High-conductivity ferrous phosphate lithium cathode material for lithium ion battery and preparation method thereof

A lithium iron phosphate and lithium ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as uneven coating and material conductivity limitation, and achieve improved conductivity, excellent high-rate performance, and reversibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

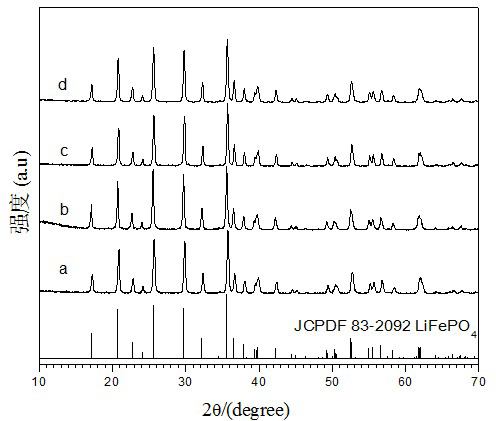

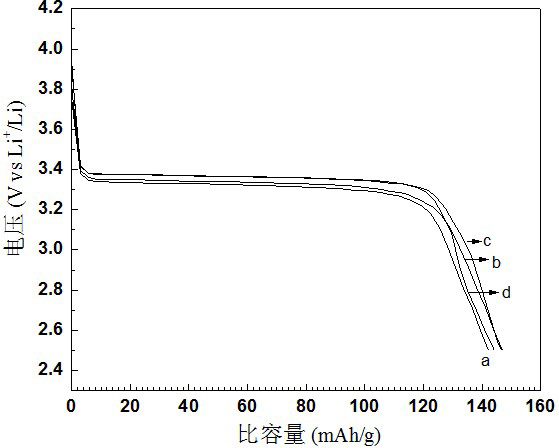

[0033] Li 2 CO 3 , NH 4 h 2 PO 4 Lithium source, phosphorus source, FeC 2 o 4 and Fe 2 o 3 as iron source and catalyst (where FeC 2 o 4 and Fe 2 o 3 The molar ratio is 20:1). Weigh according to the stoichiometric ratio of Li, Fe, P 1.02:1:1, and weigh 1 mole of NH at the same time 4 h 2 PO 4 After adding 50g of starch and weighing it, dissolve it in a certain amount of deionized water to obtain a slurry with a solid content of 60%. After ball milling for 17 hours at a speed of 300 r / min according to the mass ratio of ball to material 5:1, Stir and dry at 80°C. The dried powder material was dried in a tube furnace under N 2Under protection, the temperature was raised to 700°C at 5°C / min and roasted at a constant temperature for 14 hours, and then slowly cooled to room temperature in the furnace to obtain gray-black LiFePO 4 / C target product.

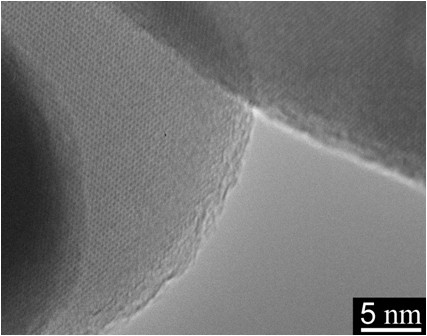

[0034] The carbon content in the prepared lithium iron phosphate material is 2.5%, the thickness of the carbon film o...

Embodiment 2

[0038] Respectively with LiOH, NH 4 h 2 PO 4 Lithium source, phosphorus source, FeC 2 o 4 and C 10 h 10 Fe is the iron source and catalyst (where FeC 2 o 4 and C 10 h 10 The molar ratio of Fe is 10:1). Weigh according to the stoichiometric ratio of Li, Fe, P 1.05:1:1, and weigh 1 mole of NH at the same time 4 h 2 PO 4 After adding 40g of polyvinyl alcohol and weighing it, dissolve it in a certain amount of alcohol solution to obtain a slurry with a solid content of 70%, and ball mill it at a speed of 400 r / min for 18 hours at a ball-to-material mass ratio of 8:1. After that, it was stirred and dried at 70°C. The dried powder material was dried in a tube furnace under N 2 Under protection, heat up at 5°C / min to 750°C and bake at constant temperature for 15 hours, then slowly cool to room temperature in the furnace to obtain gray-black LiFePO 4 / C target product.

[0039] The carbon content in the prepared lithium iron phosphate material is 2%, the thickness of t...

Embodiment 3

[0041] LiH 2 PO 4 Lithium source, phosphorus source, with Fe 2 o 3 and Ni(OH) 2 For iron source and catalyst. Weigh according to the stoichiometric ratio of Li, Fe, Ni, P 1:0.99:0.01:1, and weigh 1 mole of LiH at the same time 2 PO 4 After adding 50g of polyacrylic acid and weighing it, dissolve it in a certain amount of alcohol solution to obtain a slurry with a solid content of 60%, and ball mill it at a speed of 600 r / min for 10 hours according to the mass ratio of ball to material 10:1. , Stir and dry at 60°C. The dried powder material was dried in a tube furnace under N 2 Under protection, heat up at 5°C / min to 650°C and bake at constant temperature for 18 hours, then slowly cool to room temperature in the furnace to obtain gray-black LiFe 0.99 Ni 0.01 PO 4 / C target product.

[0042] The carbon content in the prepared lithium iron phosphate material is 3%, the thickness of the carbon film on the particle surface is about 4nm, and the degree of graphitization i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com