Permanent antistatic high-toughness talcum powder filled polypropylene material and preparation method thereof

A polypropylene material, antistatic technology, applied in the field of modified plastics, can solve the problems of poor, a period of time, exhaustion, etc., to achieve the effect of uniform dispersion, increased compatibility, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

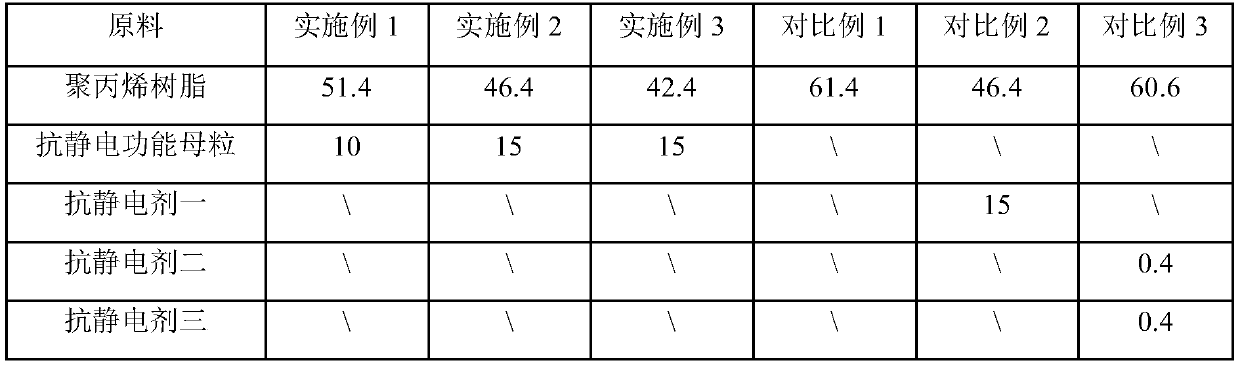

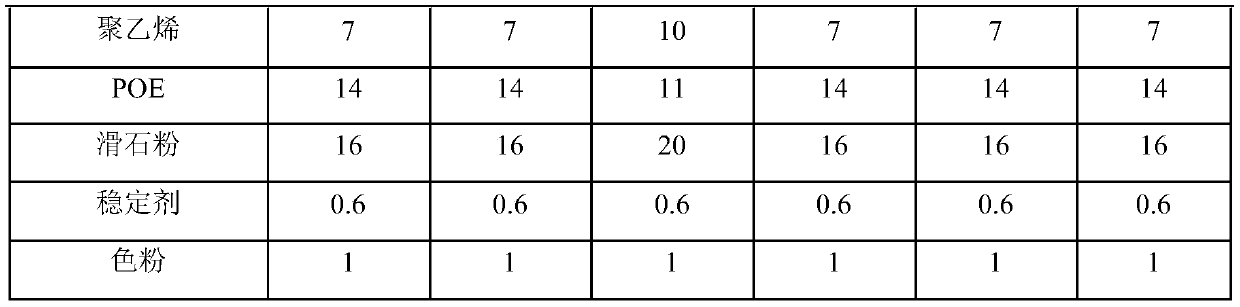

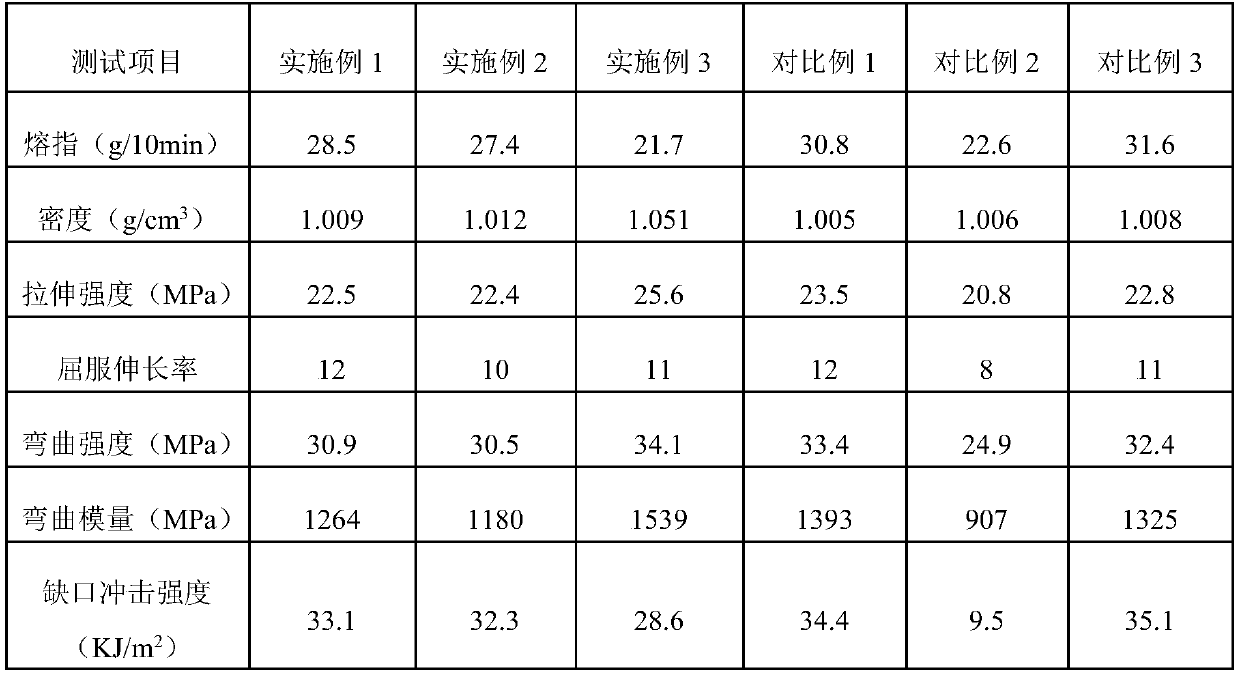

Embodiment 1

[0038] A permanent antistatic high toughness talcum powder filled polypropylene material, comprising the following components in parts by weight: 51.4 parts of polypropylene resin, 10 parts of antistatic functional masterbatch, 7 parts of polyethylene, 14 parts of POE, 16 parts of 3000 mesh talc powder 1 part, 0.6 part of stabilizer, 1 part of toner.

[0039] The preparation method of the above-mentioned permanent antistatic high toughness talcum powder filled polypropylene material is as follows: each component is placed in a high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder , melt-extruded, granulated and dried to obtain a permanent antistatic high-toughness talcum powder-filled polypropylene material.

[0040] Among them, the melt extrusion temperature of the twin-screw extruder is: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature...

Embodiment 2

[0042] A permanent antistatic high toughness talcum powder filled polypropylene material, comprising the following components in parts by weight: 46.4 parts of polypropylene resin, 15 parts of antistatic functional masterbatch, 7 parts of polyethylene, 14 parts of POE, 16 parts of 3000 mesh talc powder 1 part, 0.6 part of stabilizer, 1 part of toner.

[0043]The preparation method of the above-mentioned permanent antistatic high toughness talcum powder filled polypropylene material is as follows: each component is placed in a high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder , melt-extruded, granulated and dried to obtain a permanent antistatic high-toughness talcum powder-filled polypropylene material.

[0044] Among them, the melt extrusion temperature of the twin-screw extruder is: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature ...

Embodiment 3

[0046] A permanent antistatic high tenacity talcum powder filled polypropylene material, comprising the following components in parts by weight: 42.4 parts of polypropylene resin, 15 parts of antistatic functional masterbatch, 10 parts of polyethylene, 11 parts of POE, 20 parts of 3000 mesh talc powder 1 part, 0.6 part of stabilizer, 1 part of toner.

[0047] The preparation method of the above-mentioned permanent antistatic high toughness talcum powder filled polypropylene material is as follows: each component is placed in a high-speed mixer and fully stirred to obtain a premix, and the premix is added to the main feeding port of the twin-screw extruder , melt-extruded, granulated and dried to obtain a permanent antistatic high-toughness talcum powder-filled polypropylene material.

[0048] Among them, the melt extrusion temperature of the twin-screw extruder is: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com