Liquid seashell powder interior wall coating and preparation method thereof

A technology for interior wall paint and shell powder, which is applied in conductive coatings, coatings and other directions, can solve the problems of toxic substances, large errors, and difficulty in construction of dry powder shell powder coatings, so as to extend the shelf life, facilitate construction, Good anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

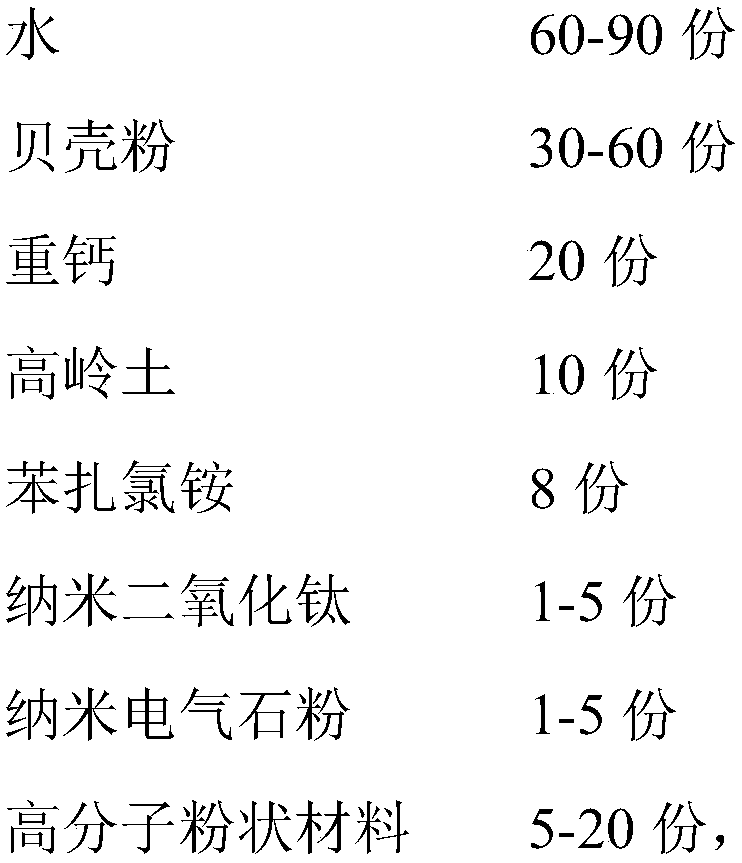

[0021] A liquid shell powder interior wall paint, the paint is based on natural or artificially cultivated shell powder, and simultaneously adds nano-titanium dioxide and nano-tourmaline powder and polymer powdery materials irradiated with cobalt-60 gamma rays, which includes The components in parts by weight are:

[0022]

[0023]

[0024] The particle size of the shell powder is 500 mesh.

[0025] A preparation method of liquid shell powder interior wall paint, comprising the following steps:

[0026] The first step: firstly, the nano-titanium dioxide and nano-tourmaline powder need to be surface-modified, and the nano-titanium dioxide and nano-tourmaline powder are irradiated with cobalt-60 gamma rays. The irradiation dose: 20Mrad; irradiation temperature: 20°C; Down;

[0027] Step 2: Preparation of polymer material powder

[0028] Mix 20 parts of ethylene-vinyl acetate copolymers, 10 parts of acrylic acid copolymers and 5 parts of natural cellulose;

[0029] Step...

Embodiment 2

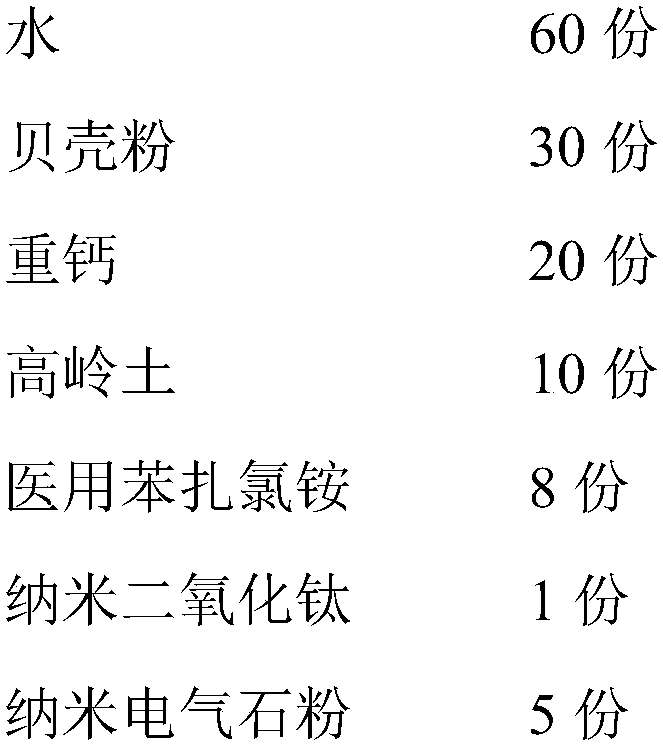

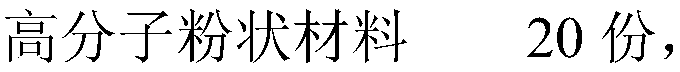

[0032] A liquid shell powder interior wall paint, the paint is based on natural or artificially cultivated shell powder, and simultaneously adds nano-titanium dioxide and nano-tourmaline powder and polymer powdery materials irradiated with cobalt-60 gamma rays, which includes The components in parts by weight are:

[0033]

[0034] The particle size of the shell powder is 1500 mesh.

[0035] A preparation method of liquid shell powder interior wall paint, comprising the following steps:

[0036] The first step: firstly, the nano-titanium dioxide and nano-tourmaline powder need to be surface-modified, and the nano-titanium dioxide and nano-tourmaline powder are irradiated with cobalt-60 gamma rays. The irradiation dose: 20Mrad; irradiation temperature: 20°C; Down;

[0037] Step 2: Preparation of polymer material powder

[0038] Mix 20 parts of ethylene-vinyl acetate copolymers, 10 parts of acrylic acid copolymers and 5 parts of natural cellulose;

[0039] Step Three: Pre...

Embodiment 3

[0042] A liquid shell powder interior wall paint, the paint is based on natural or artificially cultivated shell powder, and simultaneously adds nano-titanium dioxide and nano-tourmaline powder and polymer powdery materials irradiated with cobalt-60 gamma rays, which includes The components in parts by weight are:

[0043]

[0044] The particle size of the shell powder is 500 mesh.

[0045] A preparation method of liquid shell powder interior wall paint, comprising the following steps:

[0046] The first step: firstly, the nano-titanium dioxide and nano-tourmaline powder need to be surface-modified, and the nano-titanium dioxide and nano-tourmaline powder are irradiated with cobalt-60 gamma rays. The irradiation dose: 20Mrad; irradiation temperature: 20°C; Down;

[0047] Step 2: Preparation of polymer material powder

[0048] Mix 50 parts of ethylene-vinyl acetate copolymers, 40 parts of acrylic acid copolymers and 20 parts of natural cellulose;

[0049] Step Three: Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com