Turbine

a technology of internal combustion engine and turbine, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of reduced gas entering the impeller gas feeding passage from the impeller gas inlet, low efficiency of the turbine, etc., and achieves excellent succession, high casting yield, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

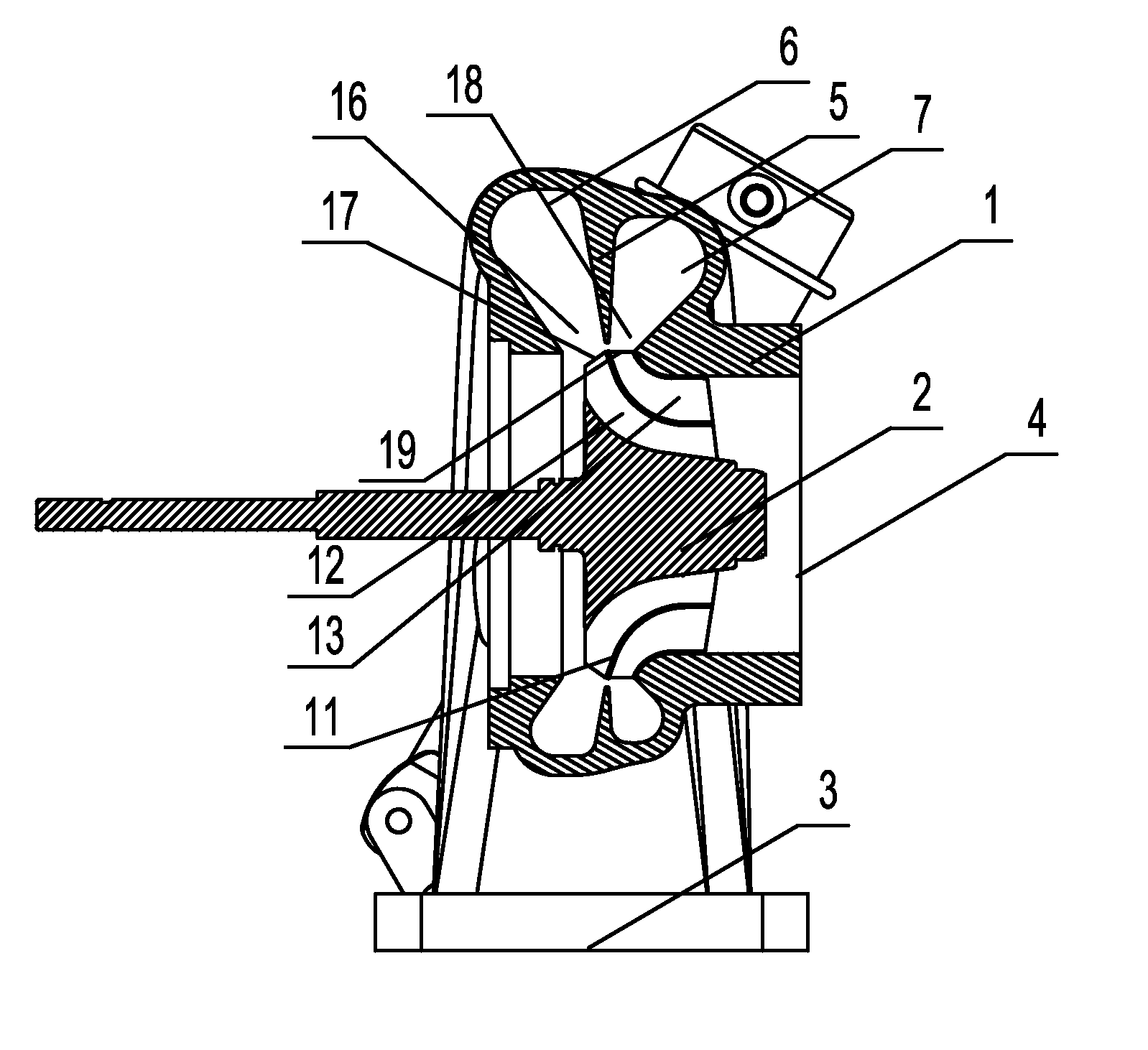

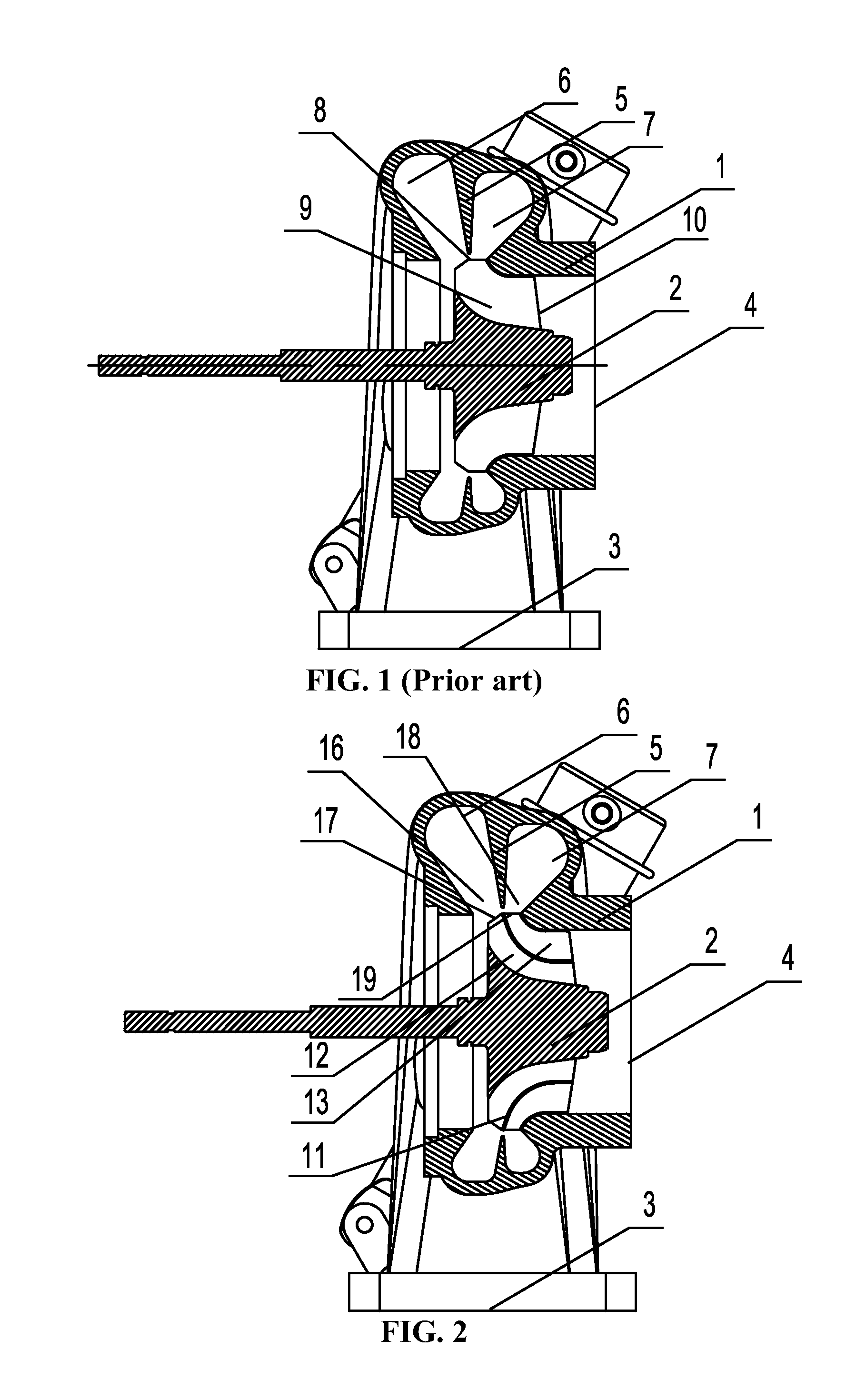

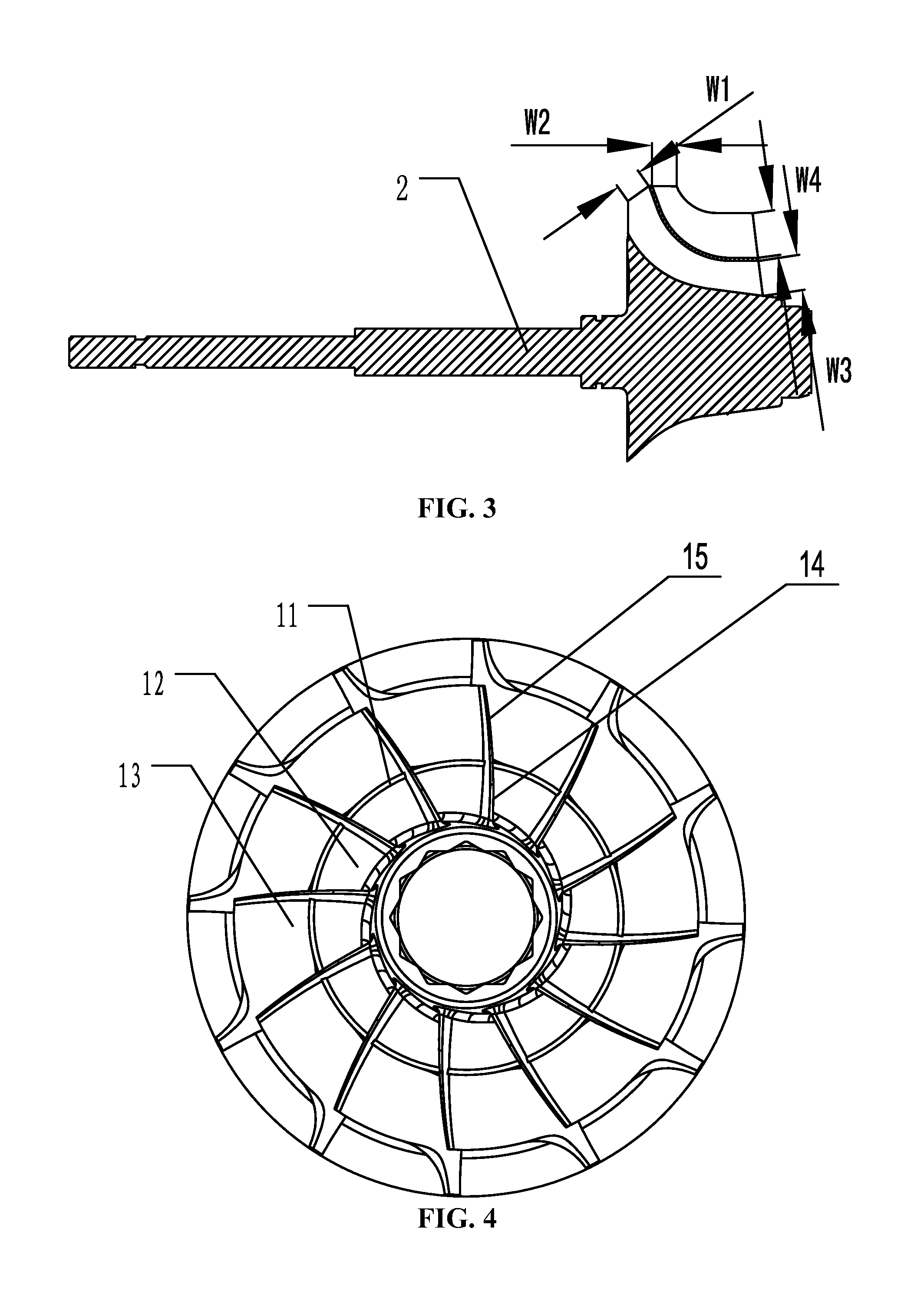

[0038]As shown in FIGS. 2-3, a double-area turbine for turbocharging comprises a volute 1 and an impeller 2 disposed inside the volute 1. Blades are disposed at an outer part of the impeller 2. The volute 1 comprises: a volute gas inlet 3, a volute gas feeding flow passage, and a volute gas outlet 4.

[0039]The impeller 2 comprises: an impeller gas inlet, an impeller gas feeding flow passage, an impeller gas outlet, and blades.

[0040]A partition plate 11 is circumferentially disposed between the impeller gas inlet and the impeller gas outlet. The shape of the partition plate 11 satisfies aerodynamic performance requirements and reliability requirements.

[0041]The partition plate 11 divides the impeller gas feeding flow passage into an inner flow passage 12 and an outer flow passage 13.

[0042]The inner flow passage 12 adopts a radial inflow channel or Francis channel. The outer flow passage 13 is generally designed to be a radial inflow channel and is designed to be a Francis channel in s...

example 2

[0052]As shown in FIG. 6, the turbine of this example is different from that in Example 1 in that the adjustable valve 20 herein is disposed inside the right flow passage 7 in the vicinity of the volute gas inlet 3 rather than being disposed inside the left flow passage 6 in the vicinity of the volute gas inlet 3 in Example 1. The adjustable valve 20 is connected to a control mechanism. The rotation of the adjustable valve 20 can be realized driven by the control mechanism, so that the right flow passage 7 is opened or closed.

[0053]When the motor operates at the low rotational speed working condition, a relatively small amount of exhaust gas is discharged from the motor, and the adjustable valve 20 is in a close state driven by the control mechanism. Thus, the right flow passage 7, the gas inlet 19 of the outer flow passage, and the outer flow passage 13 are also in the close sate. The exhaust gas discharged from the motor only passes through the left flow passage 6, the gas inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com