Patents

Literature

71results about How to "Achieving antistatic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-static woven bag and manufacturing method thereof

InactiveCN104609010AReduce coefficient of frictionImprove anti-static effectElectroconductive/antistatic filament manufactureBagsLinear low-density polyethyleneEngineering

The invention discloses an anti-static woven bag and a manufacturing method thereof. The anti-static woven bag comprises, by weight, 2-3.5% of dispersing agent, 1.5-3% of cross-linking agent, 0.8-1.5% of coupling agent, 0.8-2.0% of nano calcium carbonate, 1-2% of antioxidant, 9-11% of linear low density polyethylene, 2.0-4.0% of anti-static agent and the balance polypropylene. According to the anti-static woven bag and the manufacturing method of the anti-static woven bag, due to the fact that the 2-4% of anti-static agent is added in ingredients of the woven bag, the surface of the woven bag can have lubricity, the friction coefficient of the woven bag is obviously lowered, meanwhile, static charges generated on the surface of the woven bag are restrained and reduced, and thus the woven bag has the excellent anti-static performance. In addition, in the process of manufacturing the anti-static woven bag, the anti-static performance of the woven bag can be effectively achieved by adjusting the specific parameters of drawing, weaving and other links, and the anti-static effect of the woven bag is finally achieved.

Owner:LIAONING TENGHUA PLASTIC

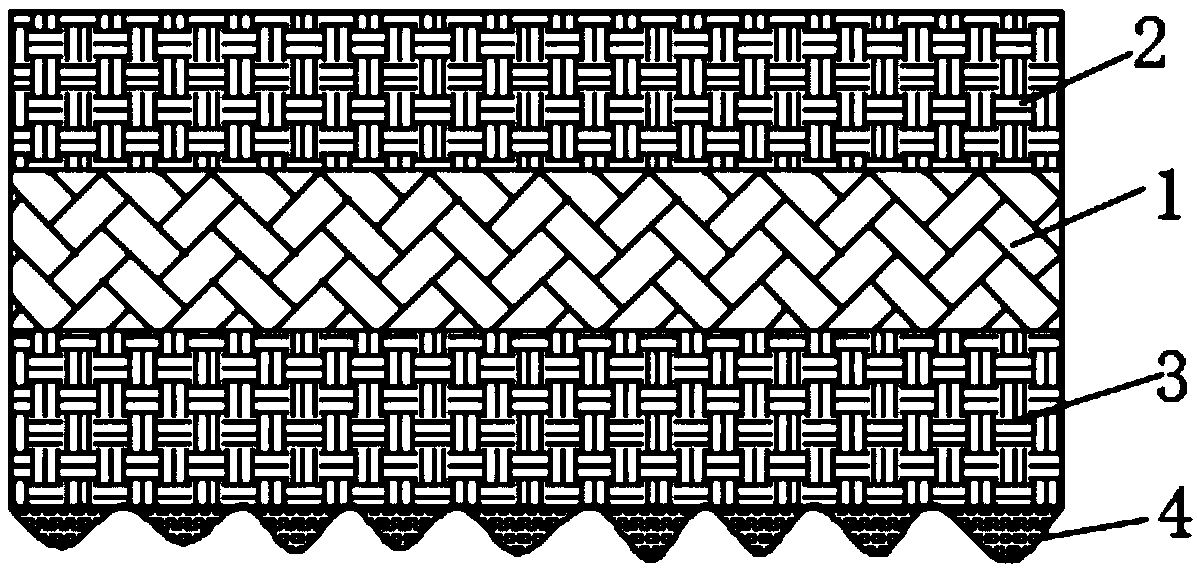

Multifunctional protection knitted fabric

PendingCN109706606APermanent Flame RetardancyImprove flame retardant performanceWeft knittingYarnYarnPolyester

The invention relates to a multifunctional protection knitted fabric and belongs to the field of spinning. According to the multifunctional protection knitted fabric, the gram weight of the fabric is190-230 g / m<2>, the surface layer and the inner layer are connected through connection yarn to form a dual-layer structure, the surface layer is woven through polyester yarn and flame-retardant yarn,6 pieces of polyester yarn and 2 pieces of flame-retardant yarn are used for alternative circulation weaving, needle drawing weave is adopted for the surface-layer fabric, the surface-layer fabric isin a grid shape, and the polyester yarn is dyed with the fluorescent color; the flame-retardant yarn is blended yarn with 60% of vinyon and 40% of cotton and dyed with the fluorescent color, the inner-layer yarn is formed by blending 60% of vinyon, 27% of flame-retardant viscose, 10% of para-aramid and 3% of transparent conductive fibers, and the inner-layer yarn is in a natural color; the connection yarn and the inner-layer yarn belongs to the same yarn. The fabric has high-temperature-resistance and high warning functions and has excellent anti-arc performance, the inner-layer fabric is formed through carbonization burning, and the fabric is comfortable, soft and good in heat retention property and can be worn next to the skin.

Owner:钱俊瑜

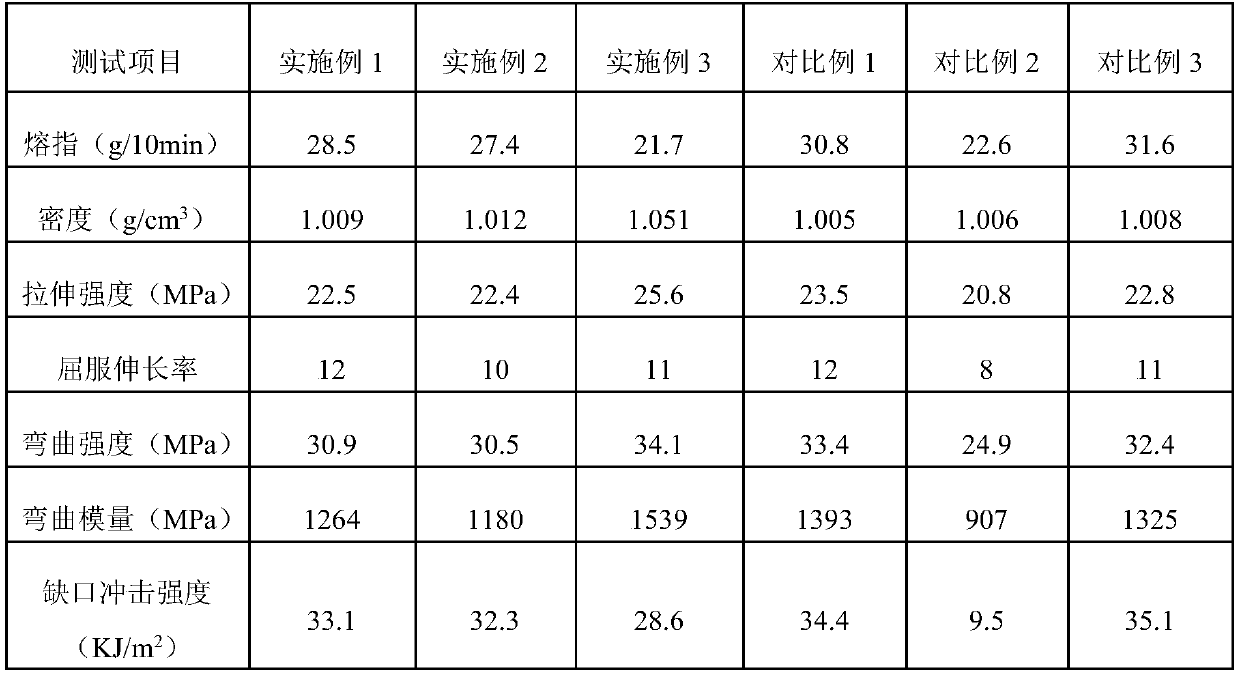

High-strength antistatic alloy and preparation method thereof

The invention discloses a high-strength antistatic alloy and a preparation method thereof. a PC (Polycarbonate) / PBT (Polybutylece Terephthalate) alloy is prepared from the following raw materials in parts by weight: 50 to 80 parts of PC, 20 to 40 parts of PBT, 8 to 18 parts of antistatic filler, 3 to 11 parts of compatibilizer, 0.05 to 0.3 part of ester exchange inhibitor, 0.2 to 0.6 part of antioxidant, 0.2 to 0.6 part of lubricating agent and 0.1 to 0.5 part of ultraviolet absorbent. According to the high-strength antistatic alloy disclosed by the invention, the PC / PBT alloy is subjected to blending modification by adopting assistants such as the compatibilizer, the ester exchange inhibitor and the antistatic filler, so that a prepared alloy system has the advantages of respective excellent properties of the PC and the PBT baste materials, excellent antistatic property, high strength, small warp, good dimensional stability, good processing fluidity and excellent chemical solvent resistance, and further the high-strength antistatic alloy can be widely applied to the fields of automobiles, household appliances, illumination, electronic communication and the like.

Owner:DONGGUAN HONOUR E P

Comfortable environment-protection functional knitting fabric and weaving method

InactiveCN101245524ASoft textureImprove breathabilityCircular knitting machinesYarnYarnCellulose fiber

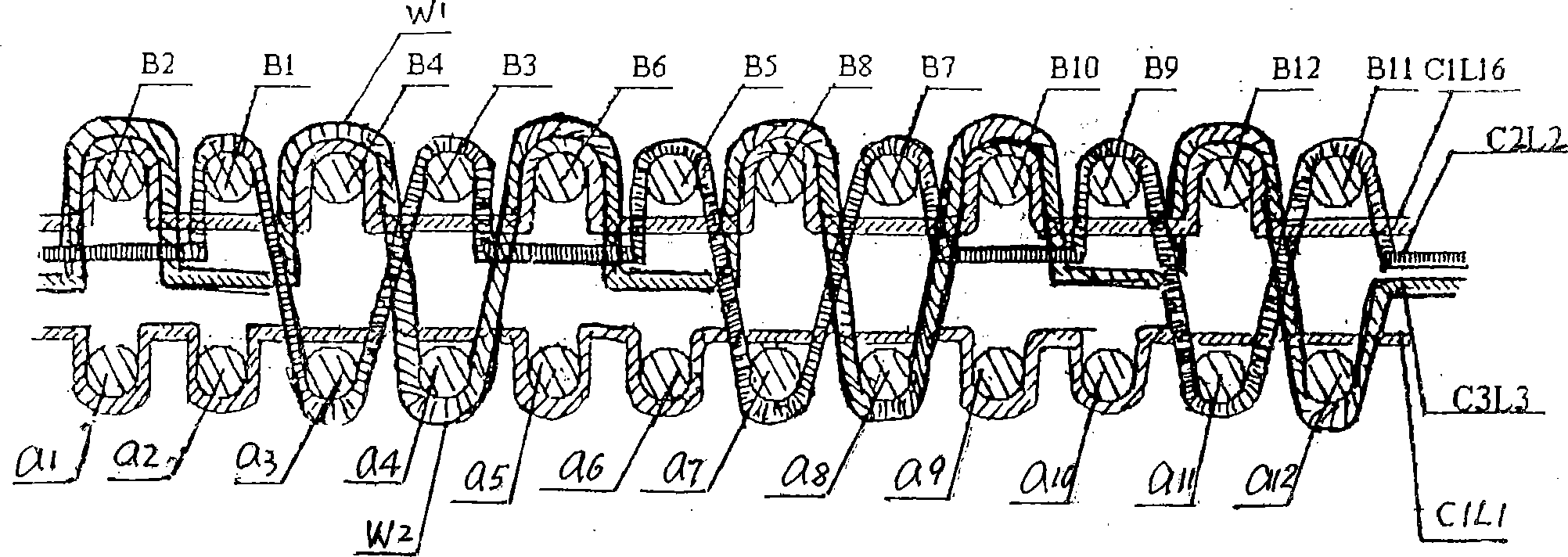

The invention provides a functional skin-friendly environment protective knitting fabric and a weaving method thereof. The invention is characterized in that the knitting fabric is a repeated circulation structure by taking four connected weaving sections along the longitudinal direction as a circulation unit structure. Each weaving section is a structure woven by four routes of degradable functional fiber blended spinning yarn and comfortable, hygienical and degradable fibrin fiber blended spinning yarn. Each layer of the weaving section of the four connected weaving sections is a twill convex-concave tissue structure woven by the buckling and winding of two routes of the comfortable, hygienical and degradable fibrin fiber blended spinning yarn and two routes of the degradable functional fiber blended spinning yarn respectively along the longitudinal spinning of an inner row and the longitudinal spinning of an outer row. The functional skin-friendly environment protective knitting fabric realizes the functions of skin-friendly, heat preservation, wet conduction and static resistance, strengthens the comfortable and hygienical property of the fabric as well as having the function of environment protection. The weaving method of the knitting fabric is mature and the technique is reasonable.

Owner:QINGDAO XUEDA GRP

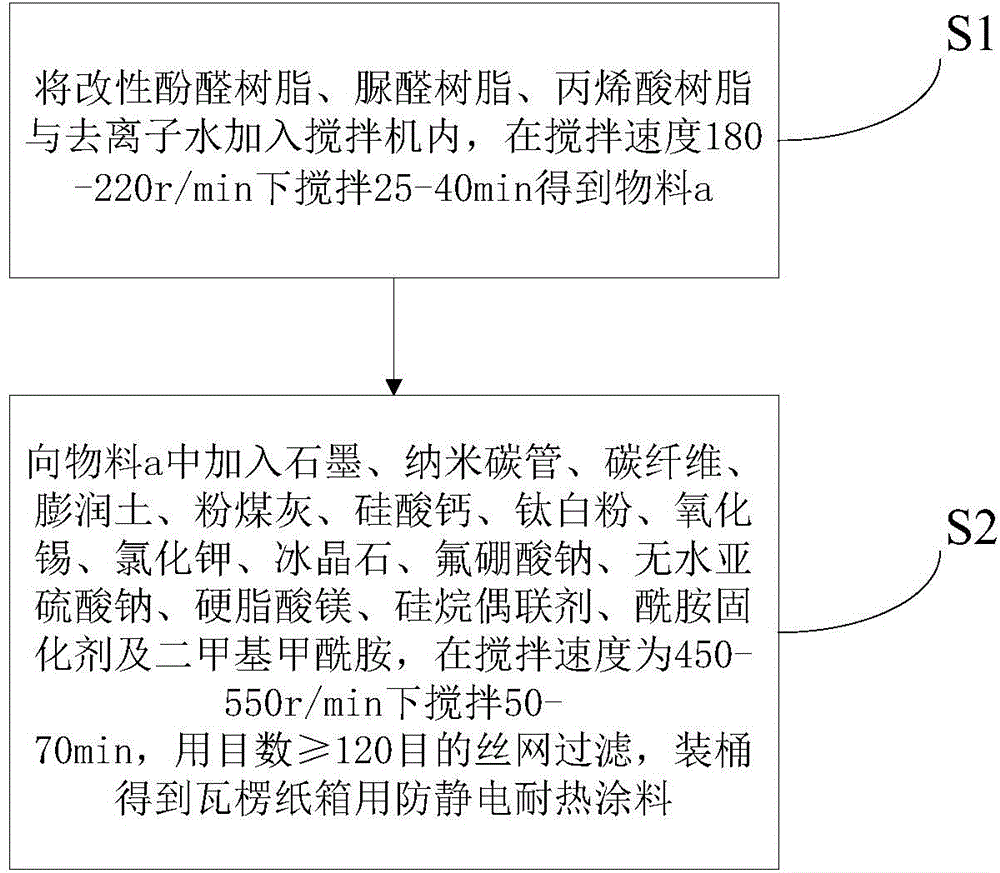

Antistatic and heat-resistant coating for corrugated carton and preparation method of antistatic and heat-resistant coating

InactiveCN104893486AImprove toughnessImprove heat resistanceCoatingsCalcium silicateSodium Bentonite

The invention discloses an antistatic and heat-resistant coating for a corrugated carton. The antistatic and heat-resistant coating comprises the following raw materials in parts by weight: 80-120 parts of modified phenolic resin, 60-90 parts of urea formaldehyde resin, 50-100 parts of acrylic resin, 20-40 parts of deionized water, 12-35 parts of graphite, 8-15 parts of carbon nanotubes, 2-9 parts of carbon fibers, 5-15 parts of bentonite, 3-9 parts of coal ash, 2-8 parts of calcium silicate, 6-12 parts of titanium dioxide, 3-9 parts of tin oxide, 3-12 parts of potassium chloride, 5-15 parts of cryolite, 1-5 parts of sodium fluoborate, 2-6 parts of anhydrous sodium sulfite, 3-8 parts of magnesium stearate, 2-9 parts of a silane coupling agent, 1-5 parts of a polyamide curing agent and 3-7 parts of dimethyl formamide. The invention also discloses a preparation method of the antistatic and heat-resistant coating for the corrugated carton. The coating prepared by using the preparation method can be used for effectively preventing static electricity from generating and also has high heat resistance.

Owner:WUHU PUCAO E COMMERCE CO LTD

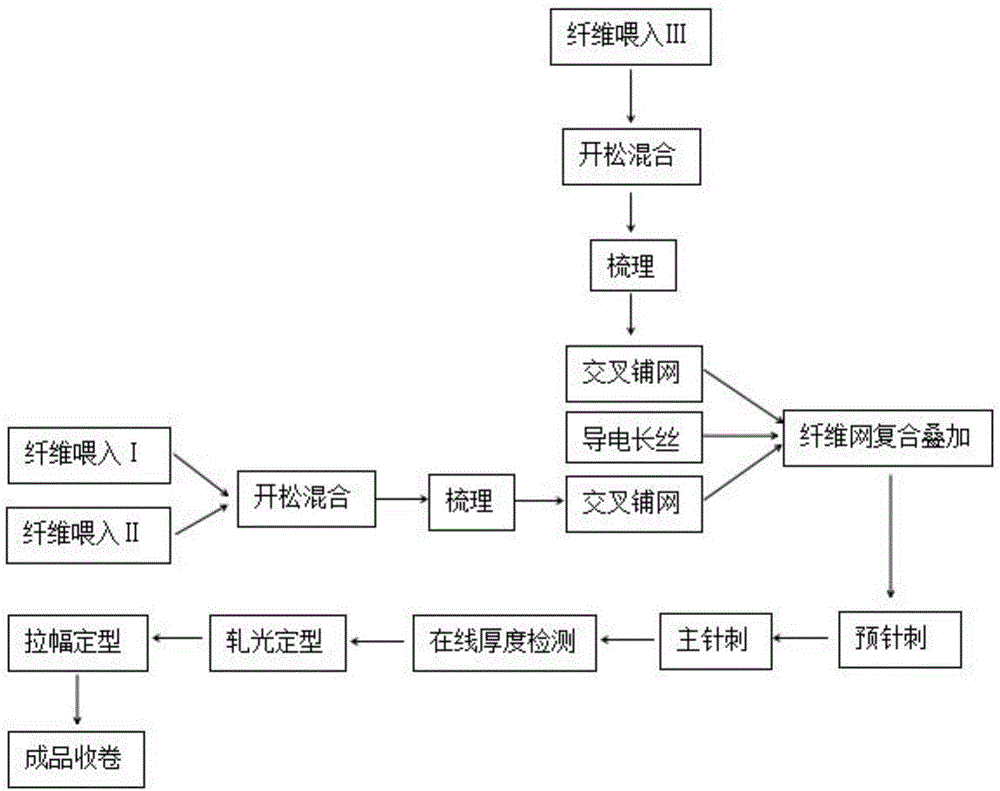

Antibacterial, fire-resistant and anti-static non-woven fabric and weaving method thereof

ActiveCN106757773AAvoid keeping time limitedAchieve antibacterialNon-woven fabricsWoven fabricConductive filament

The invention relates to an antibacterial, fire-resistant and anti-static non-woven fabric and a weaving method thereof. The non-woven fabric comprises, by weight, 30-40 parts of antibacterial deodorant fiber and 60-70 parts of polypropylene fiber. The method comprises the steps that the antibacterial deodorant fiber and the polypropylene fiber are mixed and then subjected to carding and cross lapping to form a blend fiber net; fire resistant fiber is subjected to carding and cross lapping to form a fire resistant fiber net; the blend fiber net and the fire resistant fiber net are arranged on the upper and lower faces of a conductive filament, the blend fiber net, the conductive filament and the fire-resistant fiber net are composited and stacked on a delivery apron to form a composite fiber net, and the composite fiber net forms the needling non-woven fabric through needling reinforcing. The non-woven fabric is manufactured through simple technological processes, and is easy to manufacture and good in anti-static and deodorant effect.

Owner:TIANDINGFENG NONWOVENS CO LTD

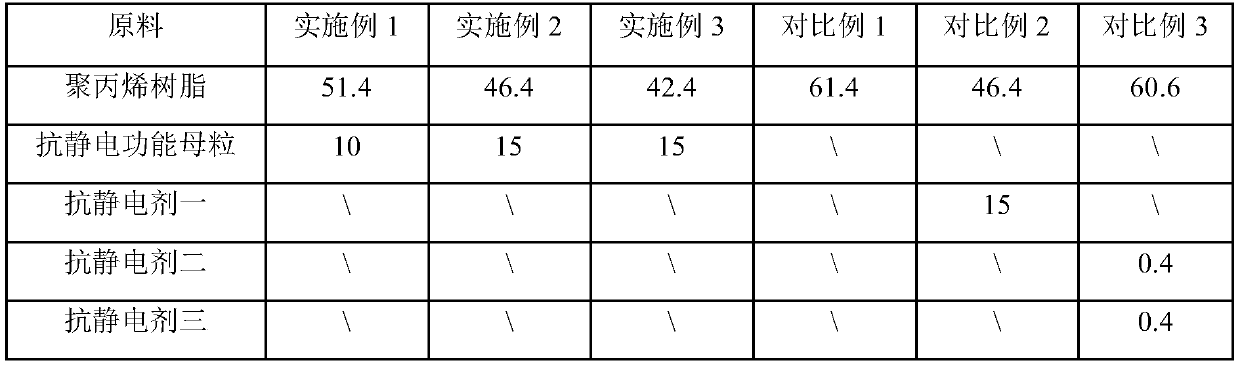

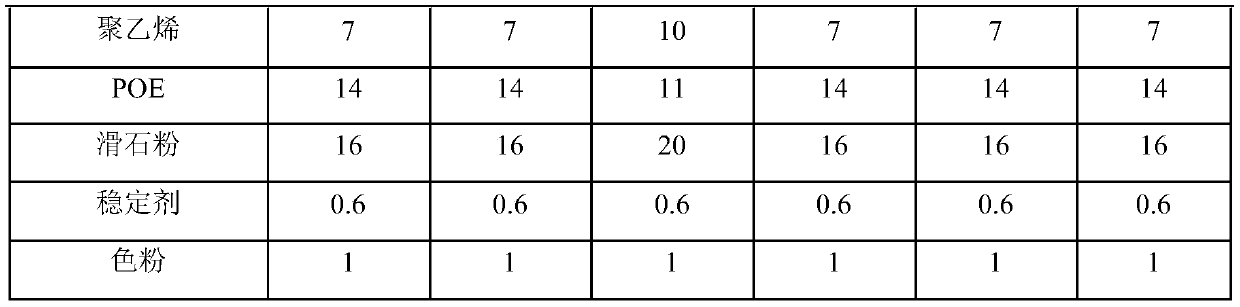

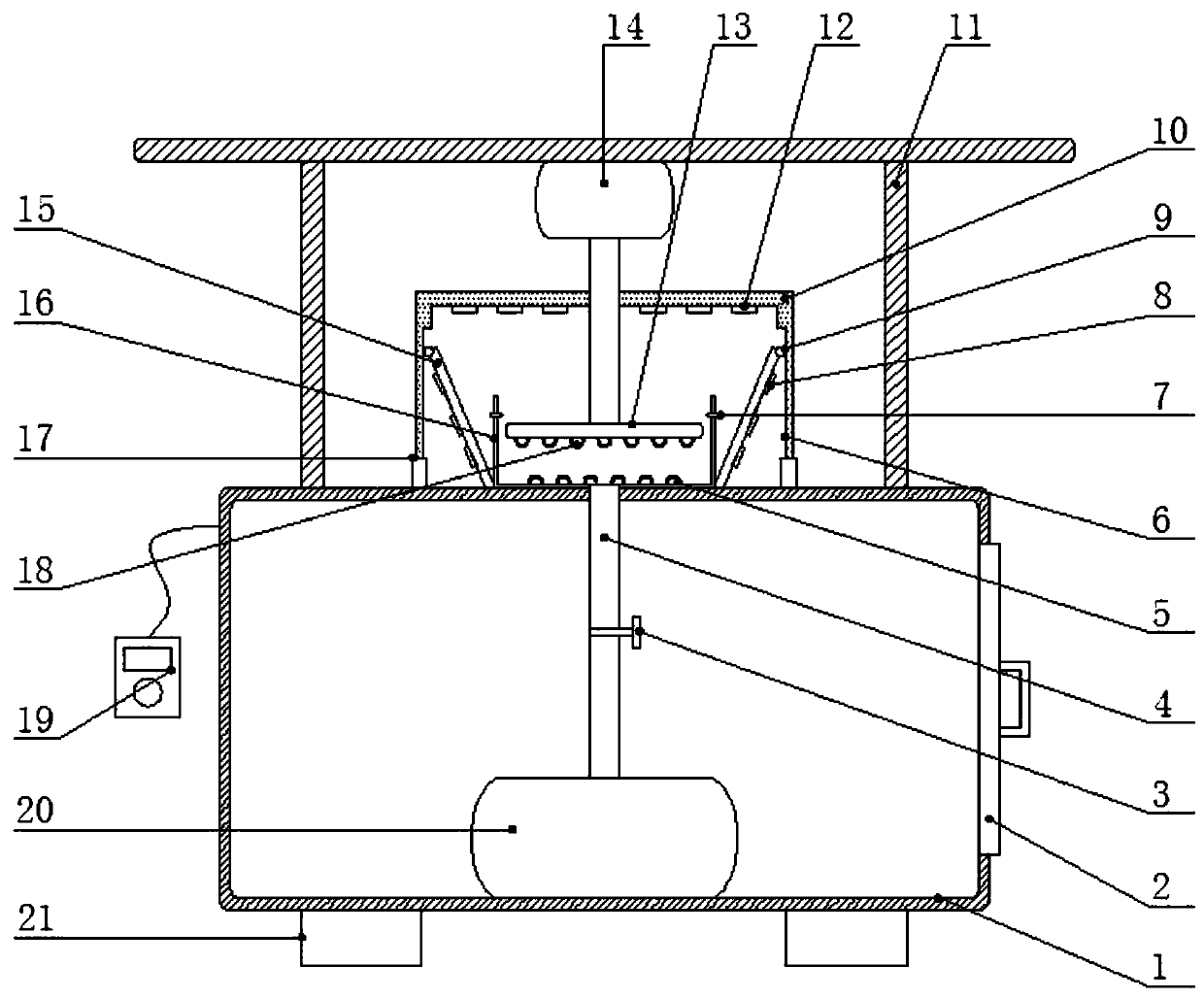

Permanent antistatic high-toughness talcum powder filled polypropylene material and preparation method thereof

InactiveCN111087739AReduced Humidity RequirementsAchieving antistatic propertiesPolymer scienceOctene

The invention provides a permanent antistatic high-toughness talcum powder filled polypropylene material and a preparation method thereof. The polypropylene material is prepared from the following components by weight: 40 to 80 parts of polypropylene resin, 5 to 20 parts of antistatic functional master batch, 2 to 10 parts of polyethylene, 5 to 20 parts of ethylene-octene copolymer (POE), 5 to 30parts of talcum powder, 0.2 to 2 parts of stabilizer and 0.5 to 2 parts of toner. The invention relates to a permanent antistatic high-toughness talcum powder filled polypropylene material and a preparation method thereof. By adding the antistatic functional master batch taking the polypropylene resin as the matrix and selecting the POE-polyethylene synergistic toughening system, the material hasa permanent antistatic effect and excellent mechanical properties, especially higher notch impact strength.

Owner:TIANJIN KINGFA NEW MATERIAL

Antistatic fabric

InactiveCN111560683ALow resistivityAvoid breakingSucessive textile treatmentsCarbon fibresPolyesterYarn

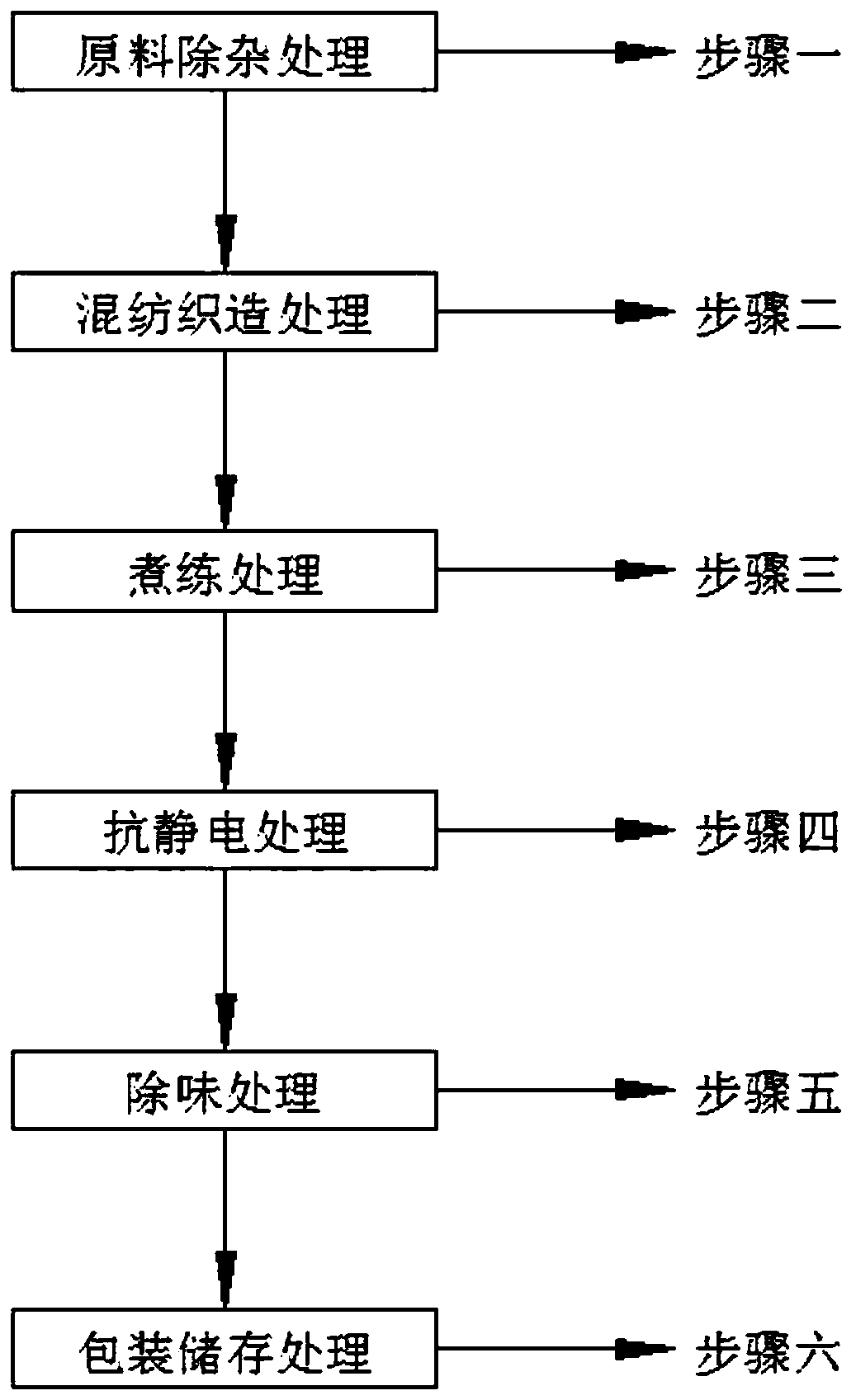

The invention discloses an antistatic fabric. The antistatic fabric is prepared from the following raw materials including, by weight, 40%-50% of polyester fibers, 15%-25% of cotton fibers, 15%-25% ofsilk fibers, 5%-10% of aluminum fibers and 5%-10% of graphite fibers. According to the antistatic fabric, the aluminum fibers, the graphite fibers, the polyester fibers, the cotton fibers and the silk fibers which have the electric conduction capacity are blended and spun after impurity removal to obtain spun yarns, the spun yarns are woven into a gray fabric through a tatting machine, then the gray fabric has low resistivity, and therefore the discharge rate is greatly increased when static electricity is generated and accumulated; meanwhile, the raw materials in a modified antistatic auxiliary agent can react with each other to generate dodecyl polyoxyethylene ether and dodecyl polyoxyethylene ether phosphate, so that the moisture absorption and the conductivity of the antistatic fabricare greatly improved, and a dual antistatic effect is achieved; and boiling-off operation in the preparation process of the antistatic fabric is divided into three stages, so that removal of residualnatural impurities and slurry in the antistatic fabric is facilitated, and the product quality is greatly improved.

Owner:杭州悦仕达新材料科技有限公司

Reproducible temperature-sensitive textile fabric and preparation method thereof

InactiveCN108374223AAchieving antistatic capabilityAchieve integrationElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentAmmonium polyphosphateChitin

The invention discloses a reproducible temperature-sensitive textile fabric and a preparation method thereof. The fabric is prepared from warp yarns and weft yarns, the warp yarns or the weft yarns are prepared from bamboo fiber, wood fiber, cotton fibre, fire resistant fibre, temperature-sensitive antibacterial nanofiber and polylactic acid fiber; the warp yarns or the weft yarns are soaked by atemperature-sensitive mixed solution and subjected to drying treatment to form a temperature-sensitive adhesive layer, wherein the temperature-sensitive mixed solution is prepared from chitin, acrylicfiber, propyl gallate, ammonium polyphosphate, kaempferol, methyl acrylate, a coupling reagent, a dispersing agent, a heat stabilizer and antistatic suspension liquid. According to the reproducible temperature-sensitive textile fabric and the preparation method thereof, the fuse of the reproducible fabric is realized through the mixing of the bamboo fiber, the wood fiber, the cotton fibre, the fire resistant fibre and the temperature-sensitive antibacterial nanofiber and combining with the coupling reagent, the dispersing agent and the heat stabilizer, meanwhile, the functions of inflaming retarding and temperature-sensitive adjustment are realized. Furthermore, through the antistatic suspension liquid, the antistatic capacity of the fabric is realized. The reproducible temperature-sensitive textile fabric is reasonable in design and is suitable for promotion and use.

Owner:JIANGSU SHENGLAN CLOTHING CREATIVE

Wrinkling-resistant ironing agent and preparation method thereof

ActiveCN104818618AQuality improvementFor long-term storageFibre treatmentPolymer sciencePreservative

The invention provides a wrinkling-resistant ironing agent and belongs to the technical field of daily chemical products. The wrinkling-resistant ironing agent is composed of, by mass, 1-10% of modified starch, 0.1-5% of organic silicone, 0.1-5% of fibroin finishing agent, 0.05-2% of odor neutralizer, 0.02-0.5% of essence, 0.02-0.5% of preservative, 0.02-0.5% of pH adjuster and 83-95% of water. The wrinkling-resistant ironing agent is stable in quality, supportive of long-time storage and mild and nonirritant to skin, and fabric after being ironed by using the wrinkling-resistant ironing agent has wrinkling-resistant and antistatic effect.

Owner:WALCH GUANGZHOU COMMODITY

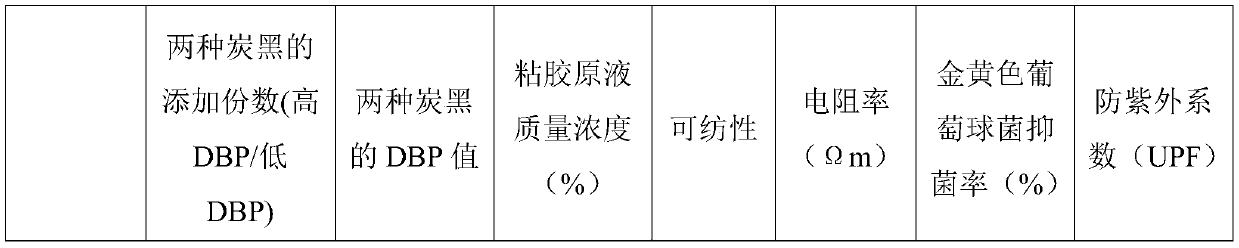

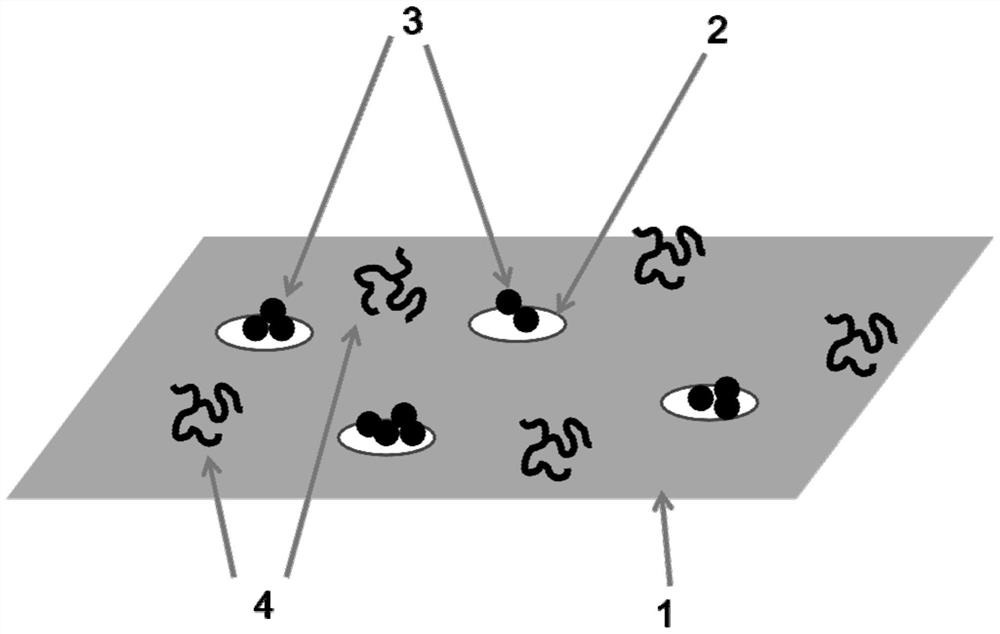

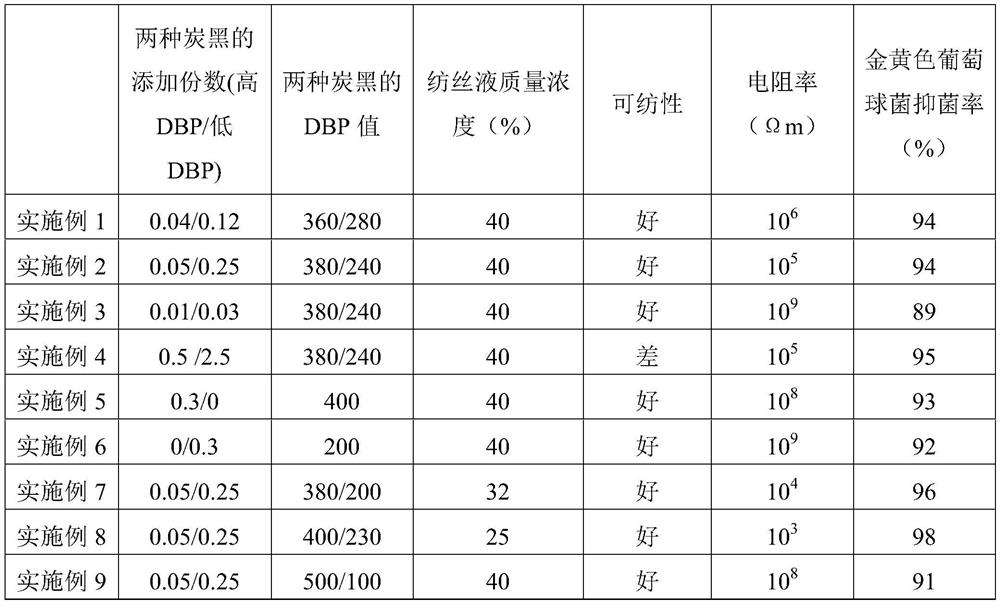

Preparation method of graphene/nano-carbon-black modified viscose fibers

ActiveCN110424060AUniform and stable dispersionReduce reunionArtificial filaments from viscoseSOCKSUltraviolet

The invention discloses a preparation method of graphene / nano-carbon-black modified viscose fibers. Nano-carbon-black with a specific DBP value is compounded with single-layer graphene oxide accordingto a specific proportion, the graphene oxide is reduced in a heating alkaline environment to form a stable compound structure, the graphene oxide can be directly mixed with viscose spinning liquid after washing, good dispersion is kept, spinning is performed to obtain the novel viscose fibers with anti-static, anti-ultraviolet and anti-bacterial functions, product functions are stable and cannotbe attenuated along with washing, the fibers can be directly prepared on a viscose fiber production line, an original process is minimally changed, and the prepared fibers can be applied to underwear,coats, pants, socks and shoe materials.

Owner:HANGZHOU GAOXI TECH CO LTD

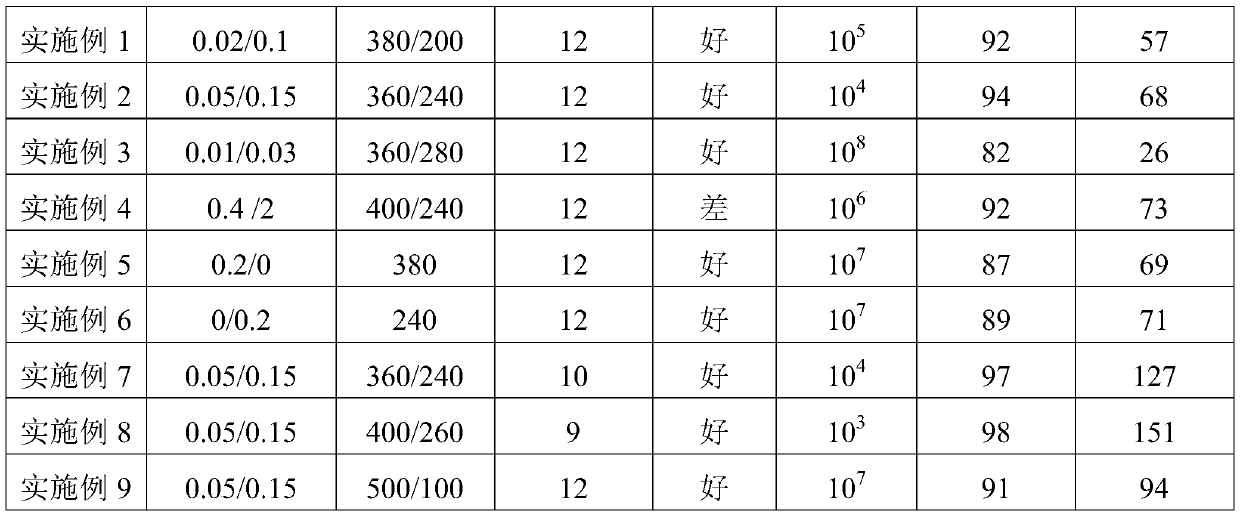

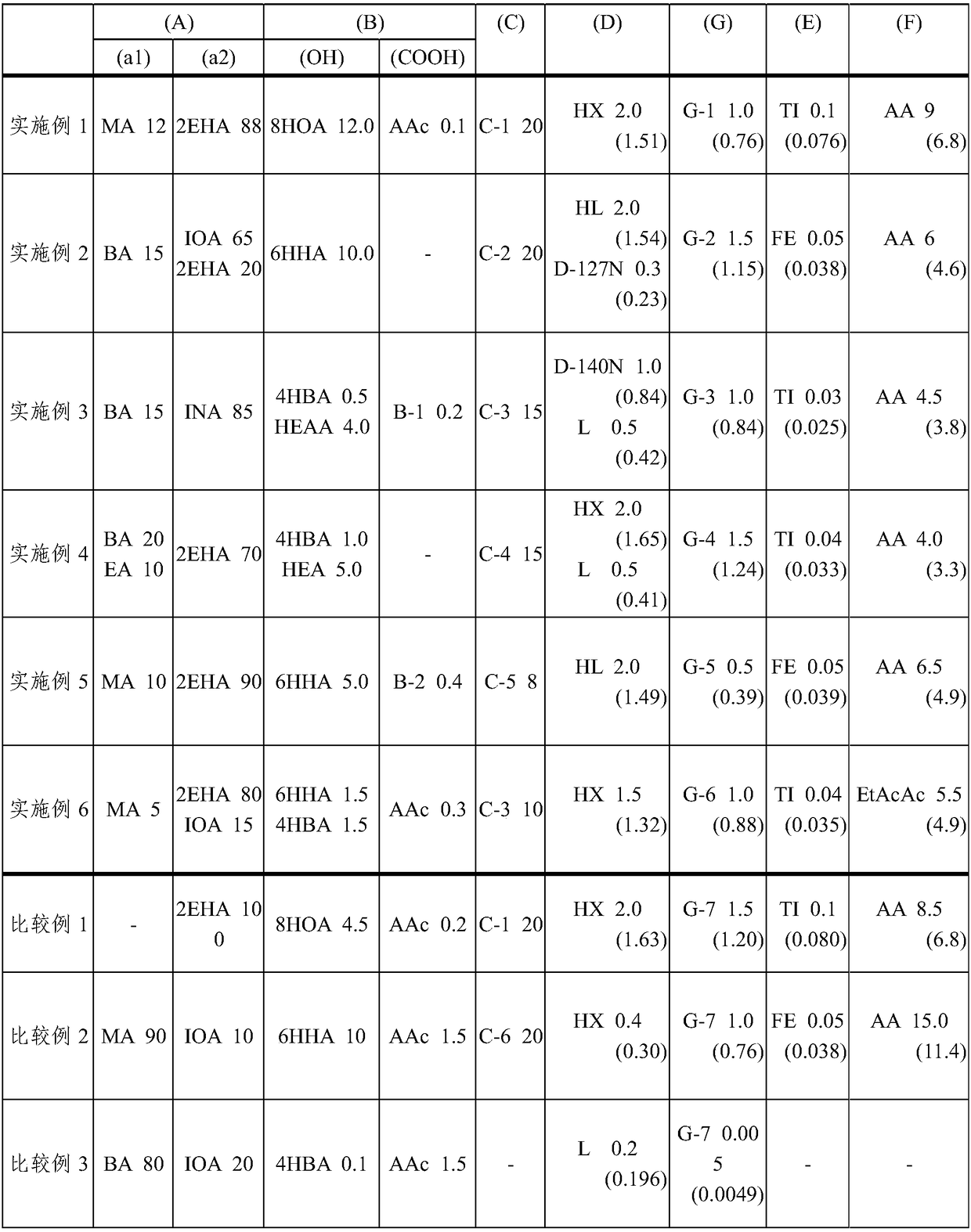

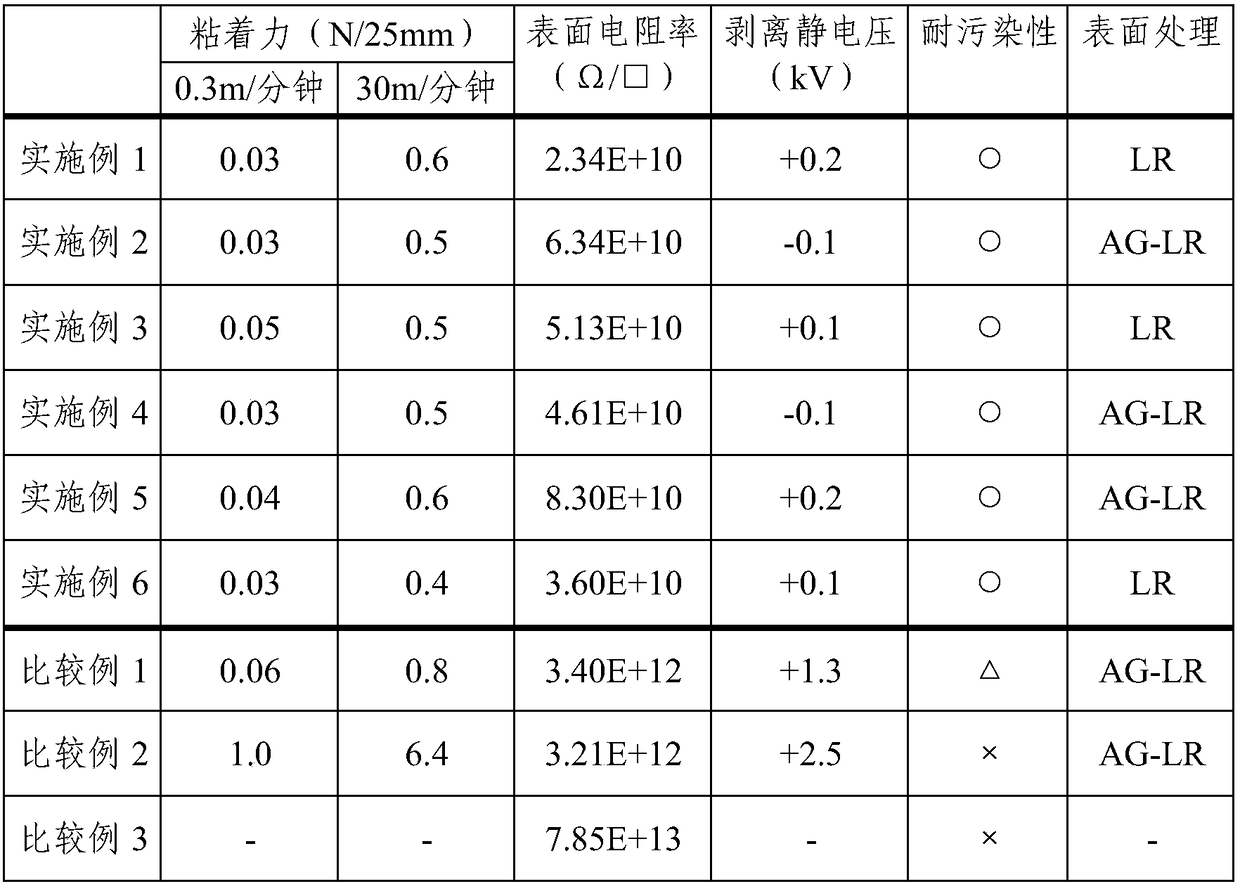

Adhesive composition and surface-protective film

ActiveCN108865017AExcellent adhesionExcellent anti-stripping staticNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberPolymer science

The present invention provides an adhesive composition and a surface protective film. The excellent balance of adhesion is ensured at low-speed peeling speed and high-speed peeling speed. The film hasstain resistance and excellent antistatic property and excellent deterioration resistance without deterioration. The adhesive composition contains a (meth) acrylate monomer having (C) an alkyl grouphaving a C1 to C18 carbon number, (B) a hydroxyl group-containing copolymerizable monomer, and (C) a carboxyl group-containing copolymerizable group. An acrylic polymer obtained by copolymerization ofa monomer has an acid value of 0.1 to 1.0, and 100 parts by weight of (A) alkyl group having a C1-C18 (meth)acrylic group. The ester monomer contains acrylic acid ethyl hexyl acrylate in a ratio of 70 parts by weight or more. The crosslinking agent is (D) a trifunctional or higher isocyanate compound; and the antistatic agent is an anion having a fluorine atom number of F7 or more. An ionic compound has a melting point from 25 to 50 DEG C.

Owner:FUJIMORI KOGYO CO LTD

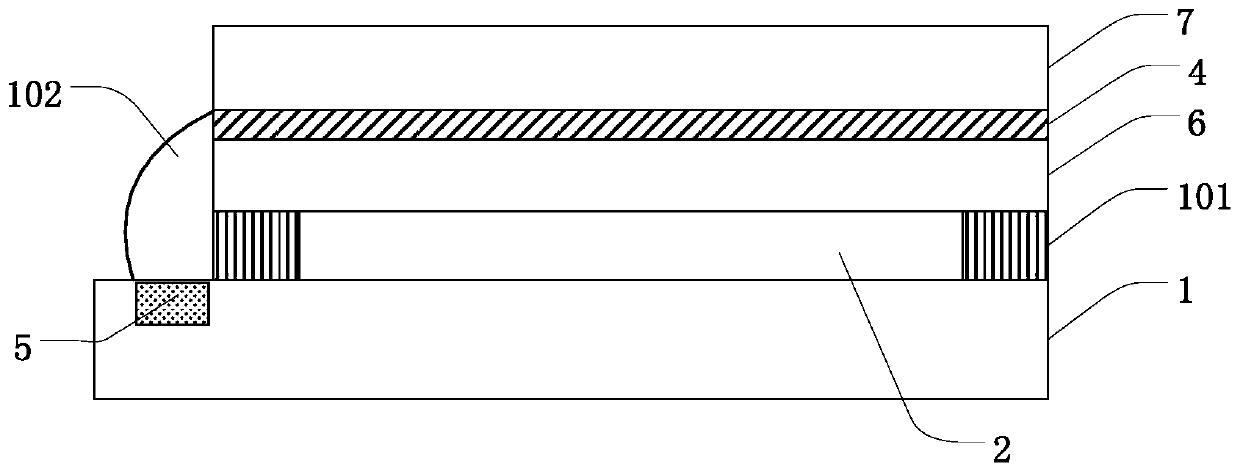

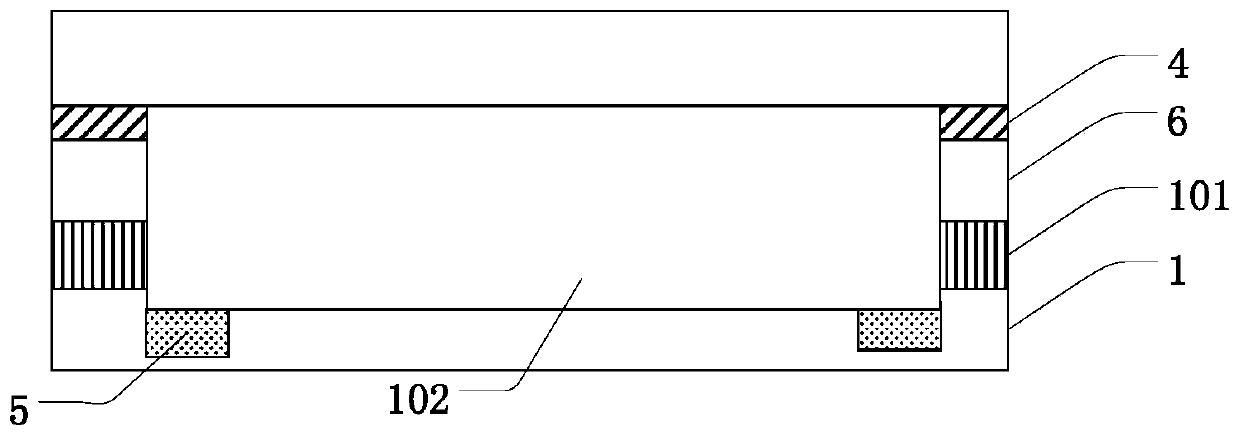

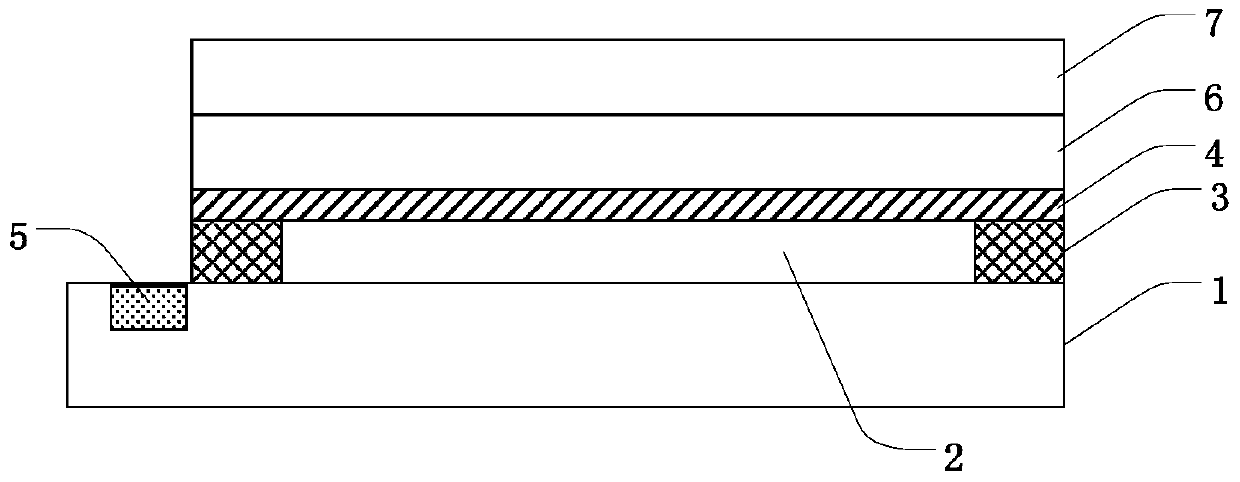

Display panel

InactiveCN109799639AAchieve the effect of ultra-narrow bezelReduce the number of layersNon-linear opticsSilver pasteHigh resistance

The invention provides a display device and a display panel. The display device comprises the display panel. The display panel comprises a first substrate, a liquid crystal layer, a conductive adhesive layer, a high-resistance film layer and grounding terminals. The display device and the display panel have the advantages that the high-resistance film layer is arranged on the upper surface of theliquid crystal layer and the conductive adhesive layer, and the high-resistance film layer is connected with the grounding terminals through conductive adhesives; when the display panel displays, thehigh-resistance film layer serving as a charge discharge approach can release charge generated by the display panel to achieve static release, and external influence on display is shielded; a conductive silver paste layer is omitted, an existing frame adhesive layer is replaced by the conductive adhesive layer to prevent static, the layers of a non-display area are reduced, and a super-narrow frame effect of the display panel is achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

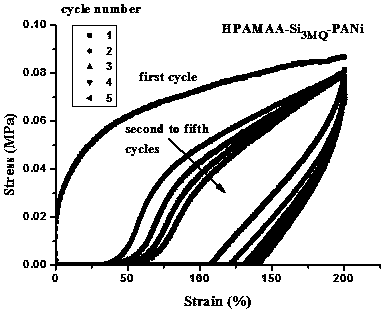

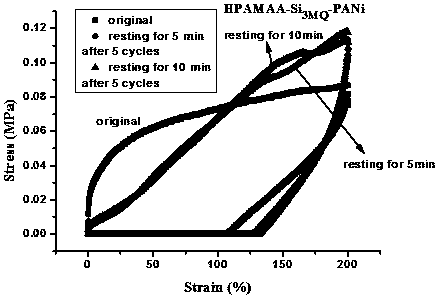

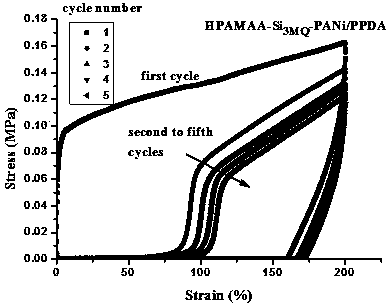

Antistatic self-recovery triple interpenetrating network silicon hydrogel and preparation method thereof

ActiveCN110591122AImprove antistatic performanceImprove mechanical propertiesCross-linkSelf recovery

The invention discloses an antistatic self-recovery triple interpenetrating network silicon hydrogel and a preparation method thereof. The preparation method comprises: carrying out addition polymerization on an alkene-based monomer to form a carbon chain polymer, and carrying out hydrophobic association cross-linking on the carbon chain polymer to form a first macromolecular network; carrying outcondensation polymerization on a silicon monomer to form a silicon-containing polymer, and forming a second polymer network from the silicon-containing polymer through hydrogen bond action; carryingout oxidation polymerization on an aniline monomer to form polyaniline, and forming a third polymer network from the polyaniline through hydrogen bond or hydrogen bond / covalent cross-linking; and interpenetrating the first polymer network, the second polymer network and the third polymer network. According to the invention, the obtained silicon hydrogel has advantages of excellent toughness, rapidself-recovery performance and antistatic performance; and the preparation method has characteristics of simple preparation process, simple and easily available raw materials, low preparation cost andgood application prospects, and is suitable for industrial production.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Preparation method of antistatic polyester fabric

ActiveCN105463833AAchieving antistatic propertiesStrong antistatic durabilityFibre typesUltrasonic/sonic fibre treatmentPolyesterBenzoyl peroxide

The invention discloses a preparation method of antistatic polyester fabric and belongs to the technical field of textile materials. The method comprises steps as follows: original polyester fabric is continuously treated in a NaOH solution, an alpha-cyclodextrin solution, a plasma processor, an acrylamide aqueous solution, a benzoyl peroxide aqueous solution, a copper chloride aqueous solution, a glycol mixture solution of silver nitrate and polyvinylpyrrolidone K55, a mixed aqueous solution of acid red G and peregal O, a hydrochloric acid aqueous solution of pyrrole and hexadecyl ammonium bromide and an ammonium persulfate aqueous solution and is subjected to in-situ growth, adsorption, a polymerization reaction, washing, drying and the like, and the antistatic polyester fabric is prepared. The conductivity of the antistatic polyester fabric prepared with the method is (2*10<-2>)-(1.1*10<-1>)S*cm<-1> according to a standard four-probe test; the preparation process is simple, the permanent antistatic performance of the product is good, and the method is suitable for the field of garments made of polyester fabric and other related fields.

Owner:MAANSHAN JINZI TEXTILE OMAMENT +1

Anti-static antibacterial PBT/ASA material and preparing method and application thereof

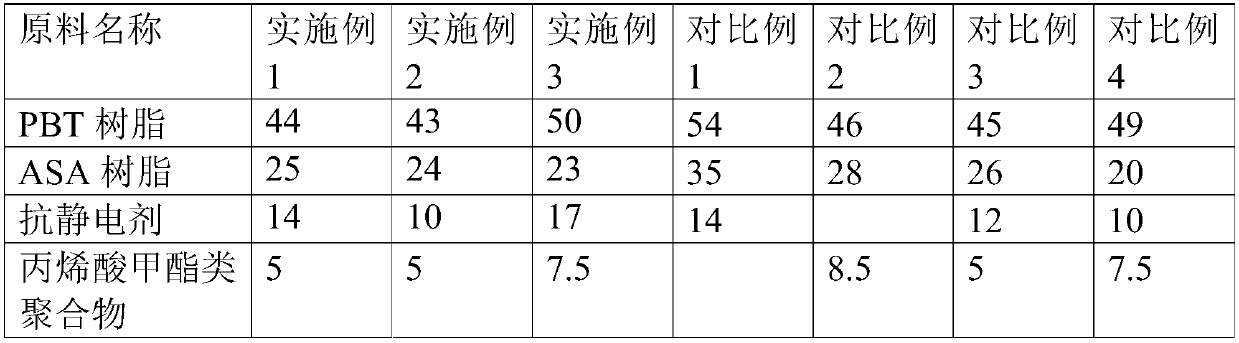

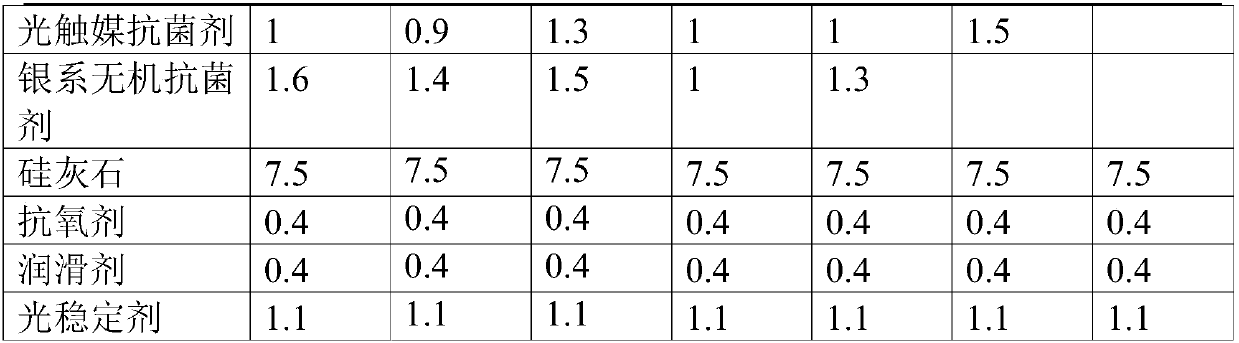

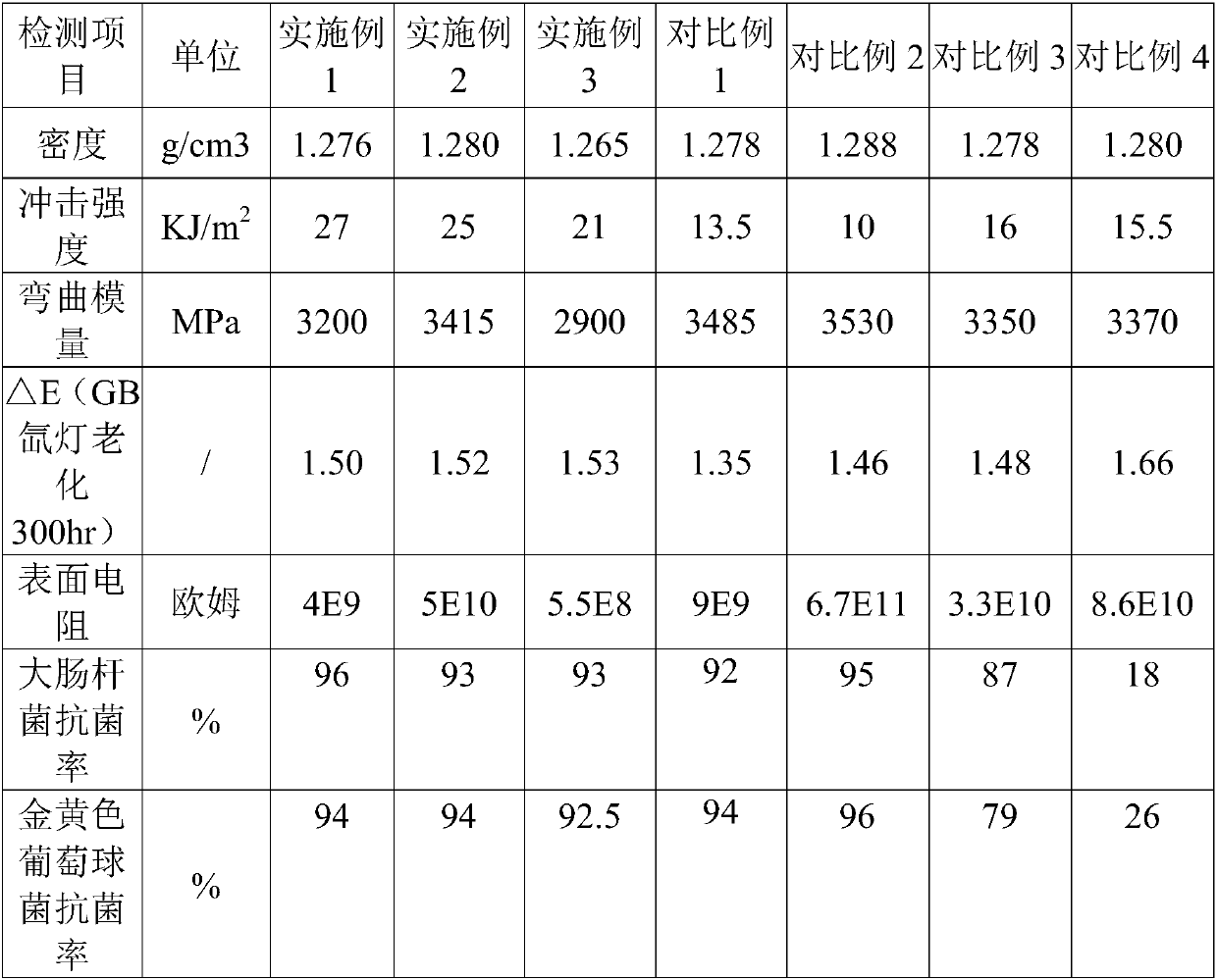

InactiveCN109627710AGood weather resistanceEnhancement and weather resistanceWeather resistanceAntistatic agent

The invention provides an anti-static antibacterial PBT / ASA material and a preparing method and application thereof. The anti-static antibacterial PBT / ASA material is prepared from, by weight, 21-58 parts of PBT resin, 20-57 parts of ASA resin, 9-23 parts of an anti-static agent, 6-14 parts of wollastonite, 4-10 parts of methyl acrylate polymers, 1-3 parts of an antibacterial agent, 0.4-1.5 partsof a light stabilizer and 0.5-2 parts of a processing additive. The anti-static antibacterial PBT / ASA material combines PBT / ASA alloy materials and sufficiently exerts excellent performance of the twomaterials, and the weather resistance, the impact resistance and rigidity of the anti-static antibacterial PBT / ASA material are improved. In addition, the antibacterial agent and the anti-static agent are added innovatively, and thus the advantages of the anti-static performance and the antibacterial performance are both achieved.

Owner:TIANJIN KINGFA NEW MATERIAL

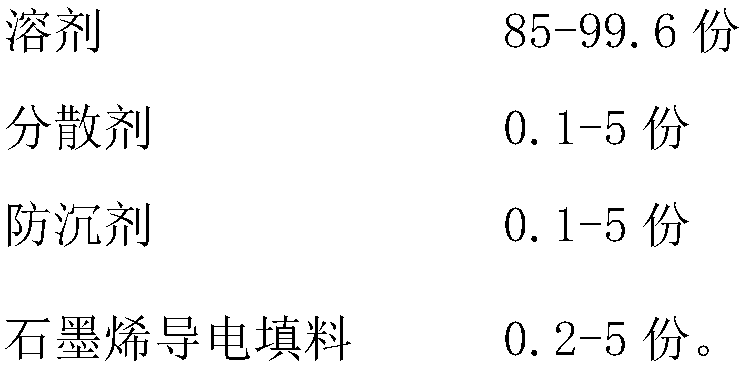

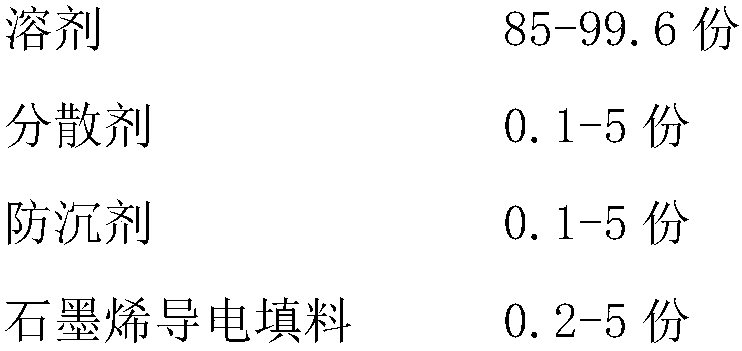

Graphene antistatic additive for floor paint as well as preparation method and application thereof

InactiveCN108395758AGood anti-static effectSolution to short lifeAntifouling/underwater paintsPaints with biocidesSlurryGraphene

Owner:SHANGHAI LEVSON ENTERPRISE GRP

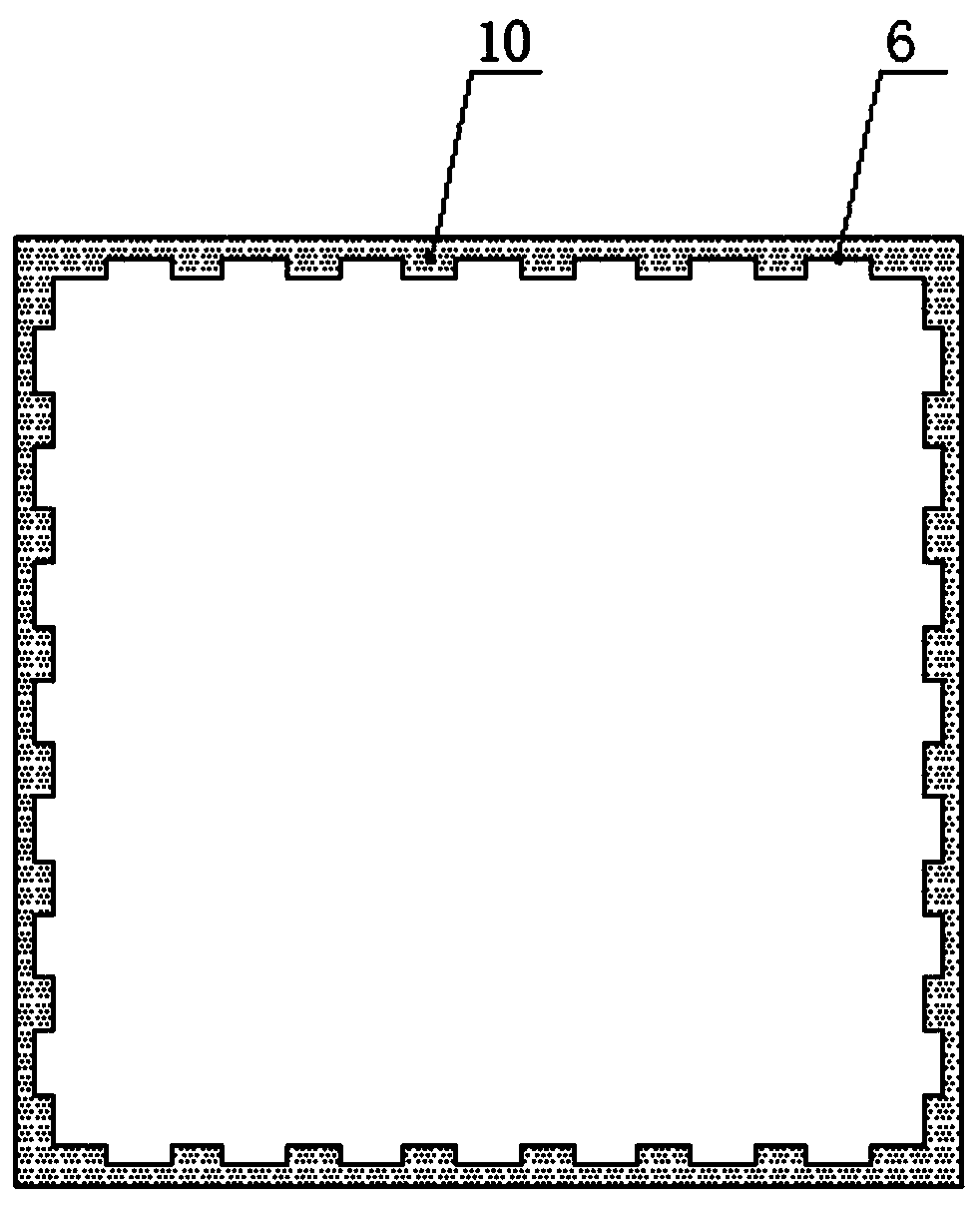

Long-acting anti-static rubber pad

ActiveCN111909469AStatic dissipative implementationAchieving antistatic propertiesRubber layered productsPolymer scienceNitrile rubber

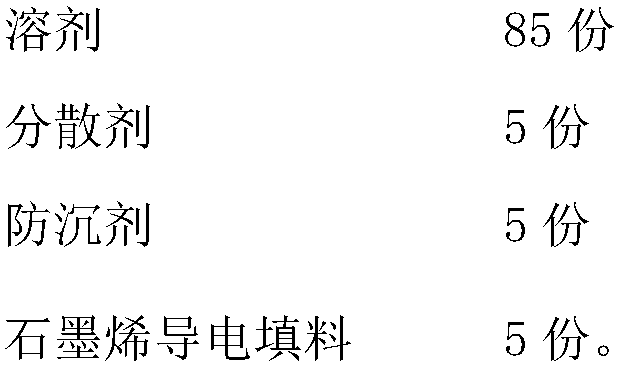

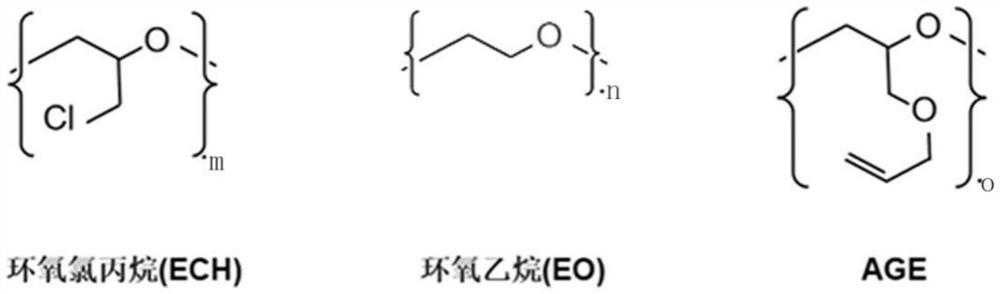

The invention relates to a long-acting anti-static rubber pad which comprises a static dissipation layer and / or a static conduction layer, and the static dissipation layer comprises the following rawmaterials in parts by weight: ECO epichlorohydrin rubber, nitrile rubber, a plasticizer, silicon dioxide, zinc oxide, an anti-aging agent, a softener, sulfur and a first accelerant; the static conductive layer is prepared from the following raw materials in parts by weight: rubber, light calcium carbonate, superconducting carbon black, high-wear-resistance carbon black, a plasticizer, white factice, a second accelerant, zinc oxide, sulfur, a defoaming agent and an anti-scorching agent. According to the invention, the ECO epichlorohydrin rubber with excellent electrostatic dissipation capability is used as a key raw material to realize durable antistatic performance, so that the problem that the antistatic performance is not durable due to the fact that an antistatic agent is easy to separate out under the influence of the environment is avoided. The volume resistance of the ECO epichlorohydrin rubber raw material can reach the grade of 106-108 ohms, and the ECO epichlorohydrin rubber raw material has a unique monomer structure and an ionic conduction mechanism and can be well compatible with various rubbers and resins.

Owner:CHUANGXUANBAO PANTUO ANTI STATIC TECH SHANGHAI CO LTD

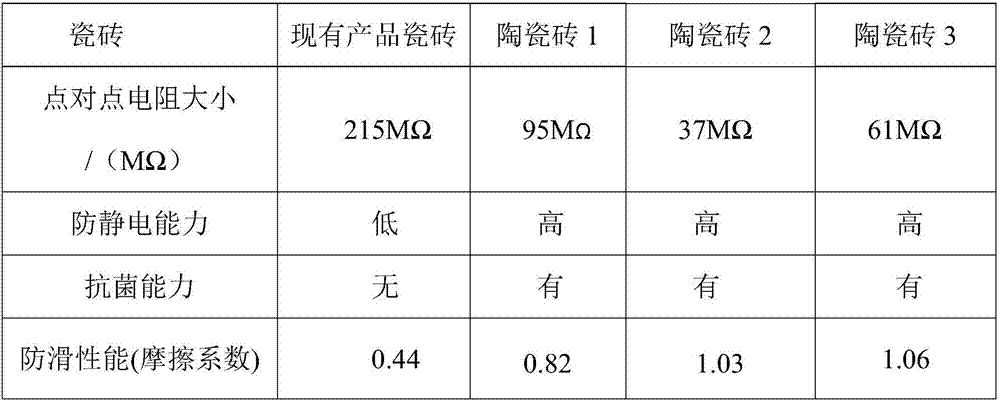

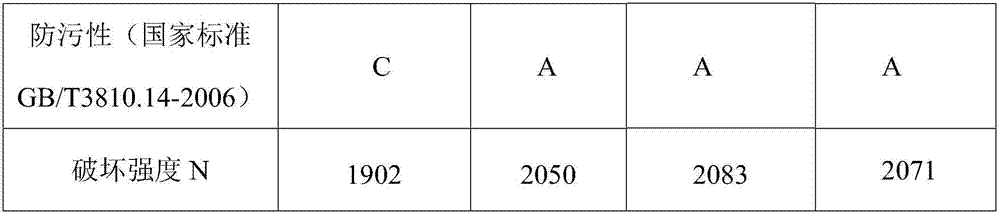

Antibacterial and antistatic ceramic glaze with high wear resistance and preparation method for ceramic tile

InactiveCN107417118AUniform and stable flow distributionStable anti-static effectCeramic glazeFineness

The invention discloses an antibacterial and antistatic ceramic glaze with high wear resistance and a preparation method for a ceramic tile. Glaze materials for the ceramic glaze comprise an antistatic glass frit, a composite antibacterial nanoparticle, an inorganic oxide whisker and stamp-pad ink, wherein the mass ratio of the antistatic glass frit, the composite antibacterial nanoparticle, the inorganic oxide whisker and the stamp-pad ink is (1-1.5):(0.5-0.8):(0.5-2):(2-2.5); the fineness of the antistatic glass frit is 60 to 125 meshes. The antibacterial and antistatic ceramic glaze with high wear resistance has the characteristics of stable antistatic effect, good antiskid effect and antifouling peroperty and high high-temperature resistance; a process for preparing an antibacterial and antistatic ceramic tile with high wear resistance from the ceramic glaze is simple and convenient to operate.

Owner:陆洁容

High-visibility flame-retardant acrylic knitted blended fabric

PendingCN111534909AImprove visibilityFull colorWeft knittingDyeing processNatural fiberElectrically conductive

The invention discloses a high-visibility flame-retardant acrylic knitted blended fabric, and relates to the technical field of individual safety protection fields. The gram weight of the fabric is 170-350g / m<2>, the fabric is fluorescent yellow or fluorescent orange, and the fabric comprises, 60-70% of flame retardant acrylic, 0-20% of acrylic, 2% of conductive fibers and 15-40% of natural fibersor cellulose fibers; the fabric is made by blending, weaving and dyeing; and fabric weaving comprises single-layer tissue weaving and double-layer tissue weaving. The fabric has the characteristics of being flame-retardant, high-temperature-resistant, heat-insulating, free of melting drops, and capable of being carbonized in case of a fire, and prevents the skin from being damaged by the meltingdrops; the fabric is dyed with a fluorescent color, so that a high warning effect is achieved; the fabric has excellent anti-electric-arc performance; the conductive fibers are added, so that the fabric has an anti-static effect; and the fabric is comfortable, soft, good in heat retention and capable of being worn next to the skin.

Owner:钱俊瑜

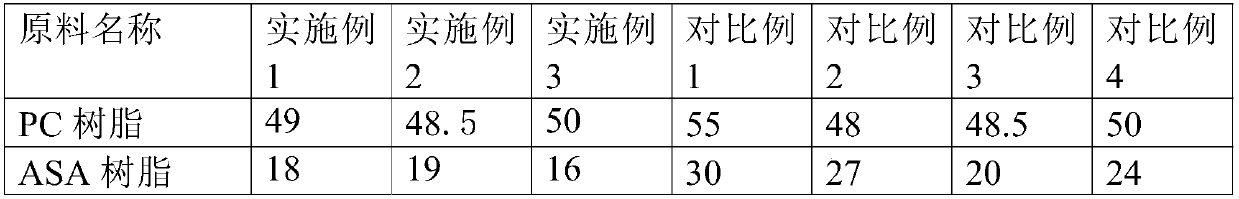

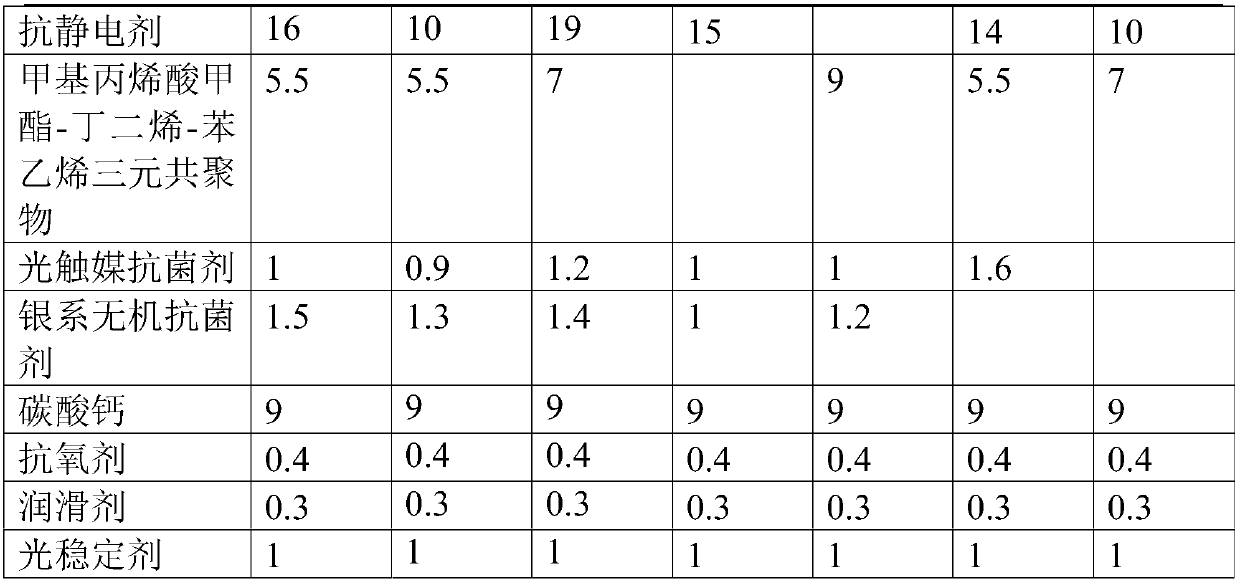

Anti-static antibacterial PC/ASA material and preparing method and application thereof

The invention provides an anti-static antibacterial PC / ASA material and a preparing method and application thereof. The anti-static antibacterial PC / ASA material is prepared from, by weight, 30-55 parts of PC resin, 15-30 parts of ASA resin, 10-25 parts of an anti-static agent, 5-15 parts of calcium carbonate, 3-10 parts of methyl methacrylate-butadiene-styrenic terpolymers, 1-3.5 parts of an antibacterial agent, 0.3-1.5 parts of a light stabilizer and 0.5-1.5 parts of a processing additive. The anti-static antibacterial PC / ASA material combines PC / ASA alloy materials and sufficiently exert excellent performance of the two materials, and the glossiness, toughness and easy formability of the anti-static antibacterial PC / ASA material are improved; in addition, the anti-bacterial agent and the anti-static agent are added innovatively, and thus the advantages such as the anti-static performance and the antibacterial performance are all achieved.

Owner:TIANJIN KINGFA NEW MATERIAL

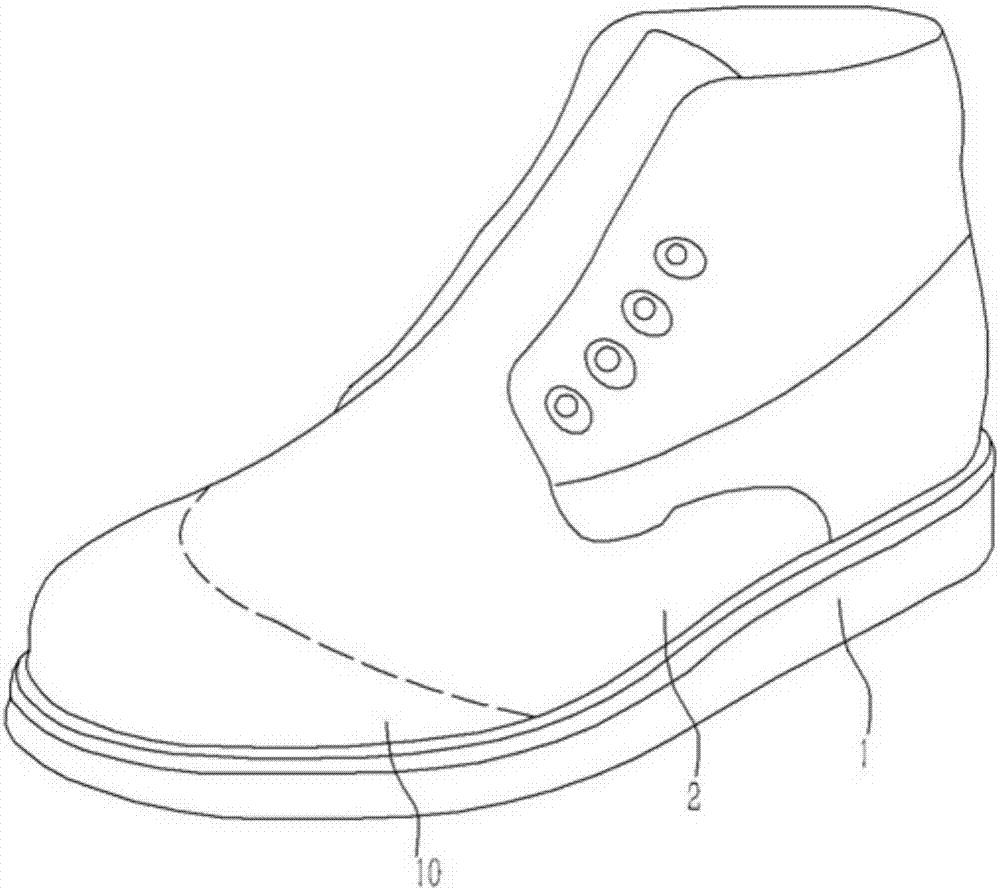

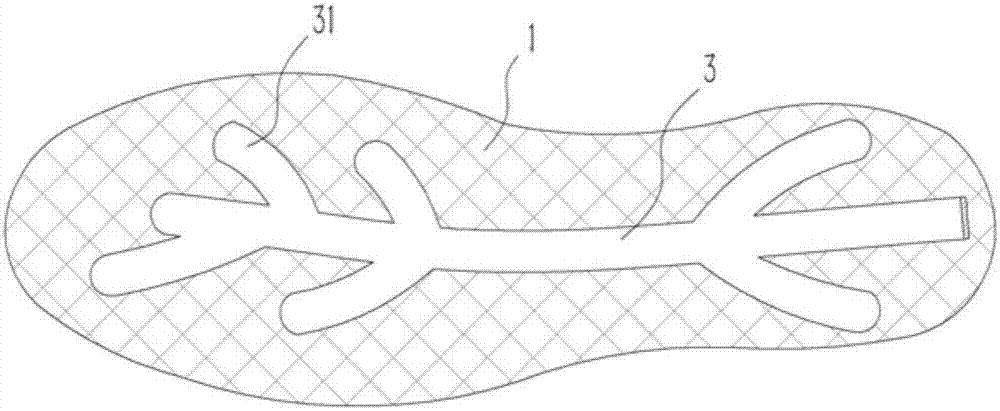

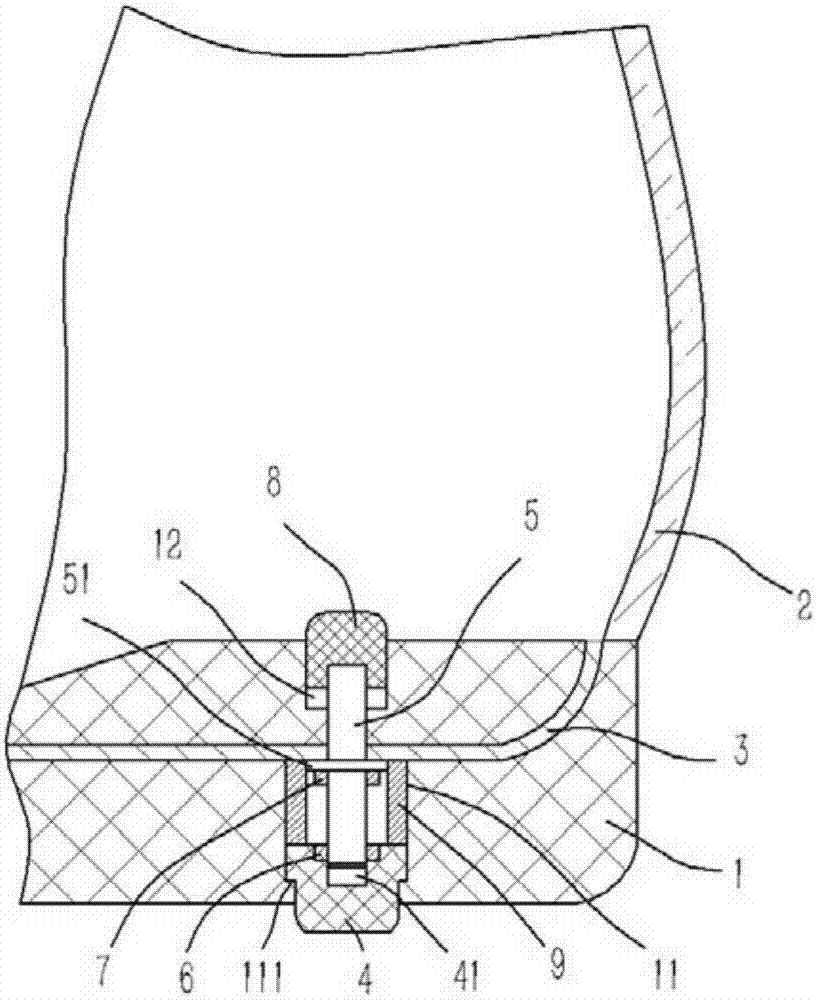

Antistatic safety shoes

InactiveCN107261320AAchieving antistatic propertiesReduce the cost of shoemakingElectrotherapyEngineeringSmall hole

The invention discloses an antistatic safety shoe, which comprises a sole and a vamp. A belt-shaped insulating gasket is embedded in the sole. A jack hole penetrating through the bottom surface of the sole is formed in the sole just below the insulating gasket. The upper sole is formed with a counterbore that runs through the upper bottom surface of the sole, and a cylindrical conductive rubber block is plugged and fixed in the socket of the sole. A stepped hole is formed on the upper end of the conductive rubber block. The stepped hole consists of a large hole at the upper end and a The small hole at the lower end is composed of a first permanent magnet ring inserted into the large hole of the step hole, and a vertical conductive column is inserted into the small hole of the stepped hole, and the upper end of the conductive column passes through the insulating gasket and is inserted into the bottom of the sole. In the counterbore, the upper end of the conductive column is plugged with a conductive massage key, and the conductive massage key is inserted into the counterbore of the sole; the conductive column is formed with an annular baffle, and the annular baffle is against the bottom of the insulating gasket. On the end face, a second permanent magnet ring is inserted and sleeved on the conductive column. The invention saves the shoe-making cost and realizes that the labor insurance shoes have the massage function in addition to anti-static.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

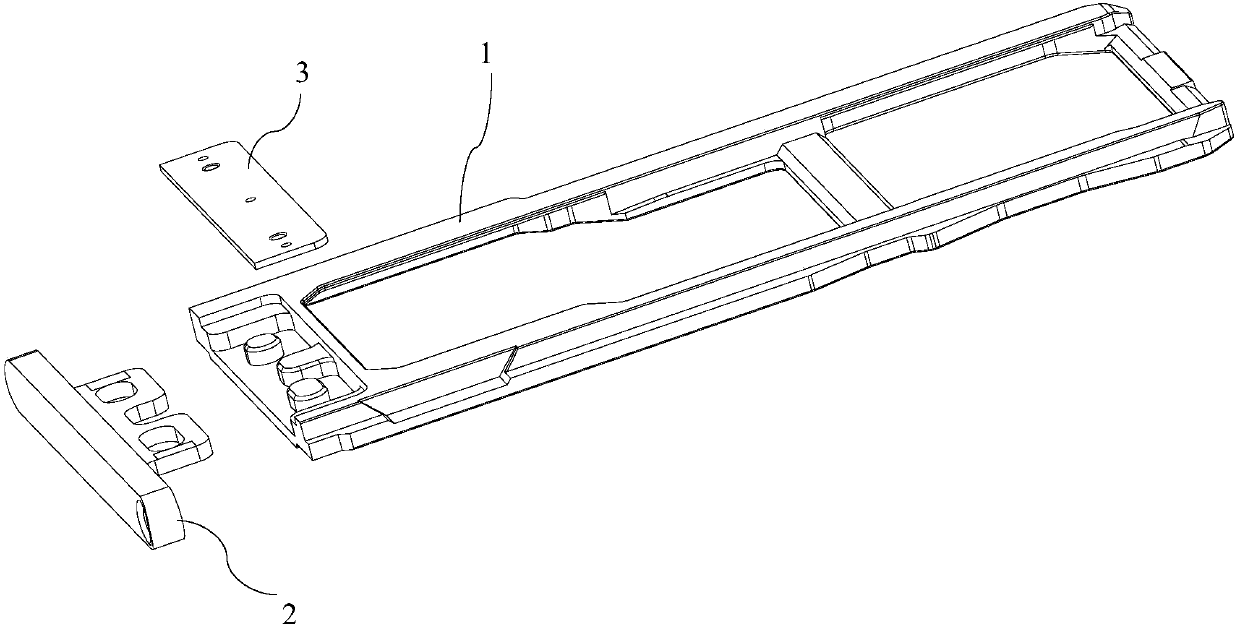

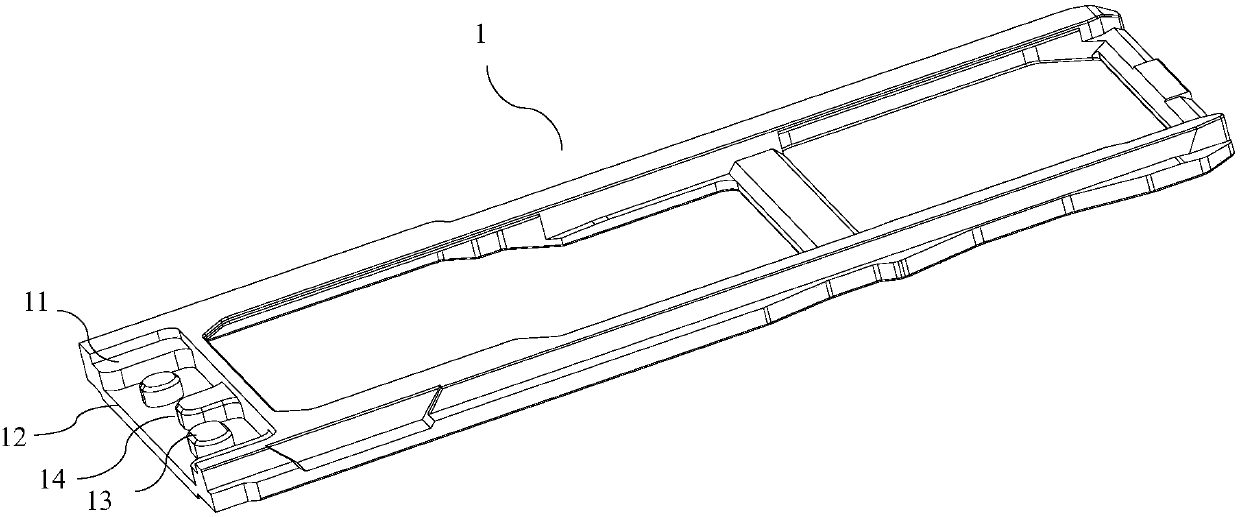

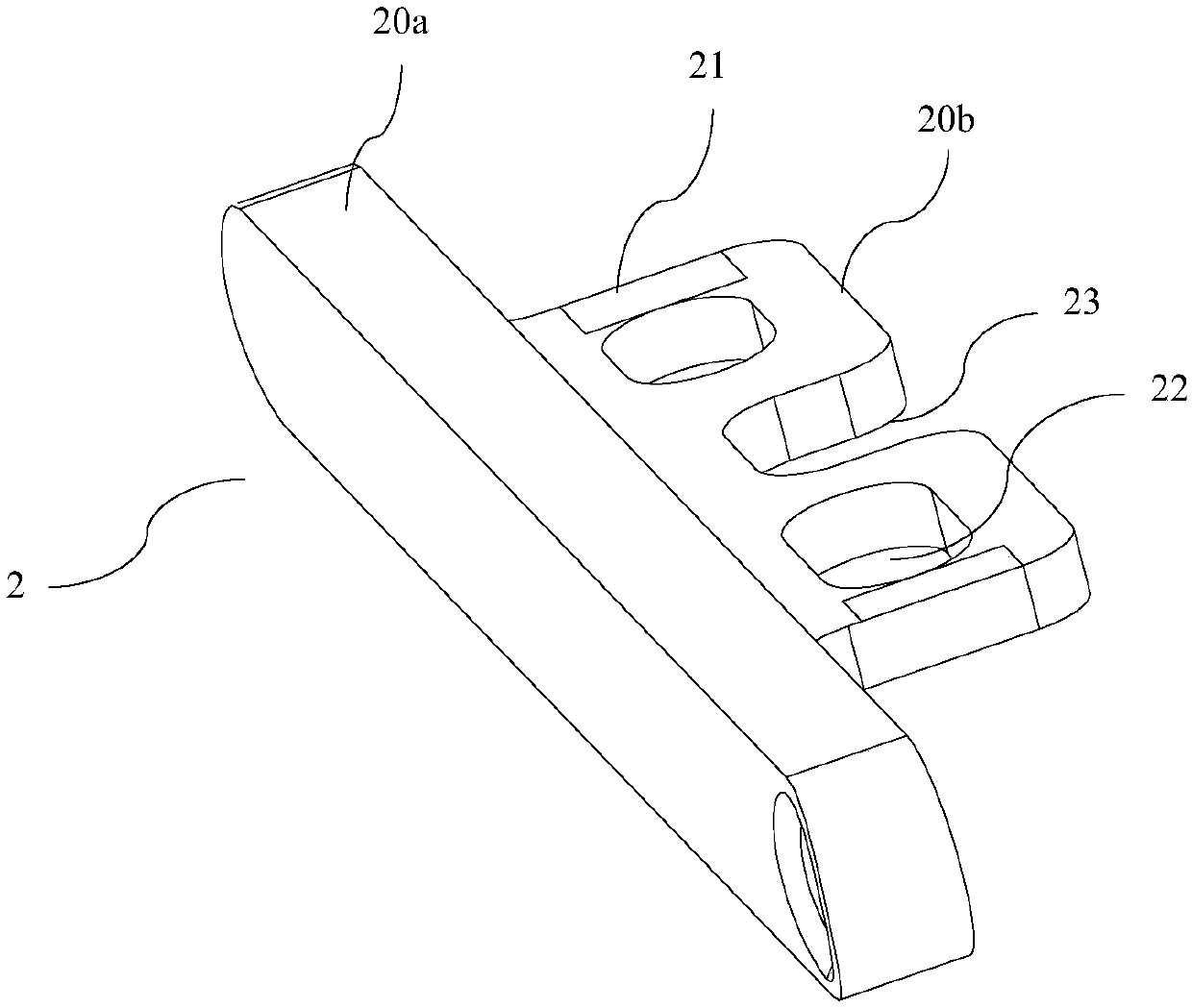

Anti-electrostatic card tray structure

InactiveCN107743040AImprove user experienceAchieving antistatic propertiesTransmissionElectrostatic chargesButt jointEngineering

The invention relates to an anti-electrostatic card tray structure, comprising a card tray and a card tray cap mounted at one end of the card tray. The card tray cap and the card tray are relatively movably connected through a welding component. The welding component is equipped with at least one first conductive part. The card tray cap is equipped with a second conductive part connected with eachfirst conductive part. The first conductive part and the corresponding second conductive part are in mutual butt joint. According to the anti-static card tray structure, the first conductive part connected with the second conductive part on the card tray cap is set on the welding component, so static electricity generated by aggregation is exported, an anti-electrostatic effect is realized, the bad influence on the mobile phone performance is avoided, and the use experience of a user is improved.

Owner:南京白下高新技术产业园区投资发展有限责任公司

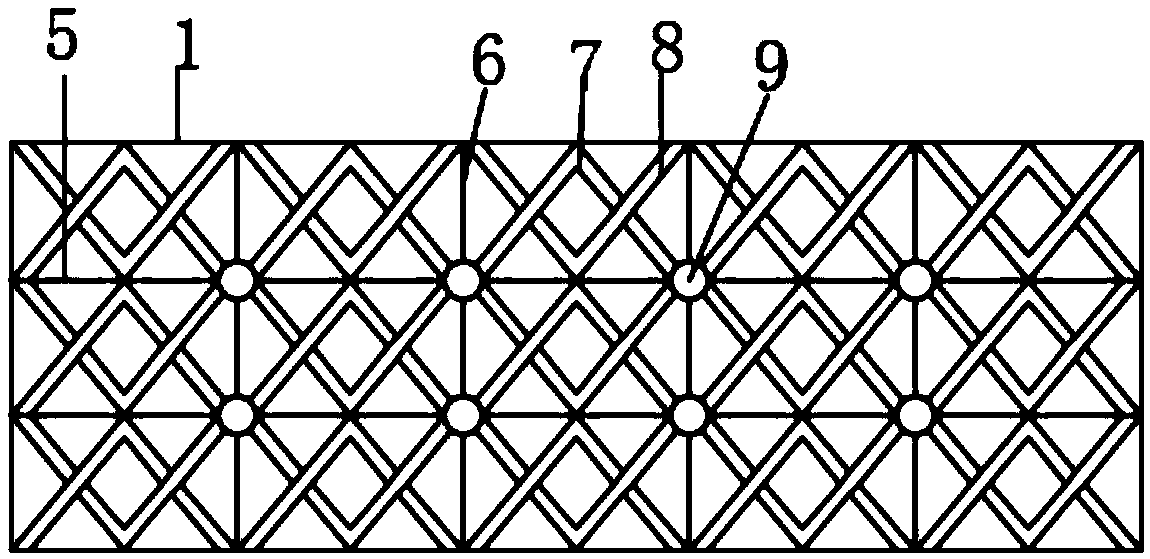

Fireproof and flame retardant aramid fiber filter material base cloth

InactiveCN109435383ASimple structureImprove tensile propertiesSynthetic resin layered productsFiltration separationEngineeringFilter material

The invention discloses fireproof and flame retardant aramid fiber filter material base cloth. The fireproof and flame retardant aramid fiber filter material base cloth comprises a base cloth body; aplurality of uniformly distributed transverse wefts are sewed in the base cloth body; a plurality of uniformly distributed vertical warps are sewed in the base cloth body; the connecting parts of theplurality of wefts and the plurality of warps are connected with each other through connecting pieces; primary tensile fiber filaments and secondary tensile fiber filaments are sewed between the adjacent connecting pieces through a needle and a thread; the primary tensile fiber filaments and the secondary tensile fiber filaments are arranged in a crossed manner; a aramid fiber mesh layer is bondedon the upper surface of the base cloth body through a bonding agent. As stainless steel fiber conductive yarns are additionally arranged, a transferring passage is available for static electricity torealize an anti-static effect; in addition, anaphylaxis of a user, which is caused because a fabric is uneasy to adsorb dust or pollen due to frictional electrification, is avoided; in addition, an anti-static fiber possesses excellent washing fastness, bending resistance and wear resistance; therefore, the anti-static fabric is easy to take care and is durable.

Owner:江苏汇达森环保材料有限公司

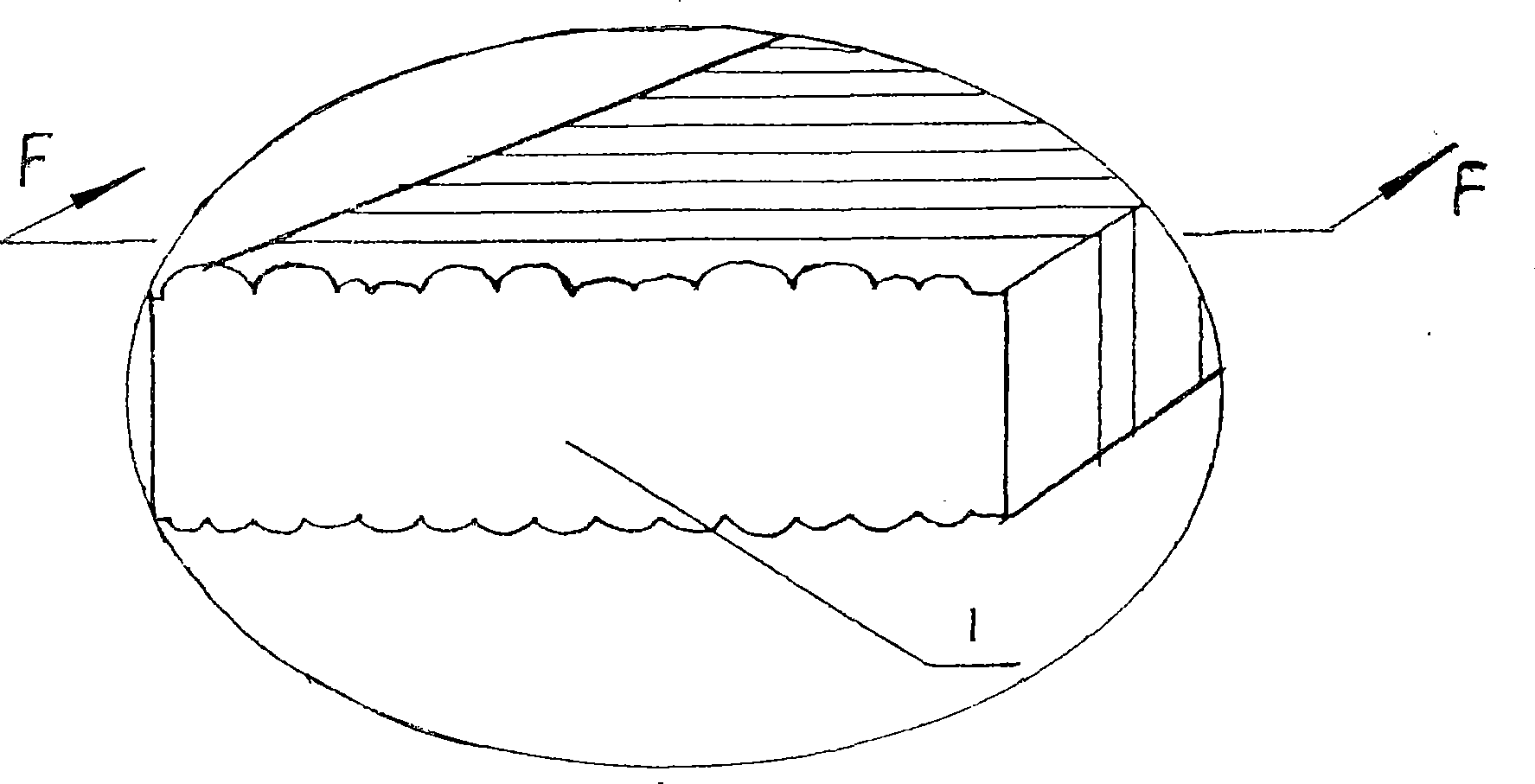

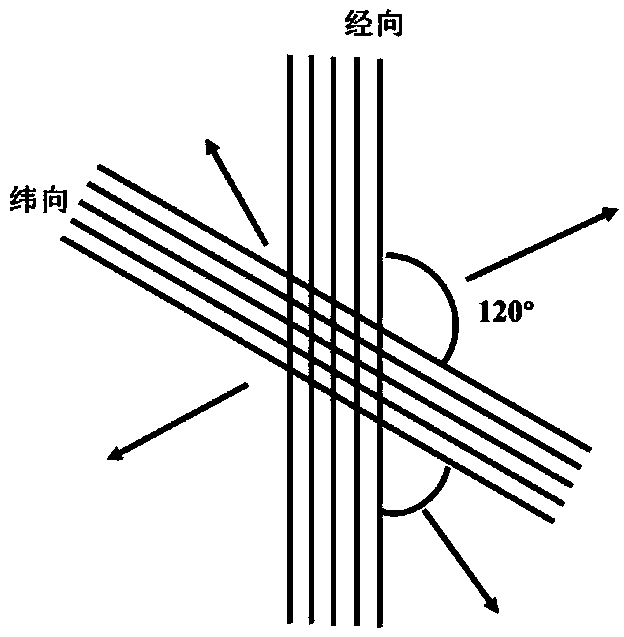

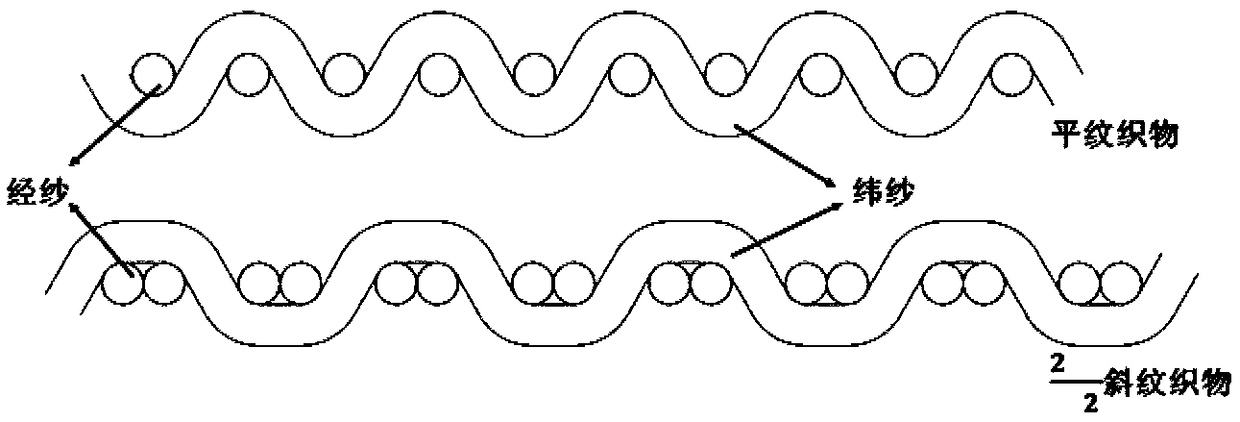

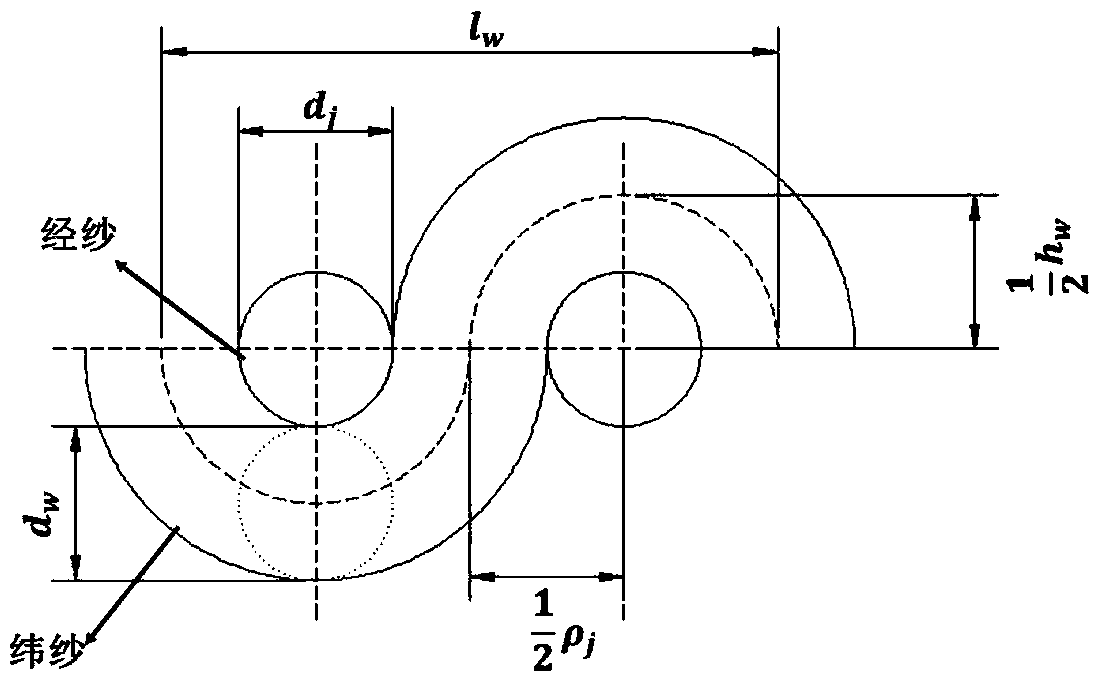

One-way elastic woven fabric with warp or weft high elasticity and production method thereof

ActiveCN109338567AImprove wear resistanceImprove interface strengthCarbon fibresWoven fabricsTemperature resistanceWoven fabric

The invention discloses a one-way elastic woven fabric with warp or weft high elasticity and a production method thereof, and belongs to the technical field of textile processing. By means of the one-way high-weaving reduction ratio fabric structure, on the basis of an impregnation curing fabric structure method, one-way high-elasticity with the fabric high-weaving reduction ratio is formed, and the one-way elastic woven fabric with the warp or weft high elasticity is obtained; the elastic stretching capability in the elastic direction can reach 130%, meanwhile, when the fabric material is selected, consumption of spandex elastic raw materials is avoided, and the high temperature resistance of the fabric is improved; meanwhile, compared with a wide-angle fabric, in the actual using process, the stress direction of the fabric is consistent with the weft and warp direction of the fabric, and the wear resistance of the fabric is greatly improved compared with the wide-angle fabric.

Owner:JIANGNAN UNIV

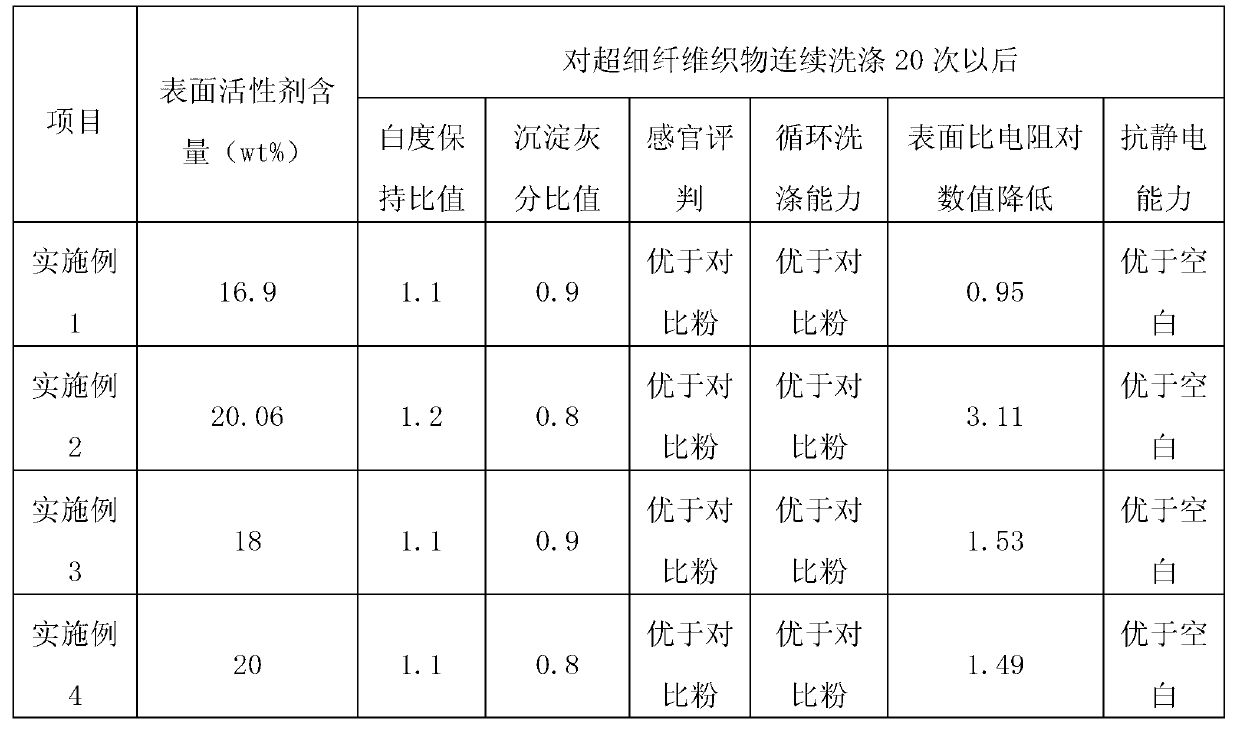

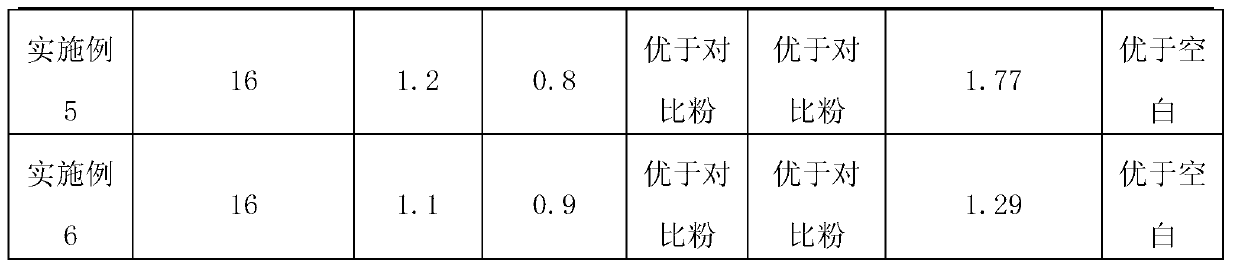

Detergent for superfine fiber fabric and preparation method of detergent

ActiveCN102660395BAchieving antistatic propertiesStrong decontaminationNon-ionic surface-active compoundsOrganic detergent compounding agentsFiberAlkane

The invention discloses a detergent for a superfine fiber fabric and a preparation method of the detergent. The detergent is prepared from the following components in parts by weight: 2-12 parts of fatty alcohol-polyoxyethylene ether, 2-8 parts of propylene glycol block polyether, 0.9-6 parts of lauryl alcohol polyoxyethylene ether phosphate potassium, 0.06-6 parts of seconary alkane sulphonate sodium, 0.04-2.7 parts of polyacrylate sodium, 1-10 parts of chelating agent, 0-1 part of essence and 50-100 parts of deionized water. The detergent disclosed by the invention is used for washing the superfine fiber fabric and is proper in foam; according to the detergent, the requirements of hand wash and machine wash can be met; the fabric washed for multiple times is still soft and the problems that the superfine fiber fabric becomes harder, yellowed and poorer in hydroscopic property; and in addition, the washed superfine fiber fabric further has a certain antistatic effect and various original advantages and performances of the superfine fiber fabric cannot be influenced and changed.

Owner:潍坊光华精细化工有限公司

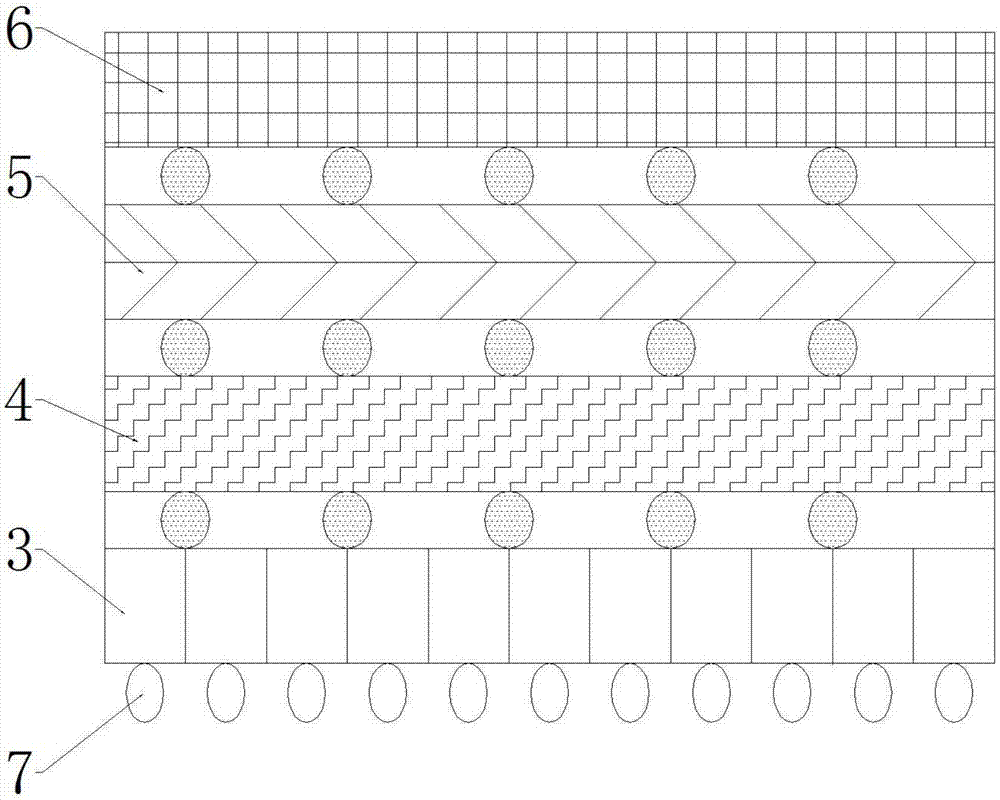

Antistatic weaved glove

InactiveCN107361434AImprove breathabilityHas antibacterial functionGarment special featuresGlovesAntibiosisAntistatic agent

The invention discloses an antistatic weaved glove. The antistatic weaved glove comprises a palm area and a finger area connected with the palm area, the palm area and the finger area are composed of an inner layer, a middle layer, a thermal insulation area and an anti-cutting layer, the inner layer is manufactured by first warp and first weft in a criss-cross mode, and several gaps are formed between the first warp and second weft; the thermal insulation layer is a loose structure formed by making third warp bent in the warp direction into loops and making the loops mutually penetrated and sleeved, and antistatic weft is weaved between third warp in a penetrating mode to form a weft insertion layer. Through the weaving mode of the first warp and the first weft in the inner layer, on one hand, the breathability is improved, on the other hand, the function of antibiosis is further achieved; through the arrangement of the middle layer, the functions of breathability, deodorizing, antibiosis, antistativity and automatic heat-emitting of the weaved glove are achieved; through the arrangement of the thermal insulation layer, on one hand, the breathability of the glove is improved, on the other hand, the antistatic function is further achieved, and the anti-cutting layer has the function of preventing the hand from being cut.

Owner:周敏

A kind of preparation method of antibacterial and antistatic spandex

ActiveCN110528111BReduce surface defectsIncrease intrinsic conductivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

Owner:HANGZHOU GAOXI TECH CO LTD

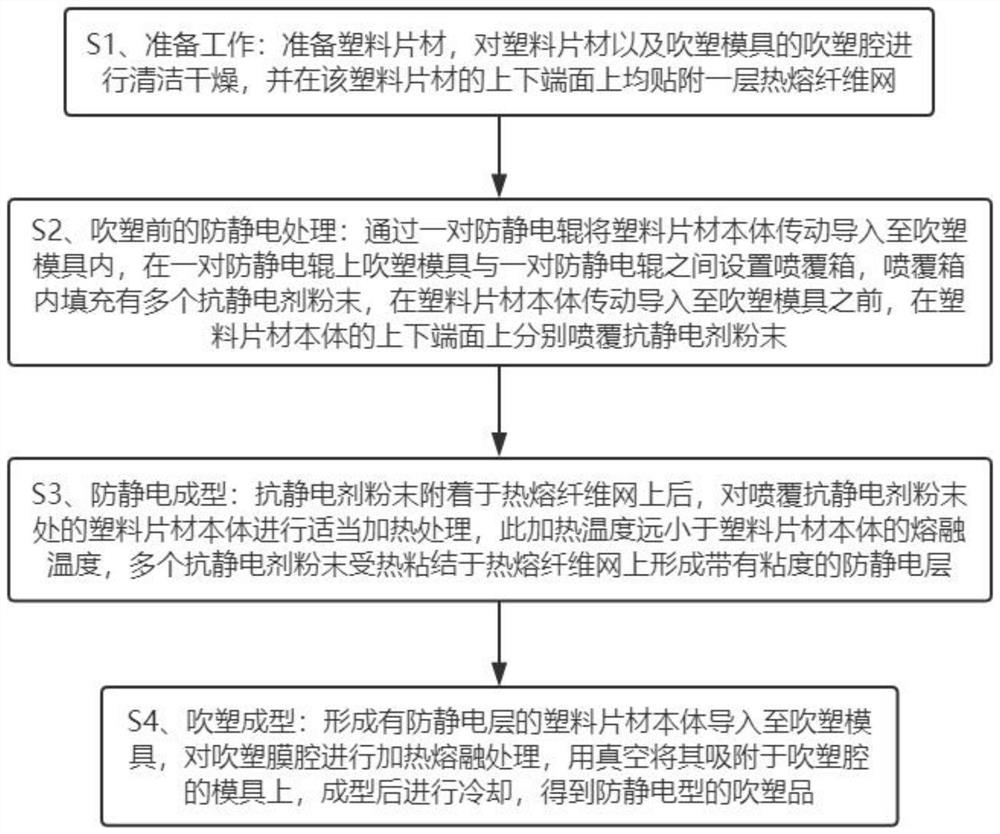

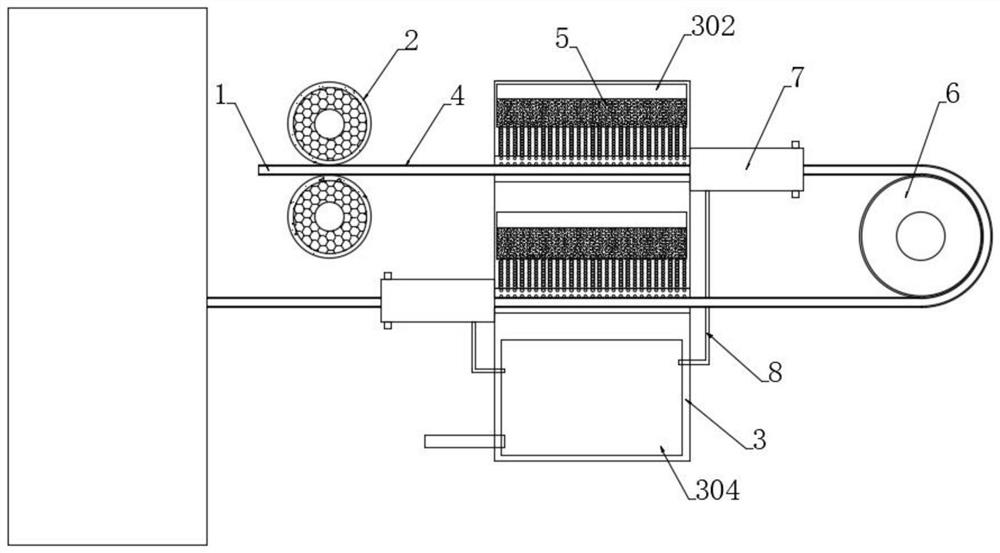

Blister molding method for anti-static plastic sheet

PendingCN112109313AAchieving antistatic propertiesWith moisture absorptionFlat articlesElectrostatic chargesFiberBlow molding

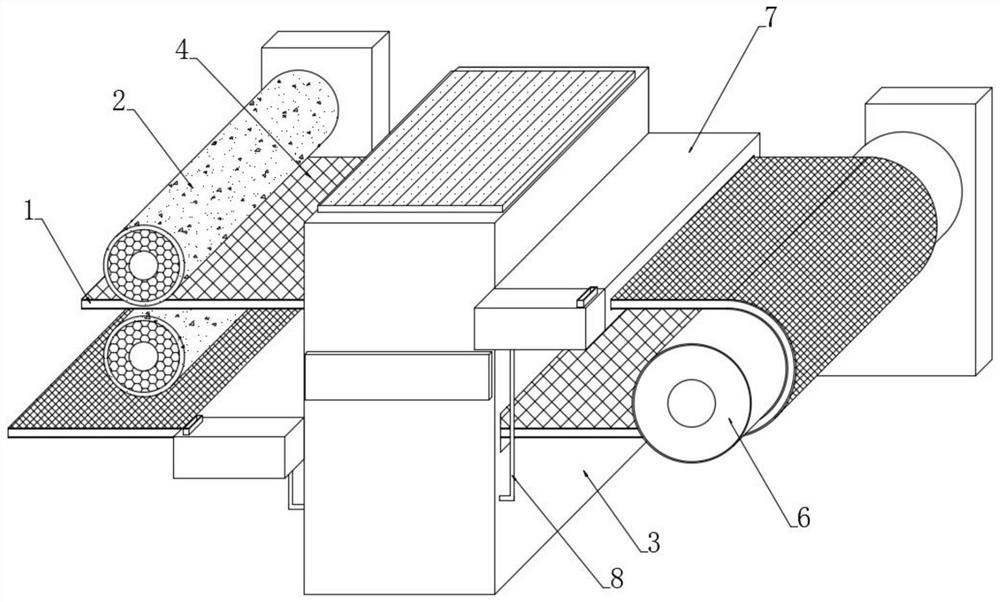

The invention discloses a blister molding method for an anti-static plastic sheet, and belongs to the technical field of plastic sheet blister molding. A plastic sheet body is guided through a pair ofanti-static rollers with static brush layers, and anti-static treatment is performed on the upper end face and the lower end face of the plastic sheet body. After the plastic sheet body is conveyed to a spraying box, anti-static agent powder filling the spraying box is sprayed on the upper end face and the lower end face of the plastic sheet body respectively, a melting box is used for melting ahot melting fiber net just sprayed with the anti-static agent powder, and bonding and forming are conducted to form an anti-static layer. In other words, in the blow molding and conveying process of the plastic sheet body, the situation that potential safety hazards are caused in blow molding production as charges are accumulated on the plastic sheet body due to carrying, contact, friction and other operations in the production process is avoided. After the plastic sheet body is subjected to blow molding fusion, the anti-static layer is embedded in a blow molding product in a fusion mode, andthe anti-static performance of the blow molding product in the subsequent using process is effectively achieved.

Owner:苏州勤联塑胶制品有限公司

Adhesive composition and surface-protective film

ActiveCN108795348AImproves stain resistanceExcellent anti-stripping static performanceNon-macromolecular adhesive additivesFilm/foil adhesivesSulfonatePolymer science

The present invention provides an adhesive composition and a surface protective film which can simultaneously achieve excellent antistatic properties and stain resistance. The adhesive composition contains an acrylic polymer, an antistatic agent, and a crosslinking agent; the acrylic polymer has a glass transition temperature of 0 deg c or lower, and the crosslinking agent is a trifunctional or higher isocyanate compound. The antistatic agent is an ionic compound having a melting point of 25 deg c or above and formed by a cation and an anion; the anion is selected from the group consisting ofa trifluoromethane sulfonate anion, a pentafluoroethane sulfonate anion, a heptafluoropropane sulfonate anion, and a nonafluoro butane sulfonate. The antistatic agent is contained as an essential component in an amount of 0.01 to 10 parts by weight based on 100 parts by weight of the acrylic polymer.

Owner:FUJIMORI KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com