One-bathing integrated finishing method for real silk fabric by natural extract

A technology of natural extracts and silk fabrics, applied in dyeing, fiber treatment, animal fibers, etc., to achieve the effect of shortening the processing procedure and improving the degree of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

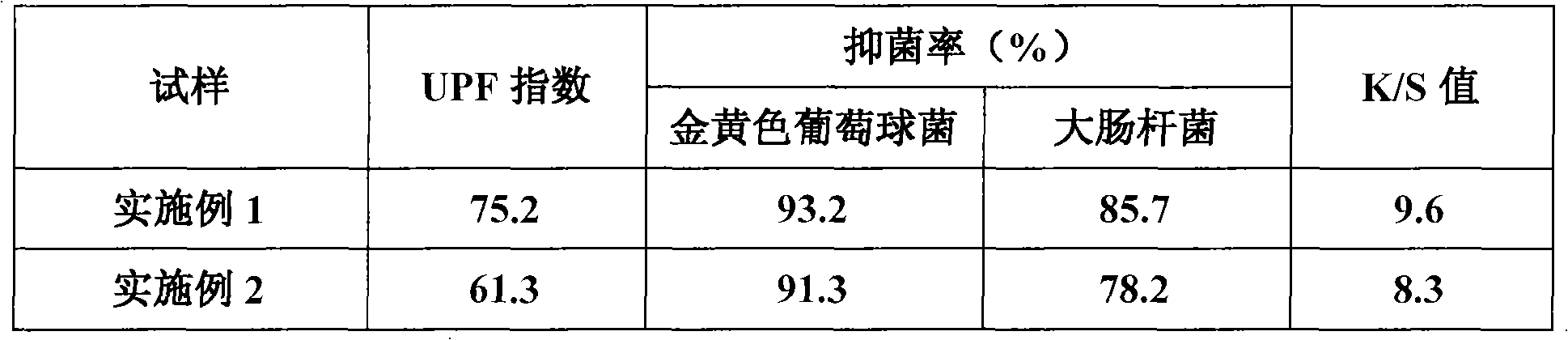

Examples

Embodiment 1

[0017] The composition of natural extracts used in this example includes (based on solid mass): 10 parts of Scutellaria baicalensis extract, 5 parts of Coptidis Rhizoma extract, 2 parts of gallnut extract, and 8 parts of lac extract. In actual use, natural extracts include shellac extract, and two or more of the extracts of Coptidis Rhizoma, Scutellaria, Pomegranate Peel, Houttuynia cordata, and Honeysuckle; One or more of them; the selection of components and proportions of each natural extract can be determined according to the product color and the index requirements of anti-ultraviolet and antibacterial functions. The above-mentioned natural extracts are active ingredients extracted from their plants or other natural products. The extraction method is the prior art. For example, the extracts of Scutellaria baicalensis and Coptis chinensis can be extracted at 100°C with water as the solvent, and the concentrate after vacuum distillation The extract method of Galla gall is t...

Embodiment 2

[0022] The composition of the natural extract used in this example includes (by solid mass): 6 parts of pomegranate peel extract, 5 parts of Scutellaria baicalensis extract, 6 parts of honeysuckle extract, 8 parts of turmeric extract, and 5 parts of shellac extract. The following extraction methods can be used to extract active ingredients from the above natural products: the extracts of pomegranate peel, scutellaria baicalensis and honeysuckle are extracted at 100°C with water as a solvent, and the concentrates are distilled under reduced pressure; the extracts of turmeric are extracted with 60% The ethanol solution is refluxed and extracted in a Soxhlet extractor, and the concentrate is distilled under reduced pressure; the shellac extract is extracted with a dilute sodium carbonate aqueous solution, neutralized and concentrated.

[0023] The treatment process of natural extracts on silk fabrics is as follows: the amount of extracts is 15% (o.w.f.), the bath ratio is 1:40, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com