Long-acting anti-static rubber pad

An anti-static, rubber pad technology, applied in the field of polymer chemical materials, can solve problems such as increased resistance and incomplete compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

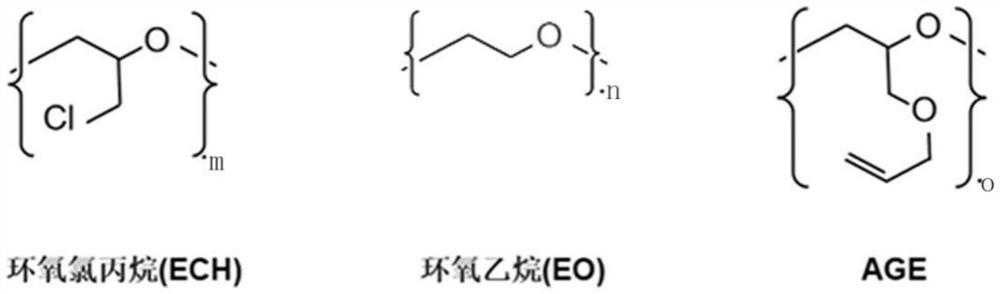

Method used

Image

Examples

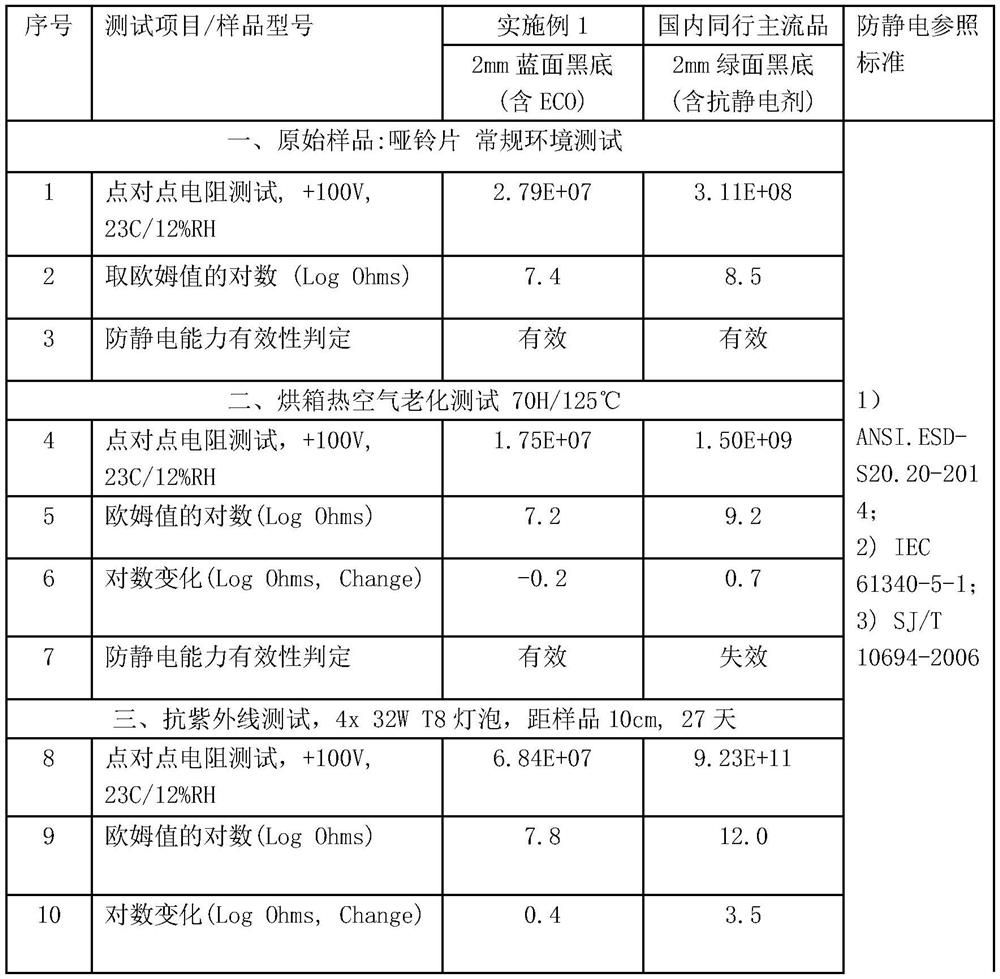

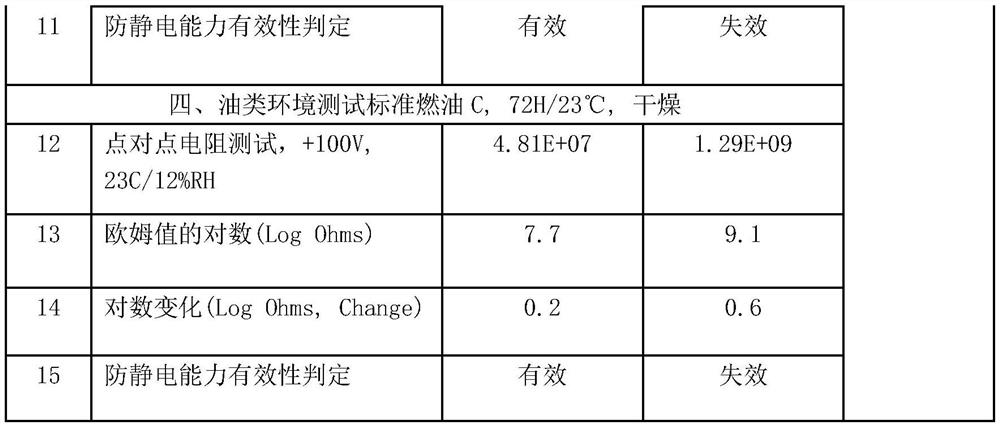

Embodiment 1

[0031] A long-lasting anti-static rubber mat, consisting of a 0.5mm upper surface static dissipative layer and a 1.5mm lower surface static conductive layer:

[0032] The static dissipative layer is composed of the following raw materials in parts by mass:

[0033] ECO Chlorine Ether Rubber 30%, Nitrile Rubber 25%, TP95 Plasticizer 10%, Silicon Dioxide 25%, Zinc Oxide 1.5%, Anti-aging Agent 1%, Softener 1%, Sulfur 0.5%, First Accelerator 6 %;

[0034] The static conductive layer is composed of the following raw materials in parts by mass: 50% of nitrile rubber, 15% of light calcium, 5% of superconducting carbon black, 10% of high wear-resistant carbon black, 10% of TP95 plasticizer, white Ointment 7%, second accelerator 7%, zinc oxide 2.5%, sulfur 0.5%, defoamer 0.%, anti-scorch agent 0.%.

[0035] The first accelerator is formed by mixing DM accelerator, PEG4000 accelerator, TT accelerator, CZ accelerator, M accelerator, and CTP accelerator in a weight ratio of 4:4:3:2:1:1;...

Embodiment 2

[0037] A long-lasting antistatic rubber mat, consisting of a 1mm upper surface static dissipative layer and a 2mm lower surface static conductive layer:

[0038] The static dissipative layer is composed of the following raw materials in parts by mass: 20% of ECO epichlorohydrin rubber, 30% of nitrile rubber, 12% of TP95 plasticizer, 30% of silicon dioxide, 3% of zinc oxide, anti-aging agent 0.6%, softener 2%, sulfur 0.4%, first accelerator 2%;

[0039] The static conductive layer is composed of the following raw materials in parts by mass: rubber 25%, light calcium 55%, superconducting carbon black 4%, high wear-resistant carbon black 4%, SD-02 plasticizer 4%, white Ointment 9%, second accelerator 1%, zinc oxide 1%, sulfur 0.6%, defoamer 0.2%, anti-scorch agent 0.2%.

[0040] The first accelerator is formed by mixing DM accelerator and PEG4000 accelerator in a weight ratio of 1:1, the rubber is formed by mixing natural rubber and styrene-butadiene rubber in a weight ratio of ...

Embodiment 3

[0042] A long-lasting antistatic rubber mat, consisting of a 2mm upper surface static dissipative layer and a 3mm lower surface static conductive layer:

[0043] The static dissipative layer is composed of the following raw materials in parts by mass: 37% of ECO epichlorohydrin rubber, 20% of nitrile rubber, 13% of TP95 plasticizer, 15% of silicon dioxide, 1% of zinc oxide, anti-aging agent 1.5%, softener 0.5%, sulfur 1%, first accelerator 11%;

[0044] The static conductive layer is composed of the following raw materials in terms of parts by mass: rubber 50%, light calcium 10%, superconducting carbon black 8%, high wear-resistant carbon black 12%, SD-02 plasticizer 1%, white Ointment 8%, second accelerator 7.2%, zinc oxide 2%, sulfur 1%, defoamer 0.5%, anti-scorch agent 0.3%.

[0045] The rubber is formed by mixing natural rubber and styrene-butadiene rubber in a weight ratio of 5:4, the first accelerator is made of PEG4000 accelerator, and the CTP accelerator is mixed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com