Patents

Literature

68results about How to "Increase intrinsic conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and preparation method thereof

ActiveCN102412398AStable structureImprove conductivityMaterial nanotechnologyCell electrodesPtru catalystPhysical chemistry

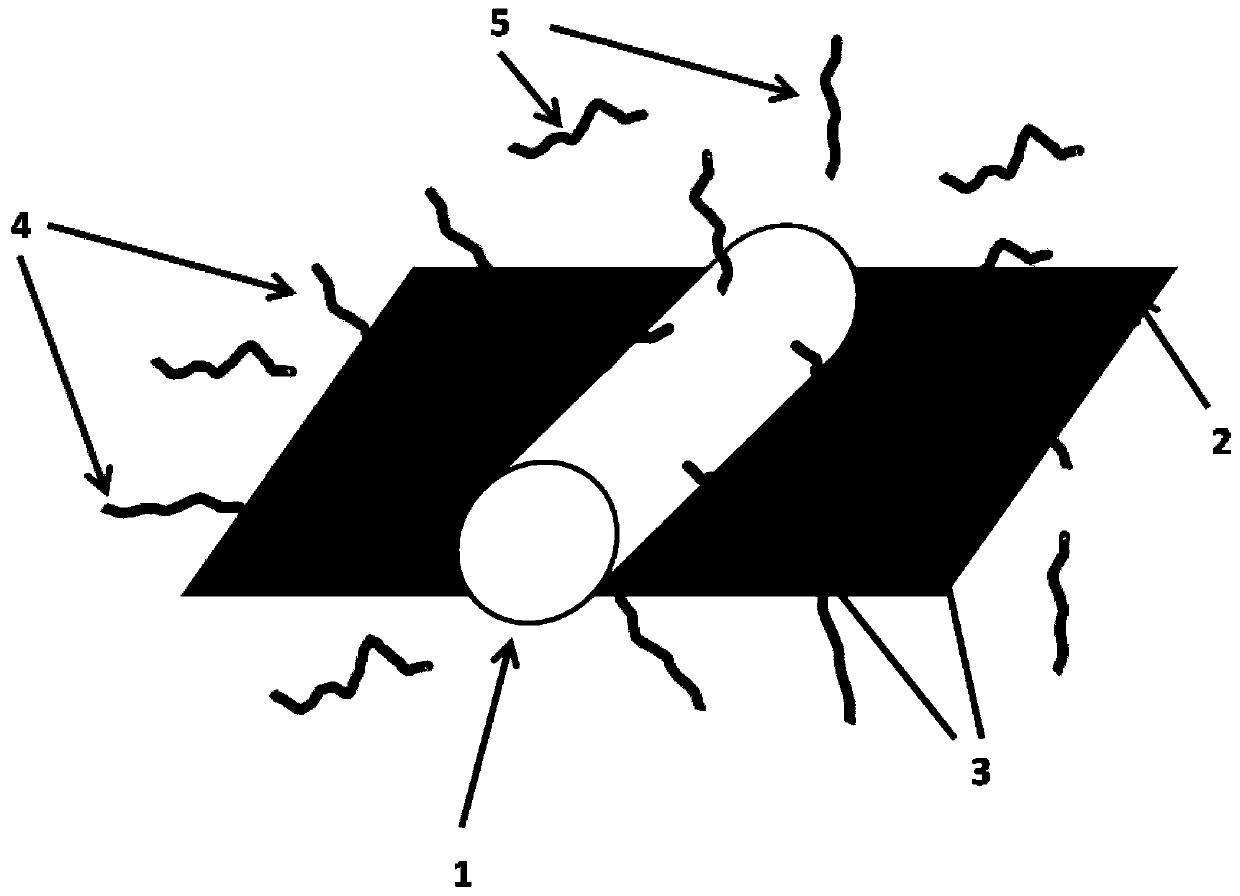

The invention provides a manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and a preparation method thereof. The chemical formula of the material is Li ( Mn 1-xMx) PO4, wherein the x is 0-0.1, M is a transition metal Fe, Co or Ni; a carbon nanometer pipe is uniformly distributed in manganese phosphate lithium grains in a synthetic process of the manganese phosphate lithium; a transition metal compound is adopted as a catalyzer and an alloying element so as to catalyze pyrolytic hydrocarbon gas and prepare a situ carbon nanometer pipe compound manganese phosphate lithium material; the preparation method provided by the invention has the advantages that the preparation method is simple, the cost is cheap, the manganese phosphate material purity is high, a structure is full, the conductivity is high, and the electrochemistry performance is excellent.

Owner:DONGFANG ELECTRIC CORP LTD

Oxygen-vacancy-containing lithium ferrous silicate and carbon composite anode material and preparation method

The invention relates to a secondary lithium battery anode composite material, in particular to an oxygen-vacancy-containing lithium ferrous silicate and carbon composite material. The chemical formula of the composite material is Li2FeSiO4-xNy / C, wherein x is more than 0 and less than or equal to 1, y is more than 0 and less than or equal to 0.5, the condition that x is more than or equal to 3y / 2 is met, and carbon content is 5-20wt%. The intrinsic conductivity and the lithium ion conductivity inside granules of the composite material are high, and the composite material has excellent performances such as high capacity and high multiplying power. The preparation method of the composite material comprises the steps of: preparing sol from lithium salt, ferrous salt, a silicon source and a carbon source and then carrying out high temperature calcination on the sol twice to obtain granular and oxygen-vacancy-containing lithium ferrous silicate and carbon composite material.

Owner:WUHAN UNIV OF TECH

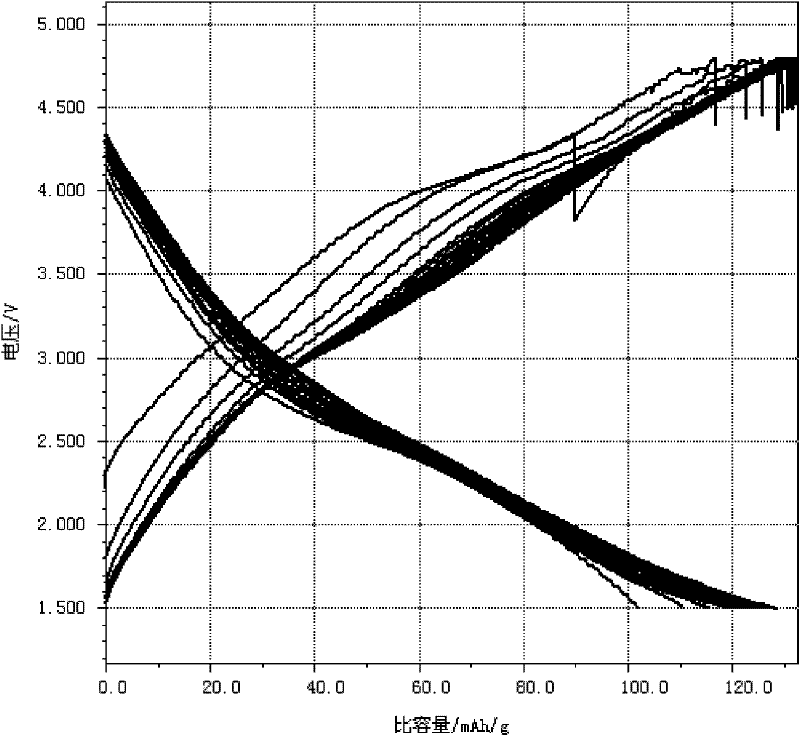

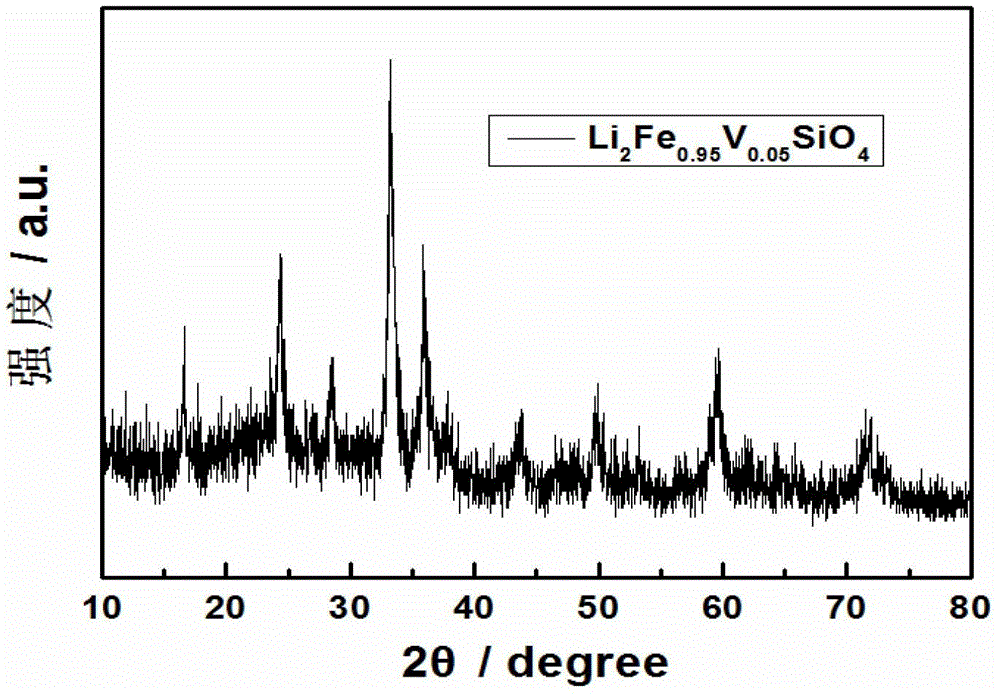

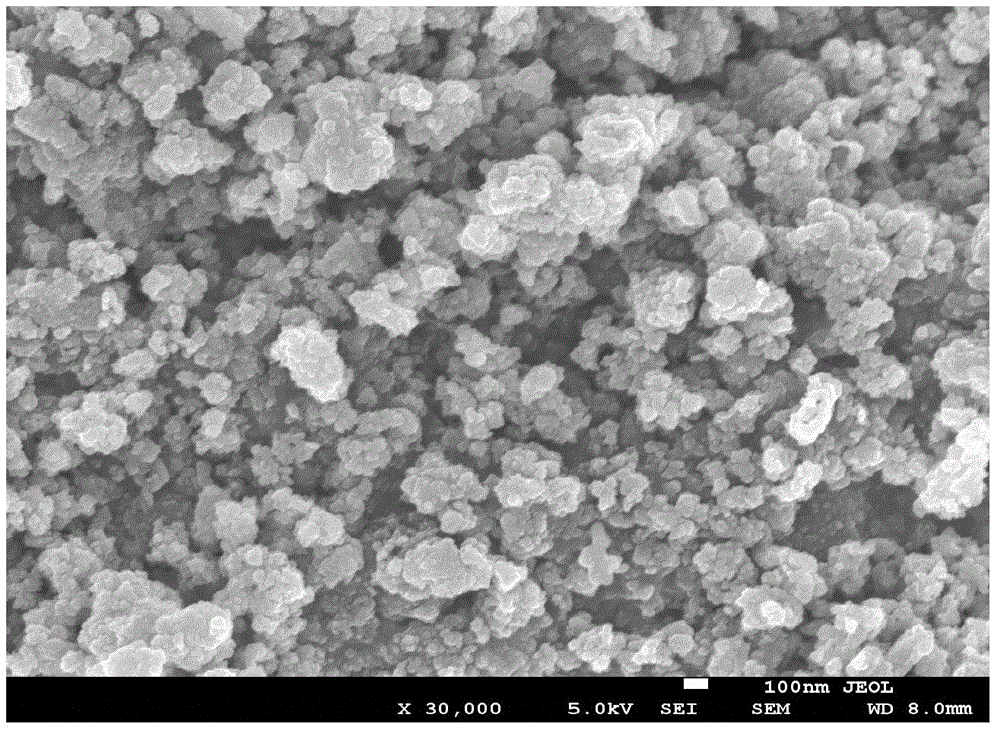

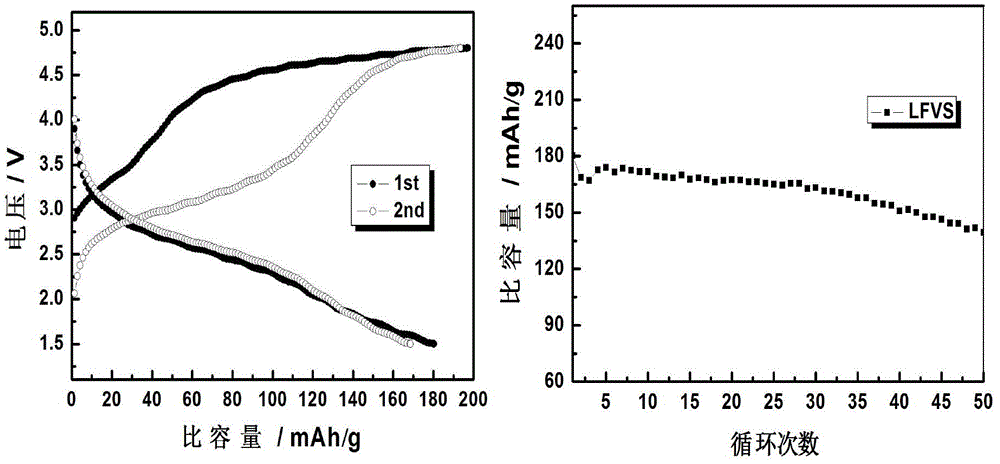

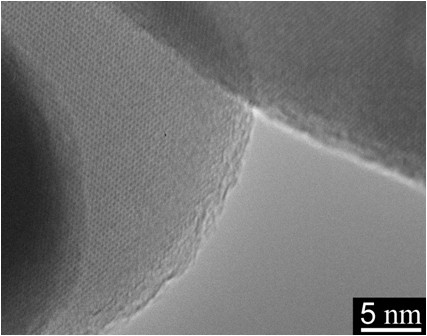

High-rate performance vanadium-doped lithium iron silicate anode material and preparation method thereof

ActiveCN102723488AReduce contact resistanceImprove intrinsic conductivityCell electrodesSolid phasesChemistry

Disclosed are high-rate performance vanadium-doped lithium iron silicate anode material Li2Fel-xVxSiO4 / C and a preparation method thereof. The preparation method includes: dissolving V2O5 or NH4VO3 in oxalic acid alcohol solution, mixing lithium salt, ferric salt and silica source in alcohol solution and adding to the oxalic acid alcohol solution, transferring the mixed solution into a reflux system for reflux, obtaining powder and carbon source after alcohol is vaporized, ball milling the powder and the carbon source in acetone medium and drying to obtain precursor powder, sintering, cooling and sieving to obtain the vanadium-doped lithium iron silicate anode material. By solid-phase sintering, a layer of amorphous carbon is coated on particle surface of the material while vanadium is doped, so that resistance among particles is reduced, intrinsic conductivity and lithium ion diffusion coefficient of the material are improved, charge generation in high-rate circulation of the material can be transmitted to other lithium iron silicate crystals or current collectors timely, and voltage lagging due to blocking of transmission of the charge can be restrained.

Owner:湖北宇隆新能源有限公司

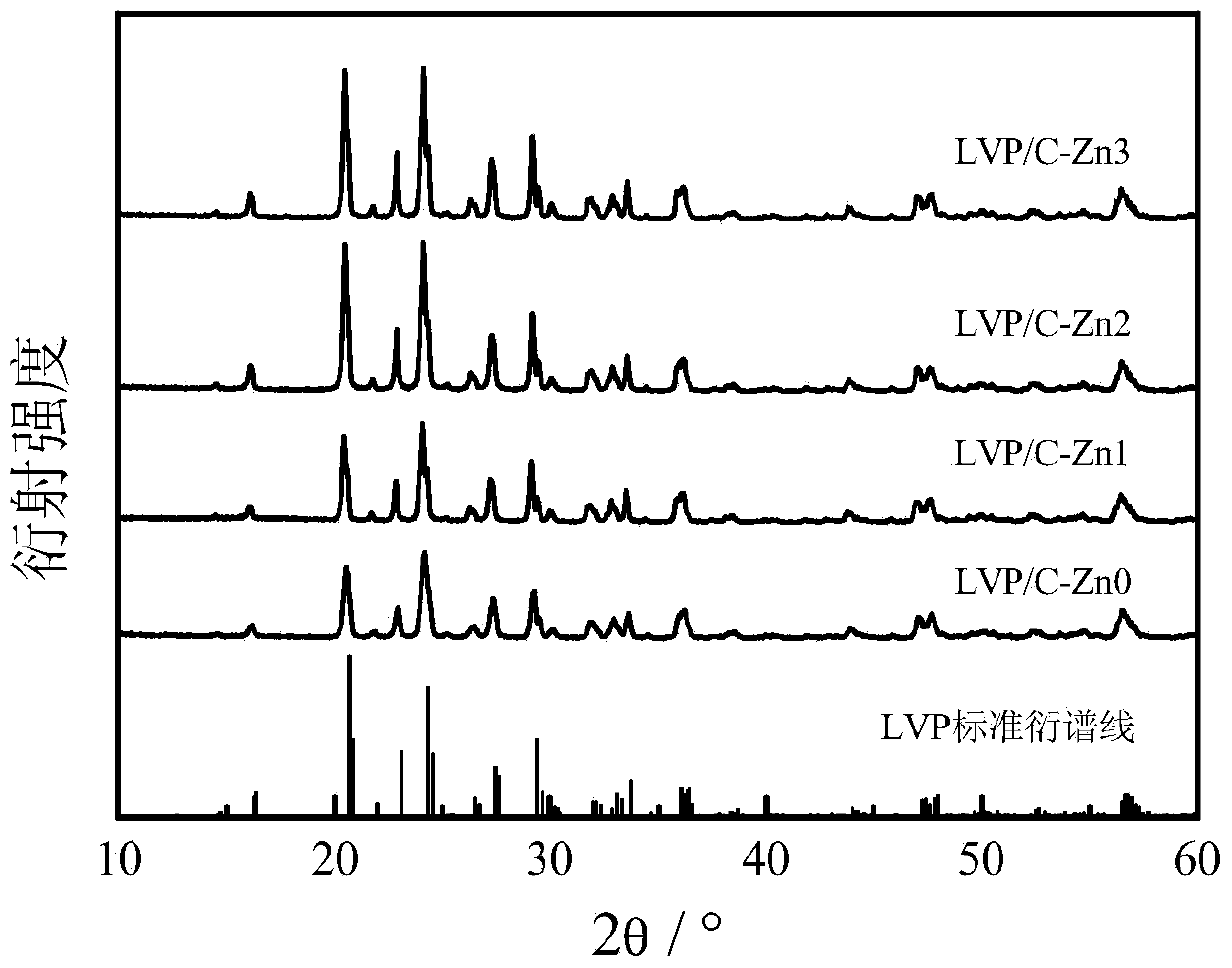

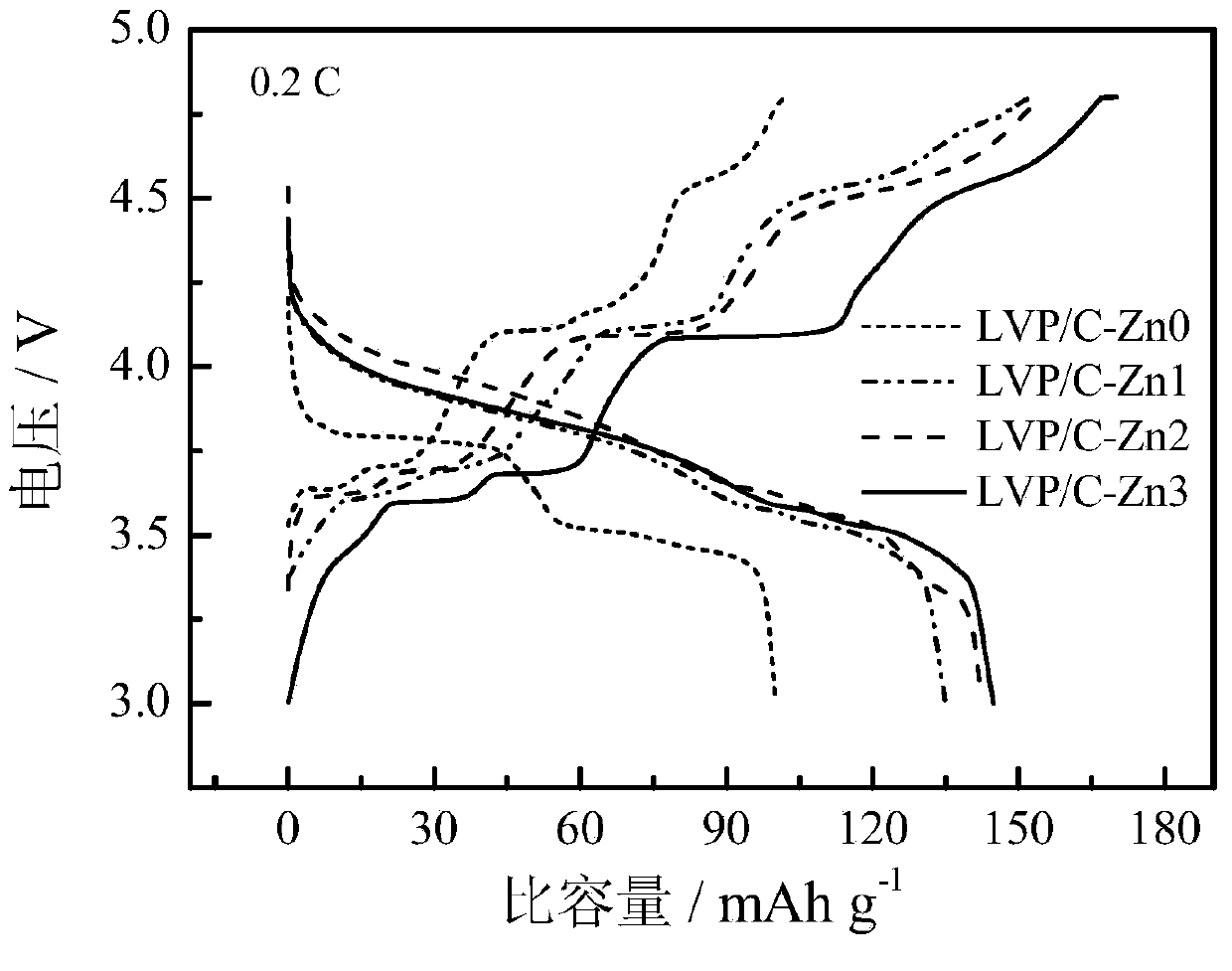

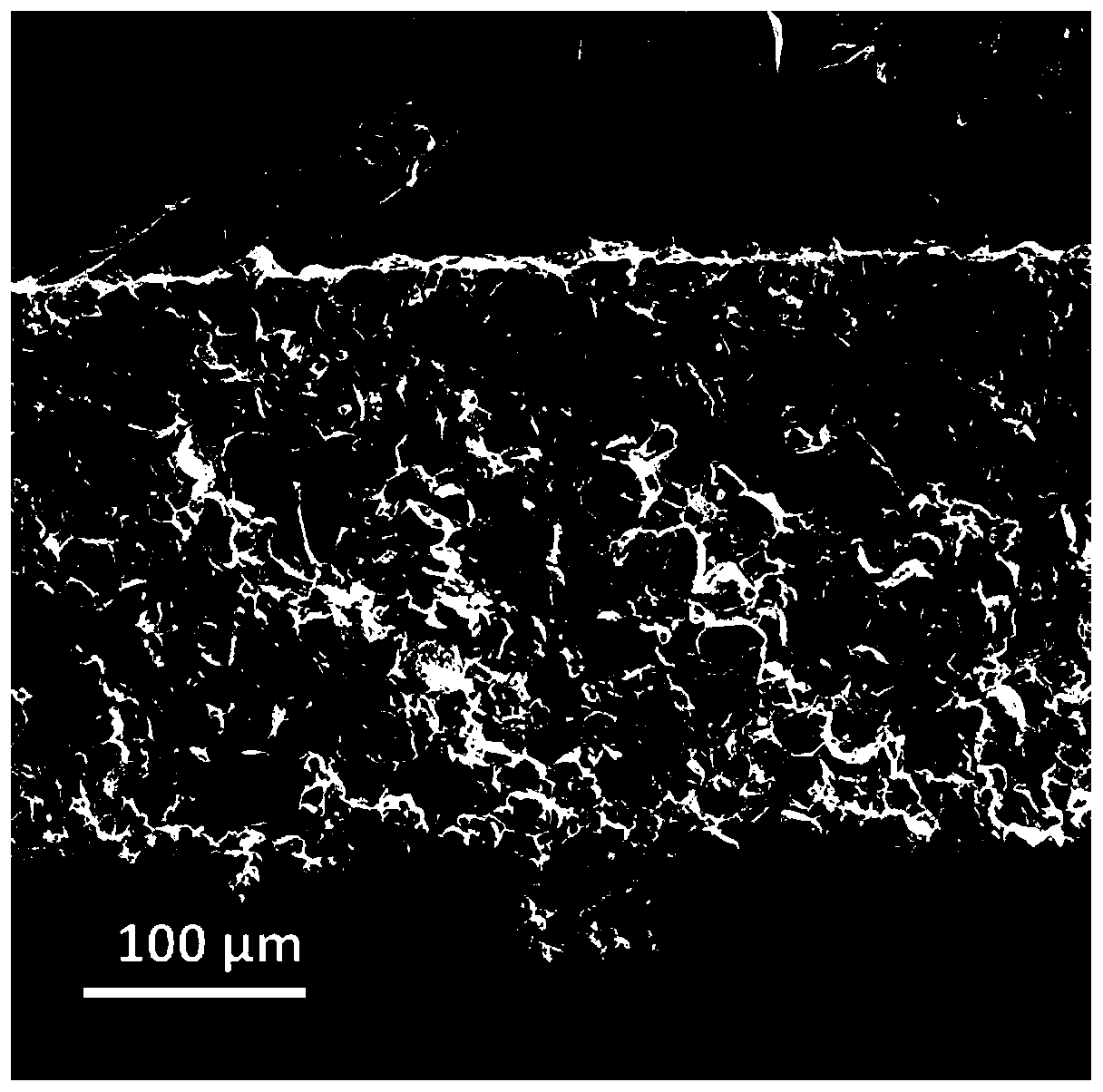

Sol-gel method for preparing zinc-ion-modified carbon-coated lithium vanadium phosphate used as anode material of lithium ion battery

InactiveCN103427080ASmall sizeIncrease intrinsic conductivityCell electrodesLithium vanadium phosphate batterySol-gel

The invention discloses a sol-gel method for preparing zinc-ion-modified carbon-coated lithium vanadium phosphate used as an anode material of a lithium ion battery. The sol-gel method is characterized in that zinc doping is carried out in a reaction environment with the pH (potential of hydrogen) of 4. The sol-gel method includes adding vanadium pentoxide, zinc oxide, citric acid, ammonium dihydrogen phosphate and lithium carbonate into deionized water and uniformly mixing the vanadium pentoxide, the zinc oxide, the citric acid, the ammonium dihydrogen phosphate, the lithium carbonate and the deionized water with one another to obtain a mixture; regulating the mixture until a pH value of the mixture reaches 4-9, enabling the mixture to form wet gel at the temperature of 80 DEG C, and shifting the wet gel into a drying oven to form dry gel at the temperature of 80 DEG C; calcining the dry gel in hydrogen and nitrogen mixed gas (with a 5:95 volume ratio of hydrogen to nitrogen) at the temperature of 750 DEG C for 8 hours, naturally cooling the calcined dry gel and then grinding and sieving the cooled calcined dry gel to obtain zinc-doped carbon-coated lithium vanadium phosphate powder (with an x ranging from 0 to 0.1). A molar ratio of the vanadium pentoxide to the zinc oxide to the citric acid to the ammonium dihydrogen phosphate to the lithium carbonate is 2-x:x:4:6:3, and the x ranges from 0 to 0.1. The citric acid is simultaneously used as a complexing agent, a reducing agent and a carbon source. The sol-gel method has the advantages that the electronic conductivity and the discharge ratio capacity of the lithium vanadium phosphate anode material are improved, the circulation performance is optimized, a process is simple, the cycle is short, the cost is low, and the soil-gel method is suitable for industrial production.

Owner:TIANJIN UNIV

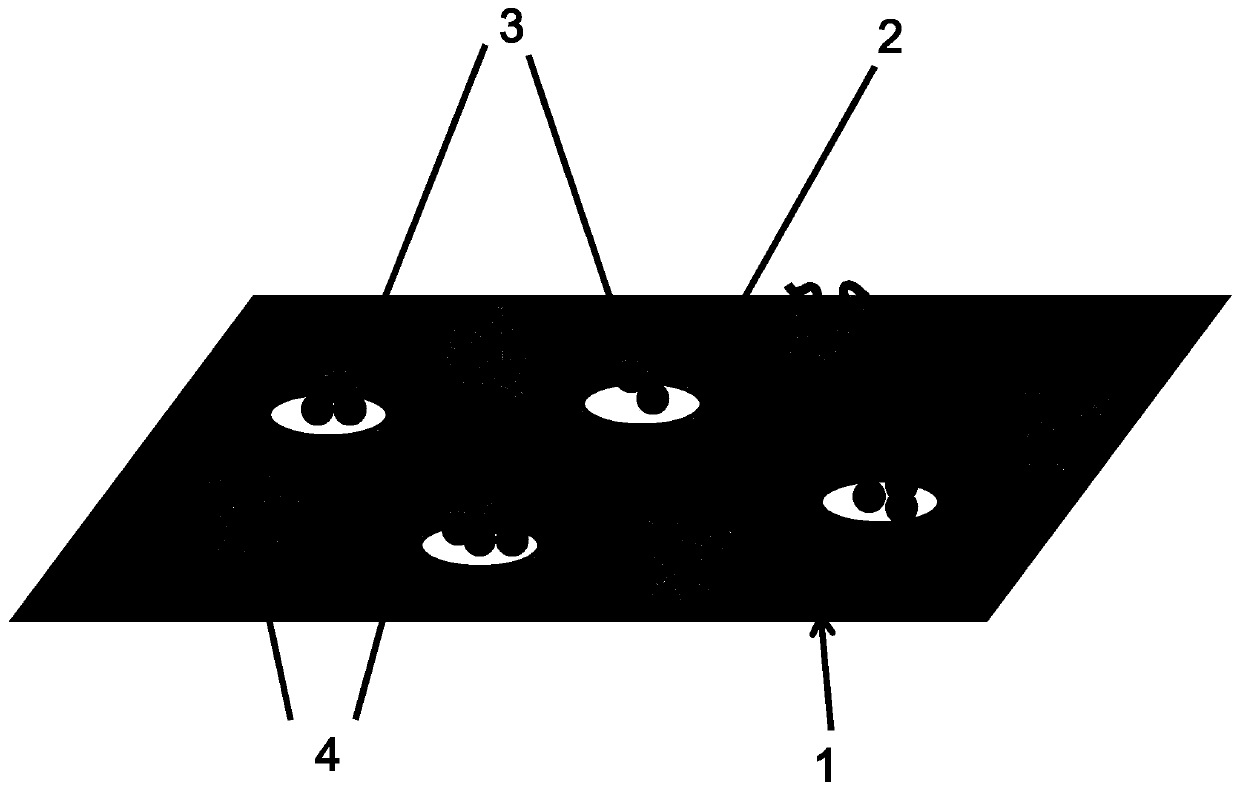

Low-impedance interface processing method of solid-state lithium battery positive electrode and positive electrode structure

ActiveCN109768215AImprove securityAvoid punctureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteEngineering

The invention discloses a low-impedance interface processing method of a solid-state lithium battery positive electrode and a positive electrode structure. By the method, impedance of two interfaces between active material particle in a positive electrode plate and solid-state electrolyte particle and between the positive electrode plate and an electrolyte piece can be effectively reduced, so thatthe capacity of active positive electrode particle in the solid-state lithium battery can be effectively developed. The dual-layer structure ceramic piece comprising a solid-state electrolyte layer and a positive electrode layer and fabricated by the method is excellent in performance and has favorable application prospect in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

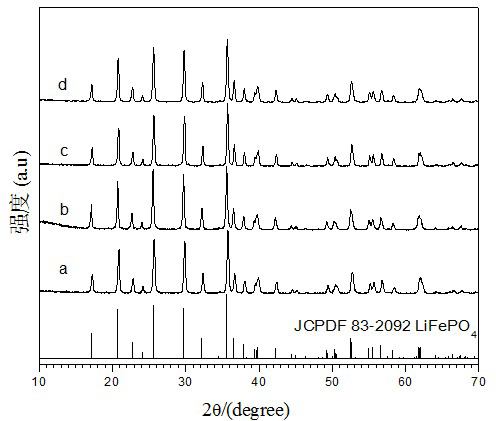

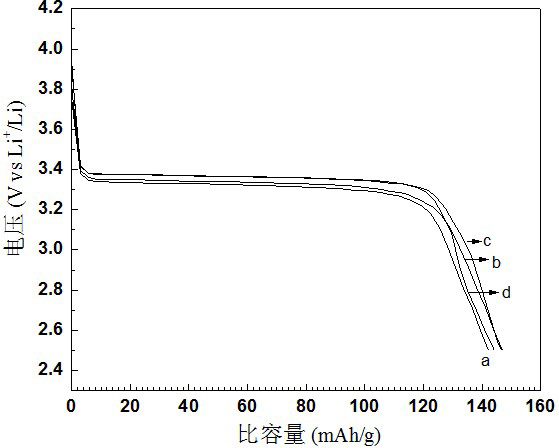

LiFePO4 positive electrode material modified jointly by doping and coating and preparation method thereof

ActiveCN104393291ALow costNo pollution in the processCell electrodesSecondary cellsZinc Acetate DihydrateTetraethyl orthosilicate

The invention provides a LiFePO4 positive electrode material modified jointly by doping and coating, and the LiFePO4 positive electrode material is modified jointly by iron doping and oxide coating. The raw materials comprise a lithium source Li2CO3, an iron source Fe2O3, a vanadium source NH4VO3, a phosphorus source NH4H2PO4, a carbon source glucose and oxide-coated acetates or esters. The acetates comprise cobalt acetate, zinc acetate or nickel acetate, and the esters comprise tetraethyl orthosilicate or zirconic acid diethyl ester. The specific method comprises the following steps: carrying out ball milling on the lithium source, the vanadium source, the iron source and the phosphorus source and then pre-roasting, carrying out carbon source ball milling and sintering, re-sintering the product after the sintered product is dissolved with the acetates or esters, and stirring the sintered sample, and then smearing the stirred sample on an aluminum foil, thus obtaining the modified LiFePO4 positive electrode material. The intrinsic conductivity of Li3V2(PO4)3 is improved by doping iron ions; the electron conductivity of Li3V2 (PO4) 3 is improved by oxide coating, the cost is low, and no pollution occurs; less harmful gas is emitted in the synthesis process; the electrochemical performance of the material is excellent.

Owner:CHINA THREE GORGES UNIV

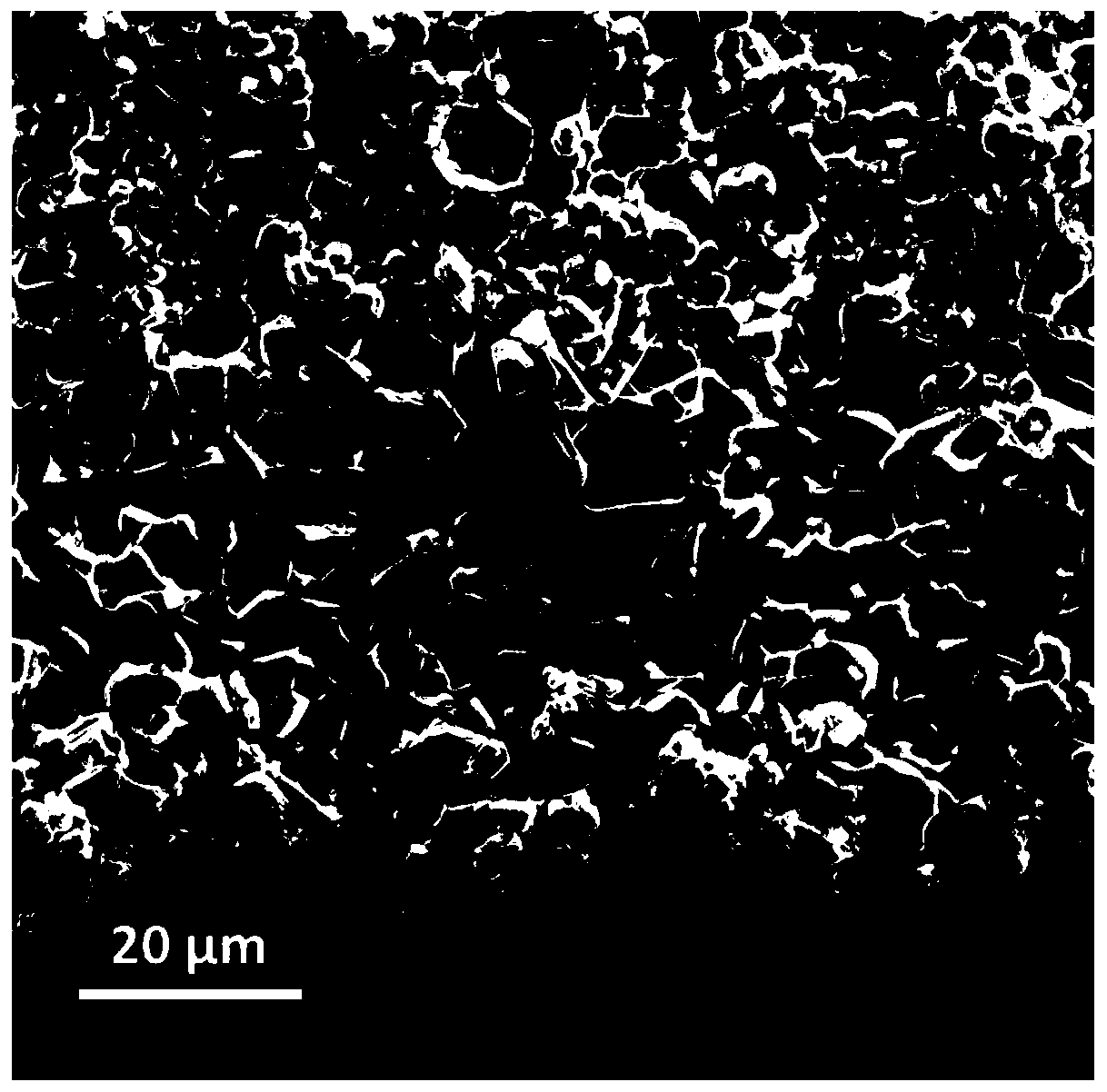

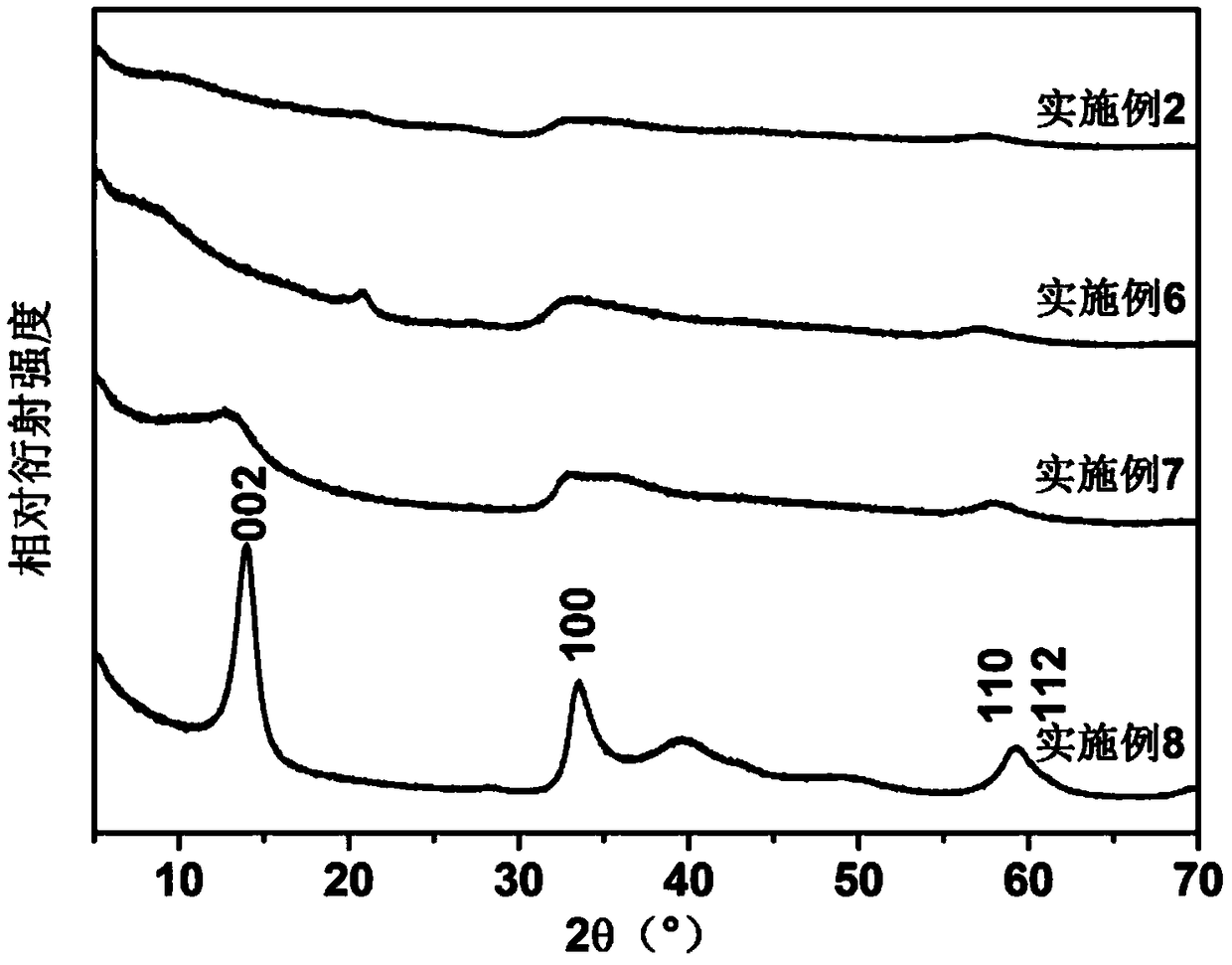

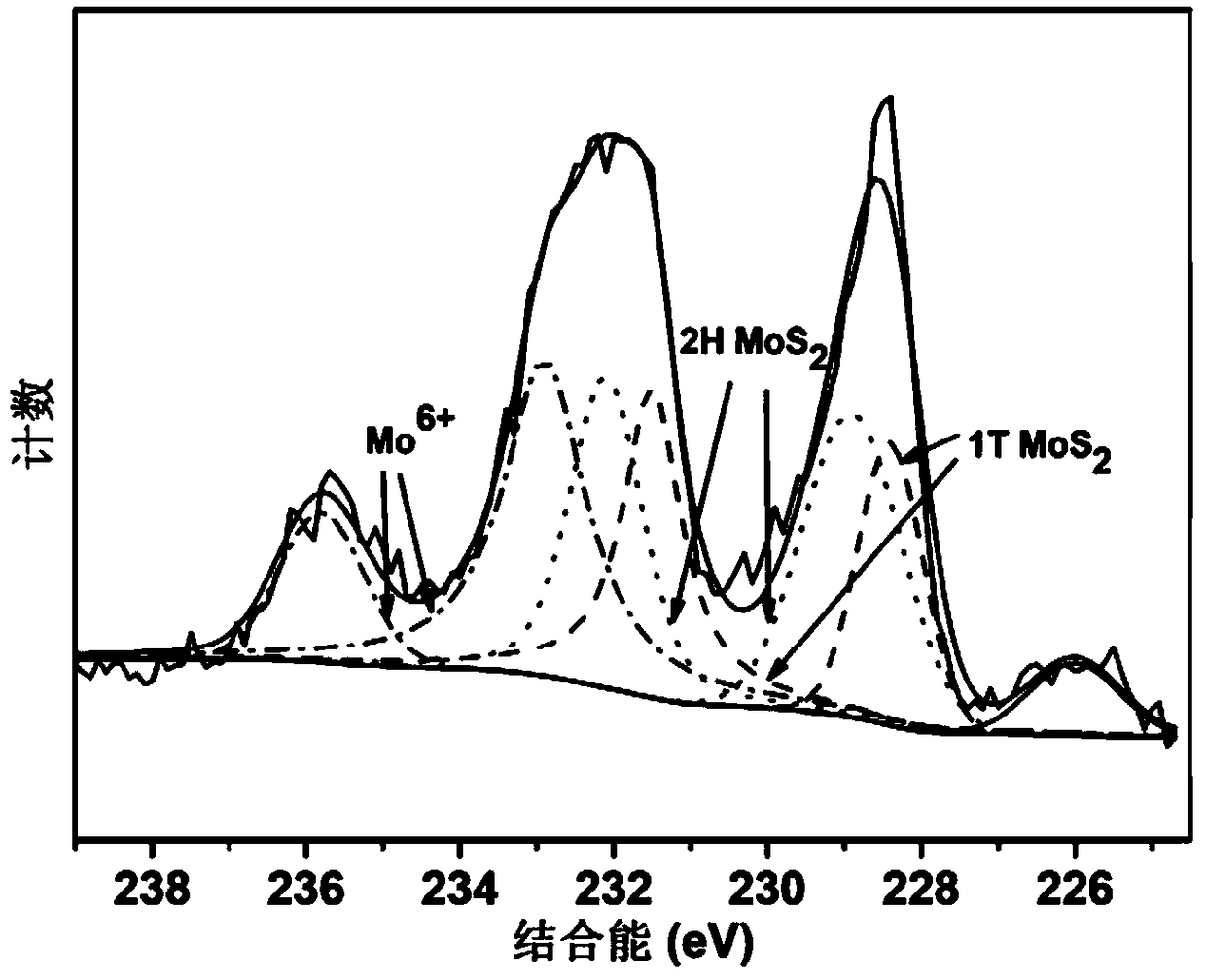

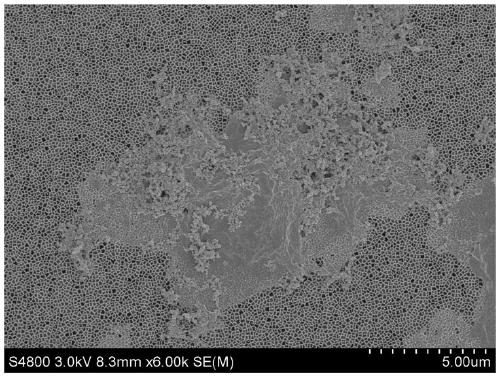

A molybdenum disulfide matrix composite material for negative electrode of lithium ion capacitor and preparation method thereof

ActiveCN109243834A(002) surface characteristic peak broadeningLow priceMaterial nanotechnologyHybrid capacitor electrodesThioureaReaction temperature

The invention belongs to the technical field of lithium ion capacitors, and discloses a molybdenum disulfide-based composite material for a negative electrode of a lithium ion capacitor and a preparation method thereof. The method includes: (1) Ammonium molybdate tetrahydrate or ammonium molybdate, aniline, phosphorus and graphene oxide were mixed uniformly in water; the pH value of the reaction system is adjusted to 4-5, the reaction temperature is kept to obtain the precursor; (2) the precursor reacts under acidic condition and initiator to obtain intermediate product; Acidic condition refers to pH 1.7 - 2.3 of the reaction solution; 3) dispering that intermediate product and thiourea in water, and place the intermediate product and thiourea in a hydrothermal reaction device for hydrothermal reaction to obtain molybdenum disulfide matrix composite material. The method of the invention is simple and efficient. As that composite material obtain has excellent electrochemical propertiesand cycle stability, the composite material has excellent lithium storage performance in a lithium ion capacitor negative electrode material, and has wide application prospect in a lithium ion capacitor.

Owner:SOUTH CHINA UNIV OF TECH

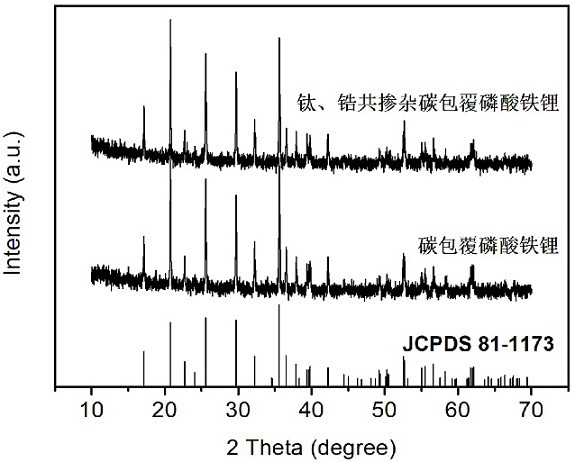

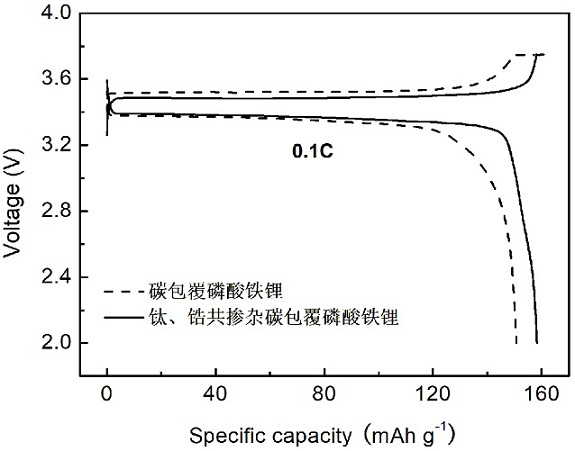

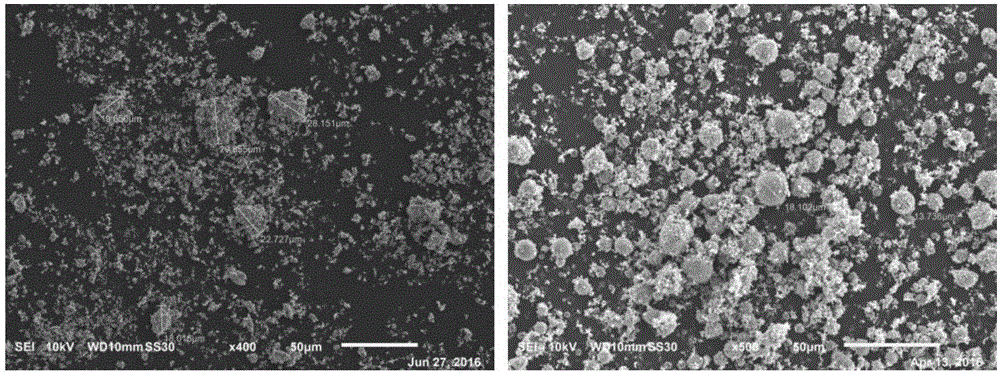

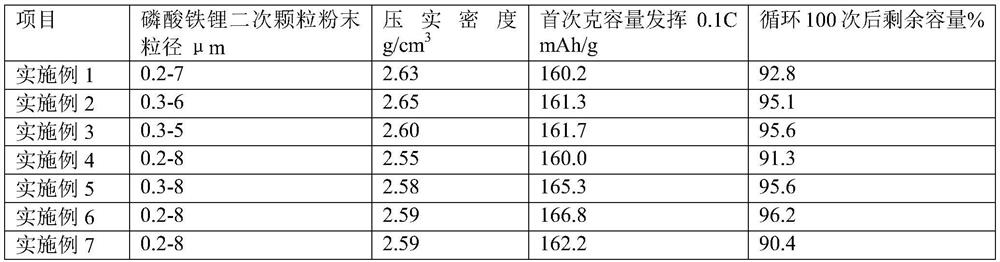

Titanium and zirconium co-doped carbon-coated lithium iron phosphate material as well as preparation method and application thereof

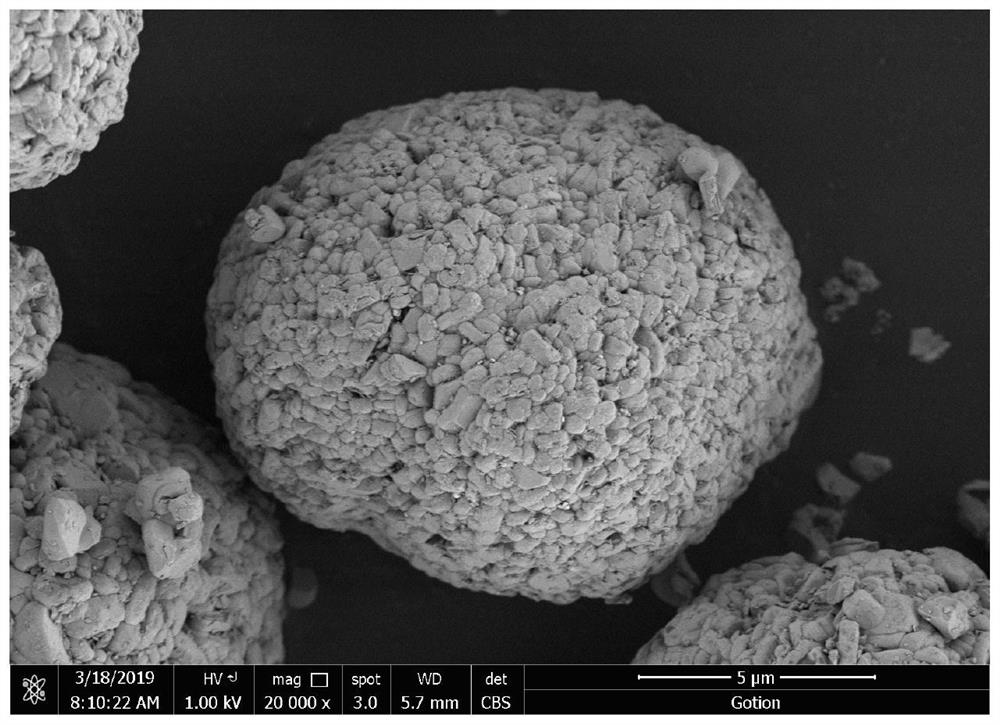

ActiveCN114314548AIncrease intrinsic conductivityWide range of raw materials and cheapSecondary cellsPositive electrodesTitanium zirconiumElectrical battery

The invention relates to a titanium and zirconium co-doped carbon-coated lithium iron phosphate material and a preparation method and application thereof, the chemical expression of the material is Li1-yZryFe1-xTixPO4 / C, titanium is doped to the Fe position, zirconium is doped to the Li position, 0.001 < = x < = 0.05, 0.001 < = y < = 0.02; the preparation method comprises the following steps: mixing iron phosphate, lithium carbonate, a carbon source, a titanium source and a zirconium source in a liquid-phase medium, carrying out ball milling and sand milling on the mixture to a certain slurry particle size, granulating by adopting a spray drying technology, and finally sintering the dried spray material in an atmosphere furnace. The material is applied to a lithium ion battery as a positive electrode material. The titanium and zirconium elements are doped into the carbon-coated lithium iron phosphate, so that the ion and electron transmission capability of the lithium iron phosphate is effectively enhanced, the compaction density of the material is improved, and the carbon-coated lithium iron phosphate is very suitable for being used as a high-energy and high-power-density lithium ion power battery positive electrode material.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Modified positive electrode material for lithium iron phosphate battery and preparation method of modified positive electrode material and lithium-ion battery

InactiveCN106602027AImprove conductivityImprove compatibilityCell electrodesSecondary cellsCharge dischargeLithium-ion battery

The invention discloses a modified positive electrode material for a lithium iron phosphate battery and a preparation method of the modified positive electrode material. The preparation method comprises the following steps of (1) carrying out mixed reaction and drying on a compound A and a compound B to obtain a zirconium-doped carbon material precursor; (2) sintering the zirconium-doped carbon material precursor obtained in the step (1) to obtain a zirconium-doped carbon material; and (3) carrying out mixed reaction and drying on lithium iron phosphate and the zirconium-doped carbon material obtained in the step (2) to obtain the modified positive electrode material for the lithium iron phosphate battery, wherein the compound A is the compound capable of providing a carbon source and a nitrogen source and the compound B is the compound capable of providing a zirconium source. Compared with the prior art, the modified positive electrode material for the lithium iron phosphate battery has the advantages that the lithium iron phosphate is modified through the zirconium-doped amorphous carbon material, the resistance of lithium ion migration is reduced, volume expansion of the material in the charge-discharge process is improved, the carbon material is prevented from falling off and the modified positive electrode material has a good application prospect. The invention further discloses a lithium-ion battery.

Owner:OPTIMUM BATTERY CO LTD

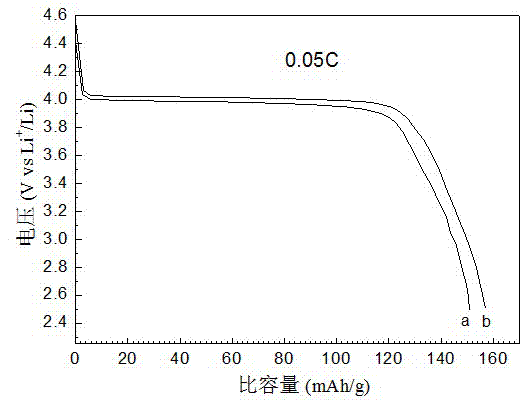

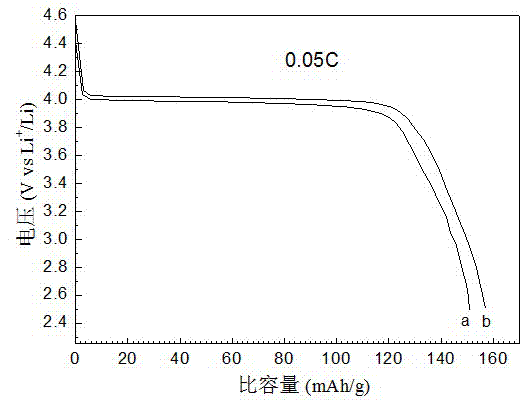

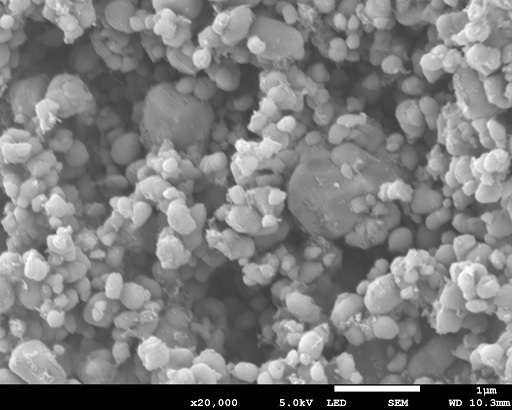

High-conductivity ferrous phosphate lithium cathode material for lithium ion battery and preparation method thereof

The invention provides a high-conductivity ferrous phosphate lithium cathode material for a lithium ion battery and a preparation method thereof. The material is made from a lithium compound, an iron compound, a phosphorous compound, a carbon compound, and a transition metal compound which serves as a graphite catalyst and a doped element, and has a chemical formula of Li(Fe1-xMx)PO4, wherein x is 0 to 0.1; and M may be a transition metal element Fe, Cr, Ni, Co, Mo or Mn. A clad carbon material is catalyzed by adopting the transition metal compound to increase the graphitizing grade of a high-carbon film, thereby improving the conductivity of the material; and the transition metal element can serve as the doped element at the same time to further improve the intrinsic conductivity of the material.

Owner:中国东方电气集团有限公司

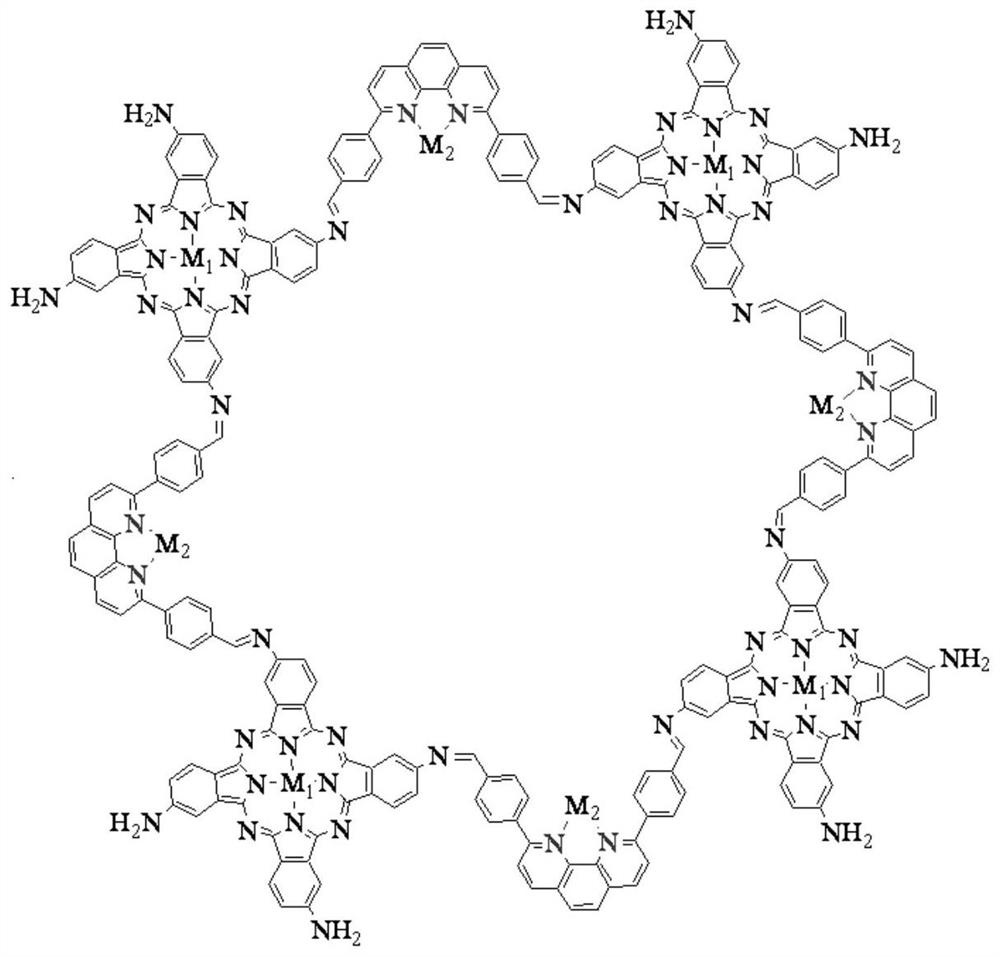

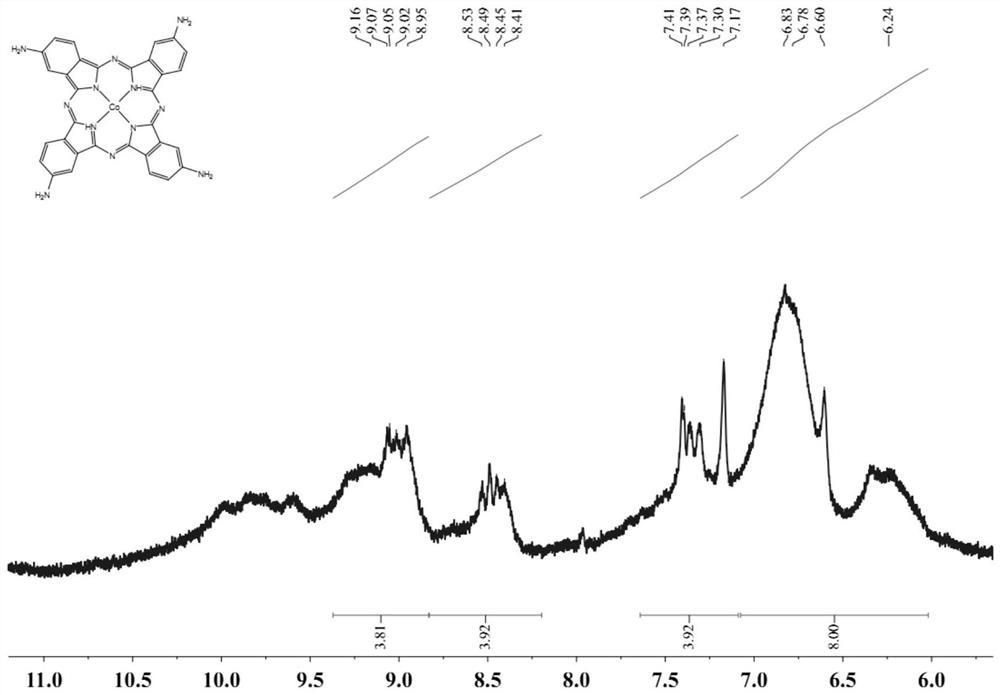

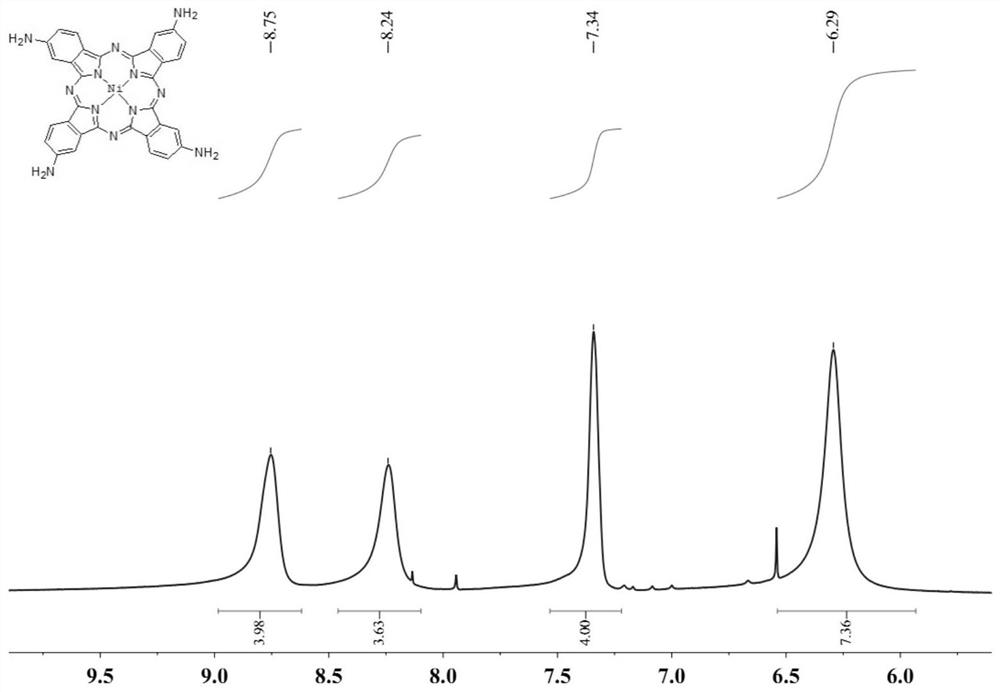

Bimetal covalent organic framework material and preparation method thereof and aptamer sensor

ActiveCN112321839AEvenly dispersedLarge specific surface areaMaterial analysis by electric/magnetic meansBiological testingCompound organicPhthalocyanine

The invention belongs to the technical field of composite functional materials, and particularly relates to a bimetal covalent organic framework material and a preparation method thereof and an aptamer sensor. The bimetal covalent organic framework material is a metal-covalent composite organic framework material, and comprises a covalent organic framework main body formed by carrying out a Schiffbase condensation reaction on tetraamino metal phthalocyanine and PTD, and metal ions compounded with a PTD unit on the covalent organic framework main body in a metal-organic coordination form, wherein the metal in the tetraamino metal phthalocyanine is selected from cobalt or nickel. The metal ions are introduced into porous COFs in a targeted manner to form metal covalent organic frameworks (MCOFs). The MCOFs can build a bridge between the MOFs and the COFs, so that the porosity, the stability, the crystallinity and the adjustability of the MOFs and the COFs can be balanced, and complementary characteristics are formed between the MOFs and the COFs.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

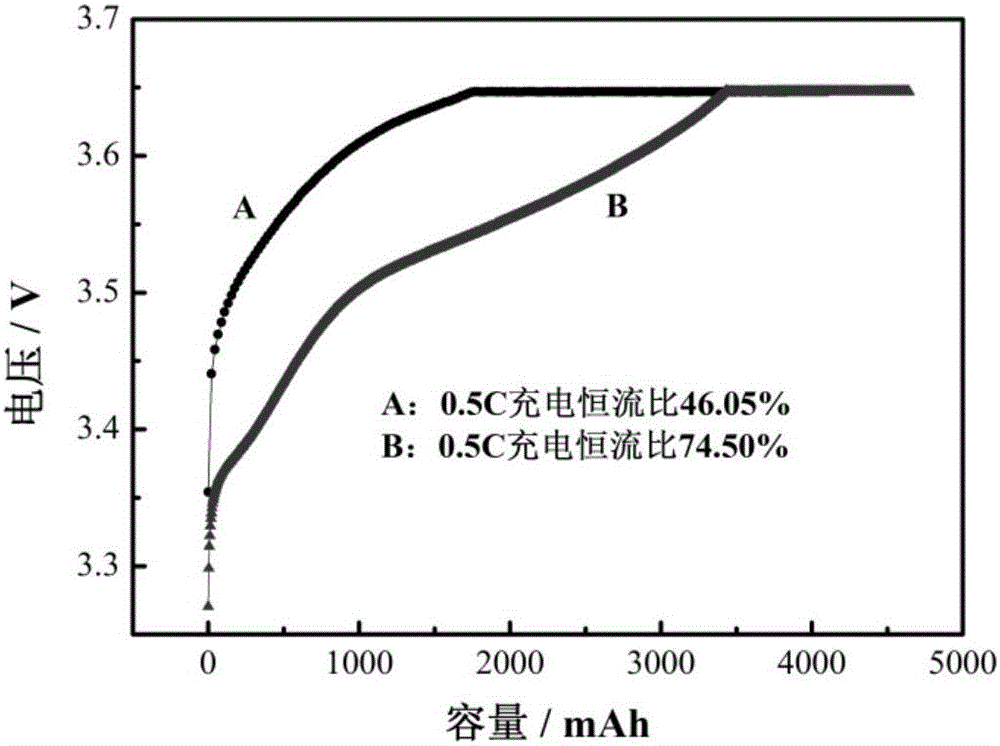

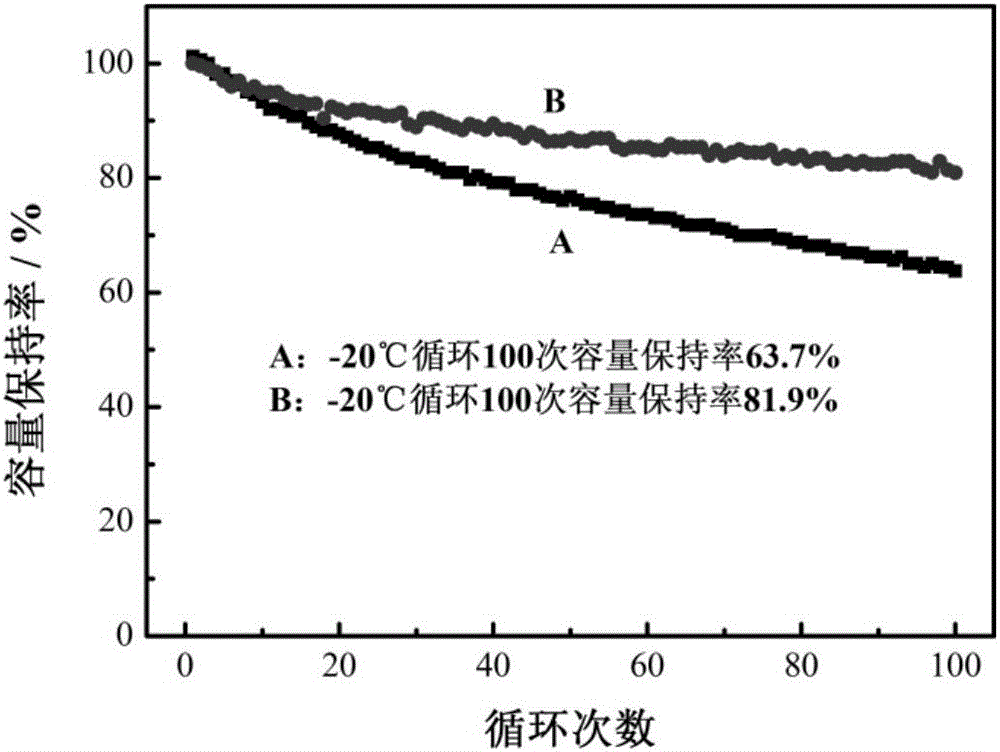

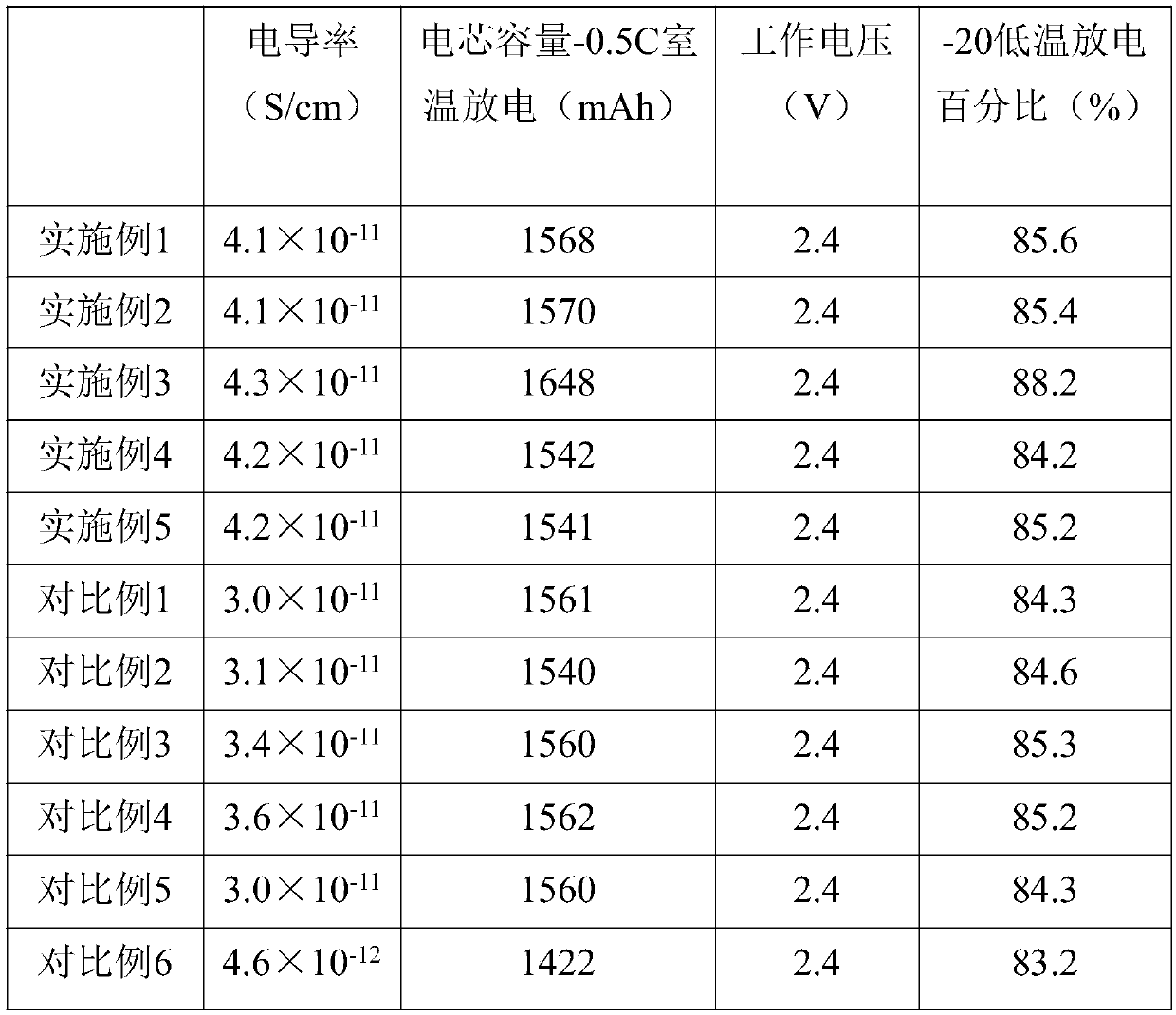

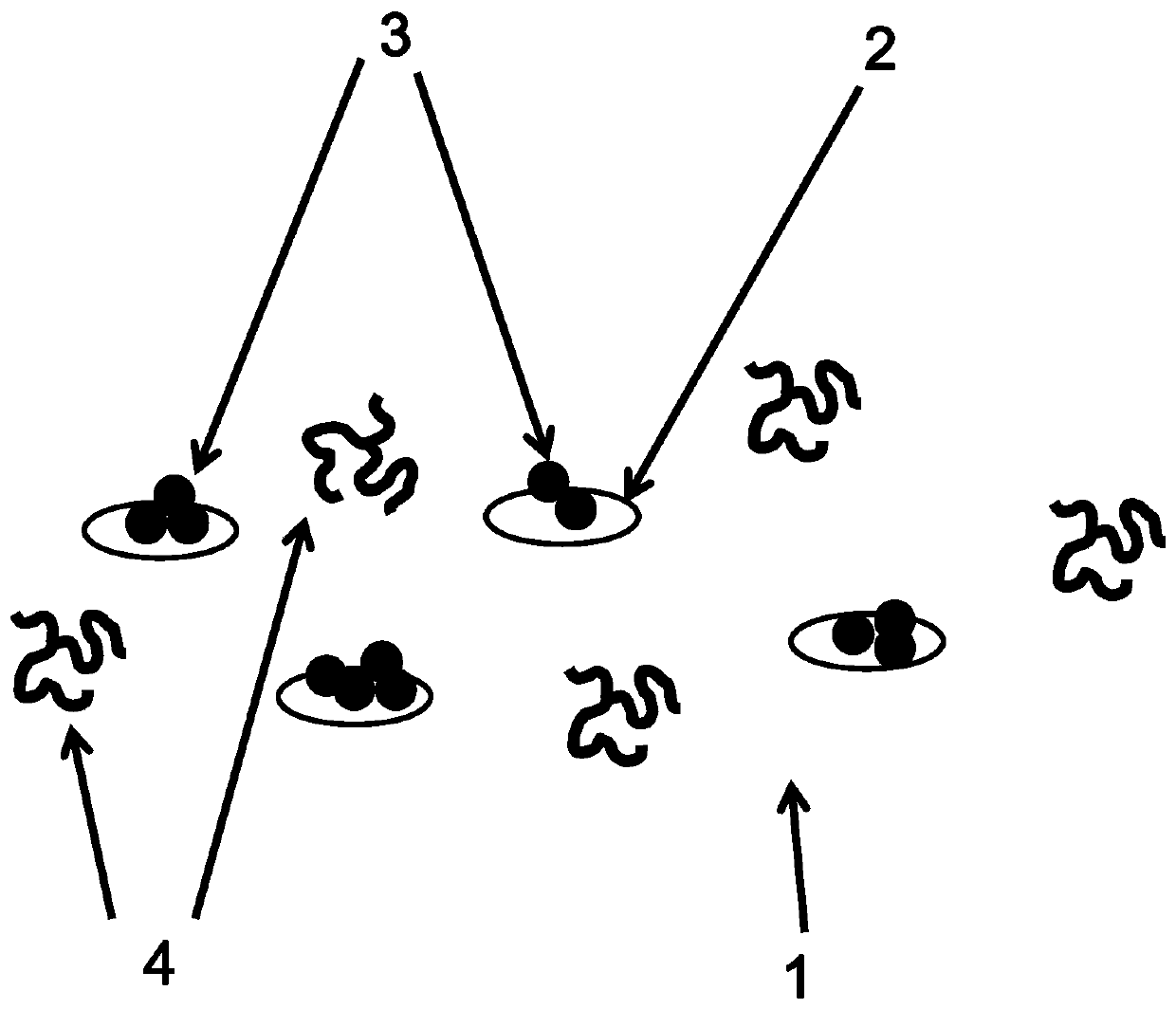

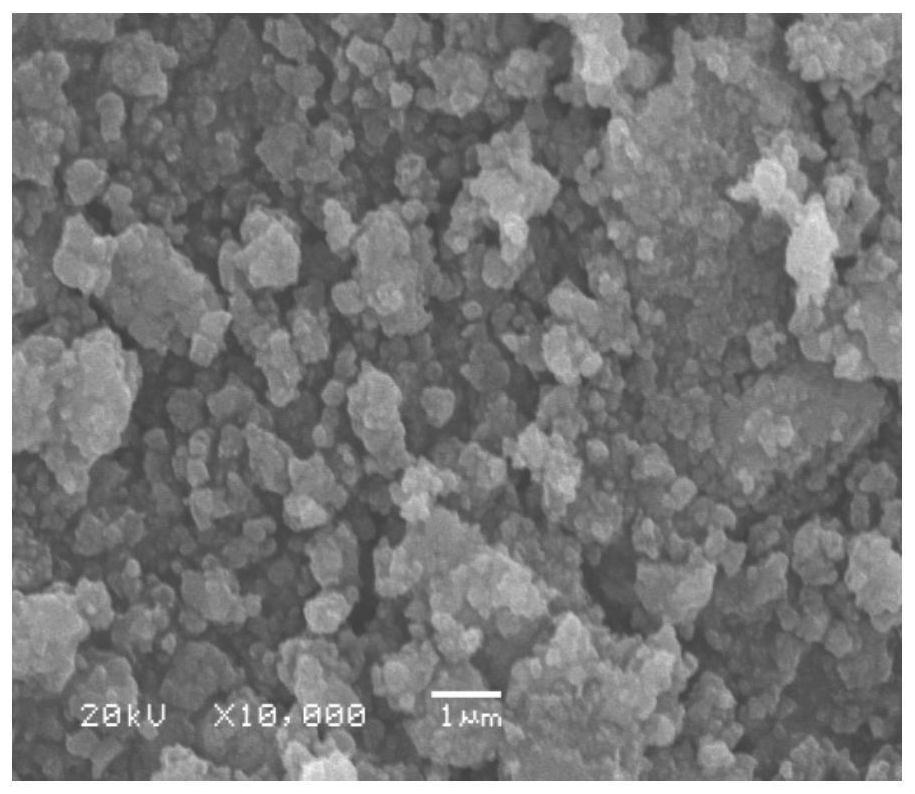

Preparation method of lithium iron phosphate-based modified positive electrode material

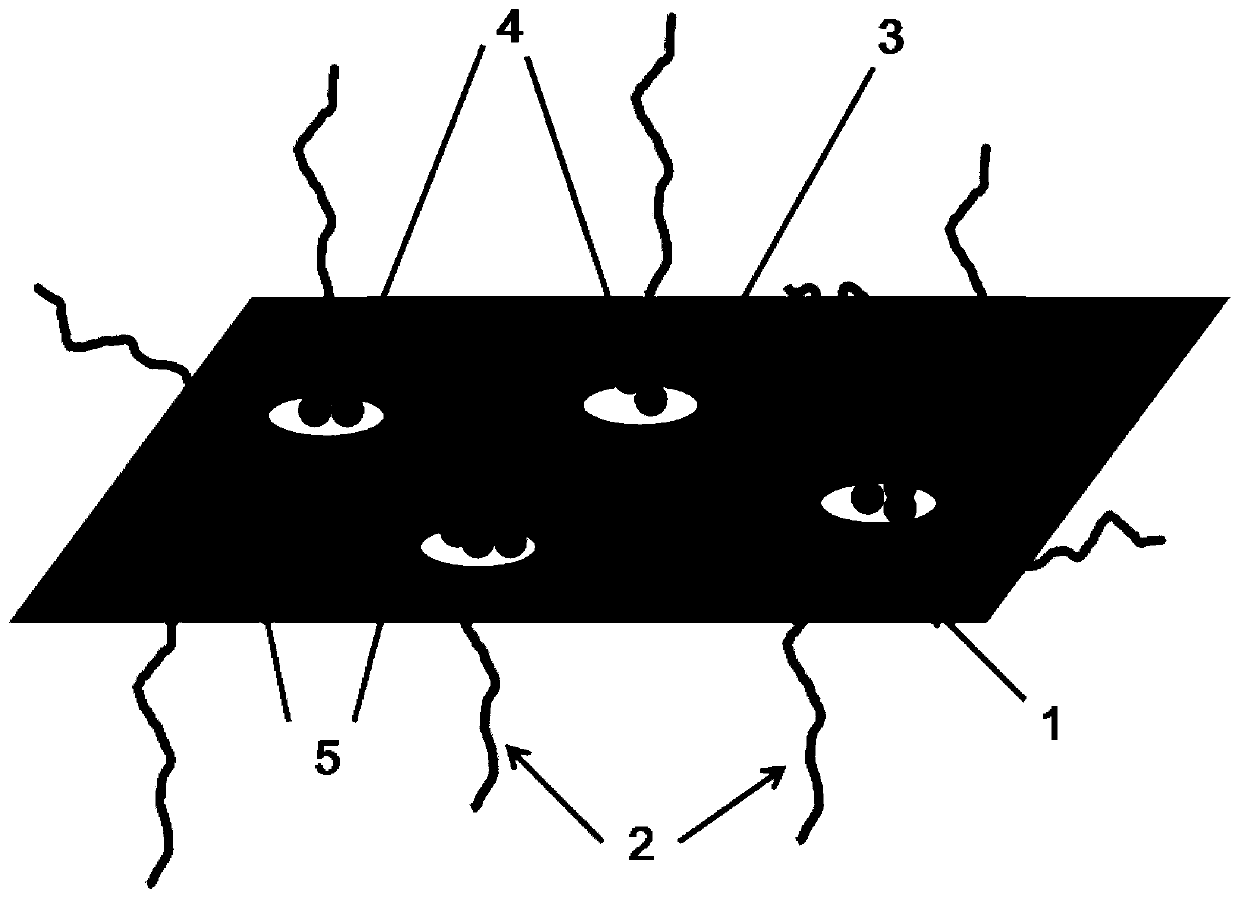

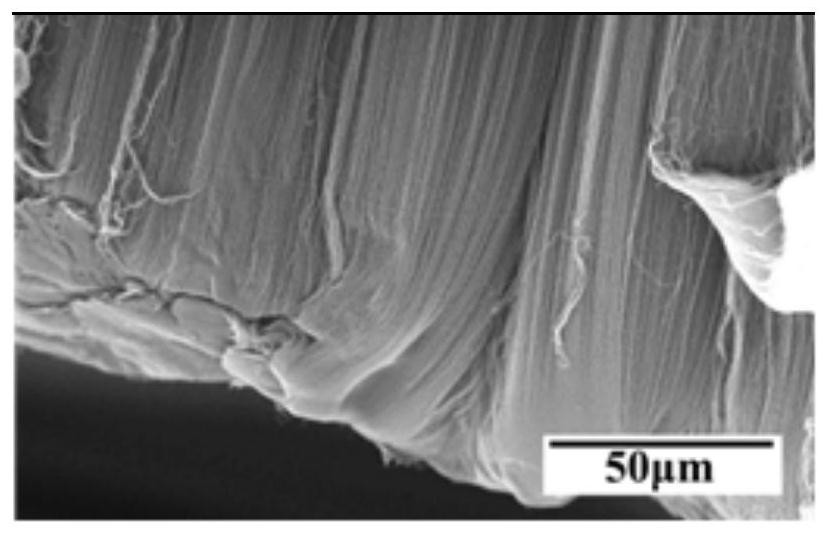

ActiveCN108682833AIncrease intrinsic conductivityImprove compatibilityCell electrodesSecondary cellsCvd grapheneCarbon nanotube

The invention relates to the technical field of a lithium ion battery electrode material, in particular to a preparation method of a lithium iron phosphate-based modified positive electrode material.The method comprises the following steps of putting a zirconium source compound into distilled water; performing crushing treatment through a ball milling machine until the particle diameter is 2 to 12 mu m; therefore firstly performing modification treatment on graphene and carbon nanometer tubes; then, bonding zirconium in the zirconium source compound with the carbon; after the heat treatment,introducing the zirconium onto the surface of the graphene to obtain zirconium doped carbon materials; then, modifying the lithium iron phosphate by the zirconium doped carbon materials to make the partial zirconium dope into the lithium iron phosphate. The conductivity between the lithium iron phosphate particles is enhanced; the compatibility of the material surface and electrolyte is improved;the resistance received during the lithium ion migration is reduced; the electrochemical performance of the battery in low-temperature environment can be further improved.

Owner:漳州雷天温斯顿动力电池研发中心有限公司

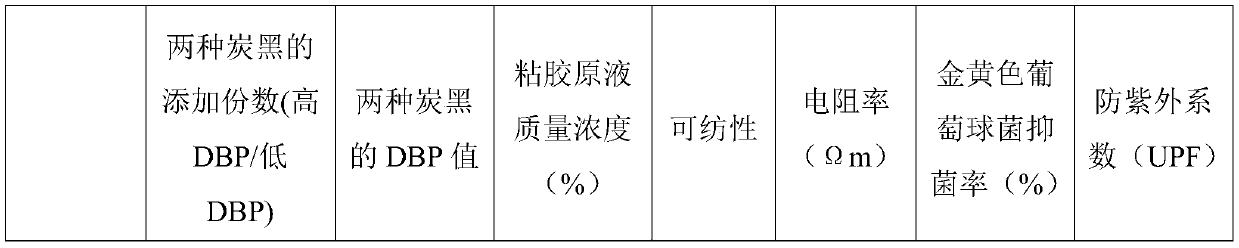

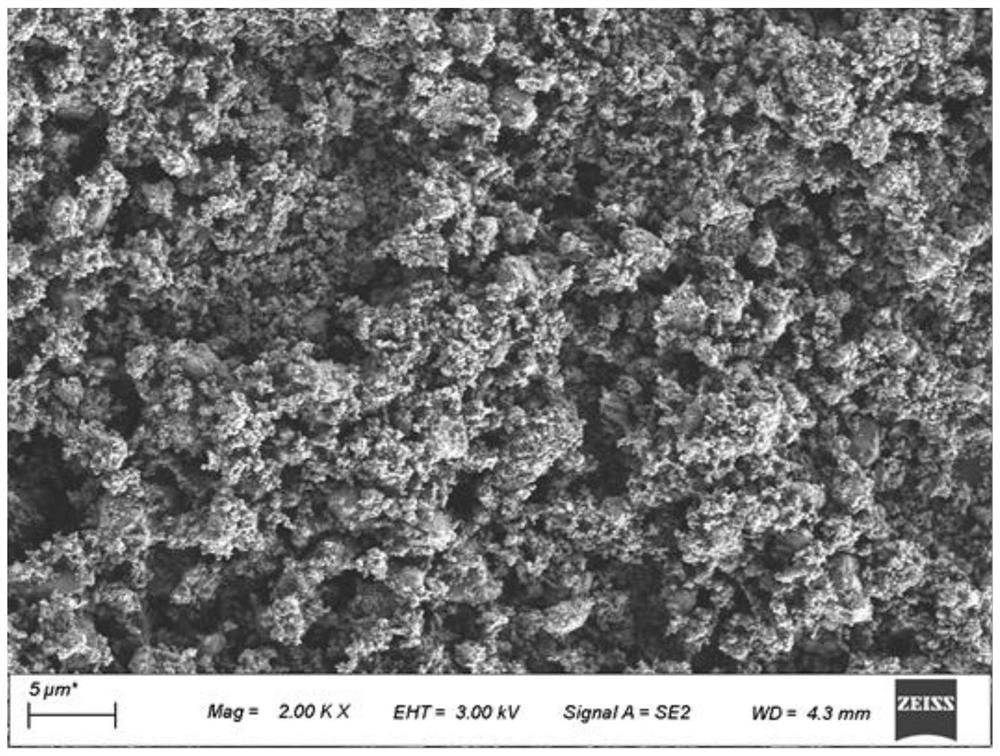

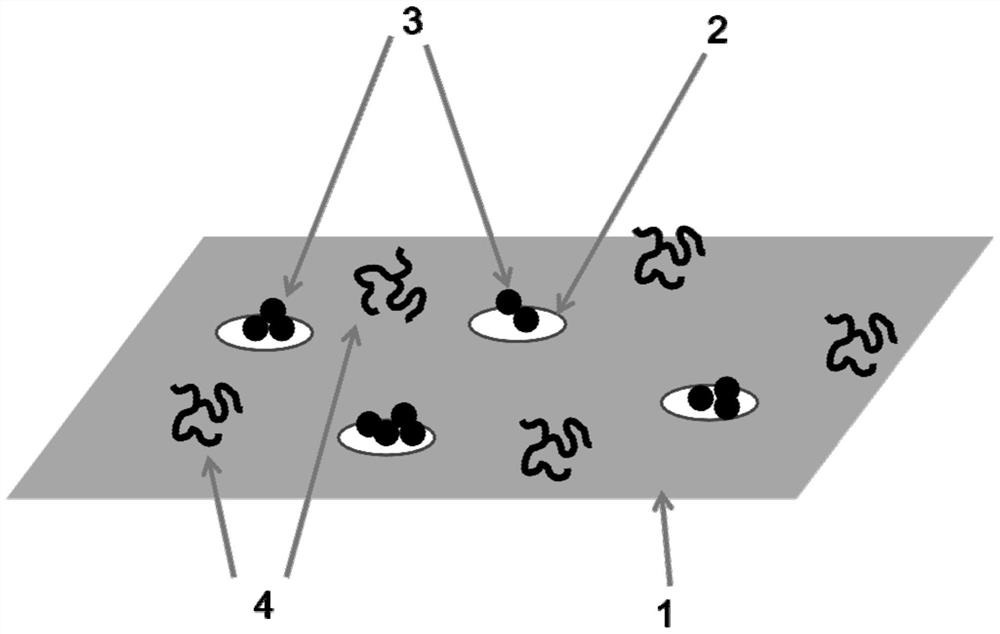

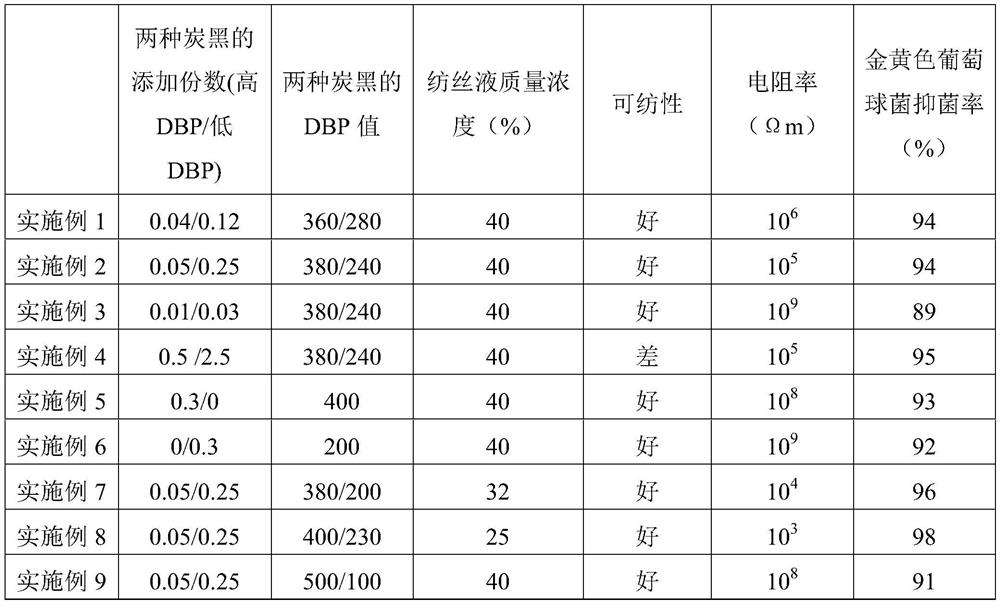

Preparation method of graphene/nano-carbon-black modified viscose fibers

ActiveCN110424060AUniform and stable dispersionReduce reunionArtificial filaments from viscoseSOCKSUltraviolet

The invention discloses a preparation method of graphene / nano-carbon-black modified viscose fibers. Nano-carbon-black with a specific DBP value is compounded with single-layer graphene oxide accordingto a specific proportion, the graphene oxide is reduced in a heating alkaline environment to form a stable compound structure, the graphene oxide can be directly mixed with viscose spinning liquid after washing, good dispersion is kept, spinning is performed to obtain the novel viscose fibers with anti-static, anti-ultraviolet and anti-bacterial functions, product functions are stable and cannotbe attenuated along with washing, the fibers can be directly prepared on a viscose fiber production line, an original process is minimally changed, and the prepared fibers can be applied to underwear,coats, pants, socks and shoe materials.

Owner:HANGZHOU GAOXI TECH CO LTD

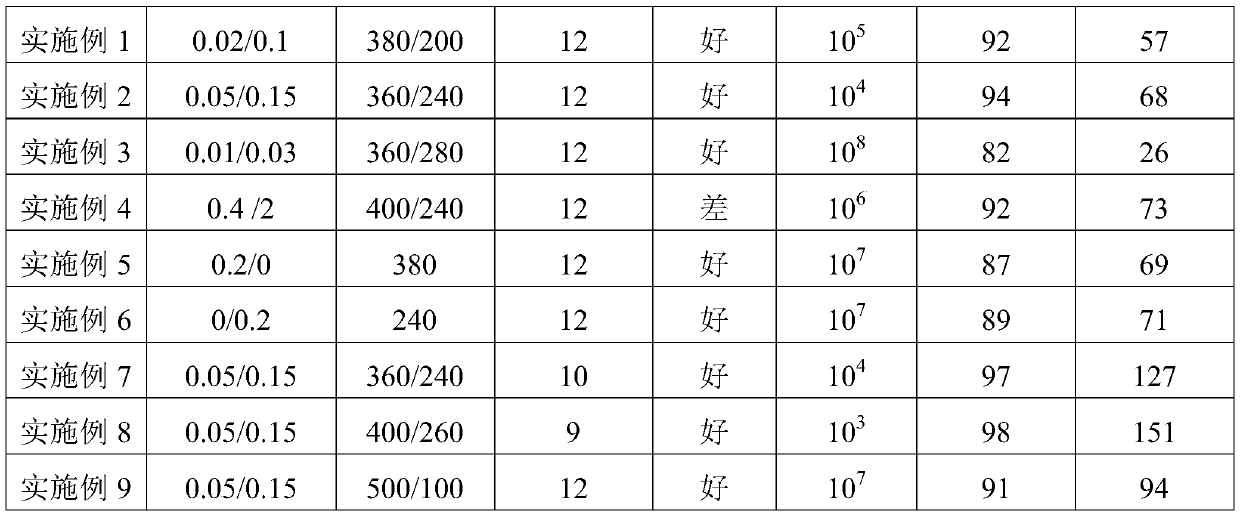

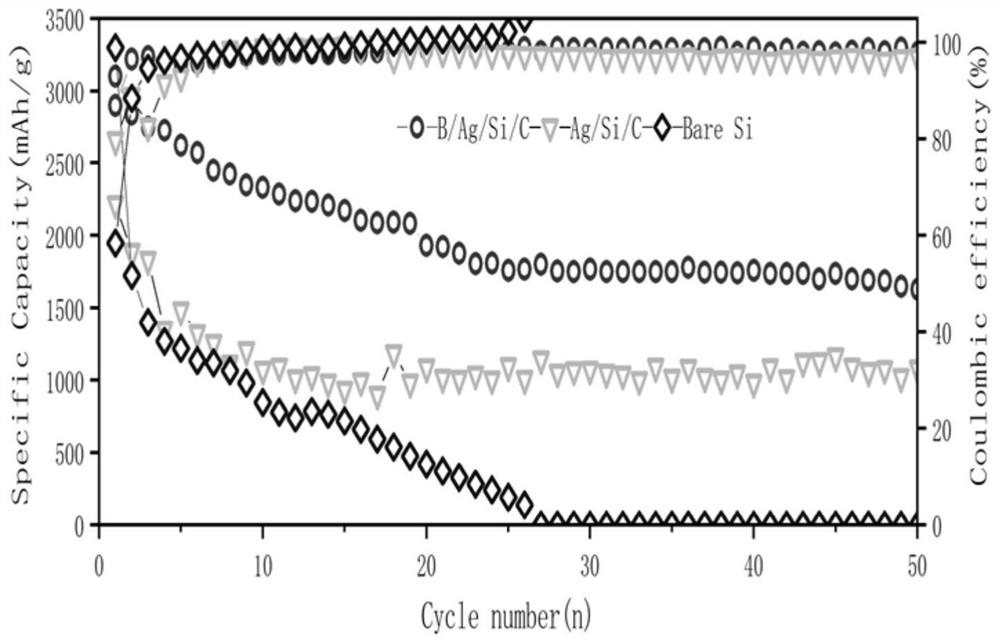

Method for preparing boron-doped nano-metal/porous silicon-carbon composite negative electrode based on cut silicon wastes

ActiveCN111799460AWide variety of sourcesLow priceMaterial nanotechnologyCarbon compoundsCarbon compositesIntrinsic conductivity

The invention relates to a method for preparing a boron-doped nano-metal / porous silicon-carbon composite negative electrode based on cut silicon wastes. The method comprises the following steps: removing impurities from cut silicon wastes, and carrying out metal-assisted etching treatment to obtain a nano-metal / porous silicon composite material; mixing the nano-metal / porous silicon composite material with a boron source, and carrying out high-temperature treatment to form substitution doping of silicon by boron; compounding with a carbon material to obtain the boron-doped nano-metal / porous silicon-carbon composite negative electrode. By adding the porous structure of silicon and the carbon material, the volume expansion of silicon can be relieved and cycling stability is increased; the metal particles are physically compounded with silicon on the surface of the silicon substrate, and the boron has the chemical doping synergistic effect of silicon on the atomic scale, so that the intrinsic conductivity of the silicon-based composite material and the electrochemical activity are finally improved, and the boron-doped nano-metal / silicon-carbon composite negative electrode material withhigh charge-discharge specific capacity and long cycle life is prepared.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of lithium iron phosphate base modified cathode material

ActiveCN108682833BIncrease intrinsic conductivityImprove compatibilityCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention relates to the technical field of a lithium ion battery electrode material, in particular to a preparation method of a lithium iron phosphate-based modified positive electrode material.The method comprises the following steps of putting a zirconium source compound into distilled water; performing crushing treatment through a ball milling machine until the particle diameter is 2 to 12 mu m; therefore firstly performing modification treatment on graphene and carbon nanometer tubes; then, bonding zirconium in the zirconium source compound with the carbon; after the heat treatment,introducing the zirconium onto the surface of the graphene to obtain zirconium doped carbon materials; then, modifying the lithium iron phosphate by the zirconium doped carbon materials to make the partial zirconium dope into the lithium iron phosphate. The conductivity between the lithium iron phosphate particles is enhanced; the compatibility of the material surface and electrolyte is improved;the resistance received during the lithium ion migration is reduced; the electrochemical performance of the battery in low-temperature environment can be further improved.

Owner:漳州雷天温斯顿动力电池研发中心有限公司

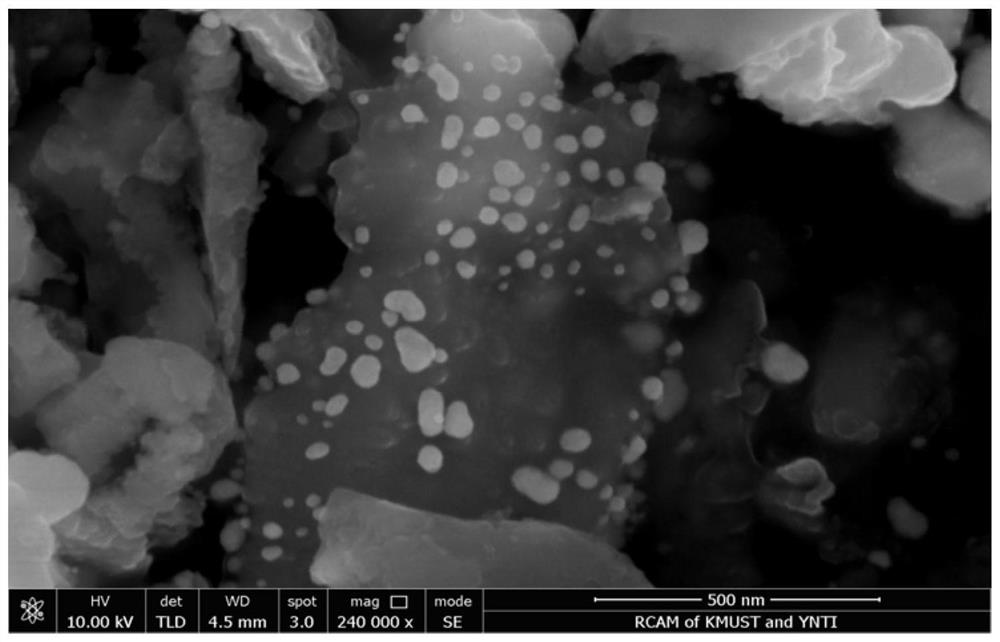

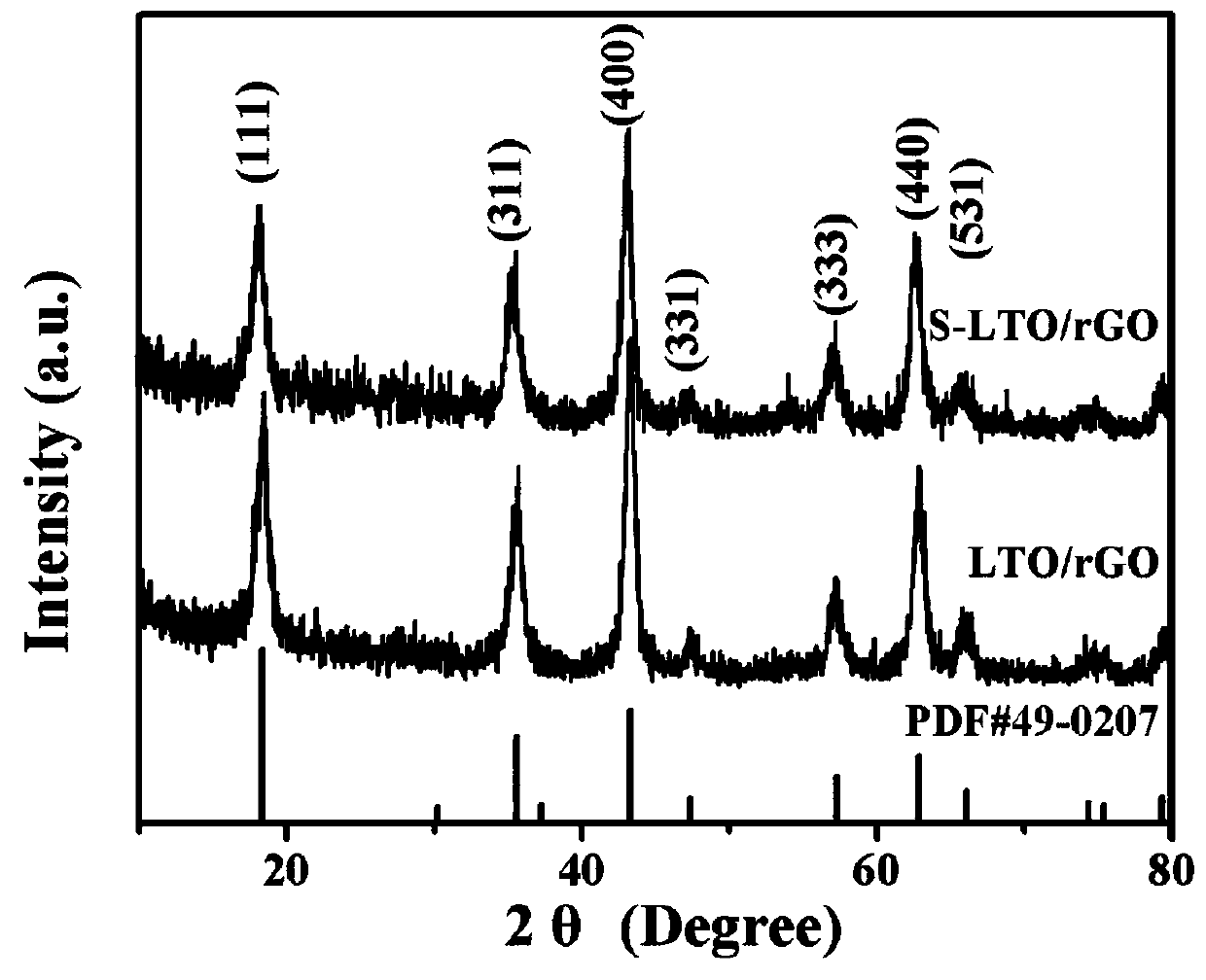

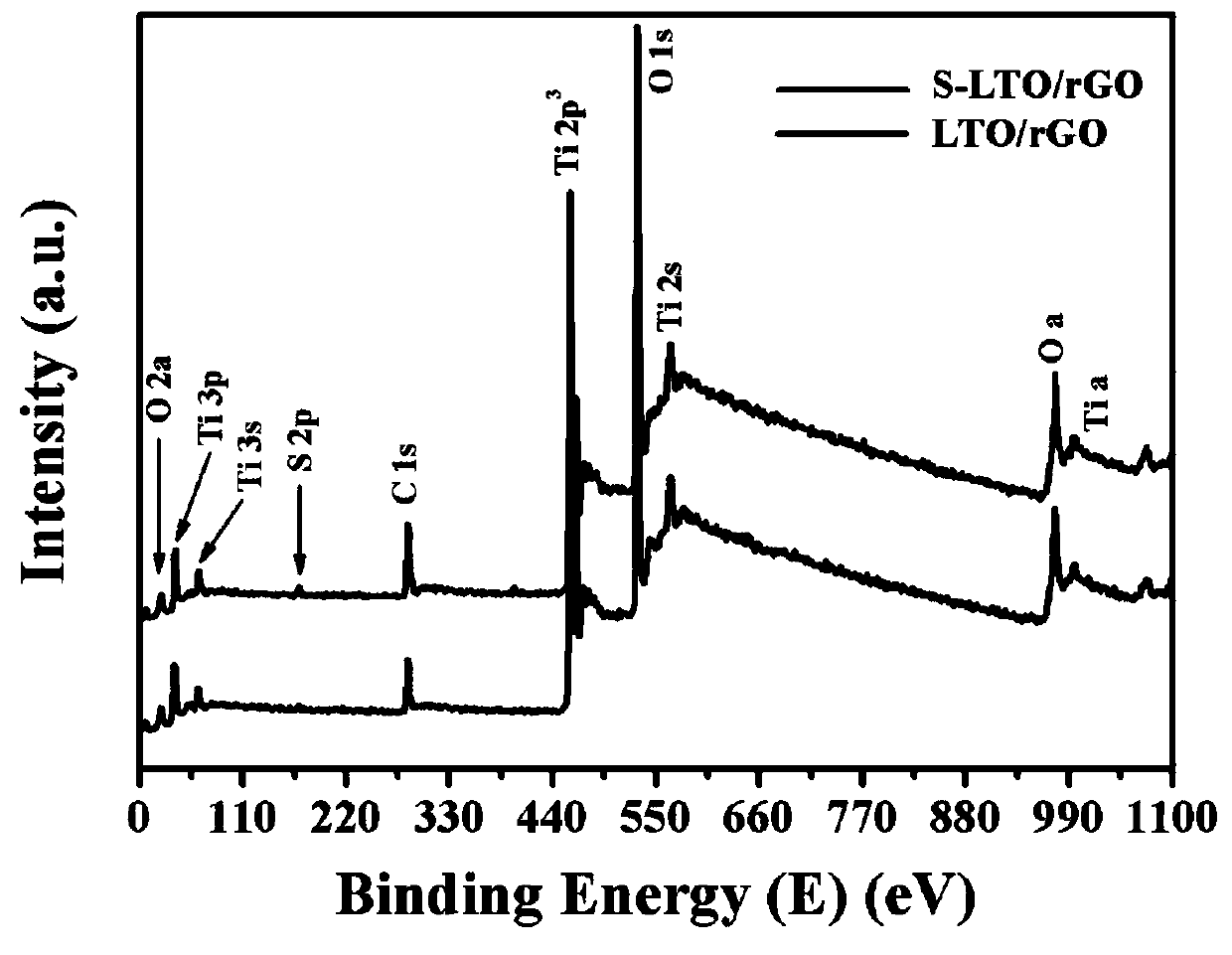

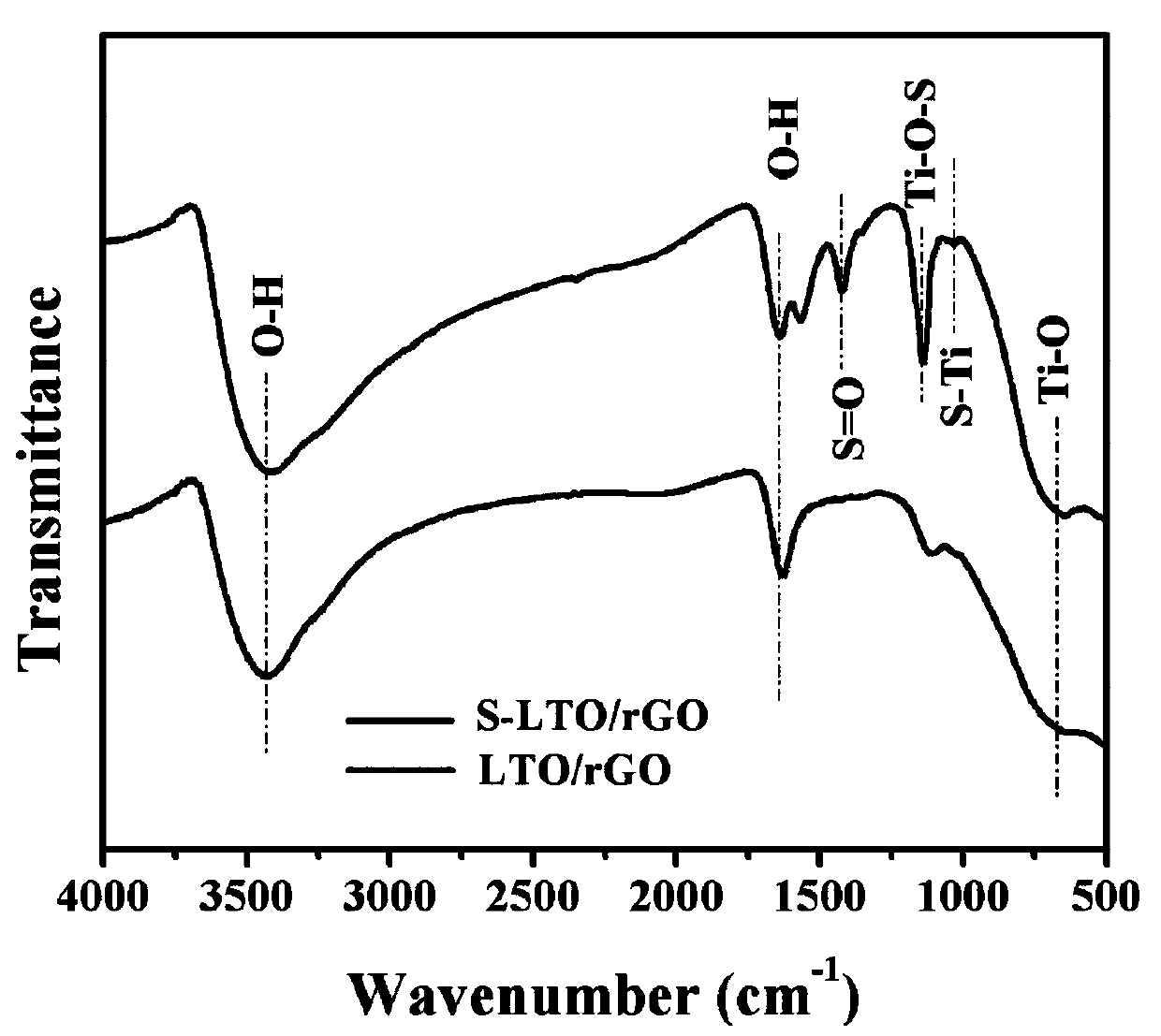

Sulfur-doped lithium titanate/graphene oxide composite material, preparation method and application of sulfur-doped lithium titanate/graphene oxide composite material

ActiveCN110620221AImprove conductivityIncrease intrinsic conductivityNegative electrodesSecondary cellsOxide compositeSodium-ion battery

The invention relates to a sulfur-doped lithium titanate / graphene oxide composite material, a preparation method and application of the sulfur-doped lithium titanate / graphene oxide composite material.The preparation method comprises the following steps that: (a) a titanium source is dissolved in a solution, and stirring is performed, so that a titanium source solution is obtained; (b) a lithium source is dissolved in deionized water, stirring is performed, so that a lithium salt solution is obtained; (c) the lithium salt solution is added into the titanium source solution, stirring is performed, so that a mixed solution is obtained; (d) PVP and graphene oxide are added into the mixed solution, ultrasonic dispersion is carried out, then a hydrothermal reaction is carried out, centrifugingand drying are performed, so that a lithium titanate / graphene oxide precursor can be obtained; (e) the lithium titanate / graphene oxide precursor is sintered in a reducing atmosphere, so that a lithiumtitanate / graphene oxide composite material can be obtained; and (f) the lithium titanate / graphene oxide composite material is mixed with a sulfur source, an obtained mixture is sintered in a reducingatmosphere, so that the sulfur-doped lithium titanate / graphene oxide composite material can be obtained. A sodium ion battery applying the composite material prepared by the above preparation methodhas the advantages of high capacity and the like. The sulfur-doped lithium titanate / graphene oxide composite material can be used as the active material of the negative electrode of the sodium ion battery.

Owner:CHANGZHOU UNIV

Efficient graphene-based conductive additive and preparation method thereof

The invention discloses an efficient graphene-based conductive additive and a preparation method thereof. Nano carbon black with a specific DBP value is selected and compounded with reduced graphene oxide in a specific ratio, and the nano carbon black with different DBP values is distributed in different regions of the surface of the reduced graphene oxide to form a unique nanocomposite structure,which exhibits excellent electrical conductivity. On one hand, the nano carbon black with the different DBP values repairs in-plane defects of graphene and improves the interfacial conductivity of graphene sheets and other materials, and on the other hand, the coverage of nano carbon black reduces the stacking among the graphene sheets and improves the dispersibility of the conductive additive.

Owner:HANGZHOU GAOXI TECH CO LTD

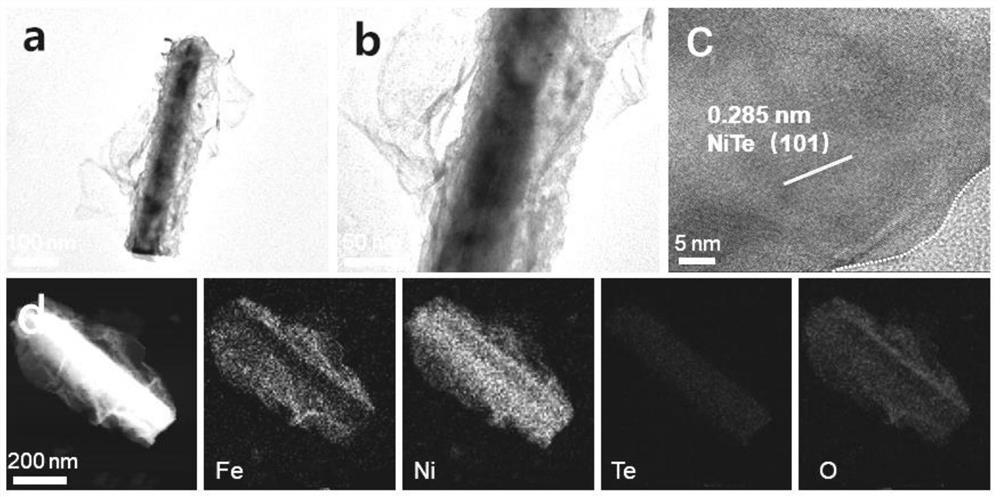

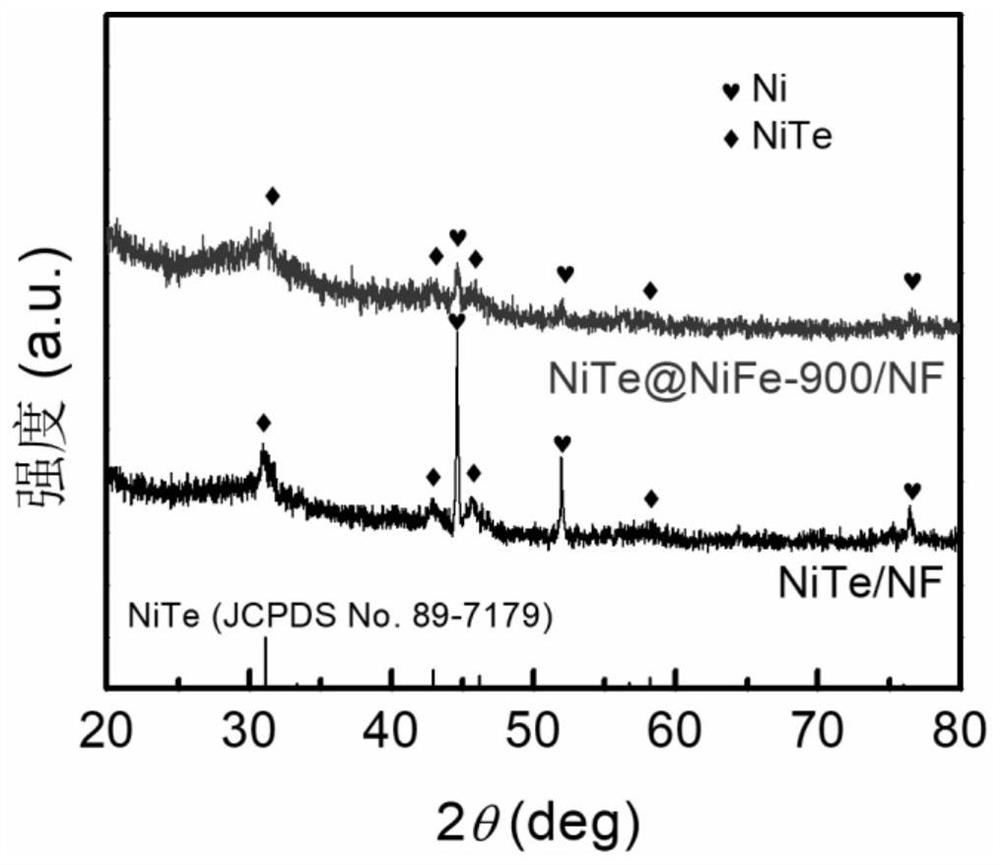

Composite catalyst with NiTe and NiFe loaded on foamed nickel as well as preparation method and application of composite catalyst

PendingCN113136587AEffective exposureImprove the shortcomings of poor intrinsic conductivityElectrodesNickel saltPtru catalyst

The invention provides a composite catalyst with NiTe and NiFe loaded on foamed nickel as well as a preparation method and application of the composite catalyst, and belongs to the technical field of preparation of composite materials. The preparation method comprises the following steps: firstly, loading NiTe on foamed nickel to obtain a catalyst NiTe / NF, then taking the catalyst NiTe / NF as a working electrode, and taking a solution containing ferric salt and nickel salt as an electroplating solution to prepare a composite catalyst with NiTe@NiFe loaded on the foamed nickel, and recording the composite catalyst as the NiTe@NiFe / NF composite catalyst, wherein the NiTe@NiFe / NF composite catalyst shows an excellent electro-catalytic property on an oxygen evolution half reaction of water decomposition.

Owner:JIANGSU UNIV

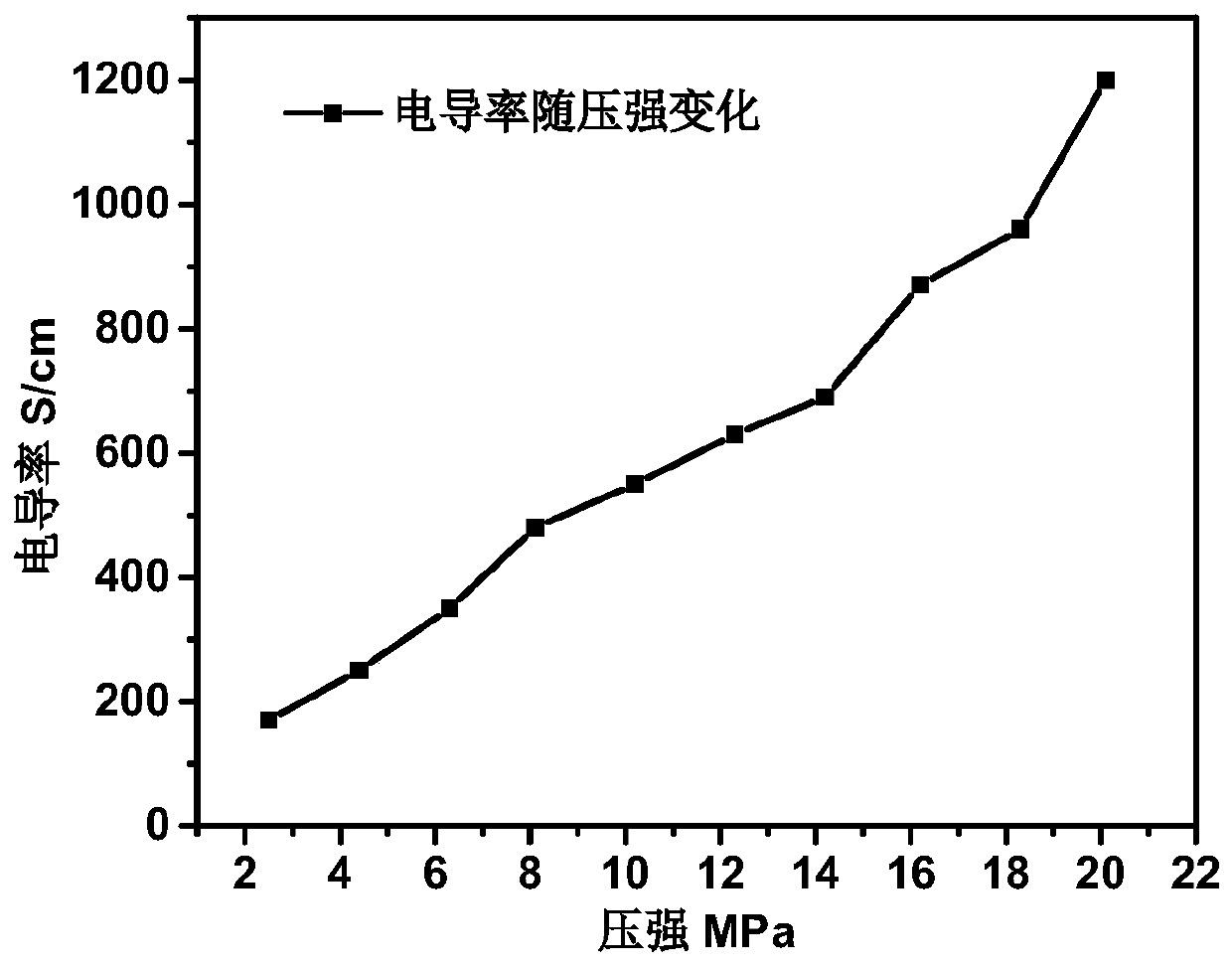

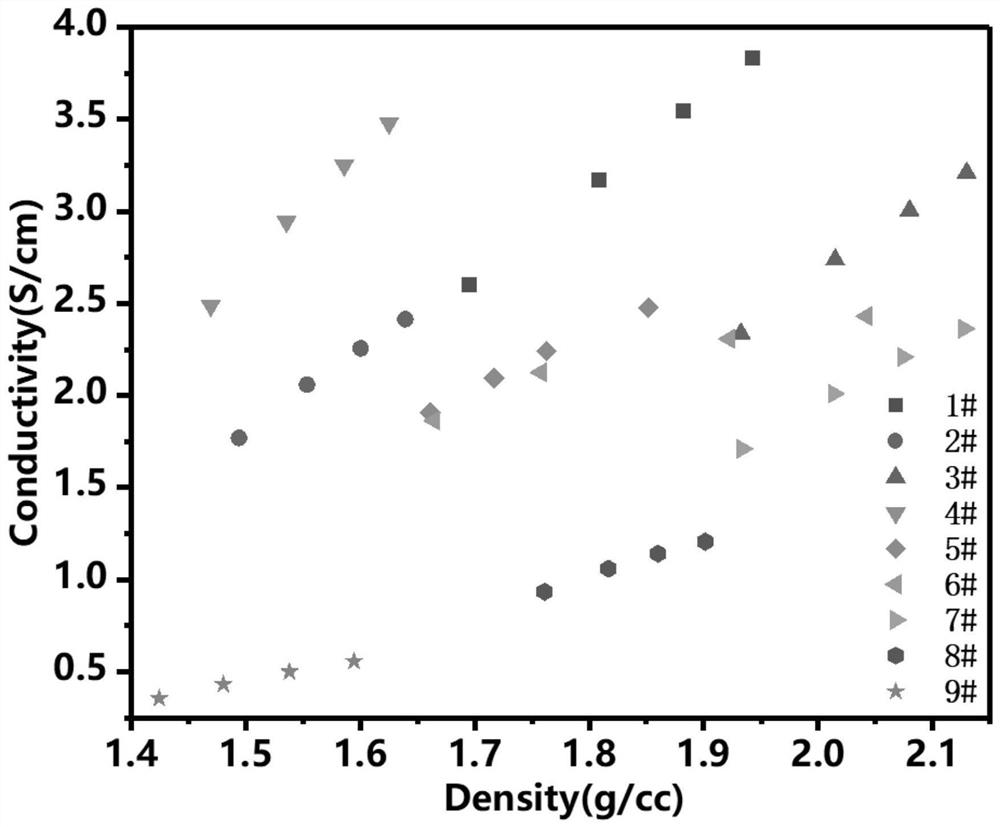

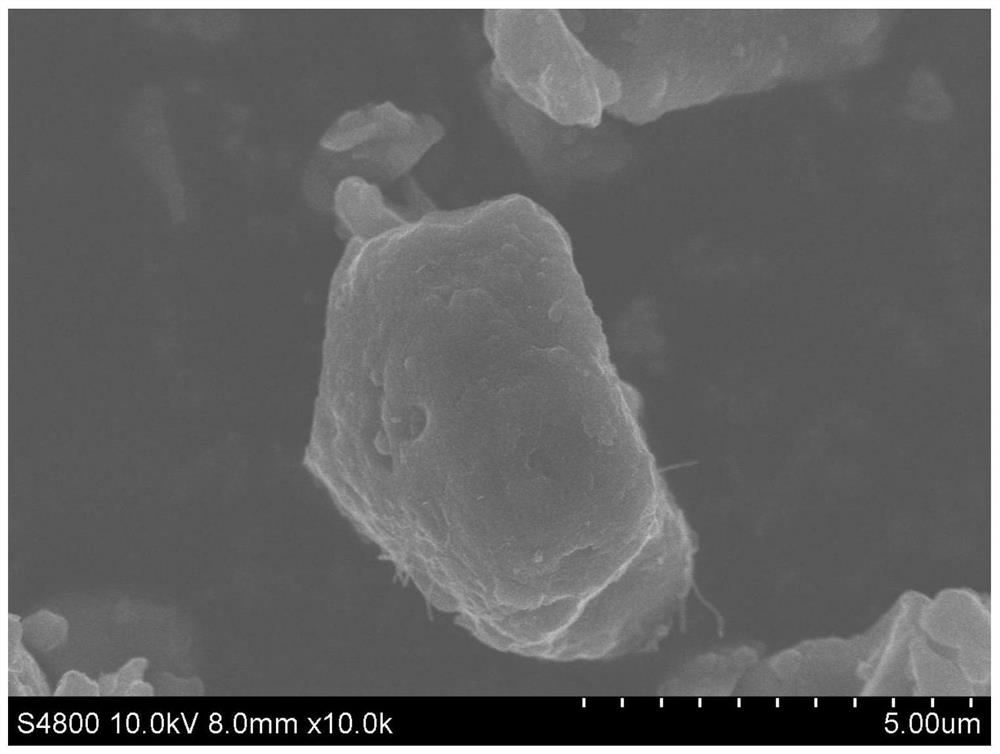

Soft carbon-coated boron-doped silicon-based negative electrode material and preparation method and application thereof

InactiveCN113363430AIncrease intrinsic conductivityIncrease capacitySecondary cellsNegative electrodesCarbon compositesCarbon layer

The embodiment of the invention relates to a soft carbon-coated boron-doped silicon-based negative electrode material and a preparation method and application thereof. The silicon-based negative electrode material is a powder material, and the powder conductivity is 2.0 S / cm to 6.0 S / cm; the soft carbon-coated boron-doped silicon-based negative electrode material comprises the following components in percentage by weight: 90wt%-99.49 wt% of a silicon-based powder material, 0.01 wt%-3wt% of a doping material doped in the silicon-based powder material and 0.5 wt%-7wt% of a soft carbon material; the silicon-based powder material is specifically a powder material containing electrochemical activity and comprises one or more of a nano silicon-carbon composite material, silicon monoxide, modified silicon monoxide, doped silicon monoxide and amorphous silicon alloy; the doping material comprises one or more of titanium boride, boron nitride, boron trichloride, boric acid, diboron trioxide, sodium tetraphenylborate, sodium borohydride and sodium borate; and the soft carbon material is coated on the outer surface of the silicon-based powder material to form a coating carbon layer of the boron-doped silicon-based negative electrode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Method for manufacturing a polyacrylonitrile-sulfur composite material

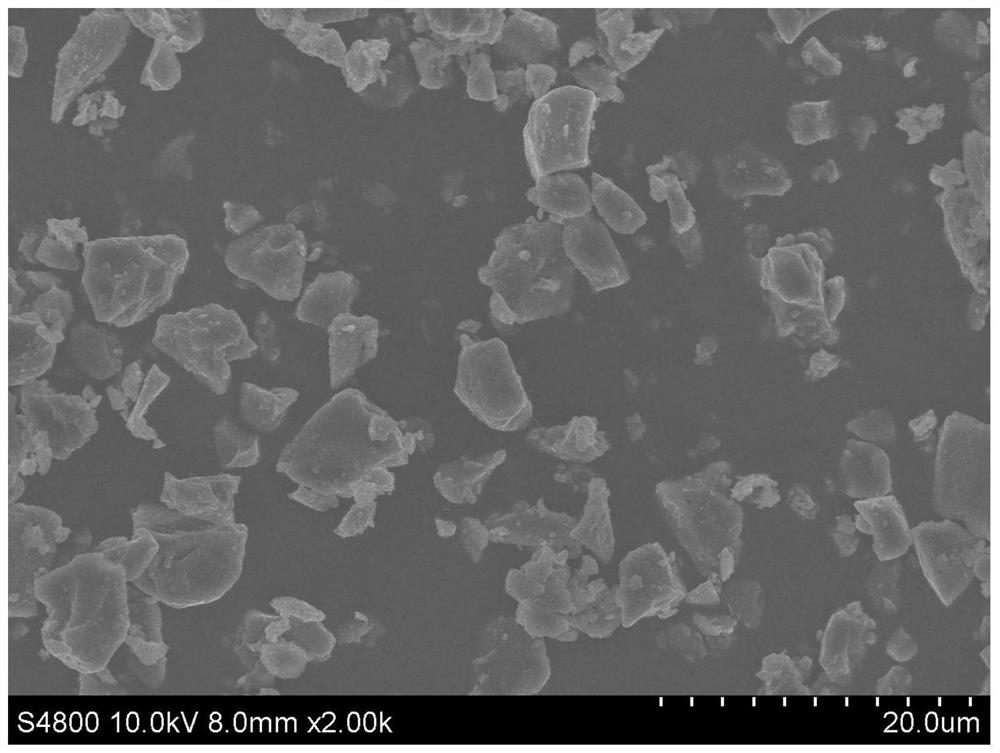

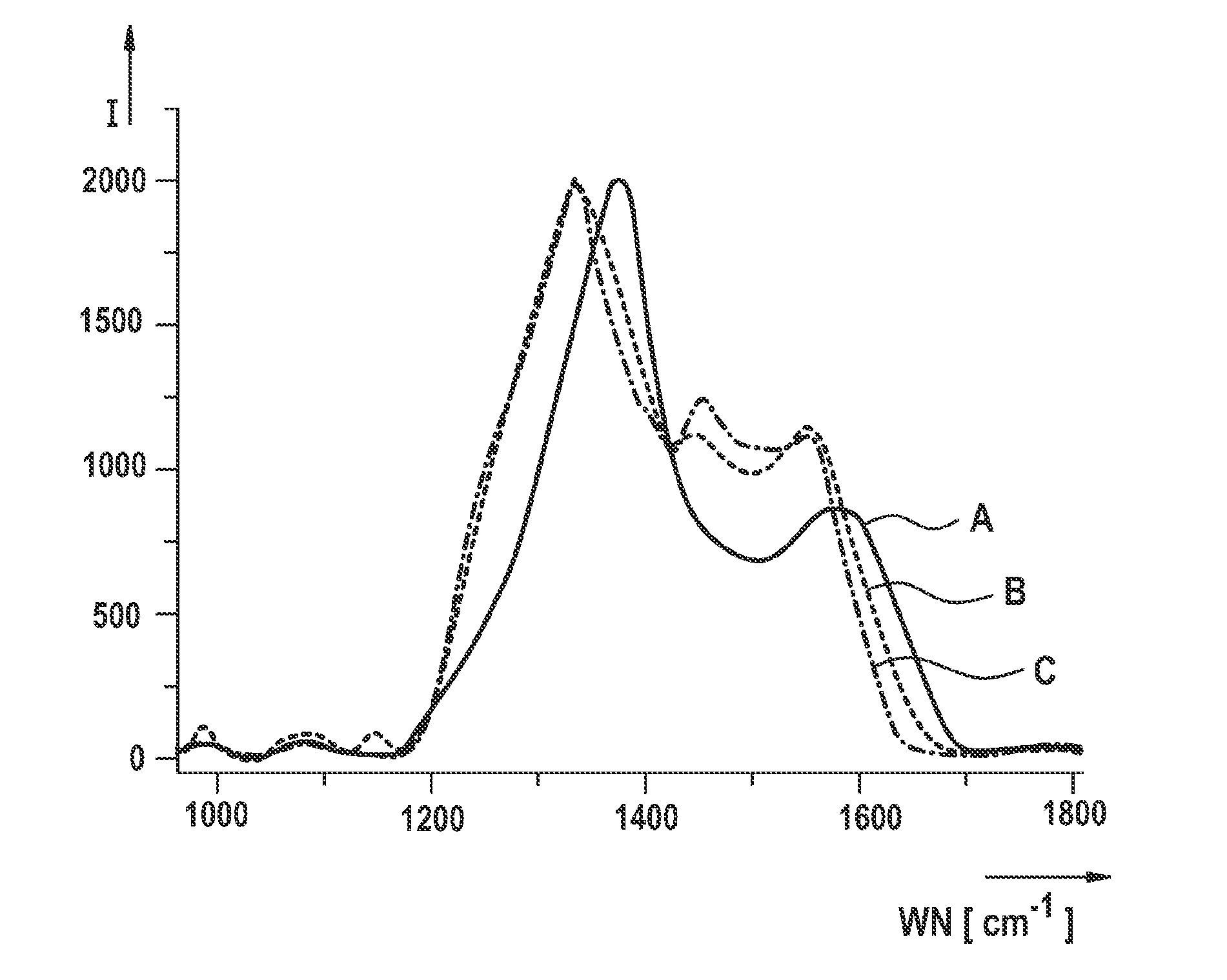

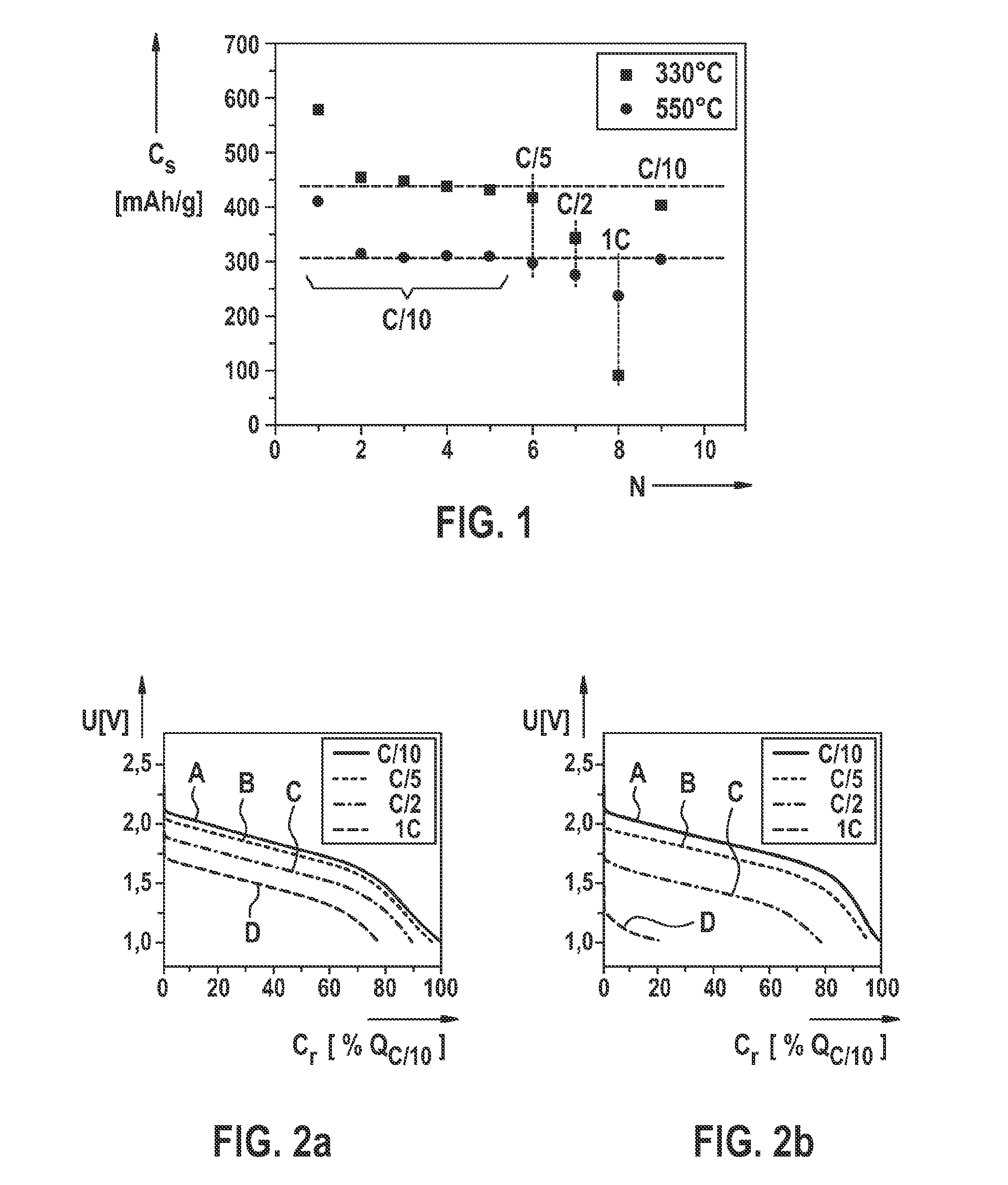

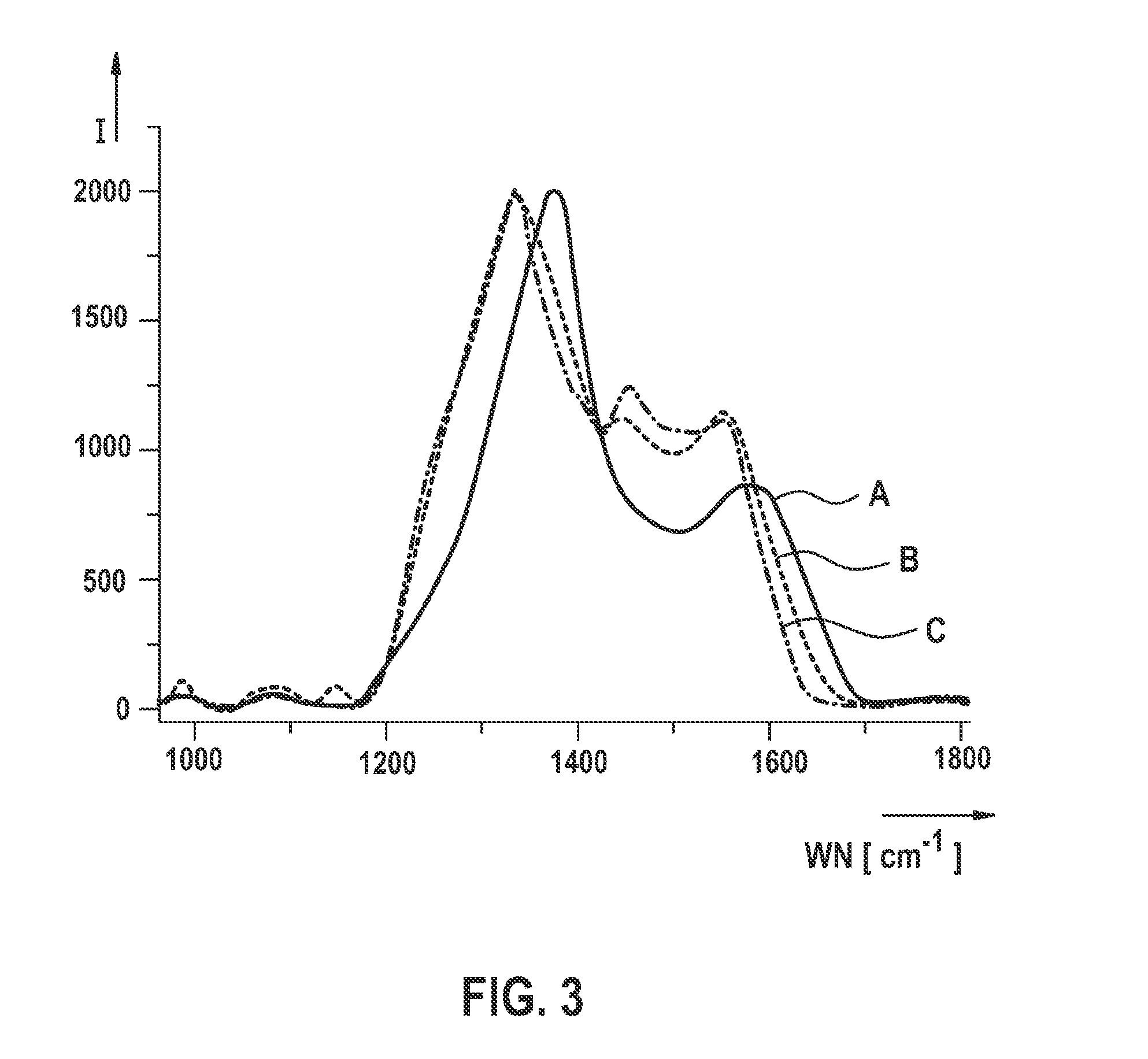

InactiveUS20150155560A1Improve conductivityIncrease intrinsic conductivityNon-metal conductorsCell electrodesHigh rateSulfur

A method is provided for manufacturing a polyacrylonitrile-sulfur composite material, the polyacrylonitrile-sulfur composite material having an sp2 hybrid proportion, with respect to the total carbon atoms included in the composite material, of greater than or equal to 85% including the method steps: a) reaction of polyacrylonitrile with sulfur at a temperature of greater than or equal to 450° C., in particular greater than or equal to 550° C.; b) immediate purification of the product obtained in method step a); and c) drying the purified product, if necessary. A composite material manufactured in this way may be used in particular in an active material of a cathode of a lithium-ion battery and offers a particularly high rate capacity. In addition, methods are provided for manufacturing an active material for an electrode, a polyacrylonitrile-sulfur composite material and an energy store.

Owner:ROBERT BOSCH GMBH

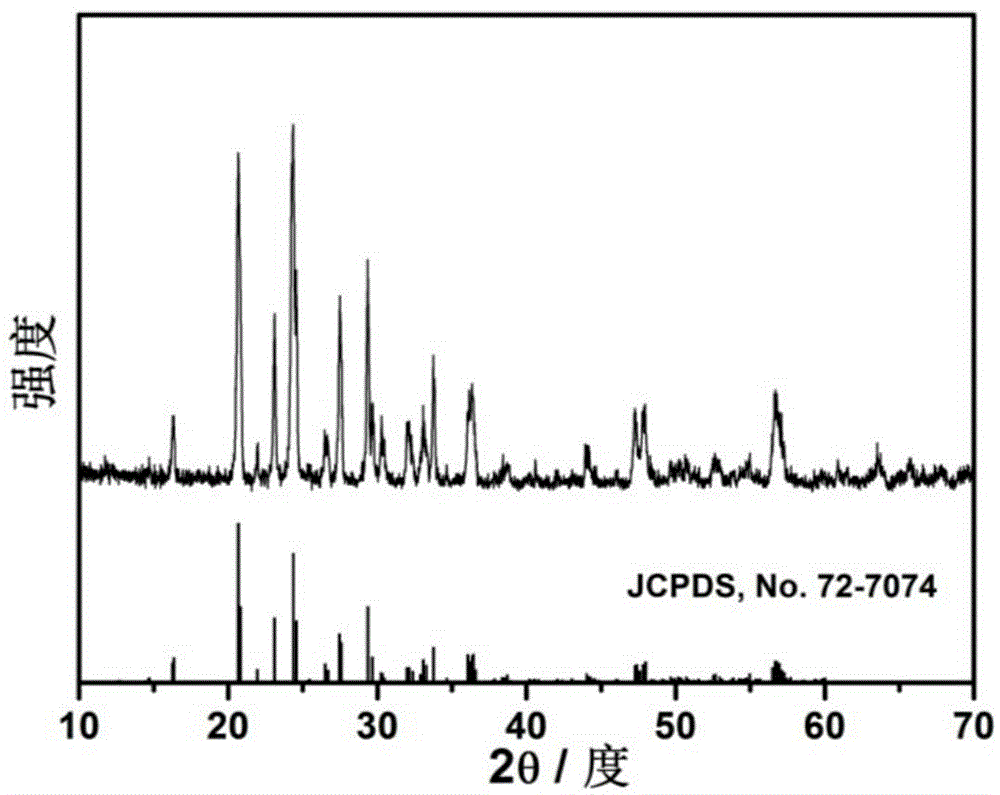

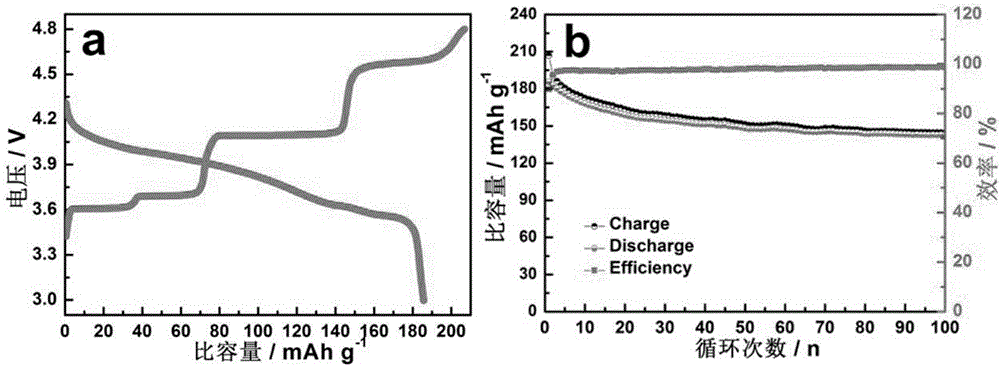

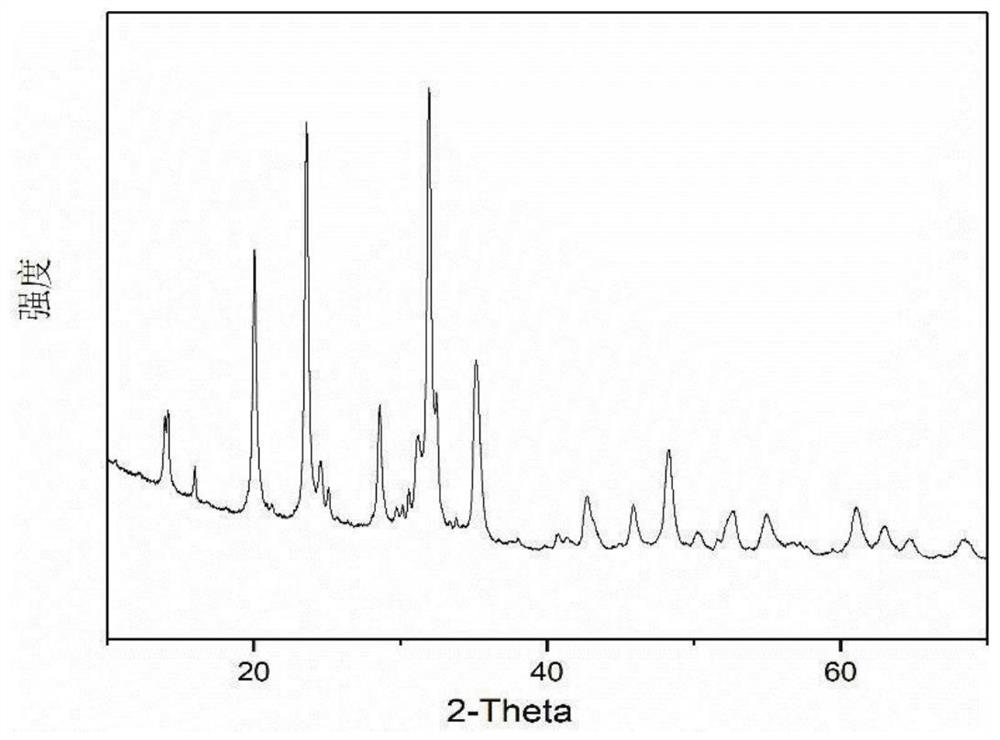

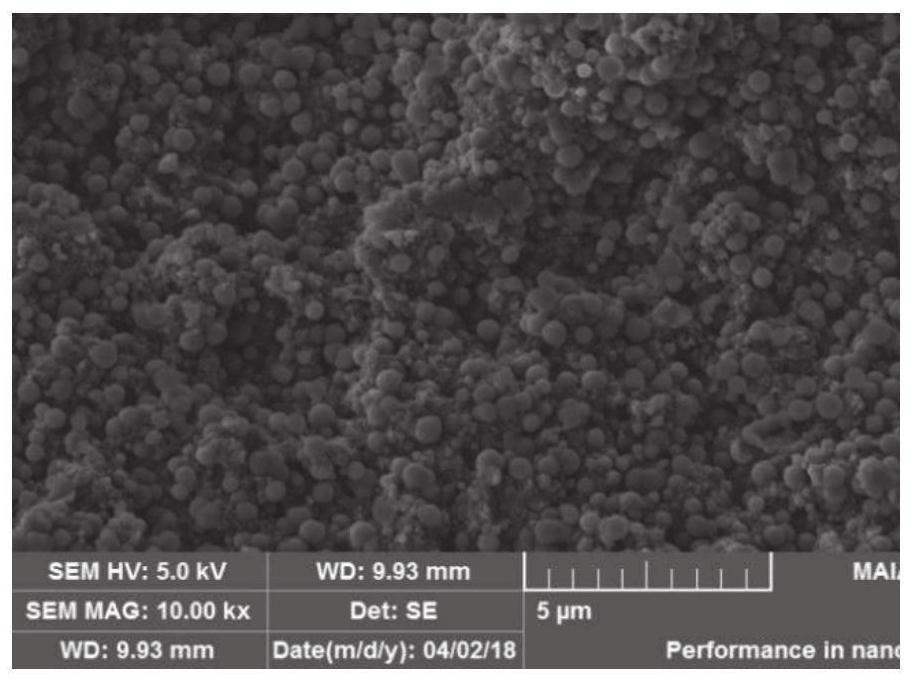

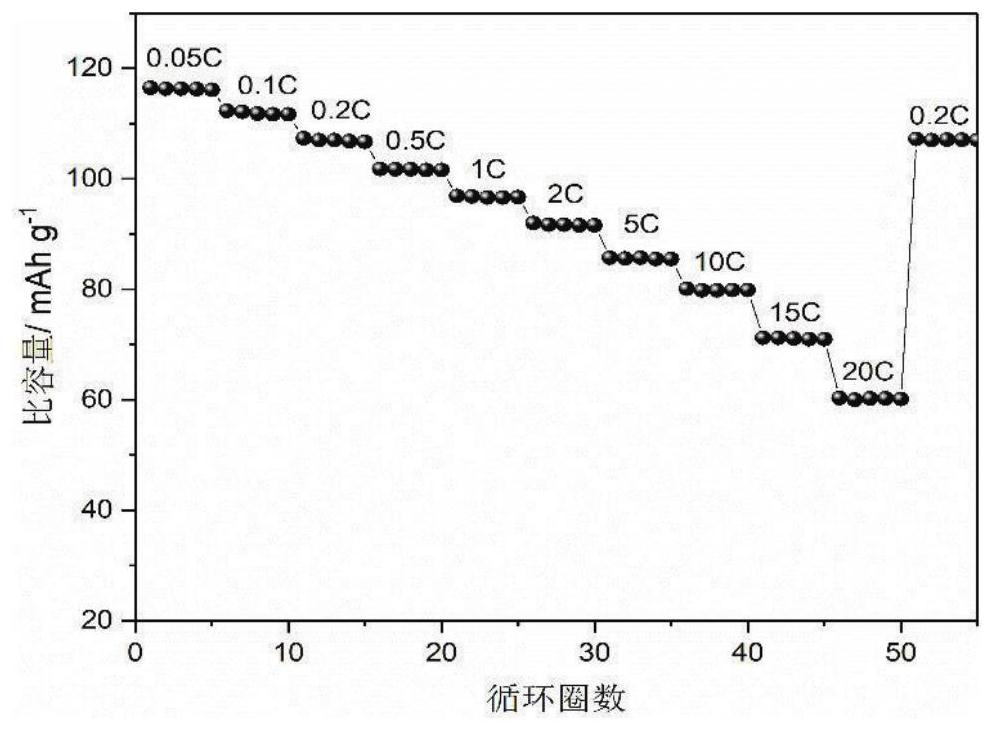

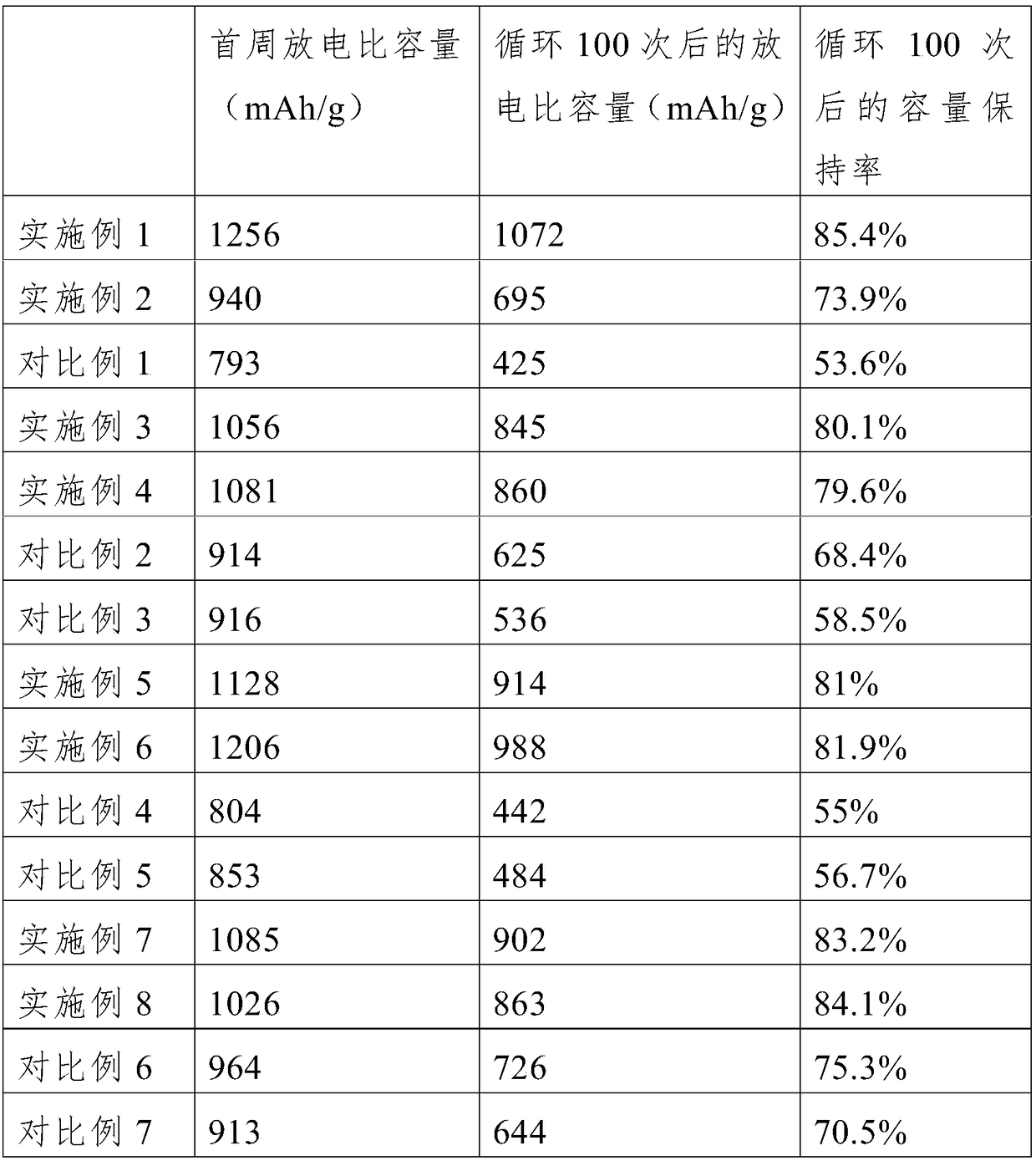

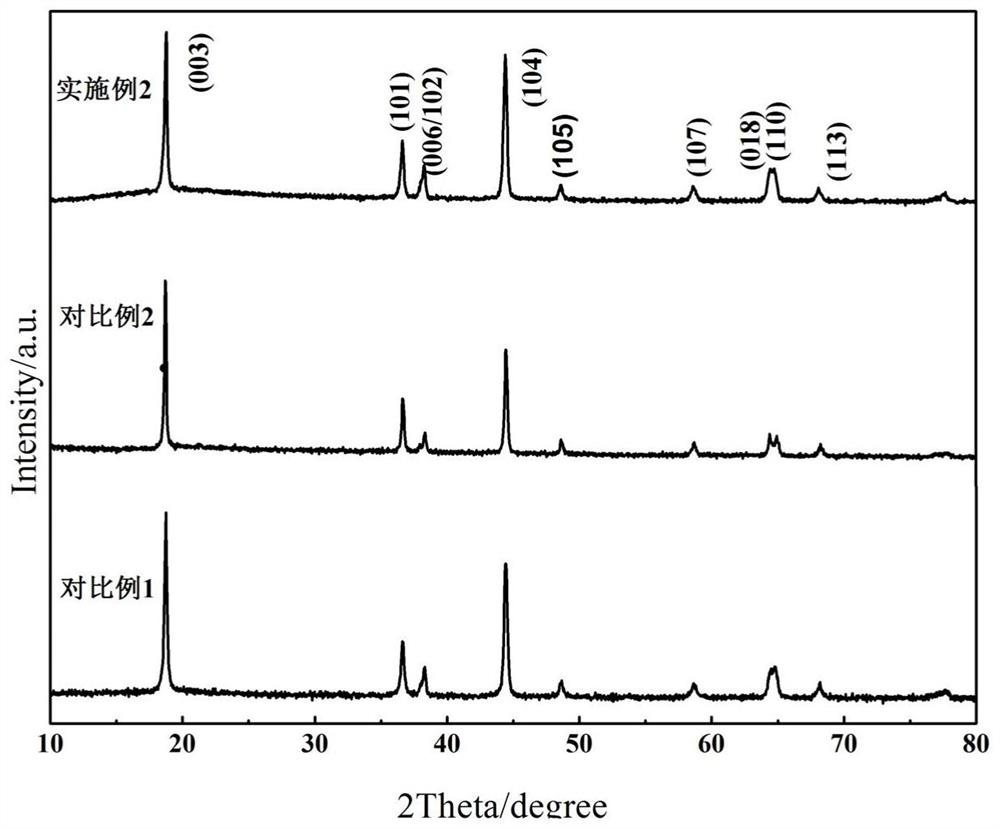

A transition metal-doped sodium titanomanganese phosphate/carbon composite positive electrode material and its preparation and application in sodium-ion batteries

ActiveCN110611080BIncrease capacityImproved magnification performanceCell electrodesSecondary cellsCarbon compositesElectrical battery

The invention belongs to the field of sodium ion battery materials, and specifically discloses a transition metal-doped sodium titanium manganese phosphate / carbon composite positive electrode material, which is a composite material of transition metal doped titanium manganese sodium phosphate and carbon materials. The chemical formula of metal doped titanium manganese sodium phosphate is Na 3 mn 1‑x m x Ti(PO 4 ) 3 , wherein, 0<x≤0.2; M is a transition metal Fe, Co or Ni. The invention also discloses the preparation and application of the composite cathode material. The present inventors found that by partially replacing the manganese in the sodium titanium manganese phosphate lattice with the transition metal, the electrical performance can be significantly improved, especially the capacity performance under high current can be significantly improved; it can be used as a positive electrode material for a sodium ion battery. High voltage, high capacity and excellent cycle stability. The preparation method is simple to operate and has broad prospects for commercial application.

Owner:湖南钠邦新能源有限公司

Anode material and manufacturing method thereof and lithium-sulfur battery

InactiveCN109360956AGood adsorption performanceImprove cycle stabilityCell electrodesSecondary cellsCyclic stabilityNitrogen

The invention discloses an anode material and a manufacturing method thereof and a lithium-sulfur battery. The anode material comprises porous C3N4-X, wherein 0<x<4; and sulfur loaded in C3N4-X. The manufacturing method of the anode material includes the following steps: S1. mixing porous C3N4 with Mg, and heating and reacting for a certain time to obtain the porous C3N4-X, wherein 0<x<4; S2. loading sulfur in the porous C3N4-X to obtain the anode material. According to the anode material, on one hand, due to C3N4-X comprises nitrogen, which has good adsorption performance for polysulfide lithium; on the other hand, due to the nitrogen content in C3N4-X is lower than C3N4, and the intrinsic conductivity is improved compared with C3N4, therefore, when the anode material is used in the lithium-sulfur battery, the cycle stability of the lithium-sulfur battery can be improved.

Owner:桑德新能源技术开发有限公司 +1

Flame-retarding anti-static polyester and preparation method thereof

ActiveCN110257949AIncrease intrinsic conductivityCompact structureElectroconductive/antistatic filament manufactureFlame-proof filament manufactureCarbon nanotubeCarbon black

The invention discloses a flame-retarding anti-static polyester and a preparation method thereof. The preparation method comprises the following steps: through selecting carbon black with a specific DBP value, in a specific proportion, compounding with carbon nano tubes and graphene, forming a nano composite structure with good electrical conductivity; and after enabling the nano composite structure to perform in-situ copolymerization and melt spinning with terephthalic acid and ethylene glycol, preparing composite polyester fibers with both flame retardance and anti-static property. The preparation method is capable of, in the case of only adding trace carbon nano tubes (0.12%), trace graphene (0.2%) and little carbon black (1.2%), remarkably improving electrical conductivity and flame retardance of a traditional polyester, in addition, a product is good in spinnability, stable in performance, low in cost, and small in industrialization difficulty, and has a remarkable practical value.

Owner:HANGZHOU GAOXI TECH CO LTD

Preparation method of zirconium-doped cerium fluoride coated nickel-cobalt-manganese ternary positive electrode material and prepared positive electrode material

PendingCN114122380AIncrease intrinsic conductivityImprove electrochemical performanceCell electrodesManganeseZirconium doping

The invention discloses a preparation method of a zirconium-doped cerium fluoride-coated nickel-cobalt-manganese ternary positive electrode material, and relates to the technical field of lithium ion positive electrode materials, and the preparation method comprises the following steps: (1) ball-milling and mixing a nickel-cobalt-manganese hydroxide precursor, a lithium source and a zirconium source, and sintering to obtain the zirconium-doped nickel-cobalt-manganese ternary positive electrode material; and (2) mixing a cerium salt solution with the zirconium-doped nickel-cobalt-manganese ternary positive electrode material in the step (1), stirring, adding an ammonium fluoride solution, reacting, drying, and calcining to obtain the zirconium-doped cerium fluoride-coated nickel-cobalt-manganese ternary positive electrode material. The preparation method has the beneficial effects that the residual alkali on the surface of the prepared ternary positive electrode material is reduced, and the ternary positive electrode material has high specific discharge capacity and cycle performance and high capacity retention ratio.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

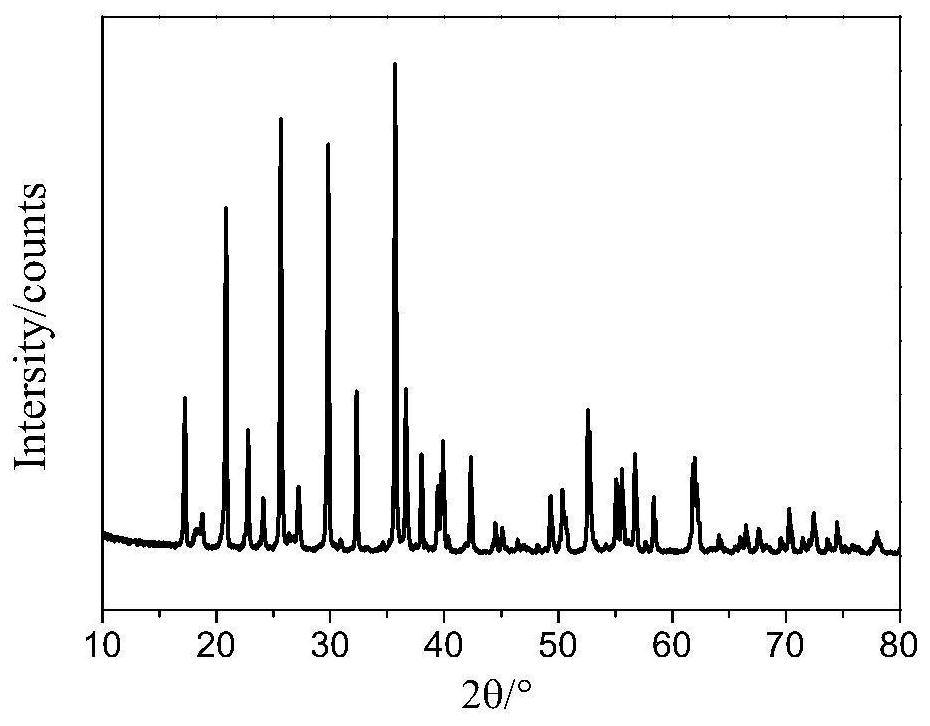

A kind of lithium iron phosphate/lithium vanadium fluorophosphate/carbon composite cathode material and preparation method thereof

ActiveCN109286005BIncrease intrinsic conductivityImprove uniformityCell electrodesSecondary cellsCarbon compositesLithium iron phosphate

The invention provides a lithium iron phosphate / lithium vanadium phosphate / carbon composite positive electrode material and a preparation method thereof, the molecular formula of which is (1-x)LiFePO 4 ·xLiVPO 4 F / C, where x=5-40wt%, and the mass fraction of C in the composite cathode material is 0.5-2.0wt%. The present invention first synthesizes lithium iron phosphate, and then synthesizes VPO 4 Intermediate, finally lithium iron phosphate, VPO 4 The intermediate is mixed with other raw materials for the synthesis of lithium vanadium phosphate, and then pressed and sintered to ensure that there is no heterophase formation of lithium vanadium phosphate in the composite material, and a composite structure with a dual-phase lithium intercalation active material is formed in the composite material to stabilize phosphoric acid The surface properties of iron-lithium materials can improve the surface / interface diffusion capacity of lithium ions and the transport rate of electrons, and improve their rate performance and cycle performance without sacrificing energy density.

Owner:宜宾天原锂电新材有限公司

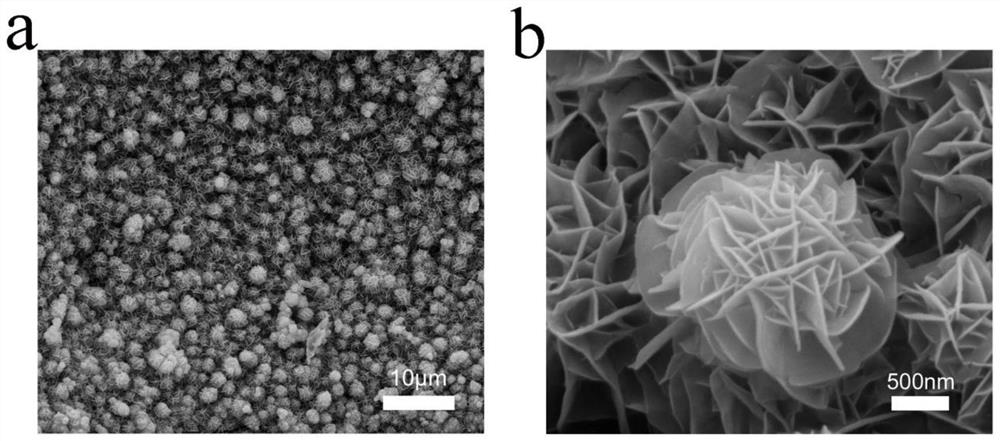

Ce-NiO-coated Ni-MOF composite material as well as preparation method and application thereof

ActiveCN111710531AImprove redox abilityIncrease capacitanceHybrid capacitor electrodesHybrid/EDL manufactureOXALIC ACID DIHYDRATEOrganosolv

The invention relates to a Ce-NiO-coated Ni-MOF composite material and a preparation method and application thereof. The preparation method comprises the following preparation steps of S1, dissolvinga nickel source, a cerium source and oxalic acid in an organic solvent, carrying out a hydrothermal reaction after even mixing, and obtaining an intermediate product after cooling, washing and dryingare conducted; S2, calcining the intermediate product obtained in the step S1 to obtain Ce-NiO; S3, adding the Ce-NiO obtained in the step S2 into a mixed solution of 1, 3, 5-trimethanesulfonic acid and DMF (Dimethyl Formamide), uniformly stirring, then carrying out hydrothermal reaction, and then cooling, washing and drying to obtain the Ce-NiO coated Ni-MOF composite material. Compared with theprior art, the Ce-NiO-coated Ni-MOF composite material has high intrinsic conductivity, high specific capacitance, high conductivity and better cycling stability, the raw materials adopted in the preparation method are pollution-free, and a solvent generated in the preparation process is non-toxic.

Owner:SHANGHAI INST OF TECH

Preparation method for negative material of high-power lithium ion power battery, negative material and application

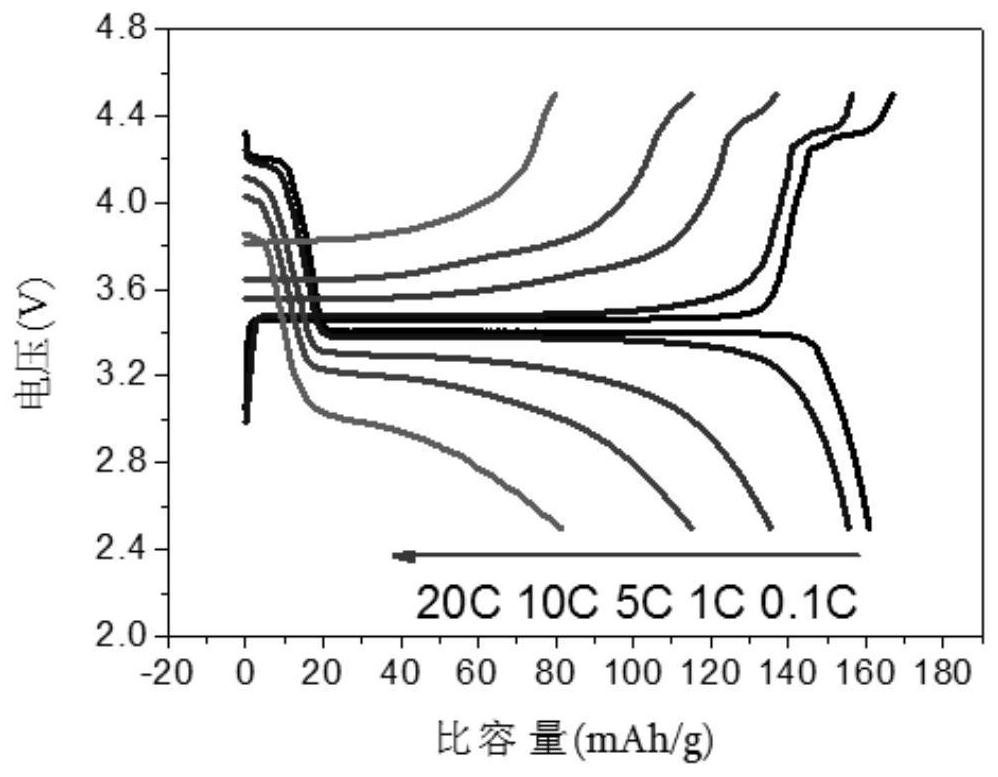

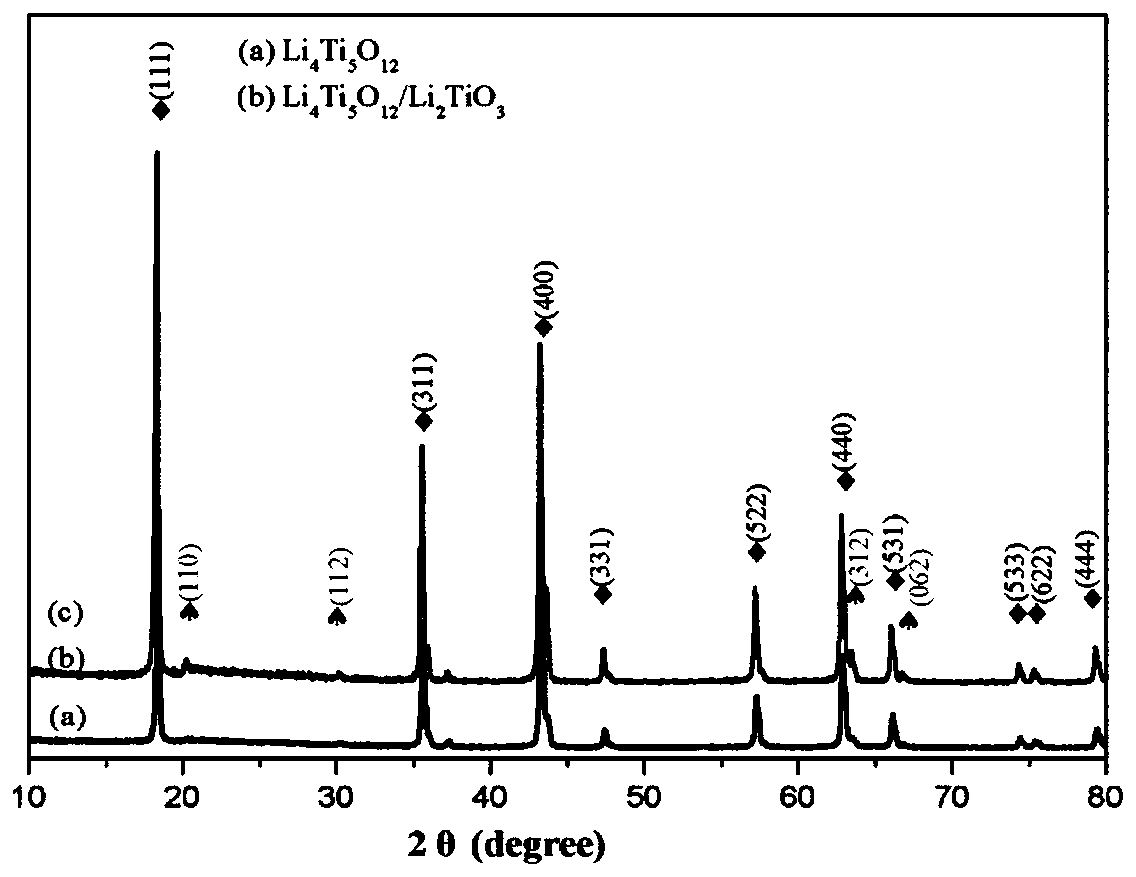

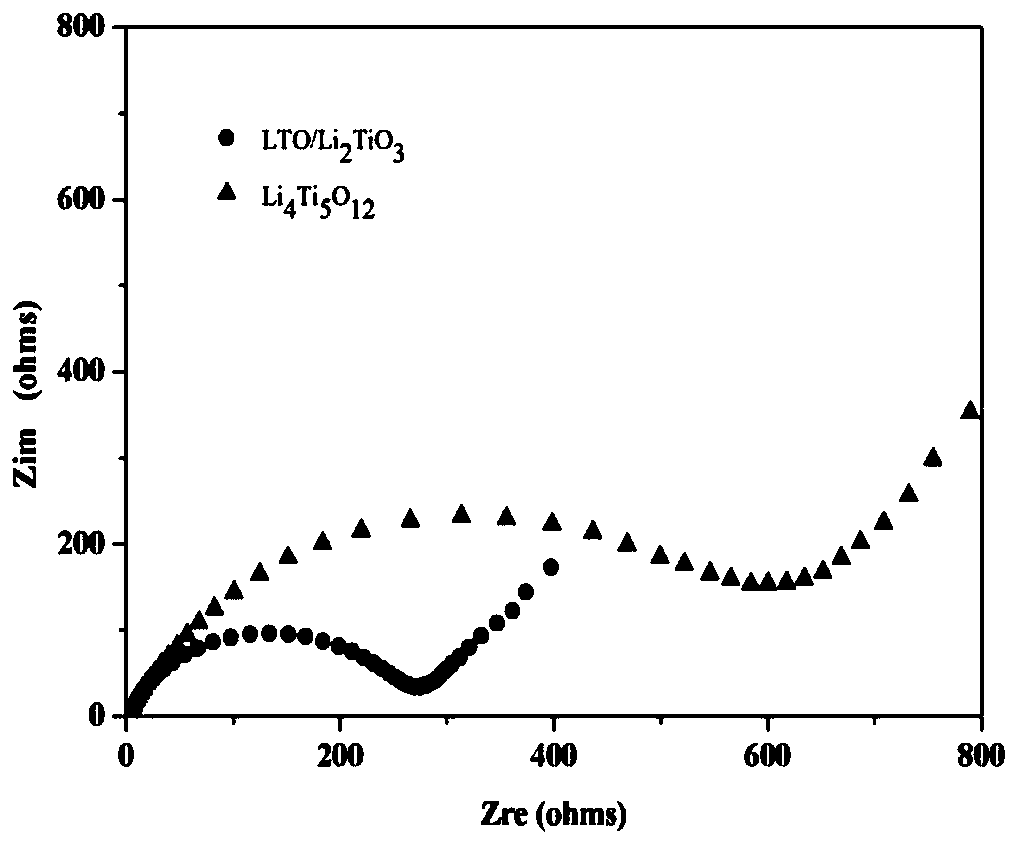

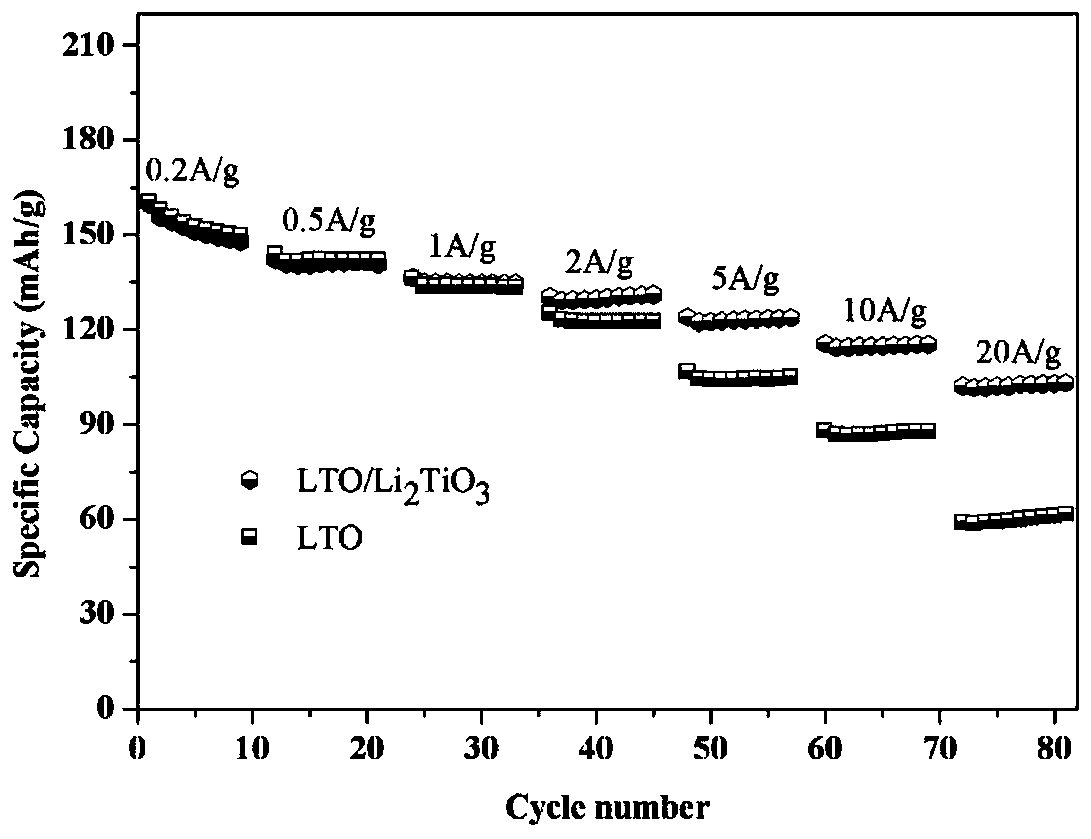

InactiveCN110071271AEasy to makeSimple reaction conditionsCell electrodesSecondary cellsPower batteryFiltration

The invention discloses a preparation method for a negative material of a high-power lithium ion power battery, the negative material and an application. The preparation method comprises the steps ofmixing a compound of 1.4-1.6% of LiOH.H2O and 98.6-98.4% of titanium in a solvent; and carrying out hydrothermal reaction, suction filtration, drying and grinding to obtain the composite phase Li4Ti5O12 / Li2TiO3 negative material. Compared with lithium titanate (Li4Ti5O12), the negative material can obviously improve the charging power and the reversible capacity of the lithium ion battery, and hasrelatively good safety performance. The method is simple in preparation process and low in requirements on environment atmosphere, can be applied to the negative material of the high-power lithium ion power battery, and is easy for industrial production.

Owner:桑顿新能源科技(长沙)有限公司

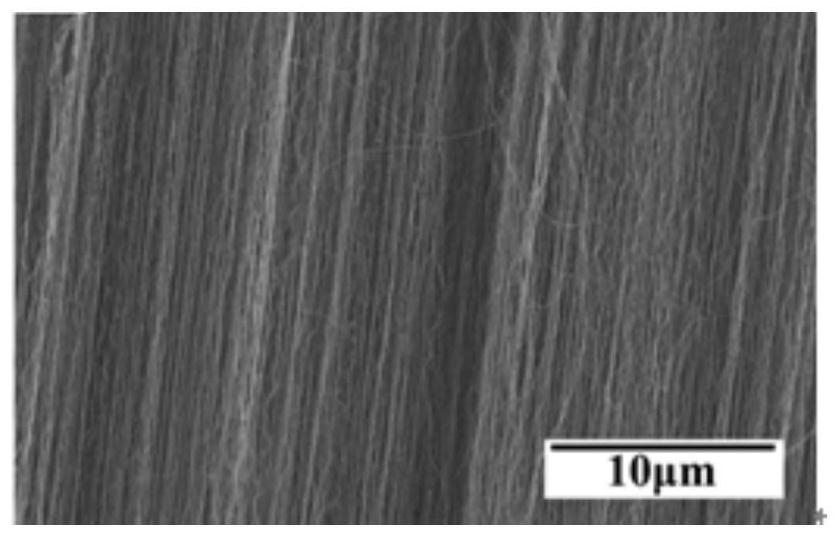

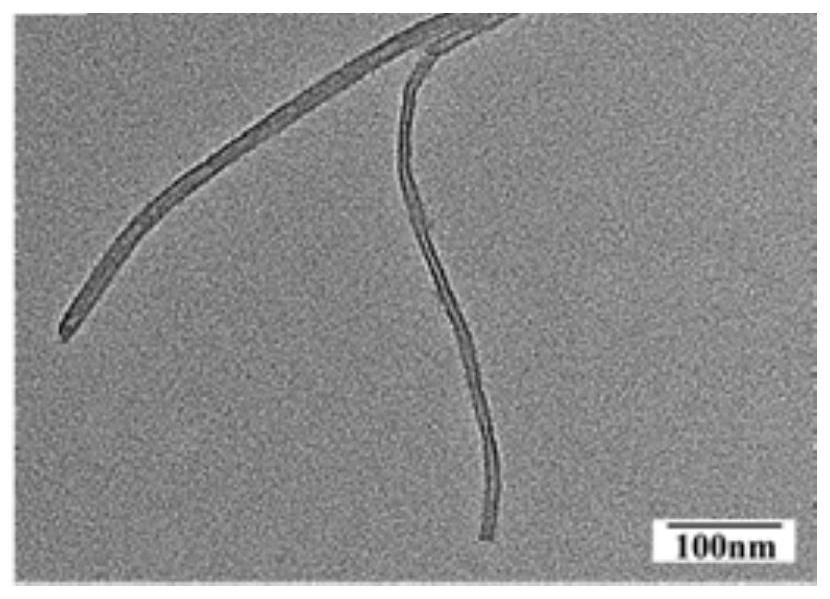

Super-smooth carbon nanotube epoxy resin composite material and preparation method and application thereof

The invention relates to a super-smooth carbon nanotube epoxy resin composite material and a preparation method and application thereof. The super-smooth carbon nanotube epoxy resin composite materialcomprises a master batch and a curing agent, wherein the master batch comprises epoxy resin and super-aligned carbon nanotubes dispersed in the epoxy resin. According to the invention, the super-smooth carbon nanotubes with higher length-diameter ratio and fewer defects are added into the epoxy resin for the first time to form the composite material, and the conductive material with high conductivity and extremely low threshold value can be obtained by only needing a very small addition amount. Furthermore, a non-covalent functionalized surface treatment technology is used for modifying the superparaxial carbon nanotubes so that the dispersion of the superparaxial carbon nanotubes in the epoxy resin and the binding capacity of the superparaxial carbon nanotubes with the epoxy resin are improved, and no defects are introduced to the surfaces of the carbon tubes, thereby improving the intrinsic conductivity of the carbon tubes. Meanwhile, through the combination of different mechanicaldispersion methods, the dispersion capability of the super-smooth carbon nanotubes in the epoxy resin is further improved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

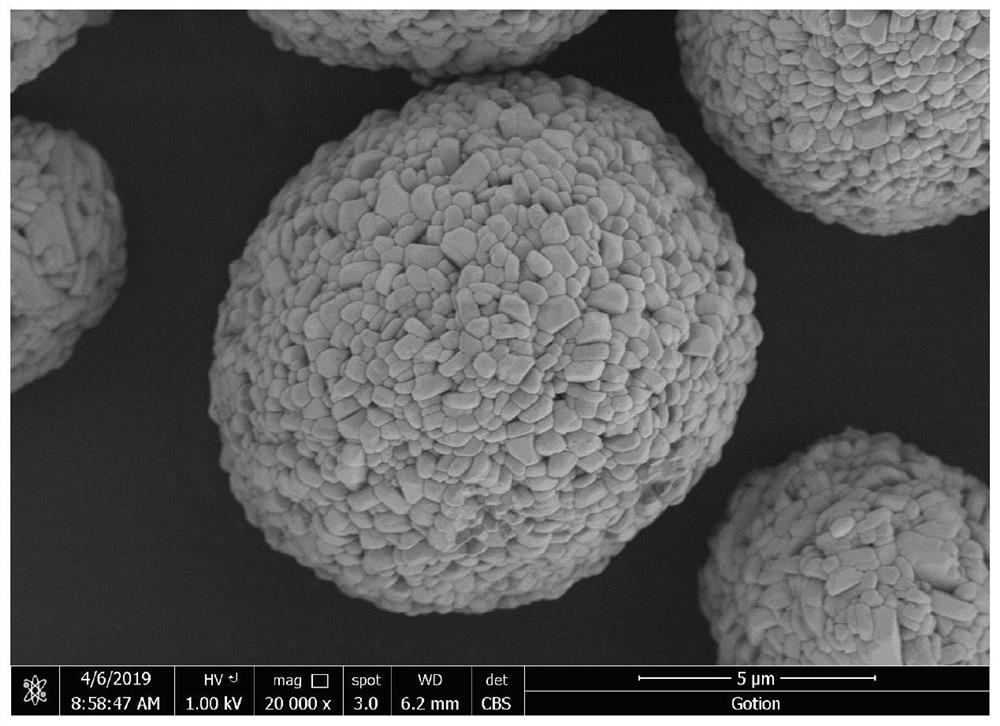

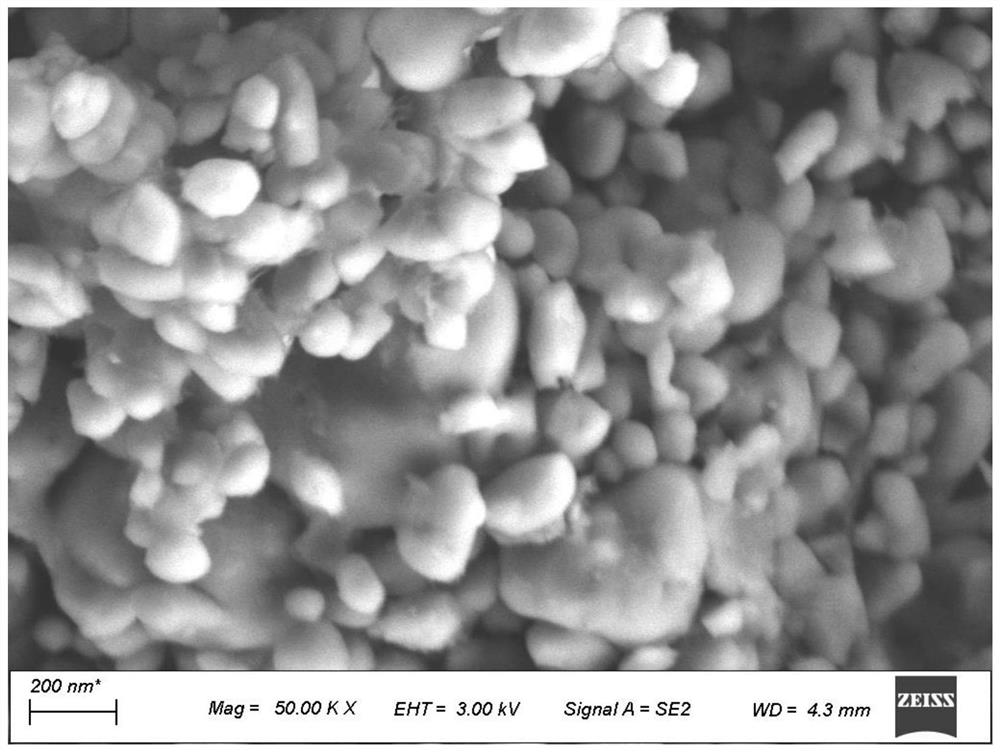

Preparation method of high-compaction lithium iron phosphate

PendingCN114538401AImprove performanceIncrease compaction densityMaterial nanotechnologyCell electrodesCarbon coatingCarbon layer

The invention relates to the field of lithium iron phosphate batteries, and discloses a preparation method of high-compaction lithium iron phosphate in order to solve the problem that the electronic conductivity and the ionic conductivity of the lithium iron phosphate cannot be improved at the same time when the compaction density of the lithium iron phosphate is improved by a method for improving the particle size of a material and reducing the carbon coating amount in the prior art. The preparation method comprises the following steps: dissolving a surfactant in an ethanol aqueous solution, adding a lithium source into the ethanol aqueous solution, and stirring to obtain a transparent solution; adding a phosphorus source, an iron source and a doped metal raw material into the solution, and stirring to obtain gel; drying the gel, grinding into powder, and calcining the powder by using a two-stage method; and calcining the powder, cooling to room temperature, and grinding to obtain powdery lithium iron phosphate. The prepared lithium iron phosphate particles are uniform in particle size distribution and free of obvious agglomeration, the compaction density and the conductivity of the lithium iron phosphate are jointly improved through an amorphous carbon layer network on the surface and doping of internal metal ions, and then the gram volume exertion is improved.

Owner:WANXIANG 123 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com