A kind of preparation method of lithium-ion battery ceramic diaphragm

A lithium-ion battery, ceramic diaphragm technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inability to truly realize industrialization, easy to block the diaphragm aperture, uneven coating thickness, etc., and meet the equipment requirements. , The effect of reducing process difficulty and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

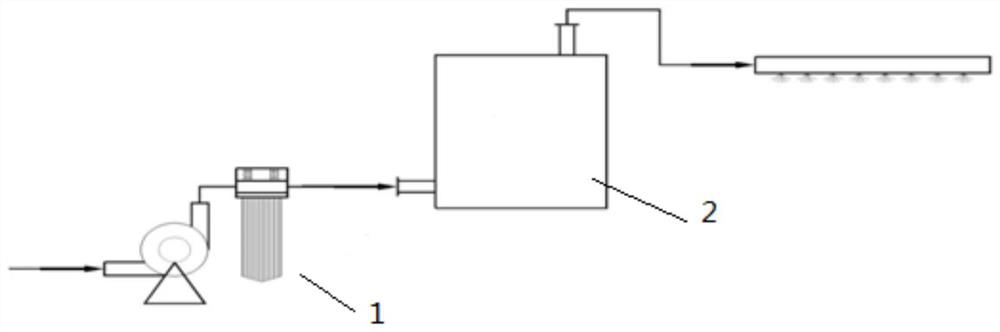

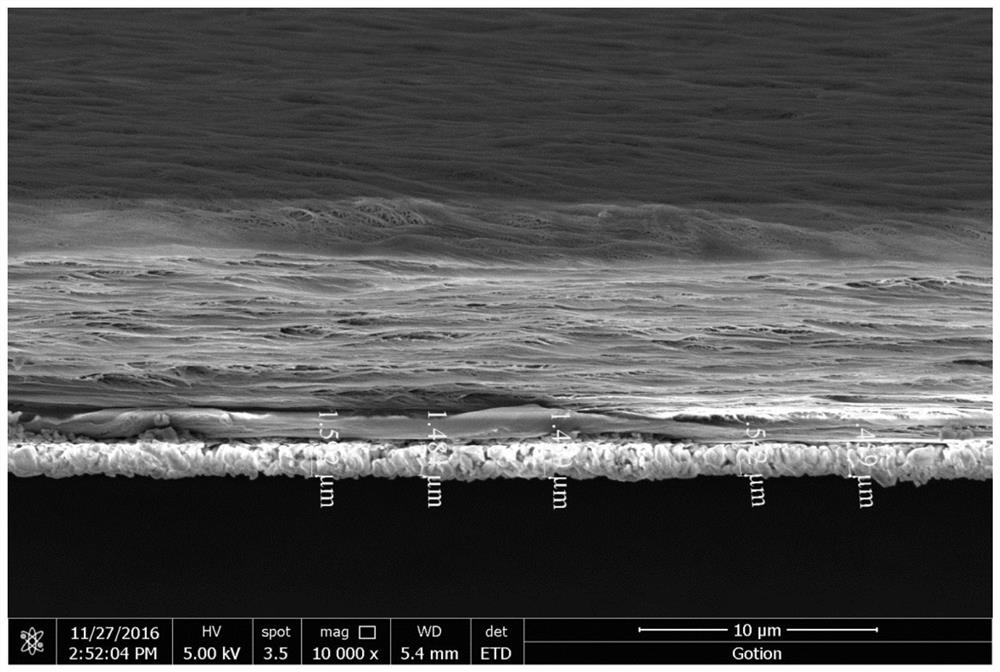

[0033] A method for preparing a lithium-ion battery ceramic diaphragm, the method specifically comprising: preparing a water-based ceramic slurry and atomizing the water-based ceramic slurry into an aerosol, specifically suspending solid particles and liquid particles in the water-based ceramic slurry in the air After the smoke and mist are formed, they are uniformly deposited on the base film to form a ceramic coating precursor, and then the ceramic coating precursor is dried to obtain the product;

[0034] Wherein, the water-based ceramic slurry comprises by weight: 0.3 part of inorganic ceramic powder, 0.6 part of deionized water, 0.05 part of styrene-butadiene rubber emulsion, and 0.05 part of sodium carboxymethyl cellulose;

[0035] The inorganic ceramic is zirconia;

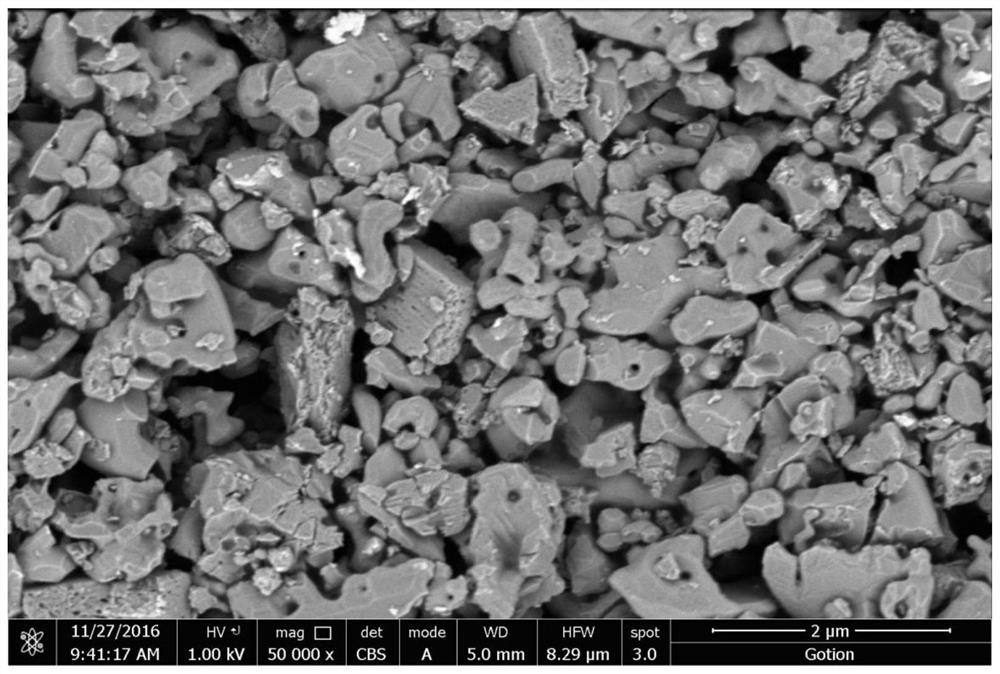

[0036] The particle diameter of described inorganic ceramic powder is 100nm;

[0037] The preparation method of described water-based ceramic slurry comprises the steps:

[0038] S1, adding sodium carboxy...

Embodiment 2

[0057] A method for preparing a lithium-ion battery ceramic diaphragm, the method specifically comprising: preparing a water-based ceramic slurry and atomizing the water-based ceramic slurry into an aerosol, specifically suspending solid particles and liquid particles in the water-based ceramic slurry in the air After the smoke and mist are formed, they are uniformly deposited on the base film to form a ceramic coating precursor, and then the ceramic coating precursor is dried to obtain the product;

[0058] Wherein, the water-based ceramic slurry comprises by weight: 0.15 part of inorganic ceramic powder, 0.8 part of deionized water, 0.03 part of styrene-butadiene rubber emulsion, and 0.02 part of sodium carboxymethyl cellulose;

[0059]The inorganic ceramic is silicon dioxide;

[0060] The particle size of the inorganic ceramic powder is 300nm;

[0061] The preparation method of described water-based ceramic slurry comprises the steps:

[0062] S1, adding sodium carboxymet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com