Bone cement with biological activity and antibacterial function and preparation method thereof

A bioactive bone cement technology, applied in the fields of materials science and medicine, can solve the problems of affecting the mechanical properties of bone cement, affecting the release rate of antibiotics, and toxic side effects, so as to speed up the bone growth process and reduce the risk of re-operation revision. The effect of clinical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

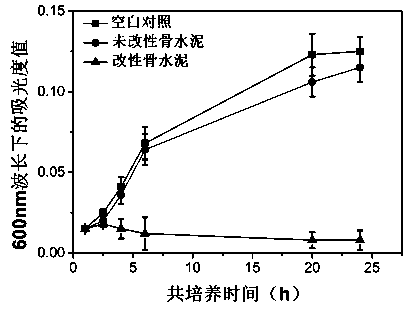

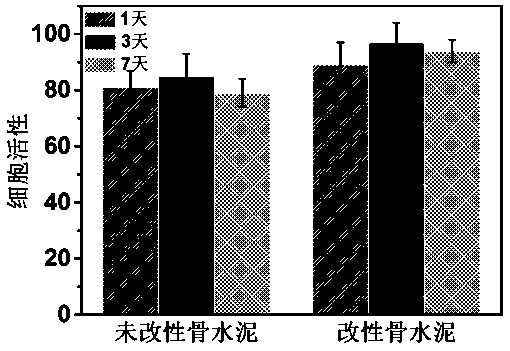

Image

Examples

preparation example Construction

[0040] The preparation method of the bone cement with biological activity and antibacterial effect comprises the following steps:

[0041](1) Preparation of antibacterial bioglass:

[0042] a. In terms of mass percentage, the method of modifying 0.05-5wt% silane coupling agent is introduced into functional groups on the surface of 95-99.95wt% bioglass;

[0043] b. In terms of mass percentage, 95-99.95wt% of the surface-modified bioglass and 0.05-5wt% of metal ions with antibacterial function are anchored through a complexation reaction;

[0044] (2) Preparation of acrylate bone cement with bioactivity and antibacterial function:

[0045] a. In terms of mass percentage, mix 59.5-99.5wt% powdered acrylate polymer, 0.5-2wt% initiator, 5-20wt% antibacterial bioglass, 10-50wt% developer, and sterilize Process to obtain the powder part of the bone cement with biological activity and antibacterial effect;

[0046] b. In terms of volume percentage, mix 95-99.9vol% of acrylate monom...

Embodiment 1

[0058] This example involves the preparation of antibacterial biological glass powder.

[0059] Disperse 9.95g of bioglass powder 45S5 into 100mL of ethanol solution, add 0.05g of silane coupling agent KH-550 after the dispersion is uniform, heat in a water bath at 60°C and stir at 100rpm for 6 hours, then suction filter and dry in an oven at 37°C; take the above steps Disperse 9.95g of the powder in 200mL ethanol solution, add 10mL 0.5wt% silver nitrate aqueous solution after dispersing evenly, stir at room temperature at 80rpm for 2 hours, then filter with suction and dry in an oven at 37°C. The glass powder is prepared.

Embodiment 2

[0061] This example involves the preparation of antibacterial biological glass powder.

[0062] Disperse 9.5g of bioglass ceravital powder into 100mL of methanol solution, add 0.5g of silane coupling agent KH-540 after the dispersion is uniform, heat in a water bath at 60°C and stir at 100rpm for 6 hours, then suction filter and dry in an oven at 37°C; take the above steps Disperse 9.5g of the powder in 200mL ethanol solution, add 10mL 5wt% silver acetate aqueous solution after dispersing evenly, stir at room temperature at 80rpm for 2 hours, then filter with suction and dry in an oven at 37°C. Powder preparation is complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com