A transition metal-doped sodium titanomanganese phosphate/carbon composite positive electrode material and its preparation and application in sodium-ion batteries

A composite positive electrode material, titanium manganese sodium phosphate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult capacity, poor rate performance, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

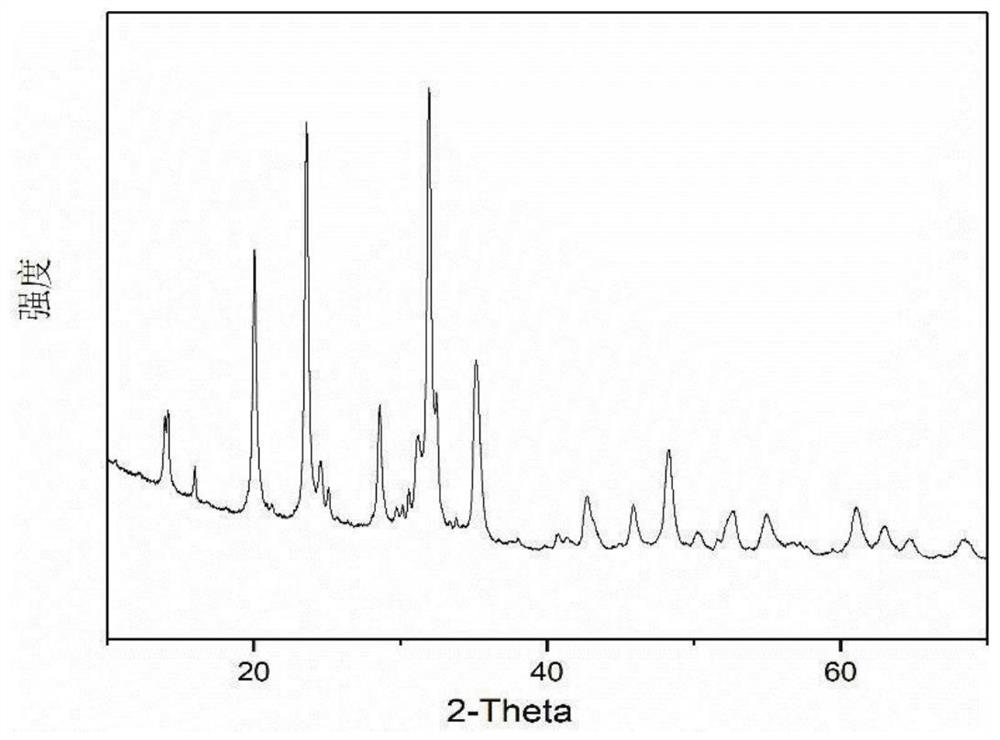

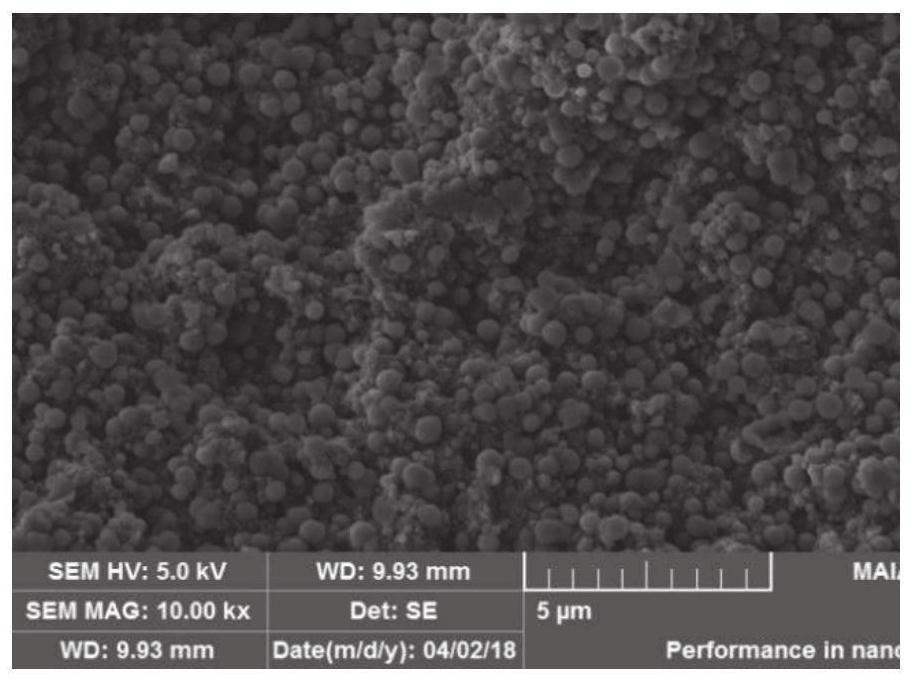

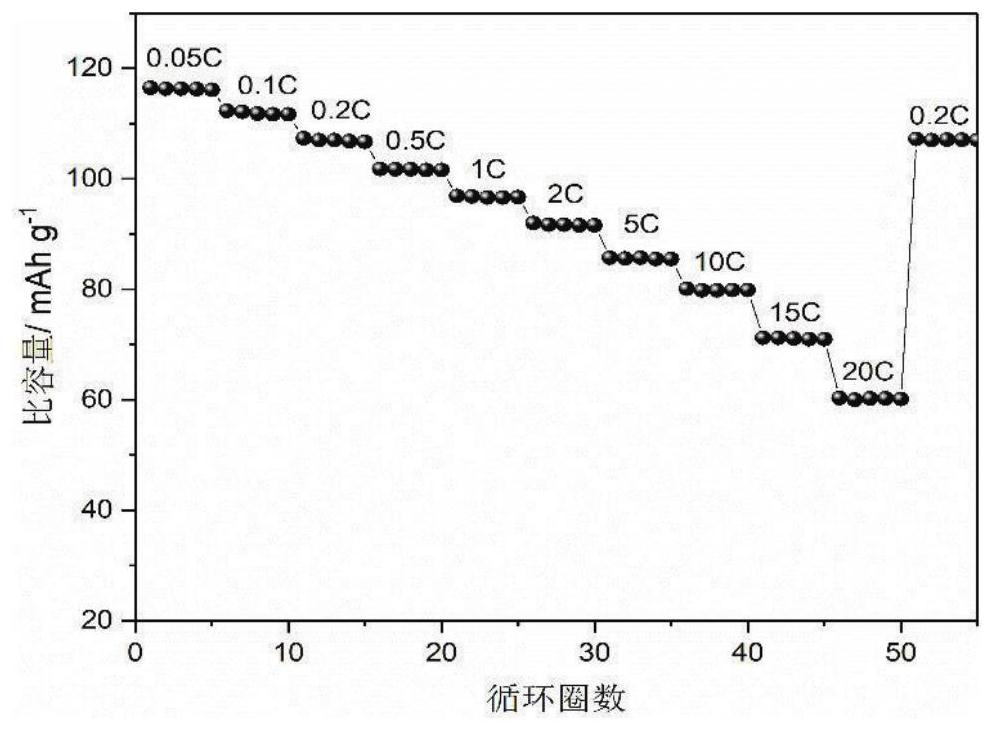

[0061] Take 0.015 mol of sodium acetate, 0.0045 mol of manganese acetate, 0.005 mol of tetrabutyl titanate, 0.0005 mol of iron acetate, 0.015 mol of ammonium dihydrogen phosphate and 0.5 g of polyvinylpyrrolidone, and dissolve them in 100 mL of deionized water in sequence. The solution was transferred to a reaction kettle, and the spherical precursor was synthesized by hydrothermal treatment at 180 °C for 24 hours; the precursor was treated at 650 °C for 6 h under an argon atmosphere to obtain nitrogen-doped carbon-modified spherical Na 3 mn 0.9 Fe 0.1 Ti(PO 4 ) 3 / C Composite. The produced Na 3 mn 0.9 Fe 0.1 Ti(PO 4 ) 3 The X-ray diffraction pattern (XRD) of / C cathode material sees figure 1 . The produced Na 3 mn 0.9 Fe 0.1 Ti(PO 4 ) 3 The shape of / C is spherical, and the particle size is 200-500nm.

[0062] The positive electrode material of the sodium ion battery prepared in this example and the sodium sheet are assembled into a button battery, as can be s...

Embodiment 2

[0064] Take 0.015mol sodium acetate, 0.004mol manganese acetate, 0.005mol tetrabutyl titanate, 0.001mol iron acetate, 0.015mol ammonium dihydrogen phosphate and 0.5g polyvinylpyrrolidone, and dissolve them in 100mL deionized water in sequence. The solution was transferred to a reaction kettle and subjected to hydrothermal treatment at 180°C for 24 hours to synthesize a spherical precursor; the precursor was treated at 650°C for 5 hours under an argon atmosphere to obtain nitrogen-doped carbon-modified spherical Na 3 mn 0.8 Fe 0.2 Ti(PO 4 ) 3 / C Composite. The sodium ion battery cathode material prepared in this embodiment and the sodium sheet are assembled into a button battery, and Na 3 mn 0.8 Fe 0.2 Ti(PO 4 ) 3 The / C sodium-ion battery has a specific capacity of 107.5mAh / g at a rate of 0.05C, and a specific capacity of 47.2mAh / g at a high rate of 20C.

Embodiment 3

[0066] Take 0.015mol sodium acetate, 0.0045mol manganese acetate, 0.005mol tetrabutyl titanate, 0.0005mol cobalt acetate, 0.015mol ammonium dihydrogen phosphate and 0.5g polyvinylpyrrolidone, and dissolve them in 100mL deionized water in sequence. The solution was transferred to a reaction kettle and subjected to hydrothermal treatment at 180°C for 24 hours to synthesize a spherical precursor; the precursor was treated at 650°C for 5 hours under an argon atmosphere to obtain nitrogen-doped carbon-modified spherical Na 3 mn 0.9 co 0.1 Ti(PO 4 ) 3 / C Composite. The sodium ion battery cathode material prepared in this embodiment and the sodium sheet are assembled into a button battery, and Na 3 mn 0.9 co 0.1 Ti(PO 4 ) 3 The / C sodium-ion battery has a specific capacity of 117.5mAh / g at a rate of 0.05C, and a specific capacity of 63.6mAh / g at a high rate of 20C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com