Graphene antistatic additive for floor paint as well as preparation method and application thereof

A graphene and anti-static technology, applied in the direction of anti-corrosion coatings, conductive coatings, paints containing biocides, etc., can solve the problems of poor conductivity, short life, poor anti-oxidation performance, etc., to improve wear resistance, long life, and construction short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

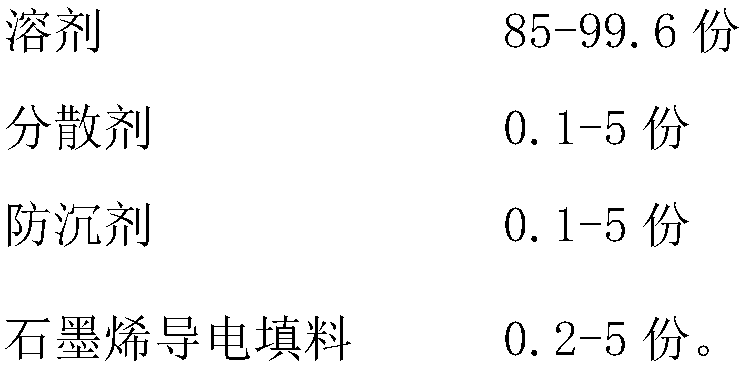

[0027] A kind of graphene antistatic additive for floor paint, proportioning is as follows:

[0028]

[0029] Concrete process route is: join weighed dispersant and anti-sedimentation agent in the solvent medium speed (1000 rev / min) stir and mix 30 minutes, then graphene conductive filler is added in the solvent gradually, constantly slow speed ( 500 rev / min) stirring to make the conductive filler infiltrate quickly. After the addition is completed, seal and mix rapidly (2000 rpm) for 1-3 hours at a low temperature of 10° C., and the prepared slurry can be used as an antistatic additive. The proportion of antistatic additives used is 4% of the floor paint. 4% addition ratio can achieve square resistance at 10 8 Ω-level anti-static effect, and can also effectively improve the wear-resistant, stain-resistant, waterproof, and anti-corrosion properties of the floor paint.

Embodiment 2

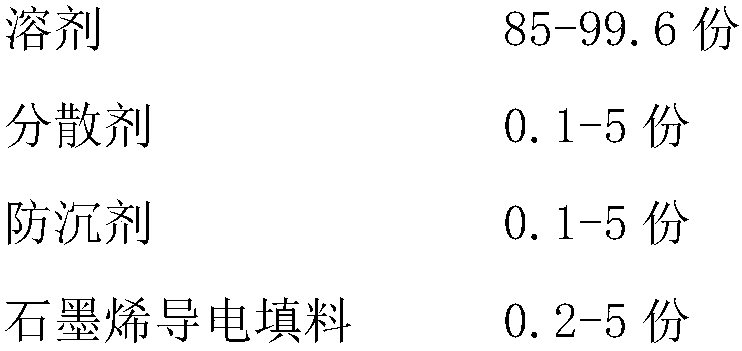

[0031] A kind of graphene antistatic additive for floor paint, proportioning is as follows:

[0032]

[0033] Concrete process route is: join weighed dispersant and anti-sedimentation agent in the solvent medium speed (1000 rev / min) stir and mix 30 minutes, then graphene conductive filler is added in the solvent gradually, constantly slow speed ( 500 rev / min) stirring to make the conductive filler infiltrate quickly. After the addition is completed, seal and mix rapidly (2000 rpm) for 1-3 hours at a low temperature of 10° C., and the prepared slurry can be used as an antistatic additive. The proportion of antistatic additives used is 6% of the floor paint. 6% addition ratio can achieve square resistance at 10 7 Ω-level anti-static effect, and can also effectively improve the wear-resistant, stain-resistant, waterproof, and anti-corrosion properties of the floor paint.

Embodiment 3

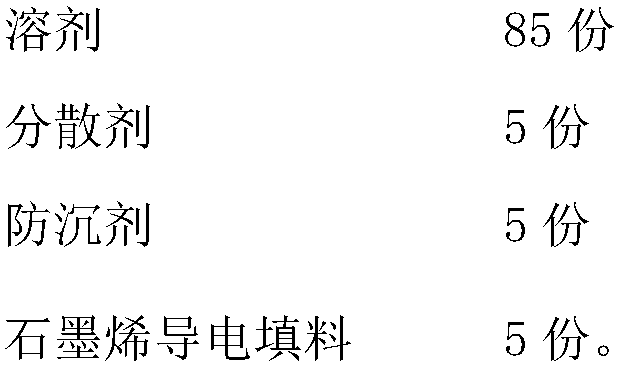

[0035] A kind of graphene antistatic additive for floor paint, proportioning is as follows:

[0036]

[0037] Concrete process route is: join weighed dispersant and anti-sedimentation agent in the solvent medium speed (1000 rev / min) stir and mix 30 minutes, then graphene conductive filler is added in the solvent gradually, constantly slow speed ( 500 rev / min) stirring to make the conductive filler infiltrate quickly. After the addition is completed, seal and mix rapidly (2000 rpm) for 1-3 hours at a low temperature of 10° C., and the prepared slurry can be used as an antistatic additive. The proportion of antistatic additives used is 8% of the floor paint. 8% addition ratio can achieve square resistance at 10 8 Ω-level anti-static effect, and can also effectively improve the wear-resistant, stain-resistant, waterproof, and anti-corrosion properties of the floor paint.

[0038] The antistatic additive for floor paint involved in the present invention is suitable for vario...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com