Compound silver zinc sulfapyrimidine ointment, and its prepn. method

A technology of silver sulfadiazine and zinc sulfadiazine, which is applied in the field of drug preparation, can solve problems such as poor absorption, and achieve the effects of improving absorption and utilization, promoting wound healing, and synergistic effect and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

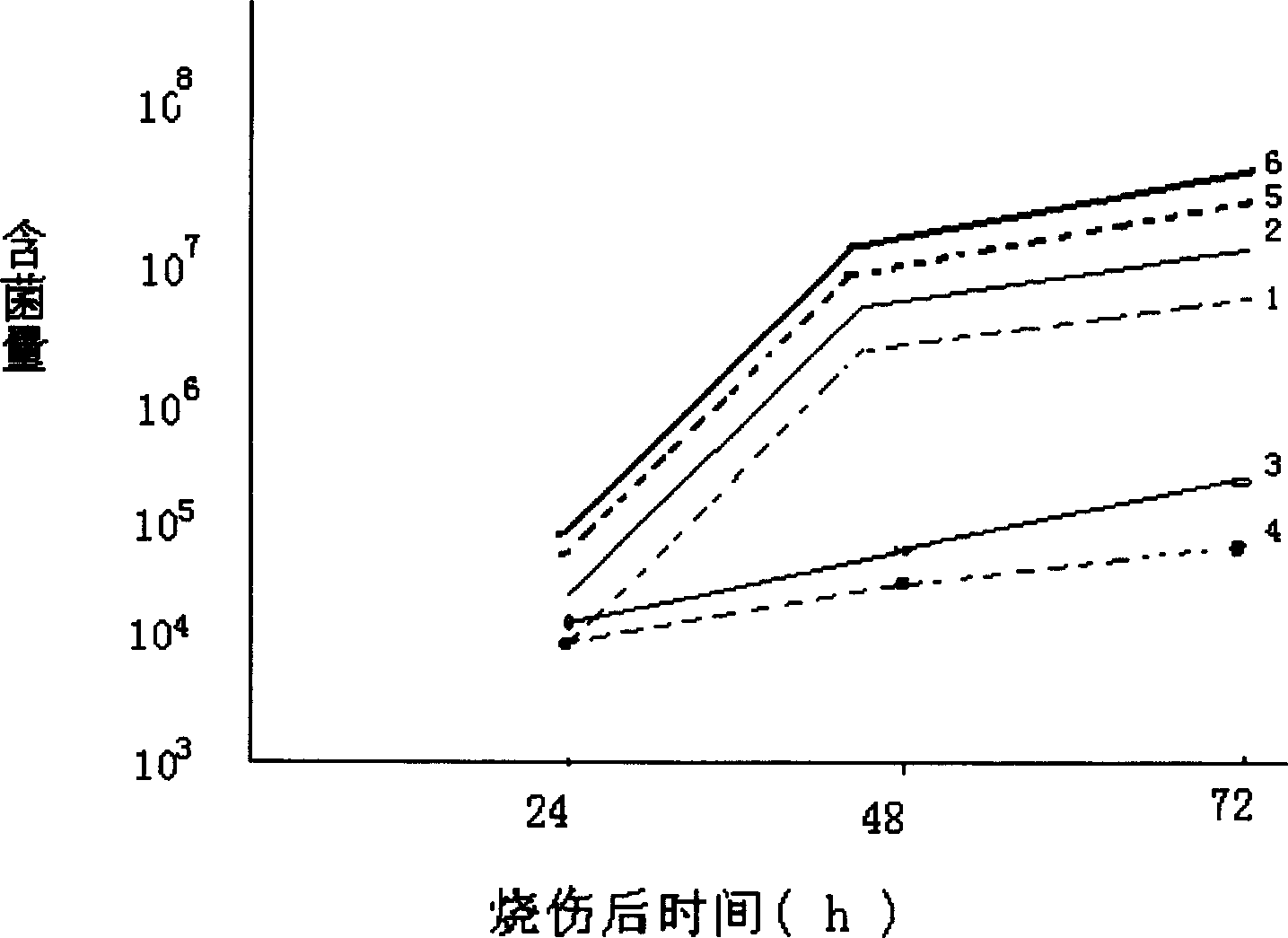

Image

Examples

Embodiment 1

[0025] The formula of the compound sulfadiazine silver-zinc ointment provided in this example is: 2 grams of sulfadiazine silver, 5 grams of sulfadiazine zinc, 50 grams of azone, 1.0 grams of ethyl p-hydroxybenzoate, 85 grams of glyceryl monostearate, white 140 grams of petrolatum, 8 grams of sodium lauryl sulfate, 110 grams of glycerin, and 600 grams of distilled water.

[0026] Its preparation method: (1) Take the above-mentioned weighed oil phase: 85 grams of glycerol monostearate, 140 grams of white petrolatum, and 50 grams of azone; put it into a beaker and heat until it melts, keeping the temperature at about 75°C;

[0027] (2) In addition, take the above-mentioned weighed water phase components: 1.0 grams of ethyl p-hydroxybenzoate, 8 grams of sodium lauryl sulfate, 110 grams of glycerin and 600 grams of distilled water, put them into a beaker and heat to melt, and keep the temperature Around 75°C;

[0028] (3) Slowly add the melted oil phase components into the water ...

Embodiment 2

[0030] Formula 2 is: 25 grams of silver sulfadiazine, 50 grams of zinc sulfadiazine, 50 grams of azone, 1.0 grams of ethyl p-hydroxybenzoate, 50 grams of glyceryl monostearate, 10 grams of stearic acid, 50 grams of lanolin, 100 grams of white petrolatum, 10 grams of sodium lauryl sulfate, 100 grams of glycerin, and 550 grams of distilled water.

[0031] Its preparation method: (1) take the above-mentioned weighed oil phase: 50 grams of glyceryl monostearate, 10 grams of stearic acid, 50 grams of lanolin, 100 grams of white petrolatum, and 50 grams of azone; put it into a beaker Heat it until it melts, and keep the temperature at about 75°C;

[0032] (2) Take the above-mentioned weighed water phase components in addition: 1.0 grams of ethyl p-hydroxybenzoate, 10 grams of sodium lauryl sulfate, 100 grams of glycerin and 550 grams of distilled water; put into a beaker and heat to melt, keep The temperature is about 75°C;

[0033] (3) Slowly add the melted oil phase ingredients ...

Embodiment 3

[0035] Formula 3 is: 10 grams of silver sulfadiazine, 10 grams of zinc sulfadiazine, 20 grams of azone, 100 grams of glycerin, 30 grams of propylene glycol, 1.0 grams of ethyl p-hydroxybenzoate, 50 grams of glyceryl monostearate, stearic acid 10 grams, 150 grams of white petrolatum, 10 grams of sodium lauryl sulfate, 609 grams of distilled water.

[0036] Its preparation method: (1) take the above-mentioned weighed oil phase: 50 grams of glyceryl monostearate, 10 grams of stearic acid, 150 grams of white vaseline, 20 grams of azone and 30 grams of propylene glycol; put into a beaker and heat Until melting, keep the temperature around 75°C;

[0037] (2) Take the above-mentioned weighed water phase components in addition: 1.0 grams of ethyl p-hydroxybenzoate, 100 grams of glycerin, 10 grams of sodium lauryl sulfate and 609 grams of distilled water; put them into a beaker and heat to melt, and keep the temperature Around 75°C;

[0038] (3) Slowly add the melted oil phase compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com