Surface air cooler serialization design method for air compressor air inlet pretreatment

A design method and technology of surface coolers, applied in computer-aided design, design optimization/simulation, special data processing applications, etc. Involving other issues to achieve the effect of power reduction, design and manufacturing cost reduction, and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The present invention will be described in detail below with reference to the drawings and specific embodiments.

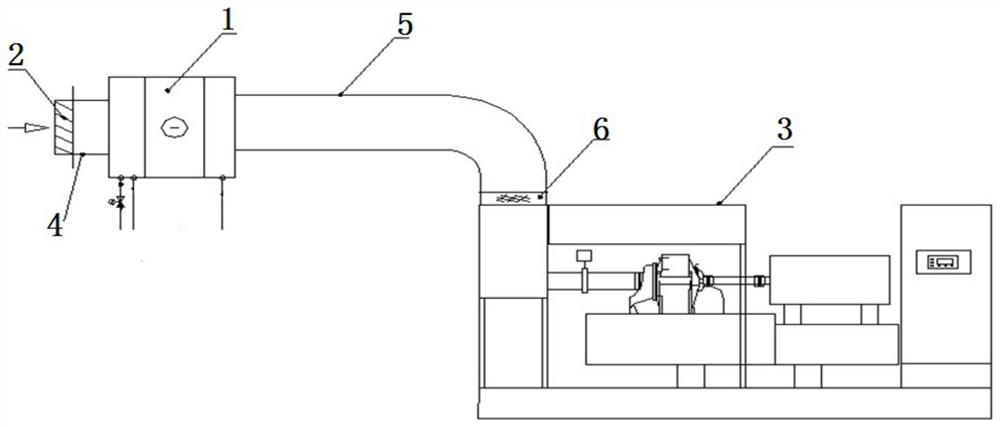

[0052]The present invention is a surface cooler series design method for air compressor intake air pretreatment, which involves air compressor intake air pretreatment equipment, such asfigure 1 As shown, the surface cooler 1 is included. The inlet end of the surface cooler 1 is connected with a filter 2 through an air inlet duct 4, the outlet end of the surface cooler 1 is connected to an air compressor 3 through an outlet duct 5, and an outlet duct 5 is connected to the air inlet of the air compressor 3 through an air inlet hose 6.

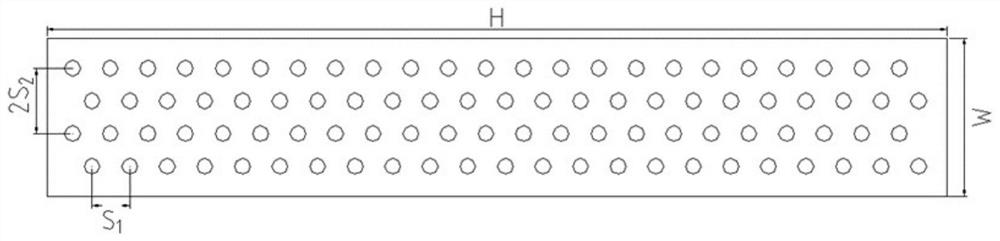

[0053]The present invention is a surface cooler serialized design method for air compressor intake pretreatment, which specifically includes the following steps:

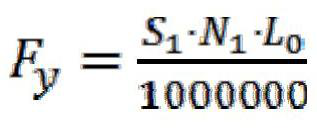

[0054]Step 1. According to the air compressor output G, the air compressor output G in this embodiment is 130-160m 3 / min, ie G=9600m3 / h, calculate the cooling capacity Q of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com