Oxygen-vacancy-containing lithium ferrous silicate and carbon composite anode material and preparation method

A technology of lithium ferrosilicate and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as inability to apply power batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

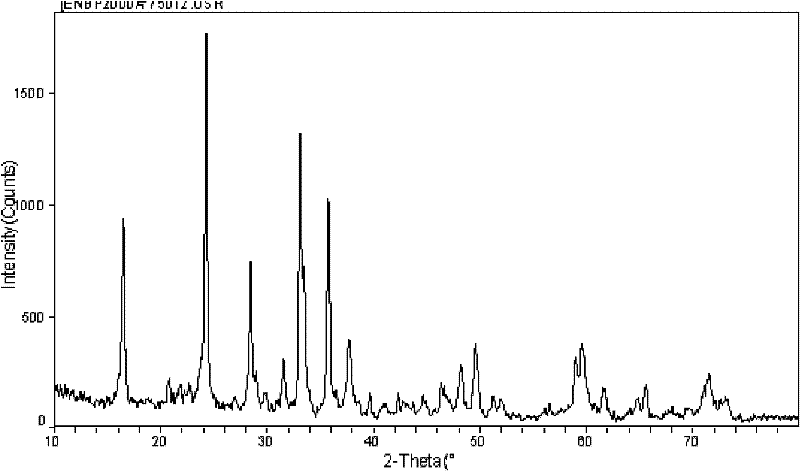

[0028] 1.799 g FeC 2 o 4 2H 2 O and 2.08 g Si(OC 2 h 5 ) 4 Mixed, added to 150ml of ethylenediamine (accounting for 20wt%) in absolute ethanol, the pH value was controlled at 9, after stirring vigorously at room temperature for 6h, 2.04g of LiAc·2H was added 2 O and 0.2 g of glucose, the temperature was raised to 80°C for 12h, and then dried at 100°C to obtain a xerogel. Transfer it to a porcelain boat in a tube resistance furnace under Ar / H 2 (H 2 accounted for 3% of the volume), first heated to 400°C at a rate of 5°C / min for 12 hours, then cooled to room temperature at a rate of 5°C / min, took out the powder and pressed it into tablets, and then calcined at a temperature of 700°C After 24 hours, it was naturally lowered to room temperature to obtain an oxygen-vacancy-containing lithium ferrous silicate / carbon composite material. The obtained material is orthorhombic and the space group is Pmn21 through target XRD analysis. A bulk crystal with a particle size of about...

Embodiment 2

[0032] 1.24 g FeAc 2 4H 2 O and 2.08 g Si(OC 2 h 5 ) 4 Mixed, added to 150ml of N-ethylethylenediamine (accounting for 20wt%) absolute ethanol, the pH value was controlled at 10, after stirring vigorously at room temperature for 12h, 2.04g of LiAc·2H was added 2 O and 0.3 g of glucose, the temperature was raised to 90° C. for 24 hours, and then dried at 100° C. to obtain a xerogel. Transfer it to a porcelain boat in a tube resistance furnace under Ar / H 2 (Ar accounted for 3% of the volume), first heated to 450°C at a rate of 5°C / min for 12 hours, then cooled to room temperature at a rate of 5°C / min, took out the powder and pressed it, and then heated it at a temperature of 750°C The temperature was calcined for 24 hours, and it was naturally lowered to room temperature to obtain the oxygen-vacancy lithium ferrous silicate and carbon composite material Li 2 FeSiO 3.78 N 0.13 / C.

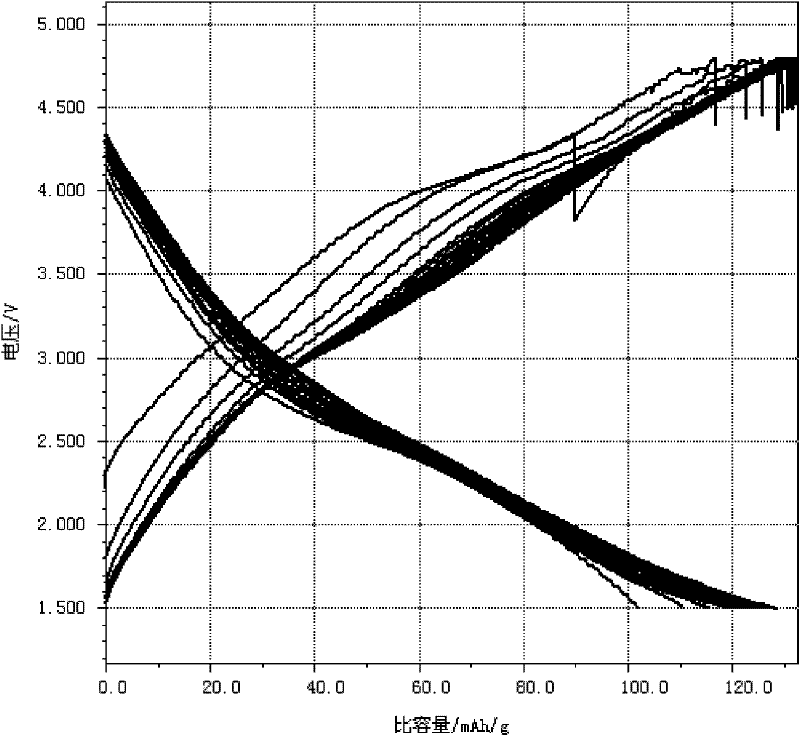

[0033] The electrochemical performance of the obtained sample is measured according to th...

Embodiment 3

[0035] 2.88 g FeC 3 h 10 o 3 and 2.08 grams of Si(OC 2 h 5 ) 4 Mixed, added to 150ml of tetramethylethylenediamine (accounting for 20wt%) in absolute ethanol, the pH value was controlled at 8.5, after vigorous stirring at room temperature for 6h, 2.04g of LiAc·2H was added 2 O and 0.1 gram of glucose, the temperature was raised to 90°C for 12h, and then dried at 100°C to obtain a xerogel. Transfer it to a porcelain boat in a tube resistance furnace under Ar / H 2 (Ar accounted for 3% of the volume), first heated to 400°C at a rate of 5°C / min for 10 h, then cooled to room temperature at a rate of 5°C / min, took out the powder and pressed it, and then heated it at a temperature of 650°C The temperature was calcined for 24 hours, and it was naturally lowered to room temperature to obtain the oxygen-vacancy lithium ferrous silicate and carbon composite material Li 2 FeSiO 3.21 N 0.48 / C.

[0036] The electrochemical performance of the obtained sample is measured according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com