Antibacterial, fire-resistant and anti-static non-woven fabric and weaving method thereof

A non-woven fabric and anti-static technology, applied in the field of non-woven fabrics, can solve the problems of difficult penetration into the fabric, easy loss of finishing agents, and functional failure, and achieve the effect of avoiding limited retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

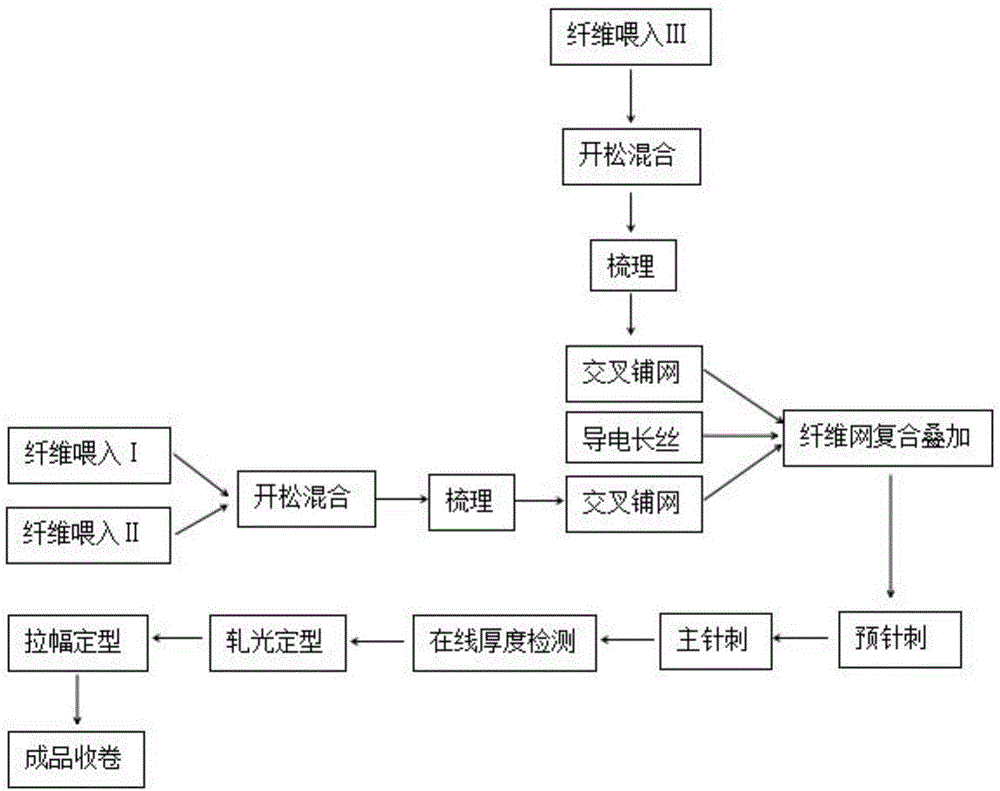

Image

Examples

Embodiment 1

[0029] The antibacterial and deodorant fiber is made of chitin fiber, chitin fiber and polypropylene fiber are blended, and the flame retardant fiber is made of flame retardant viscose fiber:

[0030] (1) Opening and mixing of antibacterial and deodorizing chitin fibers and polypropylene fibers and carding and laying: 30 parts by weight of chitin fiber raw materials and 70 parts of polypropylene fiber raw materials are opened on a bale opener to make the fiber raw materials Open from the original compacted state to a loose state, and then fully mix the loose fibers in the cotton mixer; then card the uniformly mixed fibers into a web on the carding machine, and cross-lay on the cross-lapper Net, the weight of the blended fiber net is 40g / m 2 ;

[0031] (2) Opening and carding of flame-retardant viscose fiber: Open the raw material of flame-retardant viscose fiber on the bale unpacking machine, so that the fiber raw material is loosened from the original compacted state to a lo...

Embodiment 2

[0039]The antibacterial and deodorant fiber is made of nano-silver ion fiber, blended with nano-silver ion fiber and polypropylene fiber, and the flame-retardant fiber is made of flame-retardant polysulfone fiber:

[0040] (1) Opening and mixing of antibacterial and deodorizing nano-silver ion fibers and polypropylene fibers and carding and laying: 35 parts by weight of nano-silver ion fiber raw materials and 65 parts of polypropylene fiber raw materials are opened on the bale opener to make the fibers The raw material is loosened from the original compacted state to a loose state, and then the loose fibers are fully mixed in the cotton blender; then the evenly mixed fibers are carded into a web on the carding machine, and crossed on the cross lapper Laying net, the weight of blended fiber web is 50g / m 2 ;

[0041] (2) Opening and carding of flame-retardant sulfonamide fibers: open the flame-retardant sulfone fiber raw materials on the unpacking machine, so that the fiber raw...

Embodiment 3

[0049] The antibacterial and deodorant fiber is made of bamboo charcoal fiber, blended with bamboo charcoal fiber and polypropylene fiber, and the flame retardant fiber is made of flame retardant polyester fiber:

[0050] (1) Opening and mixing of antibacterial and deodorizing bamboo charcoal fiber and polypropylene fiber and carding and laying: the bamboo charcoal fiber raw material of 40 parts by weight and the polypropylene fiber raw material of 60 parts are opened on the bag opening machine, so that the fiber raw material is changed from the original The compacted state is loosened into a loose state, and then the loose fibers are fully mixed in the cotton blender; the evenly mixed fibers are carded into a web on a carding machine, and cross-laid on a cross-lapper, blended The weight of the fiber web is 60g / m 2 ;

[0051] (2) Opening and carding of flame-retardant polyester fiber: open the flame-retardant polyester fiber raw material on the bale unpacking machine, so that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com