A new fluidity biomass briquetting machine

A fluidity and biomass technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of small application range and high production costs, reduce machine failures, make crushing devices simple and easy to implement, and avoid rigidity Collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

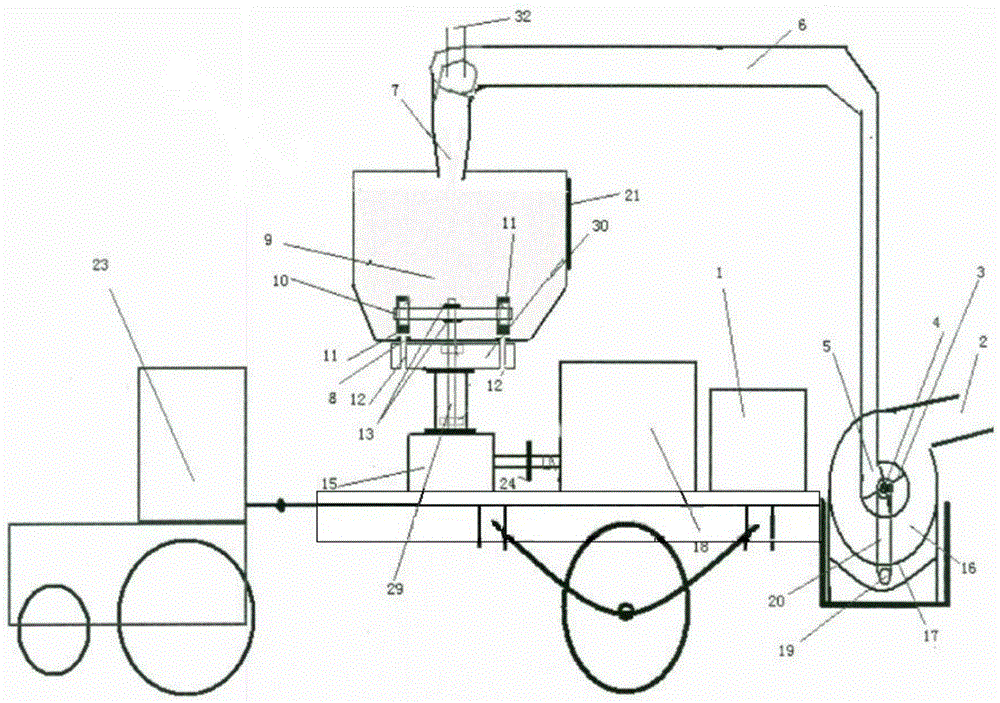

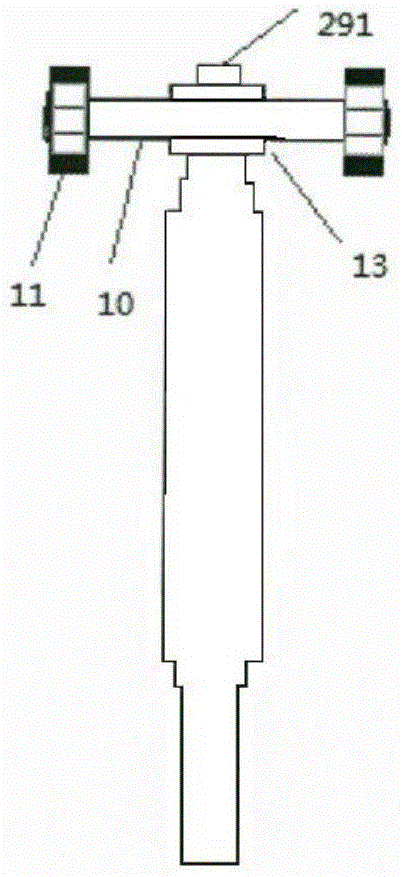

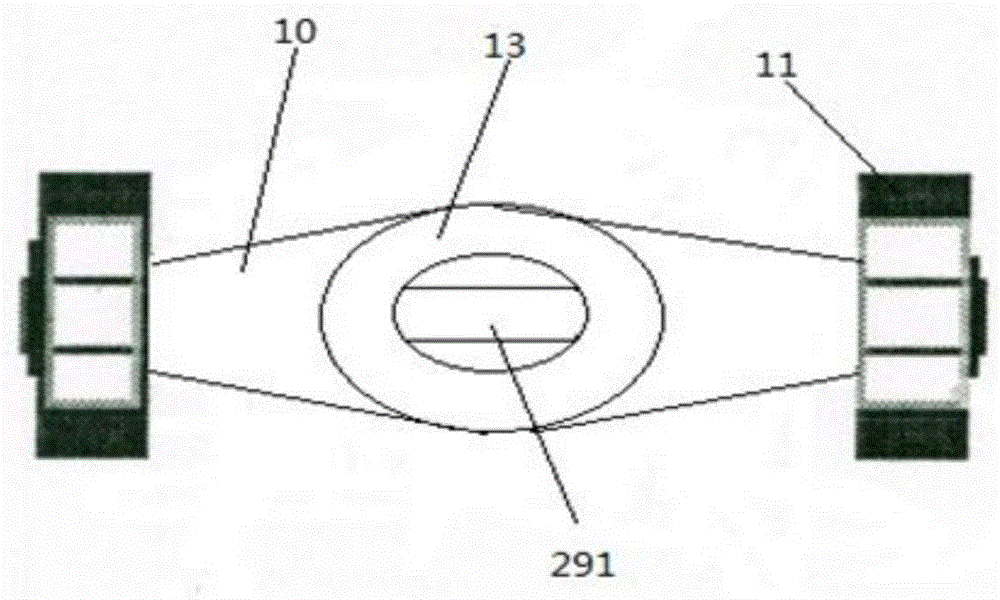

[0053] This embodiment provides a novel fluidity biomass briquette, such as figure 1 As shown, it includes a raw material processing part and a briquetting part. The above-mentioned raw material processing part includes a crushing device for crushing the raw material into a crushed material suitable for the briquetting part of the above-mentioned briquetting part and is used to transport the above-mentioned crushed material to the briquetting part for processing Conveying device for briquettes.

[0054] The above-mentioned pulverizing device includes an accommodating space 16 for accommodating the above-mentioned raw materials, a raw material feed port 2 for putting raw materials into the above-mentioned accommodating space, and a pulverizing piece located in the above-mentioned accommodating space 16, which is used to drive the above-mentioned pulverizing piece to crush the raw material. A first driving member for crushing into scraps, and a separation member for separating t...

Embodiment 2

[0075] This embodiment provides a new fluidity biomass briquetting machine, which is an improvement on the basis of Embodiment 1, such as Figure 5 As shown, the difference is that a humidifying device for increasing the humidity of the crushed material or raw material is added.

[0076] Above-mentioned humidifying device comprises water storage tank 36, and the water pipe 38 that one end communicates with above-mentioned water storage tank 36, the water pipe outlet 34 of the other end communicates with raw material processing part and is used for being stored in the water 37 ejection of water storage tank 36, in above-mentioned water pipe 38 Be provided with the valve 48 that is used to control the size of adding water on it.

[0077] As a modification to this embodiment, the water pipe outlet 34 at the other end of the water pipe 38 can also be connected to the position of the hopper 9 to increase the humidity of the crushed material when the moisture content of the raw mate...

Embodiment 3

[0079] This embodiment provides a new fluidity biomass briquetting machine, which is a modification on the basis of Embodiment 1 or 2, and the difference is that another realization mode of a humidifying device is provided.

[0080] In this embodiment, the humidifying device includes a closed water storage pressure tank; a water pipe 38, which has a water inlet inserted below the water surface inside the water storage pressure tank and a water outlet 34 extending into the hopper 9 for spraying water; The air pump, after being driven by the second power unit 18, imports air to the inside of the above-mentioned water storage pressure tank through the air pipe; Connected intake port.

[0081] The second power unit 18 drives the air pump to work through the linkage. There are many ways to realize the linkage. The power on the device 18 is transmitted to the air pump to deliver air and the like to the above-mentioned water storage pressure tank.

[0082] The above-mentioned setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com