Preparation method of zirconium-doped cerium fluoride coated nickel-cobalt-manganese ternary positive electrode material and prepared positive electrode material

A nickel-cobalt-manganese ternary, positive electrode material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor capacity and cycle performance of positive electrode materials, achieve good electrochemical inertness, good stability, and shorten the diffusion path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

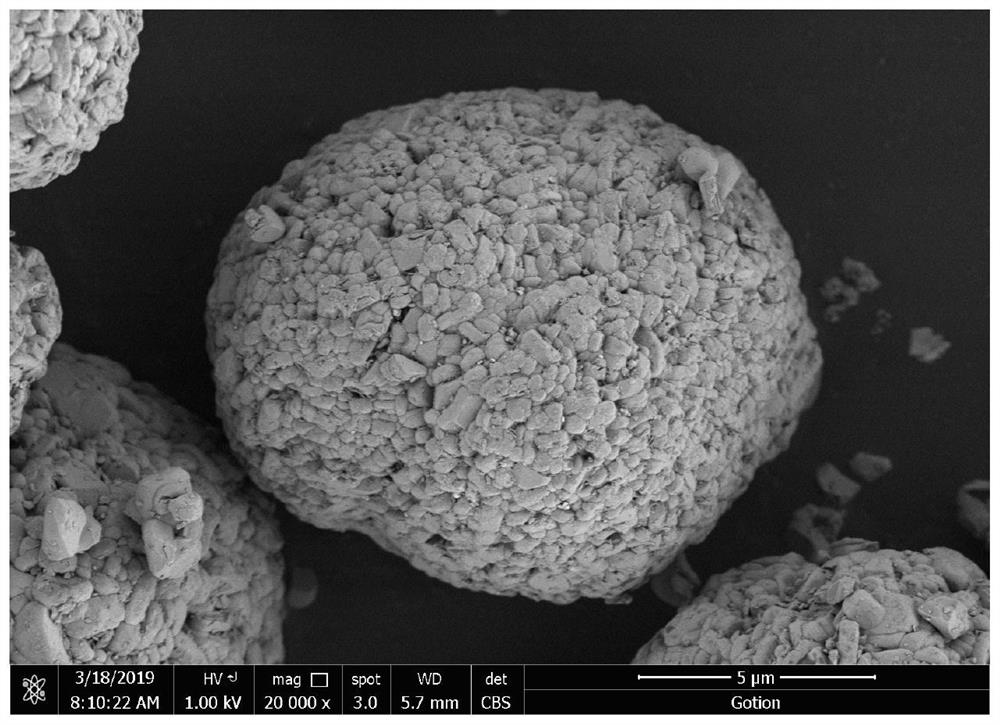

Embodiment 1

[0036] A method for preparing a zirconium-doped cerium fluoride-coated nickel-cobalt-manganese ternary positive electrode material, specifically comprising the following steps:

[0037] (1) 100g of nickel-cobalt-manganese hydroxide precursor powder, 47.94g of lithium hydroxide powder (the lithiation ratio is 1.05) and 0.2026g of zirconia were ball milled for 2 hours at a ball mill speed of 300r / min, and then In a tube furnace, heat up to 480°C at a heating rate of 2°C / min and hold for 5 hours (the first step of sintering), then raise the temperature at a rate of 2°C / min to 800°C and hold for 15 hours (second step of sintering); After cooling, it is ground and sieved to obtain nickel-cobalt-manganese lithium oxide powder, which is the zirconium-doped nickel-cobalt-manganese ternary positive electrode material. In this embodiment, the material ratio of nickel:cobalt:manganese in the nickel-cobalt-manganese hydroxide precursor is 8:1:1.

[0038] (2) Weigh cerium nitrate and put ...

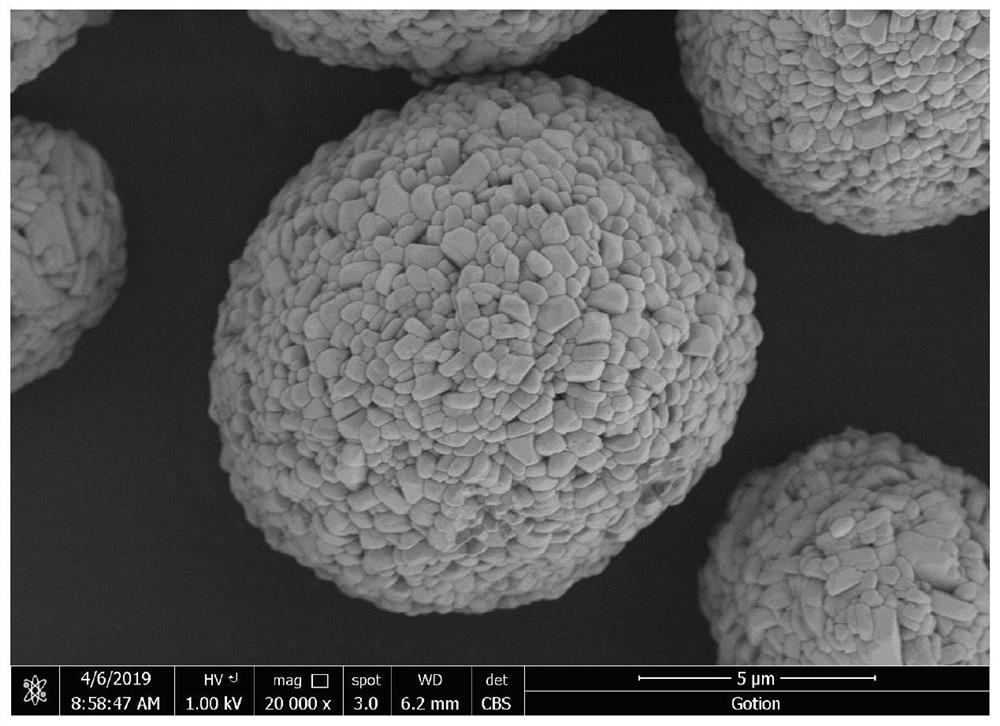

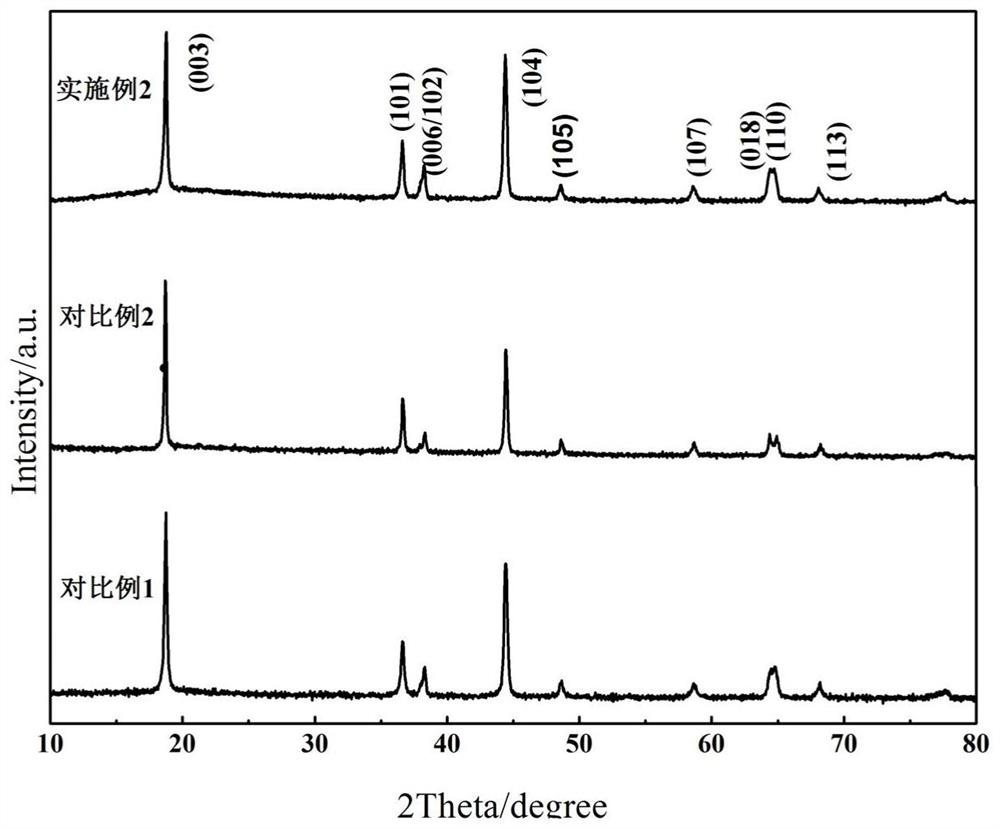

Embodiment 2

[0042] The difference between this example and Example 1 is that the total mass of cerium fluoride in step (2) is 1% of the weight of the nickel-cobalt-manganese-lithium oxide powder, so that zirconium-doped cerium fluoride-coated nickel-cobalt is obtained. Manganese ternary cathode material 2. The positive electrode of the battery was fabricated and tested in the same steps as in Example 1. The electrochemical properties of the product are shown in Table 1.

Embodiment 3

[0044] The difference between this example and Example 1 is that the total mass of cerium fluoride in step (2) is 2% of the weight of the nickel-cobalt-manganese-lithium oxide powder, so that zirconium-doped cerium fluoride-coated nickel-cobalt is obtained. Manganese ternary cathode material3. The positive electrode of the battery was fabricated and tested in the same steps as in Example 1. The electrochemical properties of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com