Soft carbon-coated boron-doped silicon-based negative electrode material and preparation method and application thereof

A technology of silicon-based negative electrode materials and doping materials, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of limiting the diffusion rate of lithium ions, limiting practical applications, and poor conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 provides a soft carbon-coated boron-doped silicon-based negative electrode material.

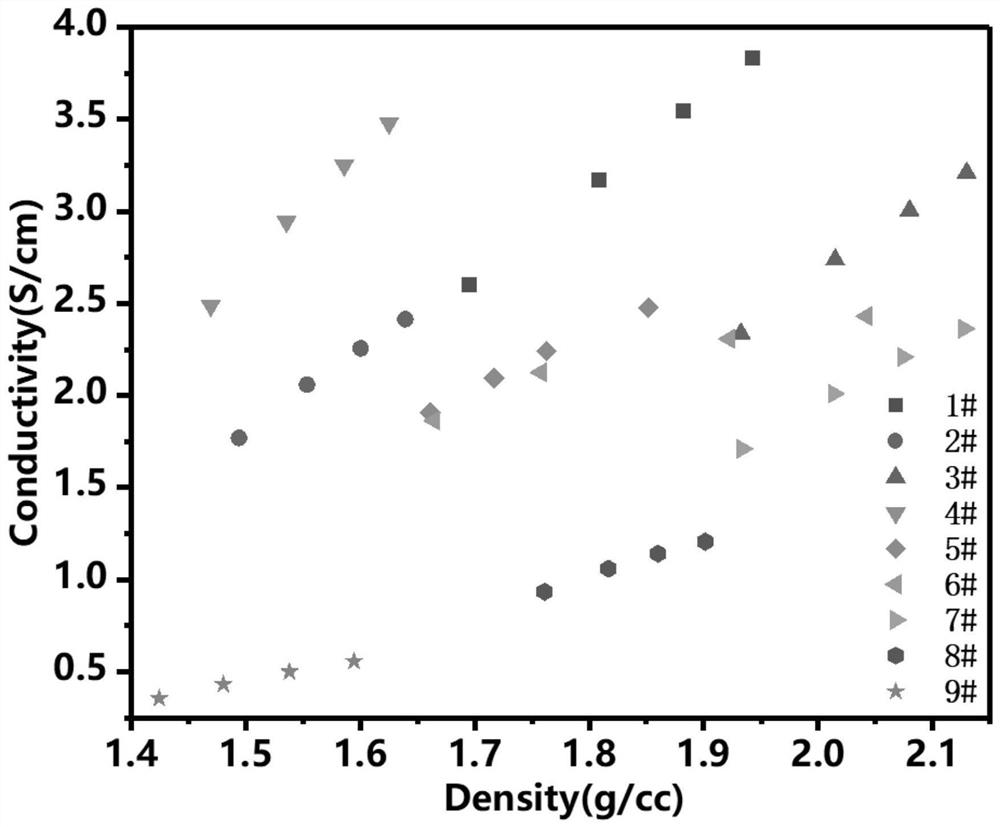

[0040] The soft carbon-coated boron-doped silicon-based lithium-ion battery anode material of this embodiment is designated as sample 1#. It is composed of 96wt% silicon oxide, 0.8wt% sodium borohydride and 3.2wt% soft carbon coated outside.

[0041] The specific preparation process is as follows: Sodium borohydride and silicon oxide are spray-dried in the above ratio to obtain the primary product, and then the primary product is placed in a high-temperature rotary furnace under an argon atmosphere to raise the temperature to 1200 ° C, and the volume ratio is 1:1. Chemical vapor deposition was carried out on propylene with an equal amount of argon, and the temperature was kept for 2 hours. The gas source was turned off and the temperature was lowered to obtain sample 1#.

[0042] Weigh the obtained negative electrode material, conductive additive carbon black, sodium cel...

Embodiment 2

[0046] Embodiment 2 provides a soft carbon-coated boron-doped silicon-based negative electrode material.

[0047] The soft carbon-coated boron-doped silicon-based lithium-ion battery anode material of this embodiment is designated as sample 2#. It is composed of 95.9wt% doped silicon oxide, 1wt% boron chloride and 3.1wt% soft carbon coated outside.

[0048] The specific preparation process is as follows: Boron chloride and doped silicon oxide are mixed mechanically in the above ratio to obtain the primary product, and then the primary product is placed in a high-temperature rotary furnace under an argon atmosphere and the temperature is raised to 1200°C, with a volume ratio of 1:1 Pass in propane equivalent to argon gas for chemical vapor deposition, keep warm for 2.5 hours, turn off the gas source and cool down to obtain sample 2#.

[0049] The preparation of the negative electrode sheet, battery assembly and testing process are the same as in Example 1. The test results sho...

Embodiment 3

[0052] Embodiment 3 provides a soft carbon-coated boron-doped silicon-based negative electrode material.

[0053] The soft carbon-coated boron-doped silicon-based lithium-ion battery anode material of this embodiment is designated as sample 3#. It is composed of 97wt% modified silicon oxide, 0.2wt% boron trioxide and 2.8wt% soft carbon coated outside. The specific preparation process is as follows: Diboron trioxide and modified silicon oxide are mixed mechanically in the above ratio to obtain the primary product, and then the primary product is placed in a high-temperature rotary furnace under an argon atmosphere to raise the temperature to 1100°C, and the volume ratio is 1:1 Introduce a mixed gas of methane and propylene equal to that of argon for chemical vapor deposition, keep it warm for 3 hours, turn off the gas source and cool down to obtain sample 3#. In the mixed gas, the ratio of methane and propylene is 2:1.

[0054] The preparation of the negative electrode sheet,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com