Antibacterial fabric as well as preparation method and application thereof

A technology of antibacterial fabrics and antibacterial materials, applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve the problems of poor antibacterial effect, poor antibacterial durability, narrow application range, etc., and achieve good antibacterial and antiviral effects and antibacterial properties Better, good anti-virus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] This embodiment provides an antibacterial fabric, which includes an antibacterial and wear-resistant layer, an antibacterial base cloth, and an antibacterial waterproof layer stacked in sequence.

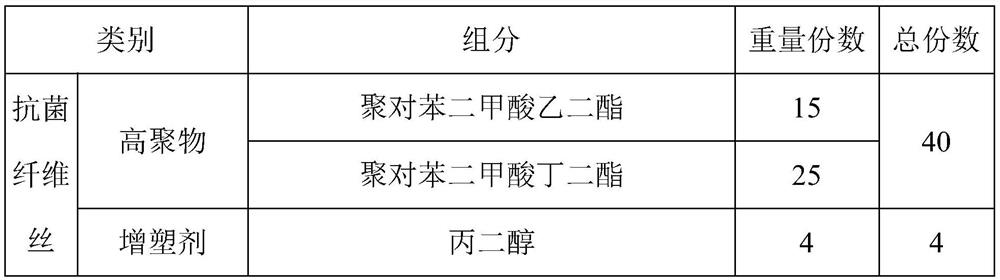

[0114] In this embodiment, the components and parts by weight of the antibacterial fiber filaments, antibacterial wear-resistant coating, antibacterial waterproof coating and antibacterial finishing solution are shown in Table 1.

[0115] Table 1

[0116]

[0117]

[0118]

[0119] The preparation method of antibacterial fabric described in the present embodiment comprises the following steps:

[0120] (1) Mix high polymer, plasticizer and photocatalytic antibacterial material, melt and spin at 250°C to make antibacterial fiber filaments, and then weave the antibacterial fiber filaments into base fabric;

[0121] (2) Mix nano-silver, nano-zinc oxide, erbium-doped nano-titanium dioxide, silane coupling agent, dispersant and deionized water, heat to 80°C, ultrasonic e...

Embodiment 2

[0127] This embodiment provides an antibacterial fabric, which includes an antibacterial and wear-resistant layer, an antibacterial base cloth, and an antibacterial waterproof layer stacked in sequence.

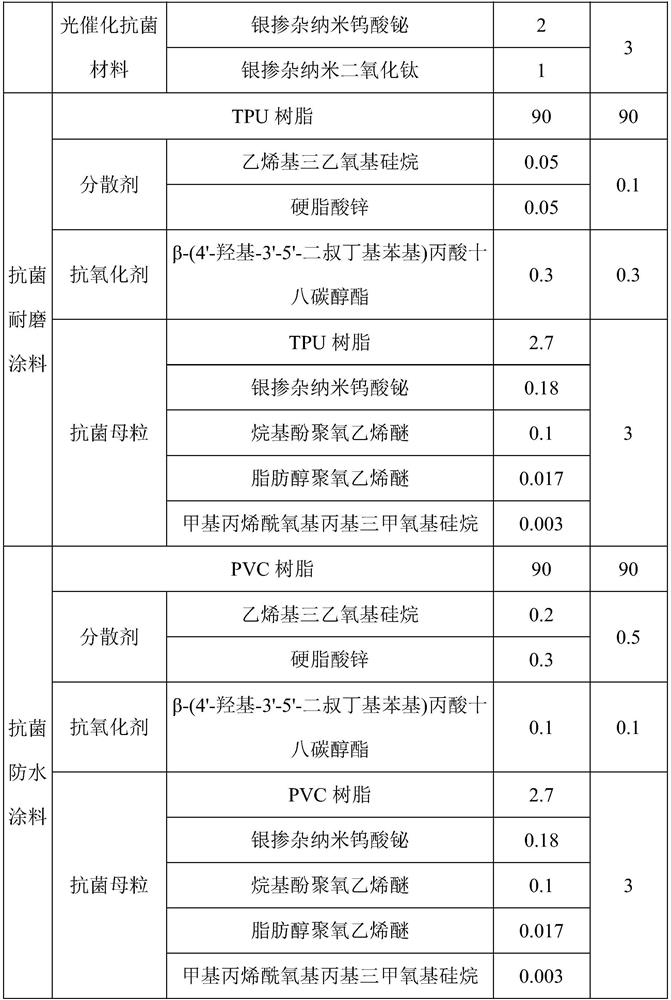

[0128] In this embodiment, the components and parts by weight of the antibacterial fiber filaments, antibacterial wear-resistant coating, antibacterial waterproof coating and antibacterial finishing solution are shown in Table 2.

[0129] Table 2

[0130]

[0131]

[0132] The preparation method of antibacterial fabric described in the present embodiment comprises the following steps:

[0133] (1) Mix high polymer, plasticizer and photocatalytic antibacterial material, melt and spin at 270°C to make antibacterial fiber silk, and then weave the antibacterial fiber silk into base fabric;

[0134] (2) Mix nano-silver, nano-zinc oxide, erbium-doped nano-titanium dioxide, silane coupling agent, dispersant and deionized water, heat to 100°C, ultrasonic emulsify at constant t...

Embodiment 3

[0140] This embodiment provides an antibacterial fabric, which includes an antibacterial and wear-resistant layer, an antibacterial base cloth, and an antibacterial waterproof layer stacked in sequence.

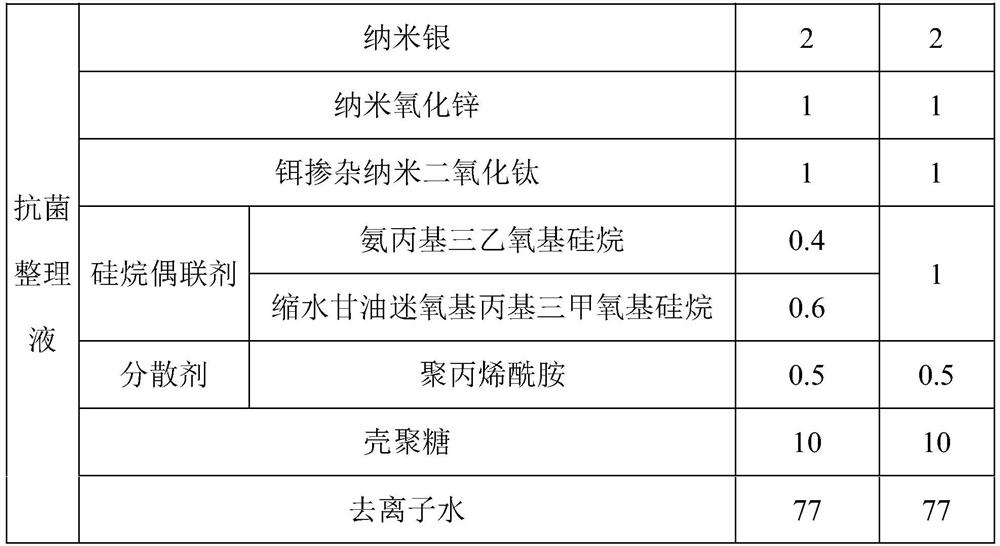

[0141] In this embodiment, the components and parts by weight of the antibacterial fiber filaments, antibacterial wear-resistant coating, antibacterial waterproof coating and antibacterial finishing solution are shown in Table 3.

[0142] table 3

[0143]

[0144]

[0145]

[0146] The preparation method of antibacterial fabric described in the present embodiment comprises the following steps:

[0147] (1) Mix high polymer, plasticizer and photocatalytic antibacterial material, melt and spin at 260°C to make antibacterial fiber silk, and then weave the antibacterial fiber silk into base fabric;

[0148] (2) Mix nano-silver, nano-zinc oxide, erbium-doped nano-titanium dioxide, silane coupling agent, dispersant and deionized water, heat to 90°C, ultrasonic emulsify fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com