrum intensityAvoid destructionJewelleryEmulsionIntermediate state

The invention relates to a method for producing nanoTiO2 Polymerization synergism-modified natural pearl. the method comprises the steps of: 1) preparing aqueous collosol, 2) carrying out a reaction between the natural pearl and aqueous collosol, drying, heat-treating to obtain intermediate state nano TiO2 modified natural pearl, 3) stirring the aqueous emulsion and deionized water for reaction to prepare precursor of aqueous solution, and 4) carrying out a polyreaction between the intermediate state nano TiO2 modified natural pearl and precursor Solution, drying, and heat-treating to obtain the final product. The product of the invention has the advantages of good uvioresistant oxidation and decay resistance performance. it is showed that the yellowing speed is reduced to 0 from the former 1.76% by 72h intensify experiment, polish descent speed is reduced to 0 from the former 2.87% by 10h sweat soaking experiment. The polish is improved with one or two rates than common pearl.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com