Preparation method of graphene/nano-carbon-black modified viscose fibers

A technology of nano-carbon black and graphene, which is applied in the direction of artificial filament made of viscose, can solve the problem of graphene oxide insulation properties being unsuitable, achieve broad market prospects and application value, increase electrical conductivity, and disperse the effect Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

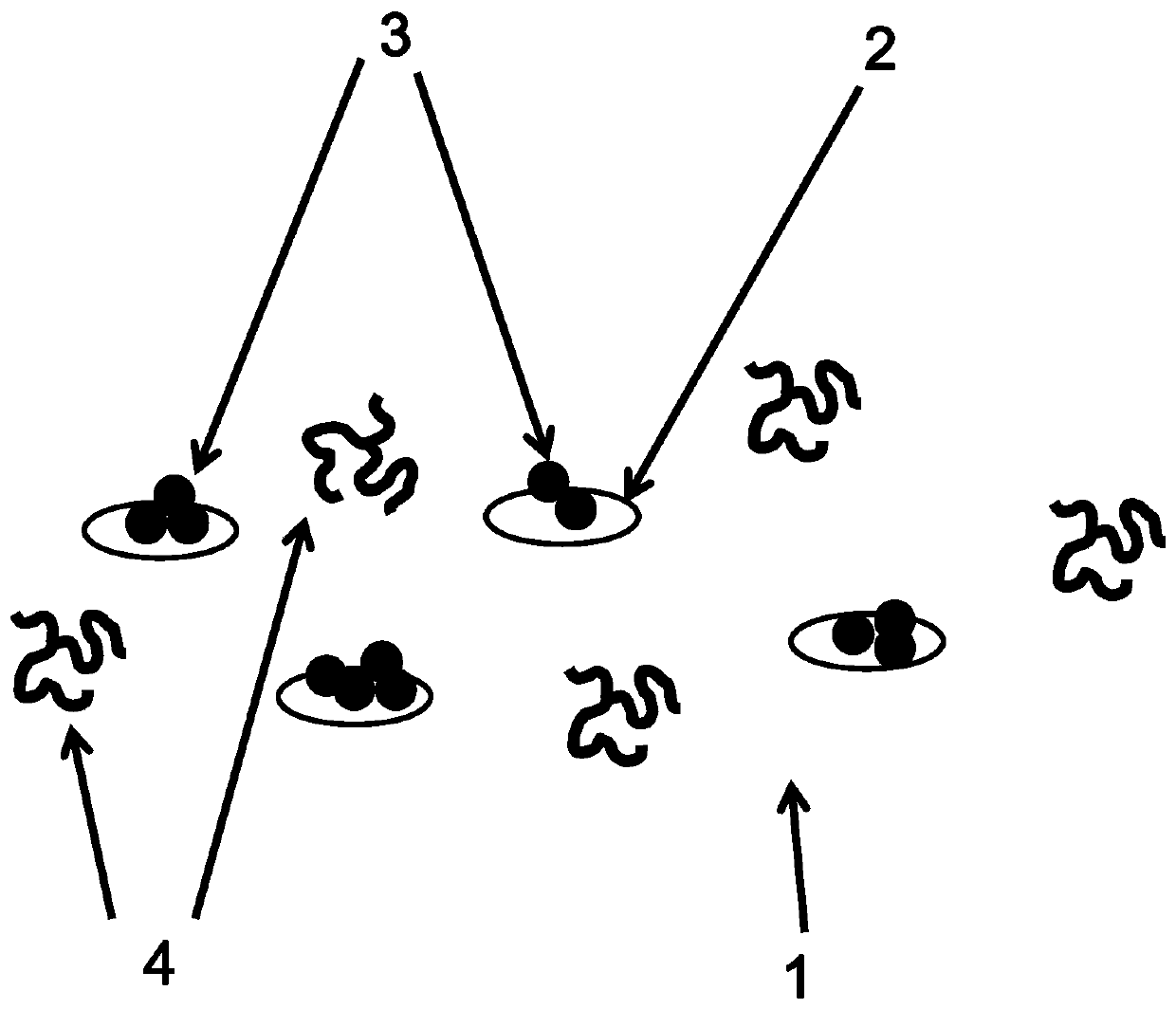

Method used

Image

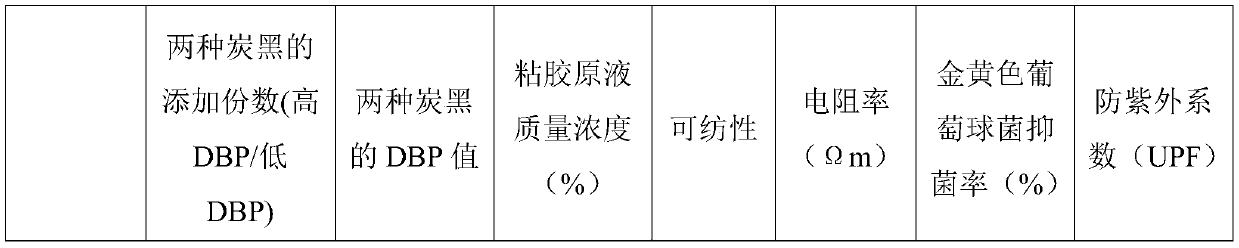

Examples

Embodiment 1

[0022] (1) Add 0.01 mass parts sodium hydroxide to 25 mass parts, mass concentration is 2mg / g graphene oxide aqueous dispersion liquid, mix and stir evenly, obtain mixed solution, wherein the carbon-oxygen ratio of graphene oxide is 3;

[0023] (2) Add 0.1 mass part of nano-carbon black with low DBP value and 0.02 mass part of nano-carbon black with high DBP value to the mixed liquid obtained in step (1), and stir and react at 100°C for 1 hour to obtain a mixed dispersion liquid, in which nano-carbon black is mixed. Carbon black gross weight is 0.12 mass parts, and the DBP value of high DBP value nano-carbon black is 380, and the DBP value of low DBP value nano-carbon black is 200;

[0024] (3) Add 100 parts by mass, a viscose spinning stock solution with a cellulose content of 12wt% in the mixed dispersion obtained in step (2), after mixing uniformly, form, draft, and spin in a coagulation bath by spinneret spinning Washing, desulfurization, oiling, drying, and packing to obt...

Embodiment 2

[0027] (1) Add 0.01 mass parts sodium hydroxide to 25 mass parts, mass concentration is 2mg / g graphene oxide aqueous dispersion liquid, mix and stir evenly, obtain mixed solution, wherein the carbon-oxygen ratio of graphene oxide is 3;

[0028] (2) Add 0.15 parts by mass of nano-carbon black with a low DBP value and 0.05 parts by mass of nano-carbon black with a high DBP value to the mixed solution obtained in step (1), stir and react at 100°C for 1 hour to obtain a mixed dispersion, in which nano-carbon black is mixed Carbon black gross weight is 0.2 mass part, and the DBP value of high DBP value nano-carbon black is 360, and the DBP value of low DBP value nano-carbon black is 240;

[0029] (3) Add 100 parts by mass, a viscose spinning stock solution with a cellulose content of 12wt% in the mixed dispersion obtained in step (2), after mixing uniformly, form, draft, and spin in a coagulation bath by spinneret spinning Washing, desulfurization, oiling, drying, and packing to ob...

Embodiment 3

[0032] (1) Add 0.01 mass part of sodium hydroxide to 25 mass parts, the graphene oxide water dispersion liquid that mass concentration is 2mg / g and mix and stir evenly, obtain mixed solution, wherein the carbon-oxygen ratio of graphene oxide is 7;

[0033] (2) Add 0.03 parts by mass of nano-carbon black with low DBP value and 0.01 part by mass of nano-carbon black with high DBP value to the mixed solution obtained in step (1), and stir and react at 100°C for 1 hour to obtain a mixed dispersion, in which nano-carbon black is mixed with Carbon black gross weight is 0.04 mass parts, and the DBP value of high DBP value nano-carbon black is 360, and the DBP value of low DBP value nano-carbon black is 280;

[0034] (3) Add 100 parts by mass, a viscose spinning stock solution with a cellulose content of 12wt% in the mixed dispersion obtained in step (2), after mixing uniformly, form, draft, and spin in a coagulation bath by spinneret spinning Washing, desulfurization, oiling, drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com