Super-smooth carbon nanotube epoxy resin composite material and preparation method and application thereof

A carbon nanotube and epoxy resin technology, applied in the field of nanomaterials, can solve the problems of easy agglomeration of carbon tubes, sharp increase in resin viscosity, large specific surface area of carbon nanotubes, etc., and achieve the effect of easy contact and straight defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0069] In this preparation example, the CVD growth method is used to prepare super-parallel carbon nanotubes (referred to as: SACNTs), and the specific preparation method is as follows:

[0070] (1) The silicon substrate is etched, and the etching is carried out in a polytetrafluoroethylene cell, and the platinum cathode is irradiated with a halogen lamp for 5 minutes under backlighting. The corrosion solution contains one part of hydrogen fluoride (50% aqueous solution) and one part of ethanol, and the anodic oxidation current density is kept at 10mA / cm 2 . The resulting porous silicon has a thin nanoporous layer (pore size; 3 nm) on top of a macroporous layer (with submicron pores);

[0071] (2) Iron powder catalyst is deposited into a thin film on a silicon substrate;

[0072] (3) Place the silicon substrate in an argon (Ar, 1000 sccm) atmosphere, and continue for 15 minutes after the temperature reaches 680°C;

preparation example 2

[0075] This preparation example prepares a surface-modified super-parallel carbon nanotube (referred to as: f-SACNTs), the method is as follows:

[0076] (1) Configure Triton X-100 (Triton) acetone solution, add Triton X-100 to the acetone solution and stir magnetically at 25°C for 1 hour to make a concentration of 2×10 -3 mol / L Triton X-100 acetone solution.

[0077] (2) Place 0.5 g of the superparallel carbon nanotubes prepared in Preparation Example 1 in 300 mL of acetone solution containing Triton X-100, and stir magnetically at 25° C. for 24 h; then use a water bath to ultrasonically disperse for 12 h, and initially disperse Carbon tubes; followed by probe-type ultrasonic dispersion for 10 minutes, so that Triton X-100 is fully adsorbed to the surface of carbon tubes, and super-parallel carbon nanotubes with surface non-covalent chemical modification are obtained.

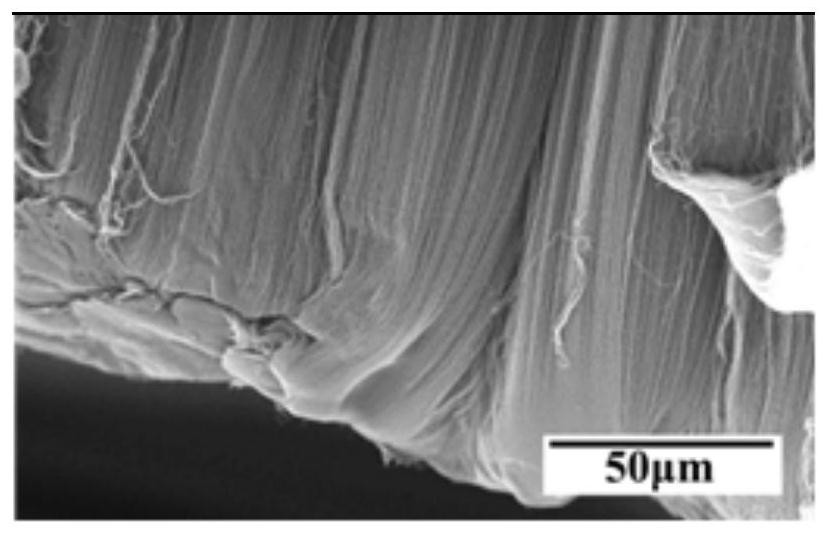

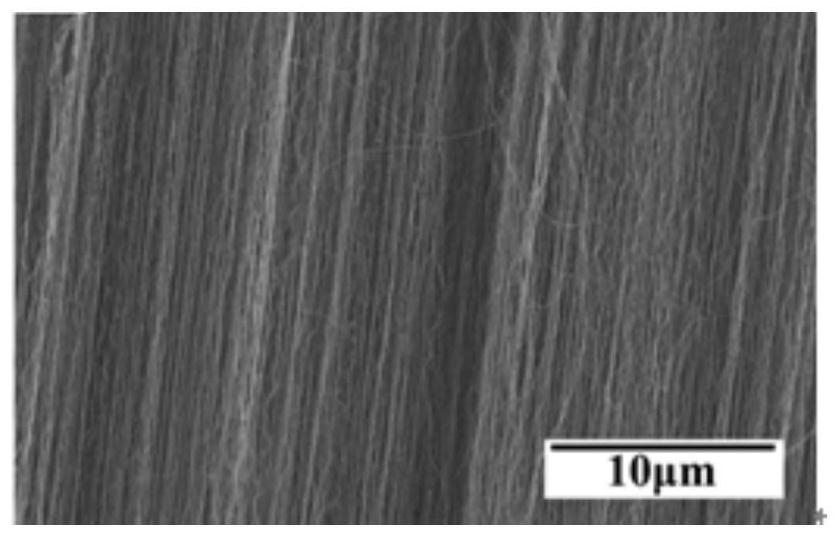

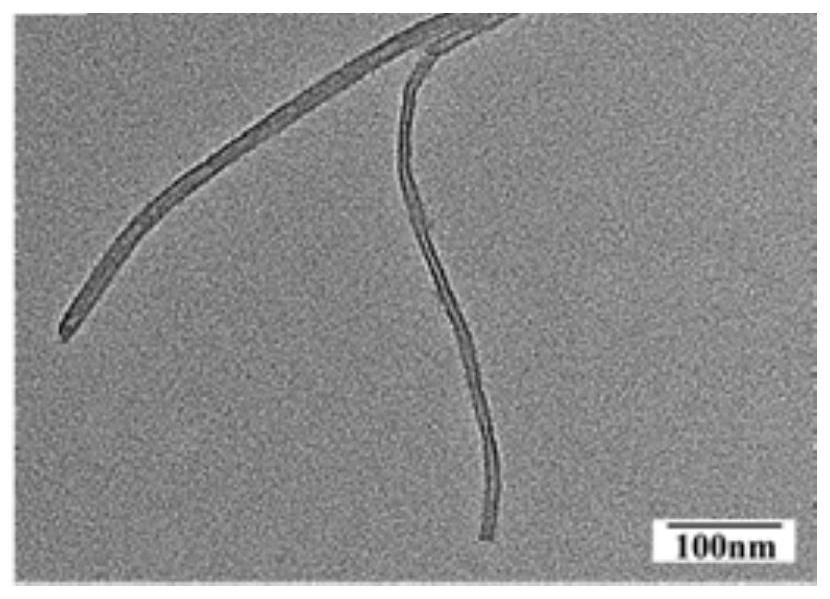

[0078] The super-parallel carbon nanotubes prepared by Preparation Example 1 are characterized by SEM, as ...

preparation example 3

[0081] This preparation example prepares a kind of super-parallel carbon nanotube / epoxy resin composite material (recorded as: SACNTs / EP), and the preparation method is as follows:

[0082](1) Blend the super-parallel carbon tube powder obtained in Preparation Example 1 with a high-speed mixer (AE03, DISPERMAT VAM-GETZMANN, Germany) and epoxy resin (type E51, preheated at 80°C for 30min), and The mixing temperature is 80°C, the stirring speed is 4000rpm, and the stirring time is 2h.

[0083] (2) The mixture obtained in (1) was further mixed and dispersed using a three-roll mill (EXAKT 80E, EXAKT Technologies, Germany). When dispersing, the spacing mode is adopted, and the roller spacing is set to 120:40, 105:35, 90:30, 60:20, 45:15, 30:10, 15:5, and each spacing process is repeated twice; the speed of the driving roller is set It was 90rpm, increased to 100rpm with the decrease of the roller spacing, and finally increased to 110rpm, and the dispersed SACNTs / EP masterbatch was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com