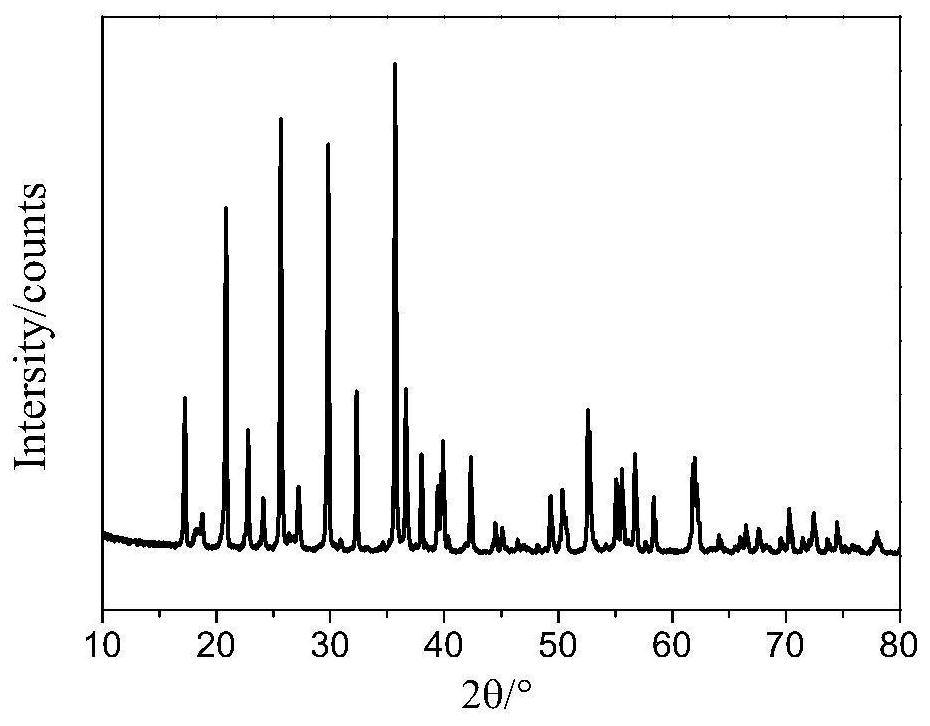

A kind of lithium iron phosphate/lithium vanadium fluorophosphate/carbon composite cathode material and preparation method thereof

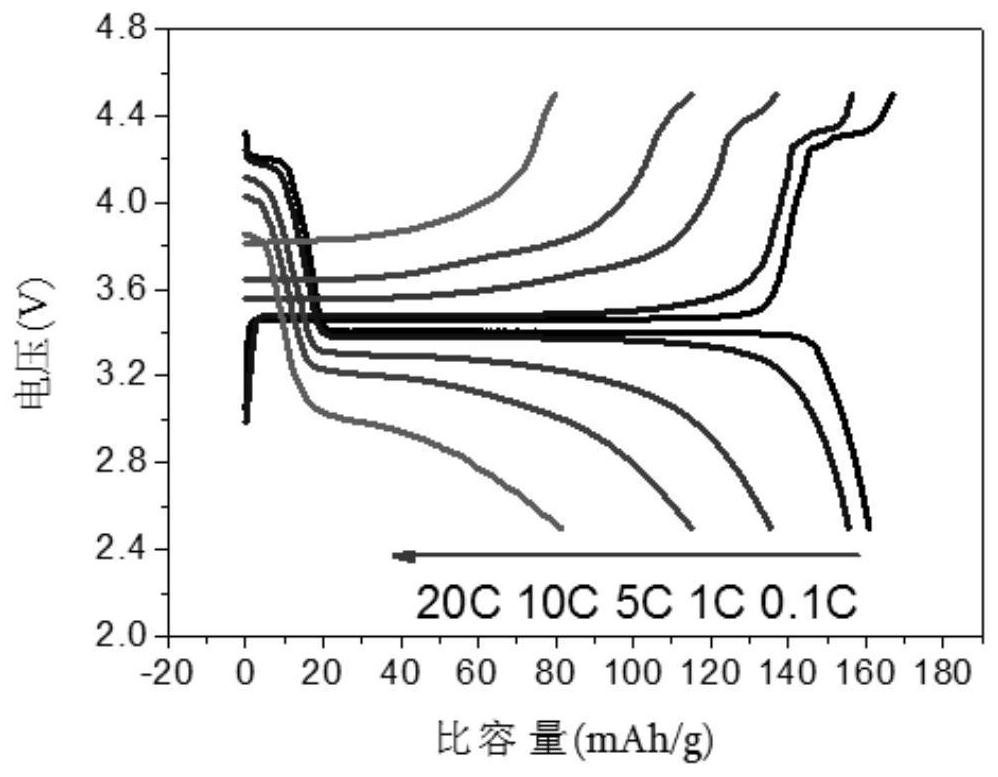

A composite positive electrode material, lithium vanadium phosphate technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of low discharge specific capacity and specific energy, and achieve improved discharge specific capacity, good high rate performance, multiple The effect of the migration channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

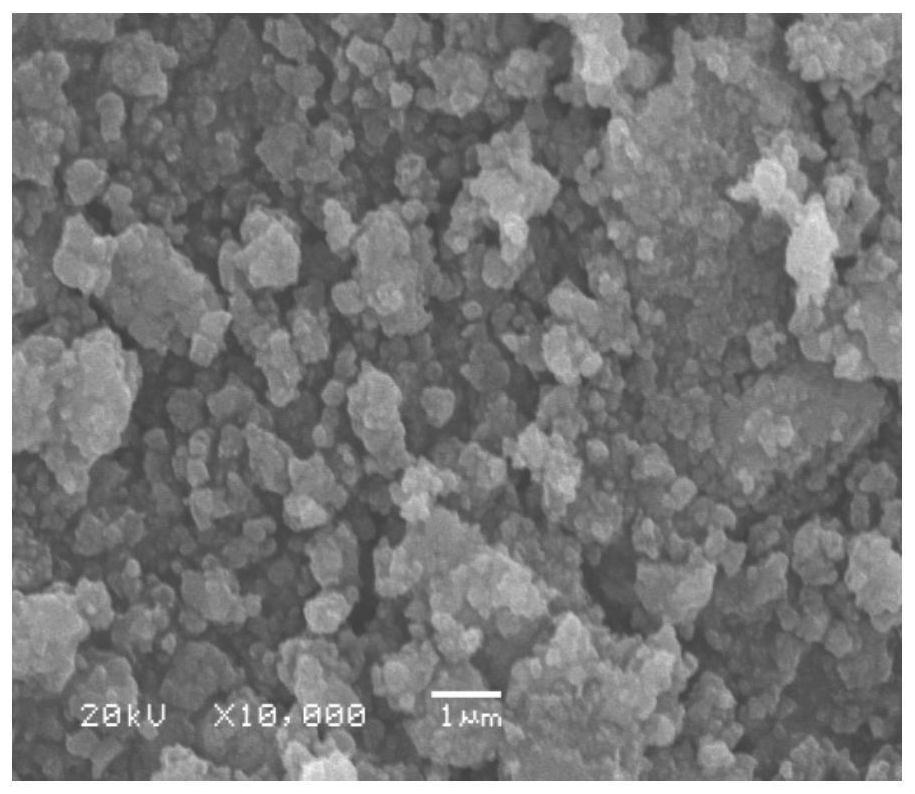

Embodiment 1

[0045]Weigh 300.2g of iron phosphate, 76.89g of lithium carbonate and 40g of glucose into an ultra-fine stirring mill, add 1600ml of deionized water, mix with an ultra-fine stirring mill, and then spray dry and granulate at 300°C , to obtain the lithium iron phosphate precursor, and then sintering at 550 ° C, heat preservation for 6 hours, to obtain the pre-lithium iron phosphate positive electrode material for use; weigh 2.902g ammonium dihydrogen phosphate, 2.285g vanadium pentoxide, and 5.7304g oxalic acid respectively in a beaker , 80ml of absolute alcohol was measured in the beaker in advance, and it was mixed with ultrasonic assisted stirring, and then vacuum-dried at 100°C, sintered at 750°C, and kept for 8 hours to obtain VPO 4 The intermediate is standby; then weigh 0.6552g lithium fluoride and the VPO obtained above 4 Intermediate and 76g pre-lithium iron phosphate positive electrode material, composite material mass ratio (lithium iron phosphate: lithium vanadium ph...

Embodiment 2

[0048] Weigh 300.2g of iron phosphate, 76.89g of lithium carbonate and 40g of glucose into an ultra-fine stirring mill, add 1600ml of deionized water, mix with a stirring mill at 300r / min for 4h, and then spray dry at 300°C Granulation treatment to obtain the lithium iron phosphate precursor, followed by sintering at 550°C and heat preservation for 6 hours to obtain the lithium iron phosphate phase material for use; weigh 1.4451g ammonium dihydrogen phosphate, 1.1425g vanadium pentoxide, and 2.8652g oxalic acid respectively in In the beaker, 50ml of absolute alcohol was measured in advance in the beaker, and it was mixed with ultrasonic-assisted stirring, and then vacuum-dried at 100°C, sintered at 750°C, and kept for 8 hours to obtain VPO 4 The intermediate is standby; then weigh 0.3276g lithium fluoride and the VPO obtained above 4 The intermediate and 18g of pre-lithium iron phosphate positive electrode material, the mass ratio of the composite material (lithium iron phosph...

Embodiment 3

[0052] Weigh 300.2g of iron phosphate, 76.89g of lithium carbonate and 40g of glucose into an ultra-fine stirring mill, add 1600ml of deionized water, mix with an ultra-fine stirring mill, and then spray dry and granulate at 300°C , to obtain the lithium iron phosphate precursor, and then sintering at 550 ° C, heat preservation for 6 hours, to obtain the pre-lithium iron phosphate positive electrode material for use; weigh 1.4451g ammonium dihydrogen phosphate, 1.1425g vanadium pentoxide, and 2.8652g oxalic acid respectively in a beaker , 50ml of absolute alcohol was measured in the beaker in advance, and it was mixed with ultrasonic assisted stirring, and then vacuum-dried at 100°C, sintered at 750°C, and kept for 8 hours to obtain VPO 4 The intermediate is standby; then weigh 0.3276g lithium fluoride and the VPO obtained above 4 Intermediate and 8g pre-lithium iron phosphate positive electrode material, composite material mass ratio (lithium iron phosphate: lithium vanadium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com