A molybdenum disulfide matrix composite material for negative electrode of lithium ion capacitor and preparation method thereof

A technology of molybdenum disulfide and composite materials, which is applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of limited ion diffusion depth and poor conductivity, and achieve low price and large layer Spacing, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

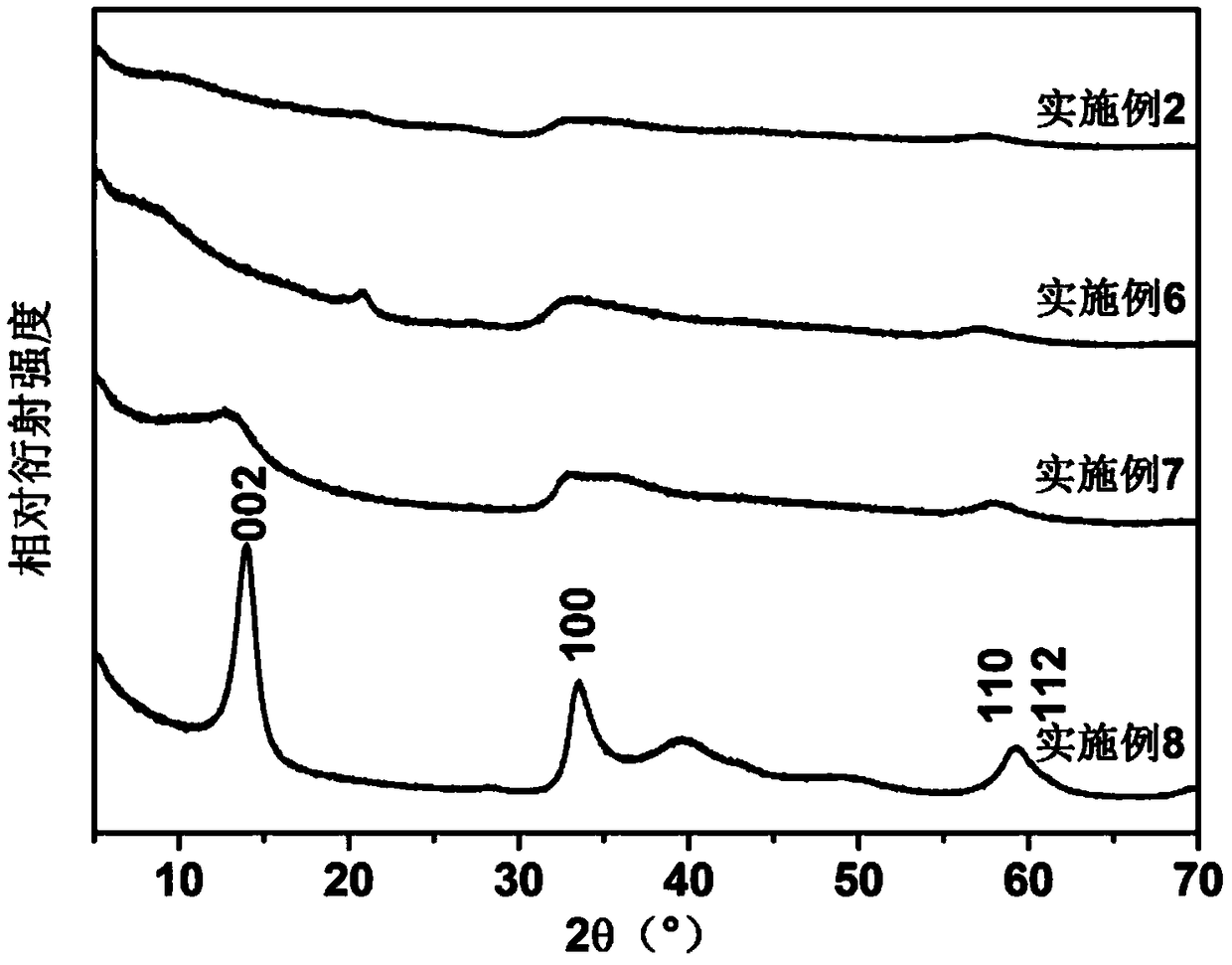

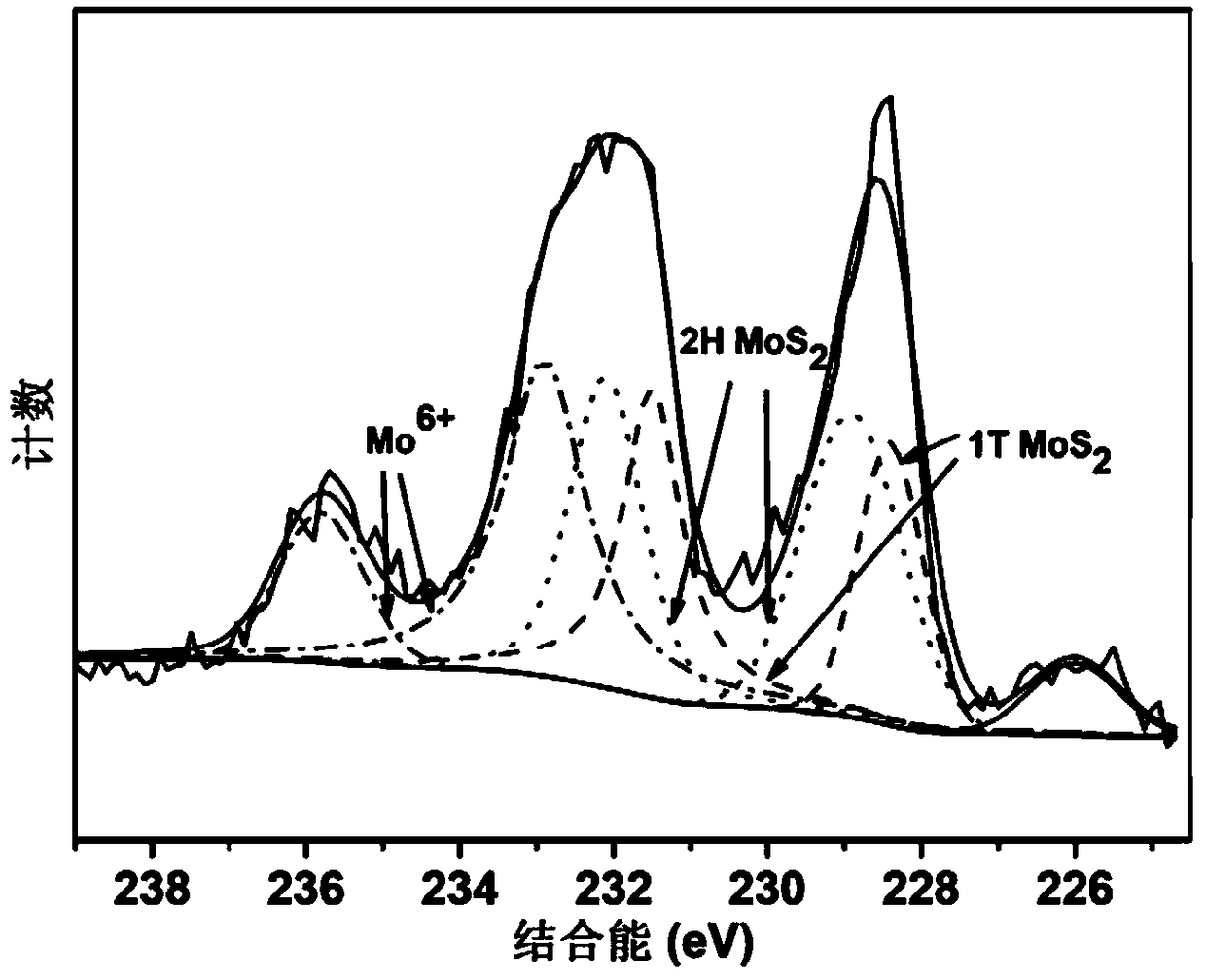

Examples

Embodiment 1

[0047] A method for preparing a molybdenum disulfide-based composite material for a lithium ion capacitor negative electrode, comprising the following steps:

[0048] (1) Ultrasonic disperse 100mg graphene oxide in 100ml deionized water to obtain a graphene oxide suspension; disperse 0.22g red phosphorus in 140ml deionized water and ultrasonically 5h to obtain a phosphorus dispersion; 1.65g molybdenum tetrahydrate Ammonium phosphate and 1.75g aniline were dissolved in the phosphorus dispersion to obtain a mixed solution; the graphene oxide suspension was added to the mixed solution, and 1mol / L HCl solution was added dropwise under stirring to adjust the pH of the solution to 4.0. Under reaction for 5h, P / Mo 3 o 10 (C 6 h 5 NH 3 ) 2 4H 2 O / graphene oxide precursor;

[0049] (2) 1.35g P / Mo 3 o 10 (C 6 h 5 NH 3 ) 2 4H 2 O / graphene oxide precursor and 2.4g potassium persulfate were dispersed in 100ml and 60ml deionized water respectively, and then the pH of the abo...

Embodiment 2

[0052] A method for preparing a molybdenum disulfide-based composite material for a lithium ion capacitor negative electrode, comprising the following steps:

[0053] (1) Ultrasonic disperse 300mg graphene oxide in 100ml deionized water to obtain a graphene oxide suspension; disperse 0.22g red phosphorus in 140ml deionized water and ultrasonically 5h to obtain a phosphorus dispersion; 1.65g molybdenum tetrahydrate Ammonium phosphate and 1.75g aniline were dissolved in the phosphorus dispersion to obtain a mixed solution; the graphene oxide suspension was added to the mixed solution, and 1mol / L HCl solution was added dropwise under stirring to adjust the pH of the solution to 4.0. Under reaction for 5h, P / Mo 3 o 10 (C 6 h 5 NH 3 ) 2 4H 2 O / graphene oxide precursor;

[0054] (2) 1.35g P / Mo 3 o 10 (C 6 h 5 NH 3 ) 2 4H 2 O / graphene oxide precursor and 2.4g potassium persulfate were dispersed in 100ml and 60ml deionized water respectively, and then the pH of the abo...

Embodiment 3

[0058] The molybdenum disulfide-based composite material (P-MoS 2 / PANI / rGO composite material) preparation method, except that pH is 5.0 in step (1), all the other are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com