Titanium and zirconium co-doped carbon-coated lithium iron phosphate material as well as preparation method and application thereof

A carbon-coated lithium iron phosphate and co-doping technology is applied in the preparation/purification of carbon, chemical instruments and methods, phosphorus compounds, etc. Electrical conductivity, cheap and wide range of raw materials, effect of improving compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the titanium and zirconium co-doped carbon-coated lithium iron phosphate material of the present invention is to mix iron phosphate, lithium carbonate, carbon source, titanium source and zirconium source in a liquid medium, and the mixture is ball milled and sand milled After reaching a certain slurry particle size, spray drying technology is used for granulation, and finally the dried spray material is sintered in an atmosphere furnace and then crushed to finally obtain titanium and zirconium co-doped carbon-coated lithium iron phosphate material; the specific steps are as follows :

[0025] (1) Weigh iron phosphate, lithium carbonate, titanium source and zirconium source according to the element molar ratio Li:Zr:Fe:Ti:P = 1-y:y:1-x:x:1 and put them in the liquid medium Mixing in, where 0.001≤x≤0.05, 0.001≤y≤0.02;

[0026] (2) Add carbon source to the mixture obtained in step (1) and then perform ball milling and sand milling, so that the pa...

Embodiment 1

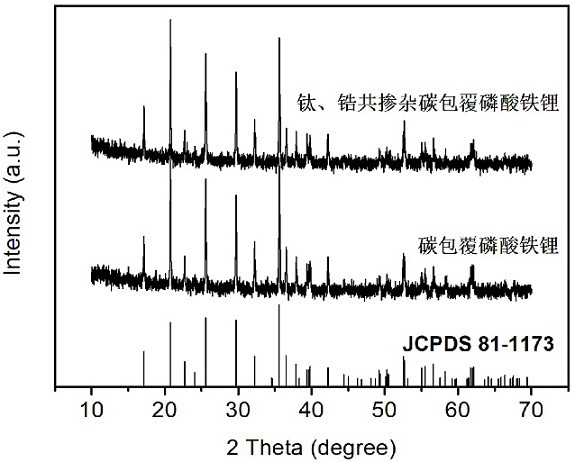

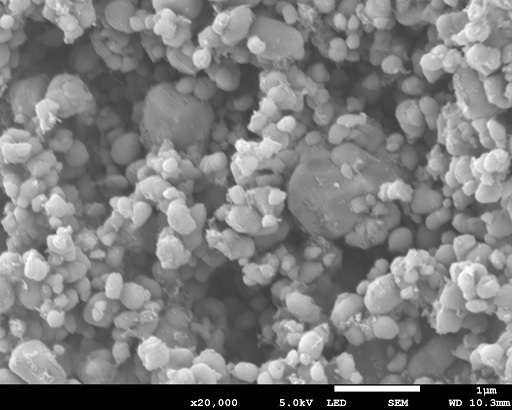

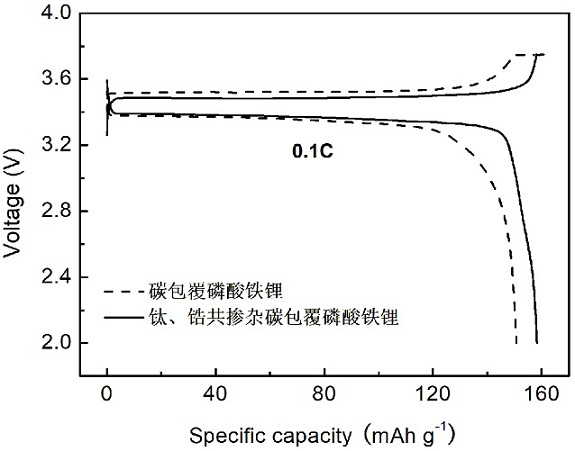

[0041] Iron phosphate, lithium carbonate, tetrabutyl titanate and zirconium hydroxide are weighed according to the elemental molar ratio Li:Zr:Fe:Ti:P =0.985:0.015:0.99:0.01:1 and mixed in deionized water; After adding glucose to the mixture, it was ball-milled and sand-milled to control the particle size of the slurry at 0.4 µm; the slurry was spray-dried, the atomization frequency was 50 Hz, and the temperature of the heated air inlet was 200 °C. The tuyere temperature is 100°C; finally, the dry spray material is pre-sintered at 350°C for 3 hours in an atmosphere furnace filled with argon, and then sintered at 800°C for 10 hours; after the calcination is completed, it can be pulverized to obtain a black powder of titanium and zirconium co-doped Carbon-coated lithium iron phosphate material with a carbon content of 0.5wt% and a discharge capacity of 158.3 mAh g at 0.1C –1 , the first Coulombic efficiency is 98.4%, and the discharge capacity of 1C is 145.5 mAh g –1 , compacte...

Embodiment 2

[0043] Iron phosphate, lithium carbonate, titanium dioxide and zirconia are weighed and mixed in deionized water according to the elemental molar ratio Li:Zr:Fe:Ti:P = 0.98:0.02:0.96:0.04:1; After adding sucrose, it is ball milled and sand milled to control the particle size of the slurry at 0.2µm; the slurry is spray-dried, the atomization frequency is 60Hz, the temperature of the heated air inlet is 150°C, and the temperature of the air outlet is 70°C ;Finally, pre-sinter the dry spray material at 300°C for 5h in an atmosphere furnace filled with nitrogen, and then continue to sinter at 750°C for 12h; after the calcination is completed, it can be pulverized to obtain a black powder of titanium and zirconium co-doped carbon-coated lithium iron phosphate material, the carbon content of the material is 1.1wt%, and the discharge capacity at 0.1C is 159.1 mAh g –1 , the first Coulombic efficiency is 97.3%, and the discharge capacity of 1C is 148.0 mAh g –1 , compacted density 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com