Contaminated soil repair method and repair device

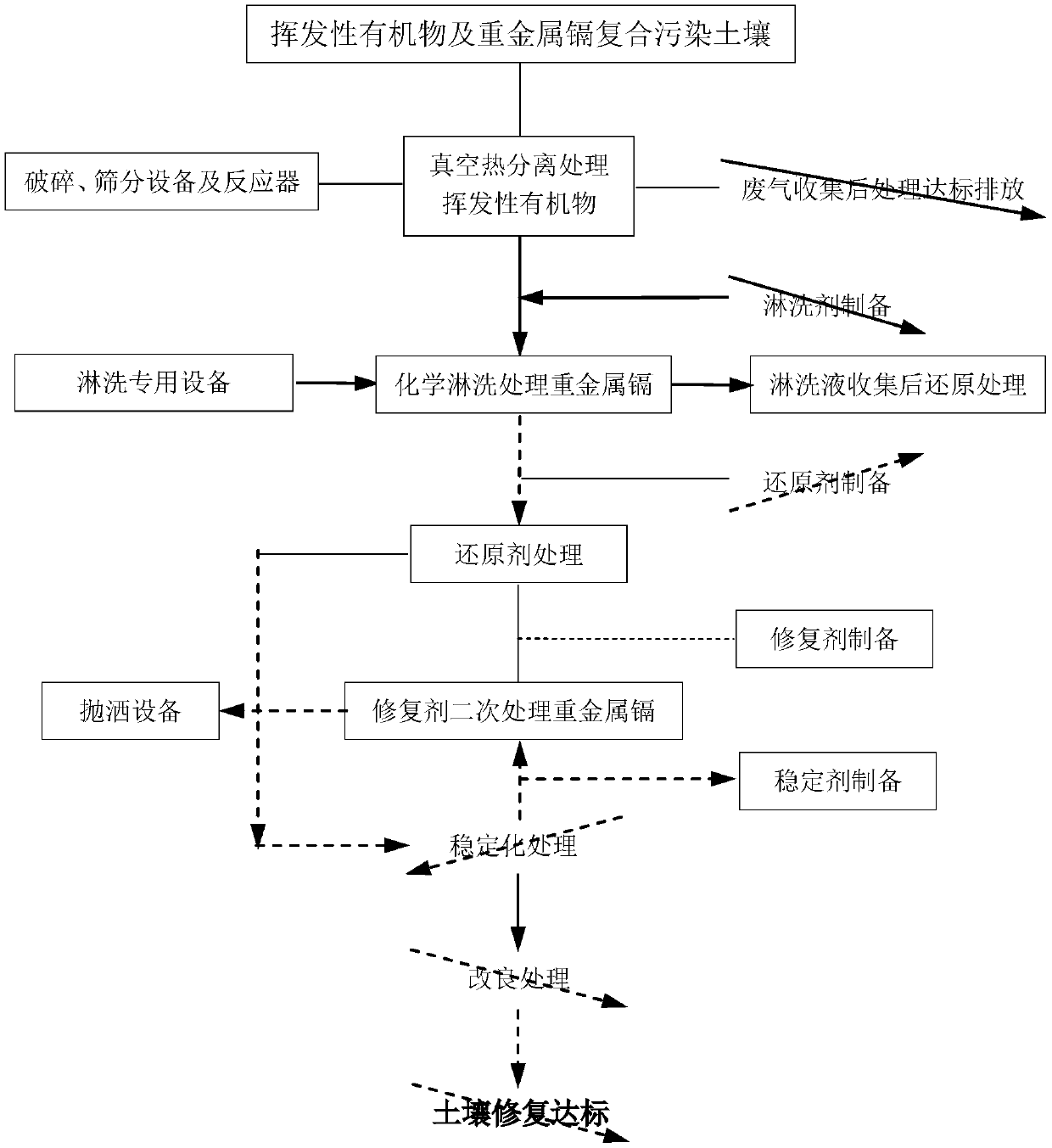

A technology for polluted soil and a remediation method is applied in the field of volatile organic compounds and heavy metal cadmium composite polluted soil remediation methods and remediation devices, which can solve the problems of low remediation efficiency, long treatment period and high treatment cost, and achieves the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

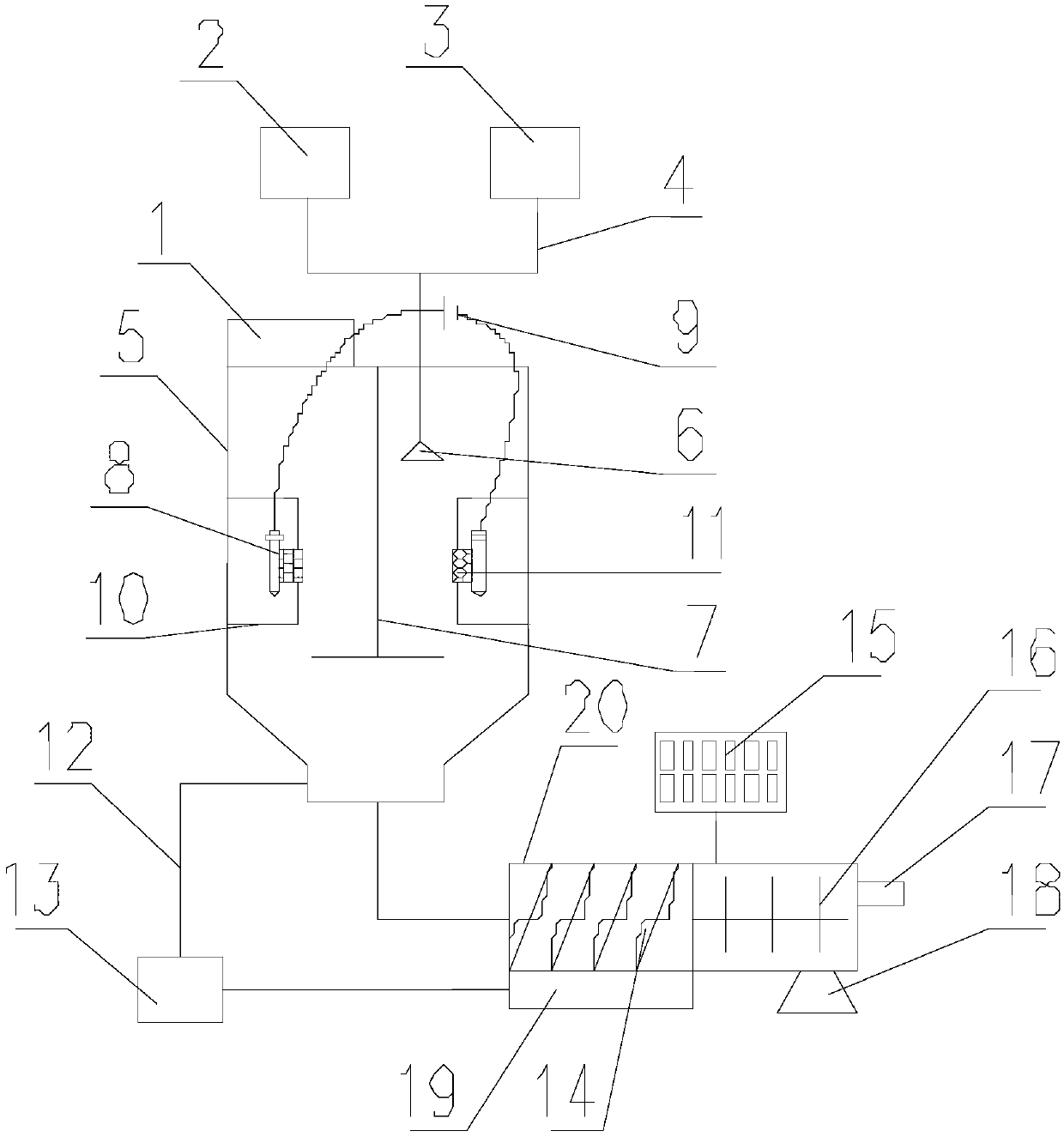

Image

Examples

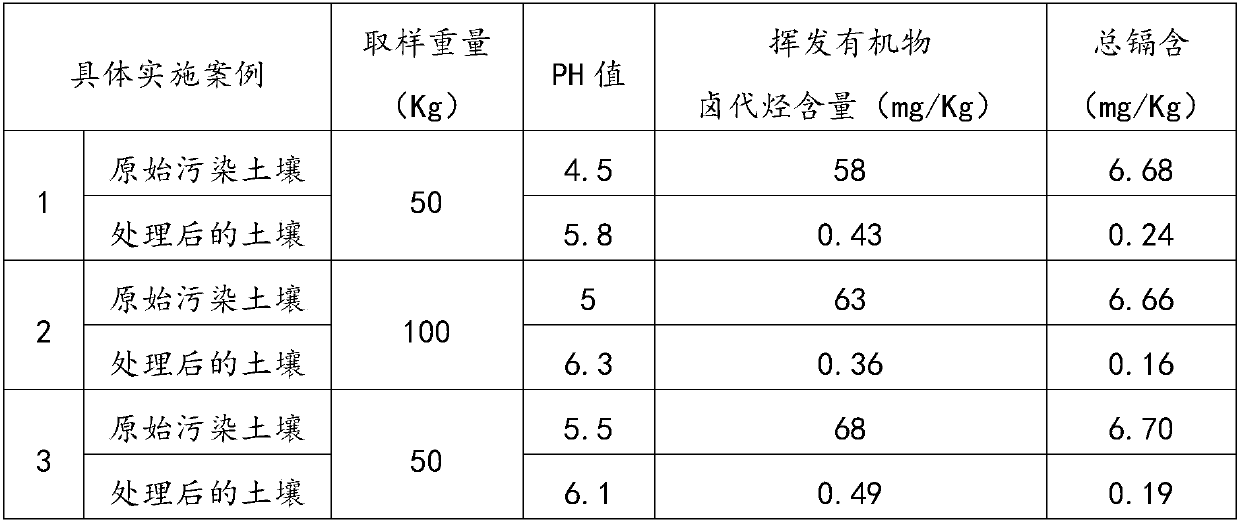

Embodiment 1

[0100]In one embodiment of the present invention, the soil of the polluted plot is dug out, and 50kg of halogenated hydrocarbon and cadmium compound polluted soil is taken, and the pH value, halogenated hydrocarbon content and total cadmium content are detected; into 3-15mm soil particles; then put the soil particles into a closed reactor, vacuumize, keep the internal pressure of the reactor at 18kpa, heat through an external device, control the internal temperature of the reactor at 145°C, and process for 15 minutes , the volatile halogenated hydrocarbons in the soil can be removed. Then the concentration of hydrochloric acid is 3mol / L, and the concentration of ethylenediaminetetraacetic acid (EDTA) is 0.04mol / L; hydrochloric acid: EDTA=1.5:1 ratio is configured into a mixed aqueous solution; The mixed aqueous solution of EDTA is used for circular washing of the soil after vacuum thermal separation for 15 minutes, and the washing liquid is collected and then subjected to redu...

Embodiment 2

[0102] In one embodiment of the present invention, the soil of the polluted plot is dug out, and 100kg of halogenated hydrocarbon and cadmium composite polluted soil is taken to detect the pH value, halogenated hydrocarbon content and total cadmium content; into 3-15mm soil particles; then put the soil particles into a closed reactor, vacuumize, keep the internal pressure of the reactor at 18kpa, and heat through an external device to control the internal temperature of the reactor at 155°C, and the processing time is 20min , the volatile halogenated hydrocarbons in the soil can be removed. Then the concentration of hydrochloric acid is 3mol / L, and the concentration of ethylenediaminetetraacetic acid (EDTA) is 0.04mol / L; hydrochloric acid: EDTA=1.5:1 ratio is configured into a mixed aqueous solution; The mixed aqueous solution of EDTA and EDTA is used for circular washing of the soil after vacuum thermal separation for 25 minutes, and the washing liquid is collected and then s...

Embodiment 3

[0106] In one embodiment of the present invention, the soil of the polluted plot is dug out, and 50kg of halogenated hydrocarbon and cadmium compound polluted soil is taken, and the pH value, halogenated hydrocarbon content and total cadmium content are detected; into 3 ~ 15mm soil particles; then put the soil particles into a closed reactor, vacuumize, keep the internal pressure of the reactor at 18kpa, heat through an external device, control the internal temperature of the reactor at 165°C, and process for 15 minutes , the volatile halogenated hydrocarbons in the soil can be removed. Then the concentration of hydrochloric acid is 3mol / L, and the concentration of ethylenediaminetetraacetic acid (EDTA) is 0.04mol / L; hydrochloric acid: EDTA=1.5:1 ratio is configured into a mixed aqueous solution; The mixed aqueous solution of EDTA is used to circulate and wash the soil after vacuum thermal separation for 20 minutes, and the washing liquid is collected and then subjected to red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com