Patents

Literature

110results about How to "Comply with processing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

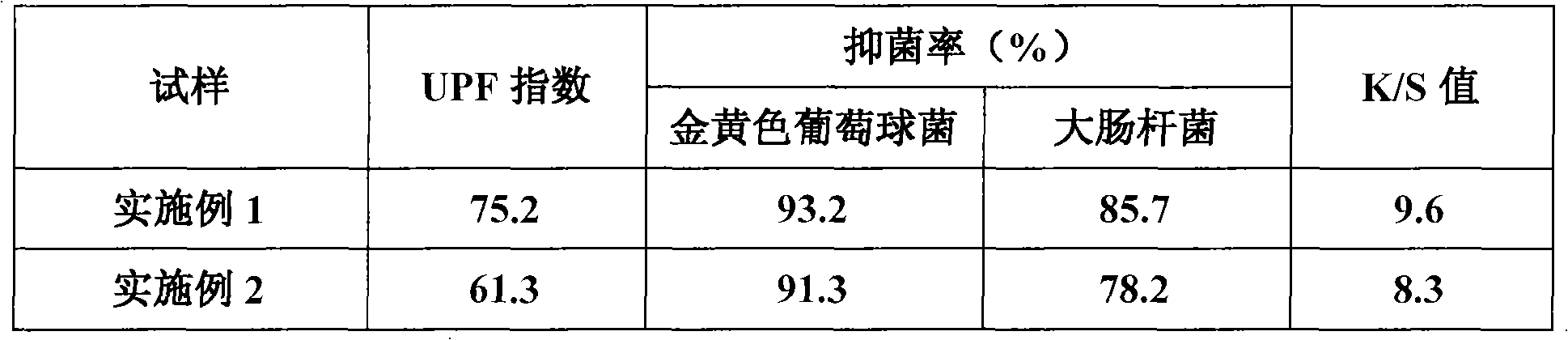

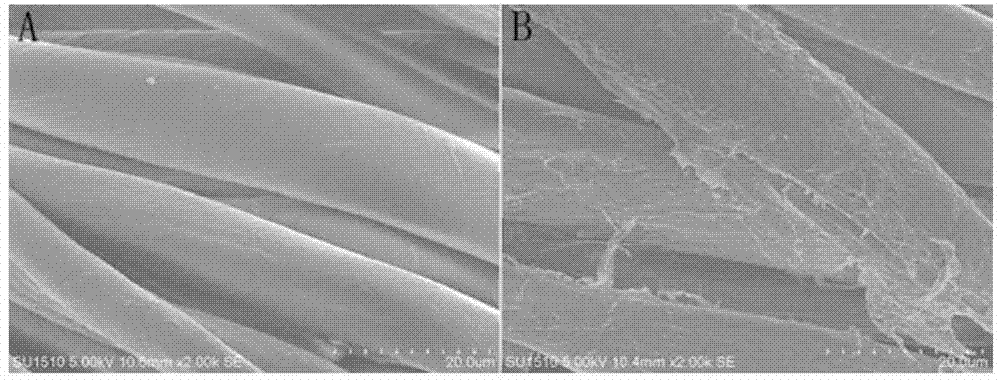

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

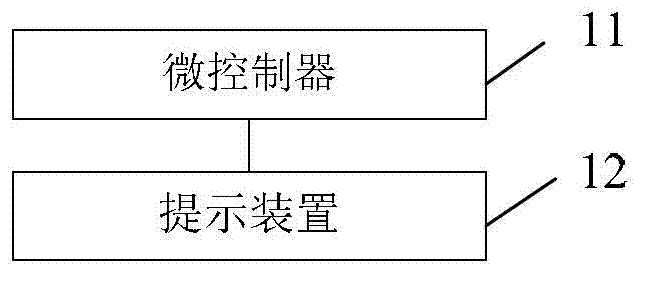

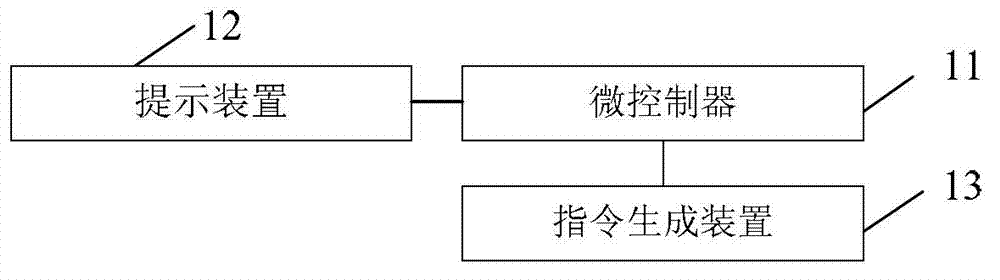

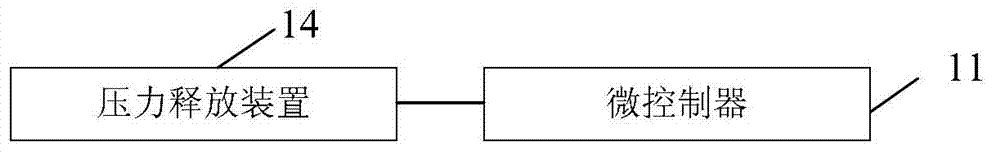

Control method and device of electric heating cooking device

ActiveCN103207581AImprove processing qualityComply with processing requirementsProgramme controlComputer controlElectric heatingEngineering

The invention provides a control method of an electric heating cooking device. The control method includes detecting a midway feeding instruction and outputting a feeding prompting signal according to the midway feeding instruction. By detecting the midway feeding instruction in the cooking process and outputting a feeding indication signal according to the midway feeding instruction, a user is prompted to add food material and ingredients midway. By means of the control method, different materials can be added in different time periods according to heating difficulty levels of food materials, the requirement for adding different food materials and the ingredients in different cooking periods is met, food processing requirement is met, and food processing quality is improved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

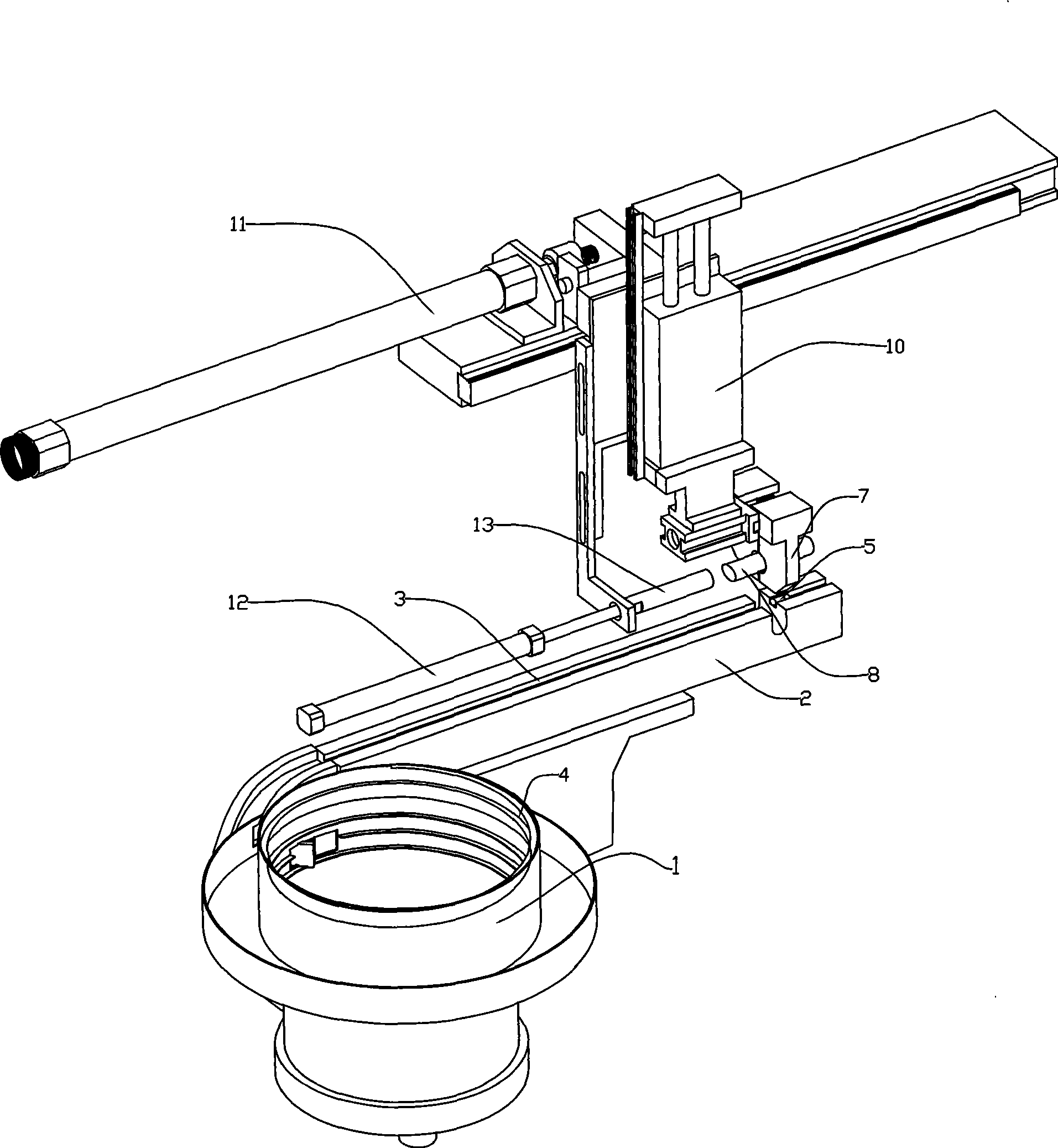

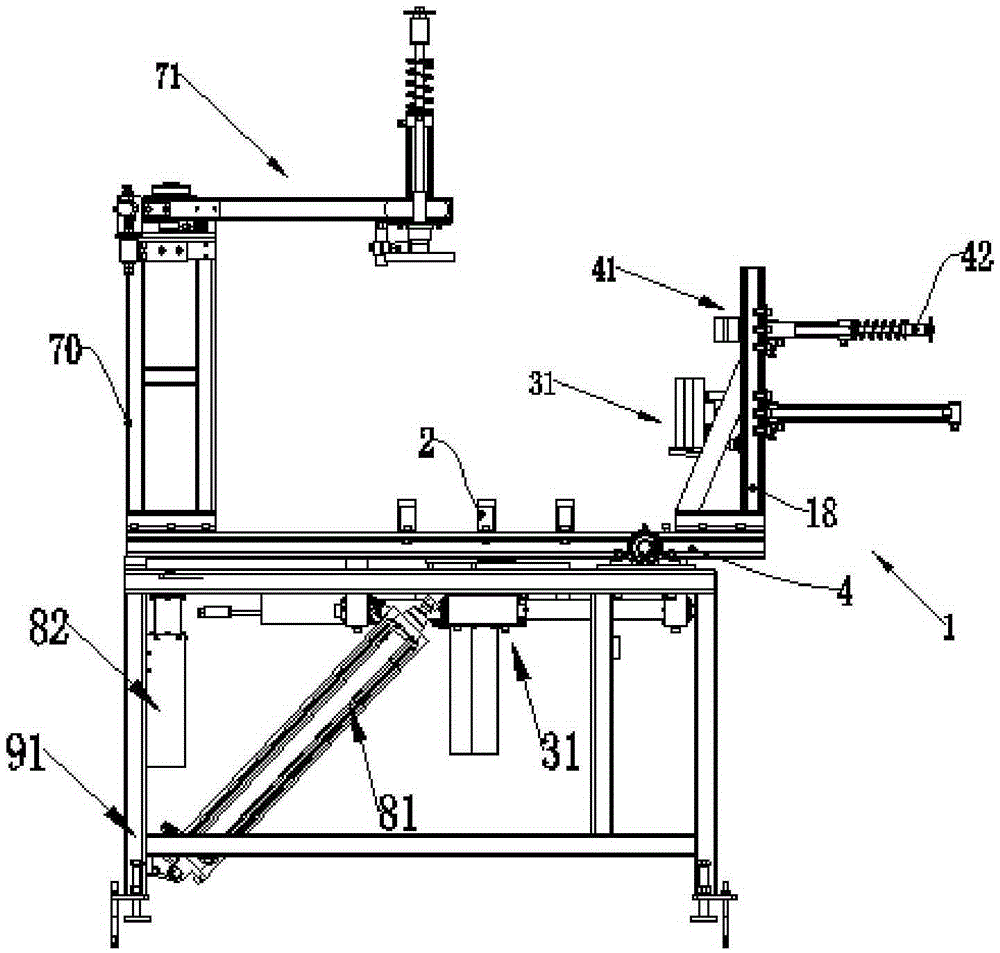

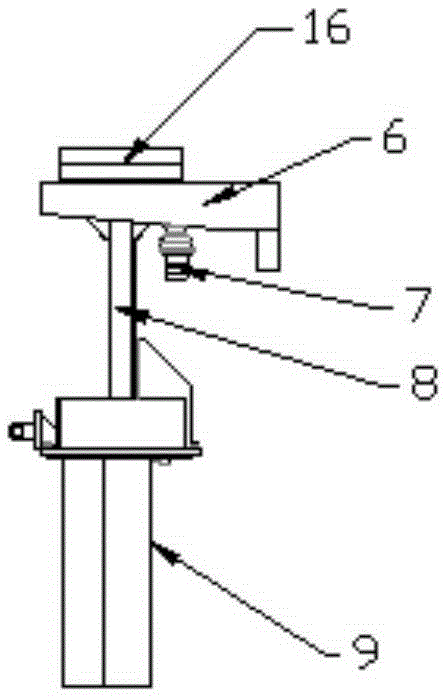

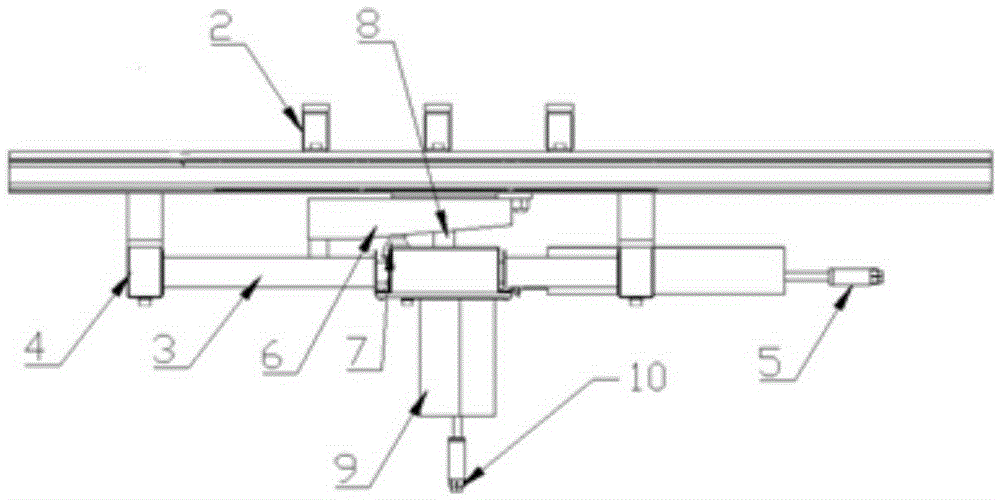

Automatic conveying apparatus for parts

ActiveCN101508384AControl insertion depthControlThread cutting feeding devicesMetal-working feeding devicesEngineeringManipulator

The invention discloses an automatic conveying device for parts. A groove for conveying the parts on a vibrating groove is connected with the outlet end of a conveying groove spirally arranged on a vibrating disc, the tail end of the vibrating groove is provided with a manipulator for clamping a workpiece, the manipulator is arranged on a first cylinder which is arranged on a second cylinder, the manipulator is moved in the vertical direction and the horizontal direction by driving the first cylinder and the second cylinder, the automatic conveying device for the parts also comprises a third cylinder, the front end of the third cylinder is provided with a pushing block for pushing the third cylinder to move forwards and backwards, and the position of the pushing block is opposite to a feed opening of a processing device. The automatic conveying device can automatically finish the conveying process of the parts, has high conveying efficiency, does not need a special personnel, reduces the manpower cost, can accurately control the inserting depth and the force through the pushing block driven by the cylinder to push the parts to be inserted into the processing device, and can reduce the defective index of the processed parts.

Owner:广州市新豪精密科技有限公司

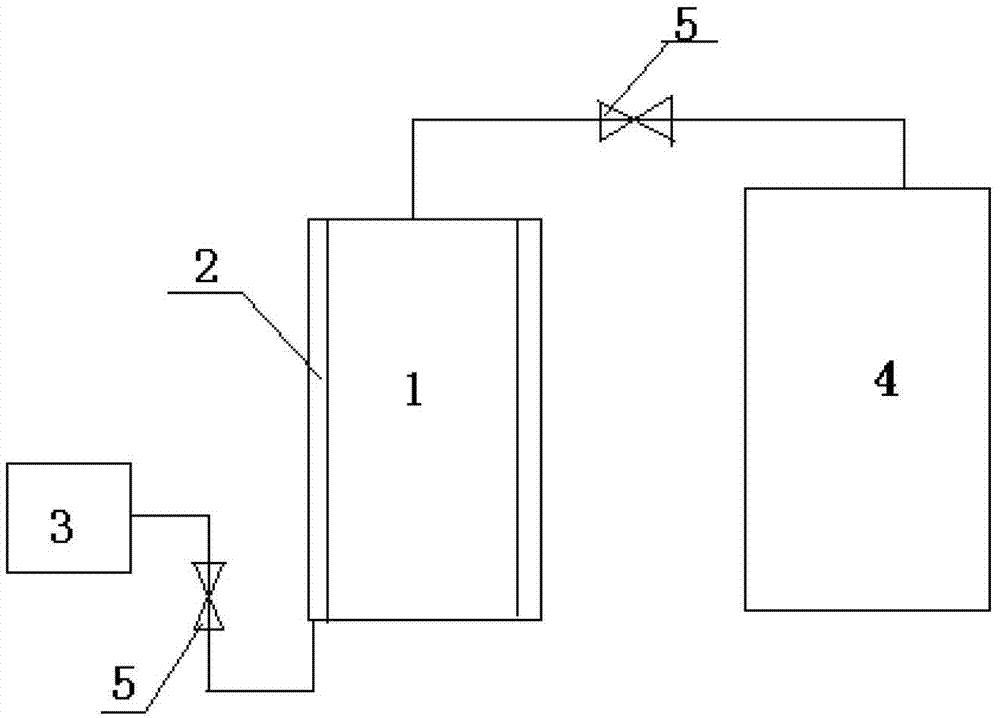

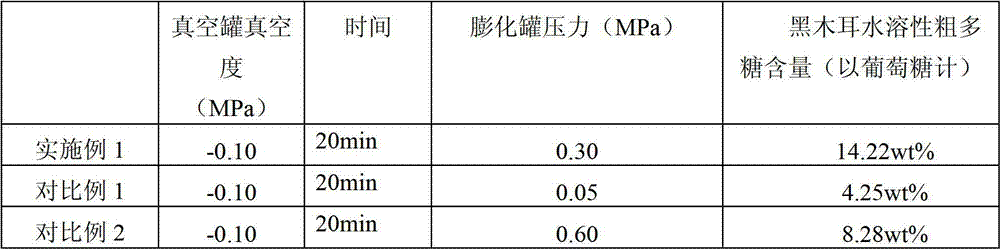

Method for preparing black fungus puffed ultramicro powder

InactiveCN102763817AGood effectThe solution is hard and not suitable for chewingFood preparationFlavorAdditive ingredient

The invention discloses a method for preparing a black fungus puffed ultramicro powder. The method includes selecting black fungus sporophores to serve as a raw material, puffing black funguses by an instantaneous alternating temperature and pressure difference of a puffing tank of a puffing device, maintaining a valve between the puffing tank of the puffing device and a vacuum tank to be in an opening state all the time, subjecting the black funguses in the puffing tank to a vacuum drying, and subjecting the puffed black funguses to a coarse grinding and a superfine grinding to obtain the black fungus puffed ultramicro powder. According to the method, a high pressure gas serves as a carrier, by means of a puffing wall breaking process, a black fungus organization structure is subjected to a cytoclasis to release whole nutritional ingredients and medicinal effect ingredients which are easy to digest and use by human bodies, and problems that the black funguses are hard and not suitable for being chewed, digested and used are solved. Besides, when the black fungus puffed ultramicro powder can be mixed with foods of flours, cakes and the like, the black fungus puffed ultramicro powder has flavor and nutrition of the black funguses, and smoothing taste is increased. The method is low in production cost and suitable for industrialization production, and products are used for foods, health care foods, medicines and raw material extraction.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

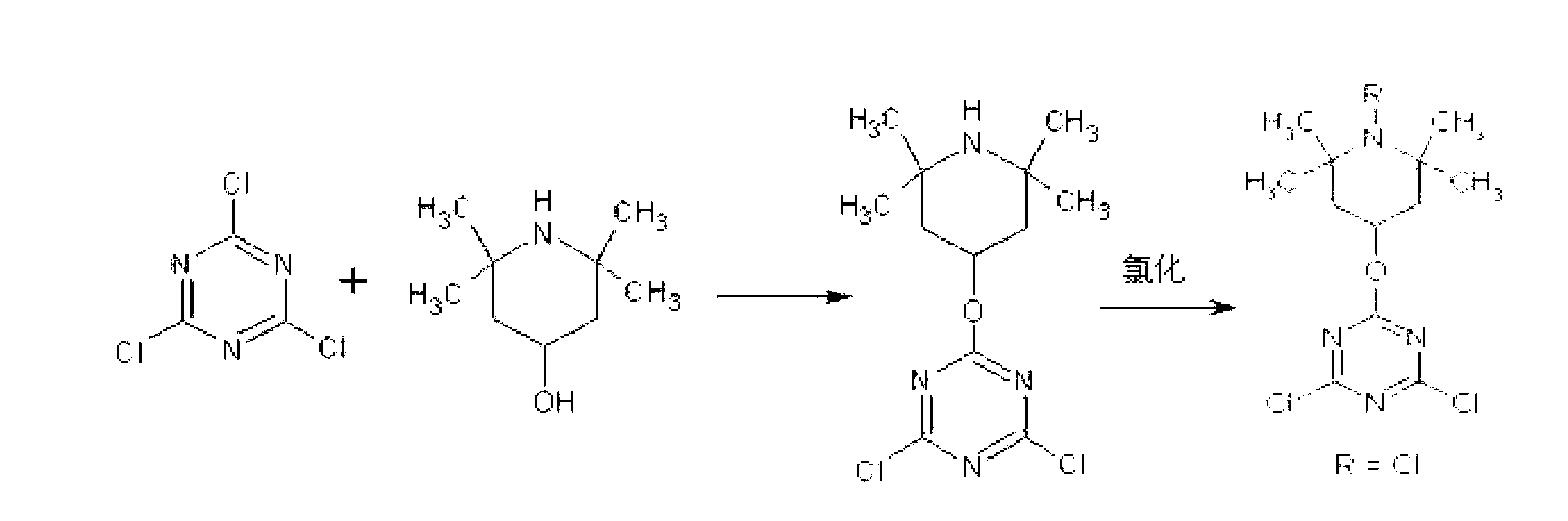

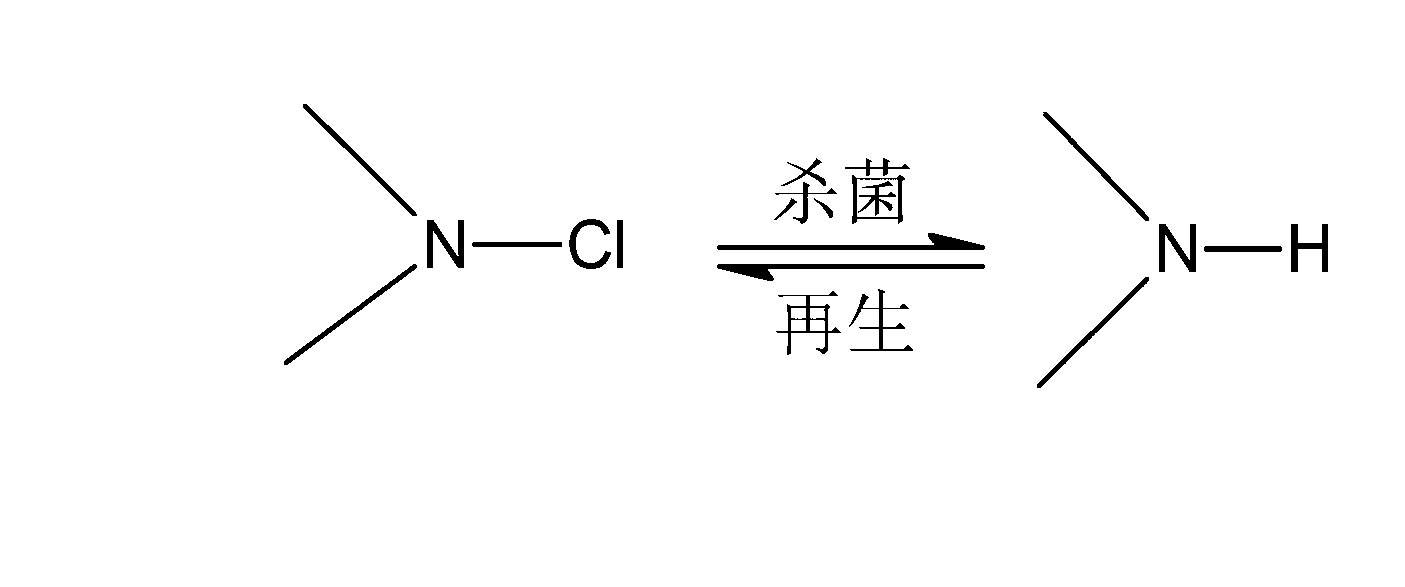

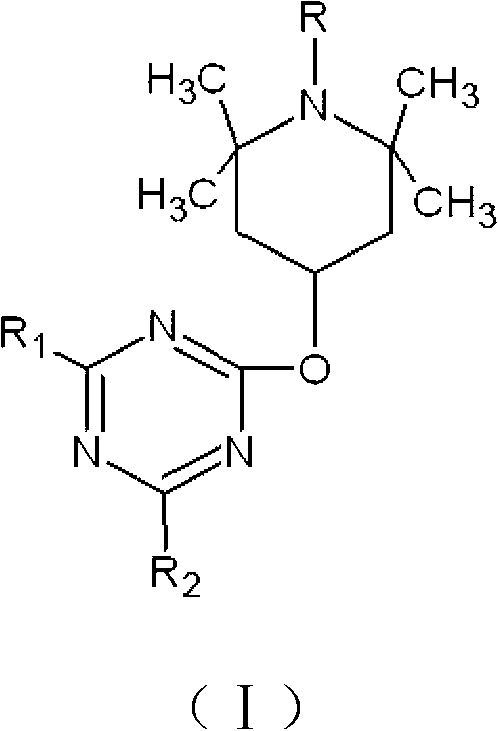

Halamine antibacterial agent, its preparation method and application

ActiveCN102797150ALow priceShort reaction timeOrganic chemistryFibre treatmentReaction temperatureAntibacterial agent

The invention provides a halamine antibacterial agent, its preparation method and application. The halamine antibacterial agent is a compound with a structure shown in formula (I). The preparation method consists of: in the presence of an acid-binding agent, taking cyanuric chloride or cyanuric fluoride or their derivative, and 2, 2, 6, 6-tetramethyl-4-piperidinol as synthesis raw materials to prepare a halamine antibacterial agent precursor with a structure shown in formula (II), and then reacting the precursor with a sodium hypochlorite solution to prepare a halamine antibacterial agent finished product. The halamine antibacterial agent can be applied in textile antibacterial finishing. Specifically, a textile to be treated is dipped in a finishing solution containing the halamine antibacterial agent precursor and a metal salt catalyst for finishing, and finally a halogenation reaction is carried out so as to obtain an antibacterial textile. The method provided in the invention for preparation of the halamine antibacterial agent has the advantages of low cost, simple process, low reaction temperature, no toxicity or pollution, and is in line with the requirements of ecological textile antibacterial finishing. According to the invention, the application process has the characteristics of simple operation and low reaction energy consumption, and antibacterial textiles with good antibacterial properties can be prepared.

Owner:JIANGNAN UNIV

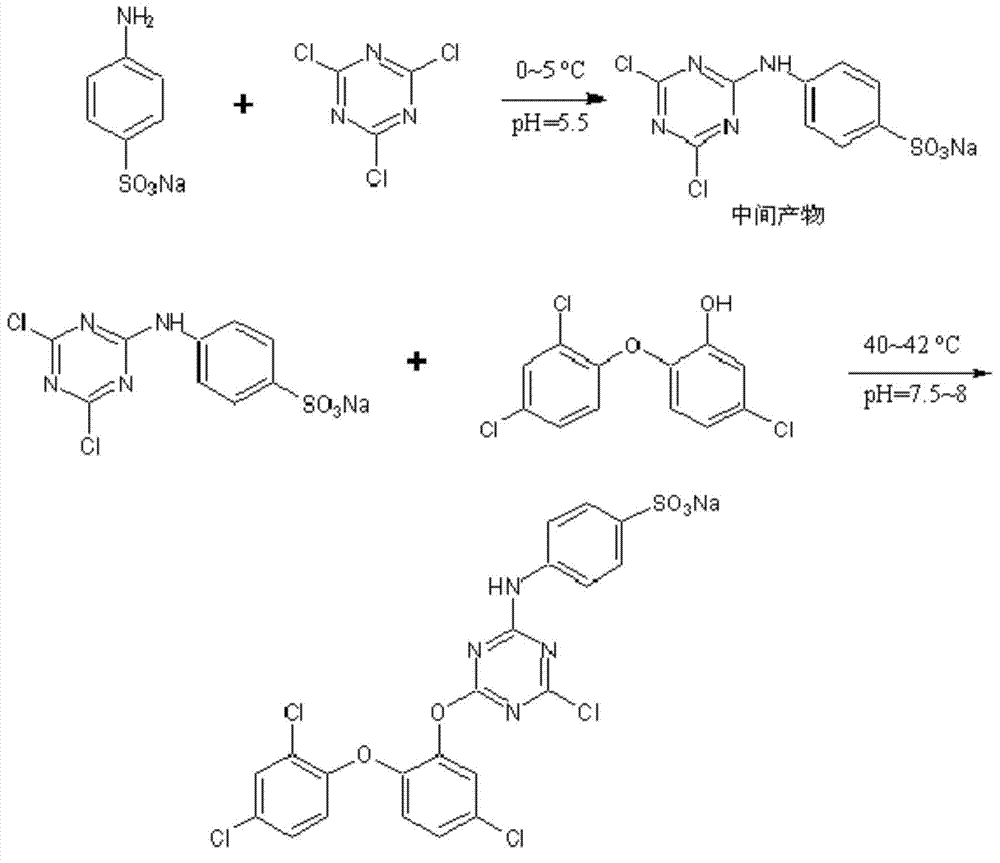

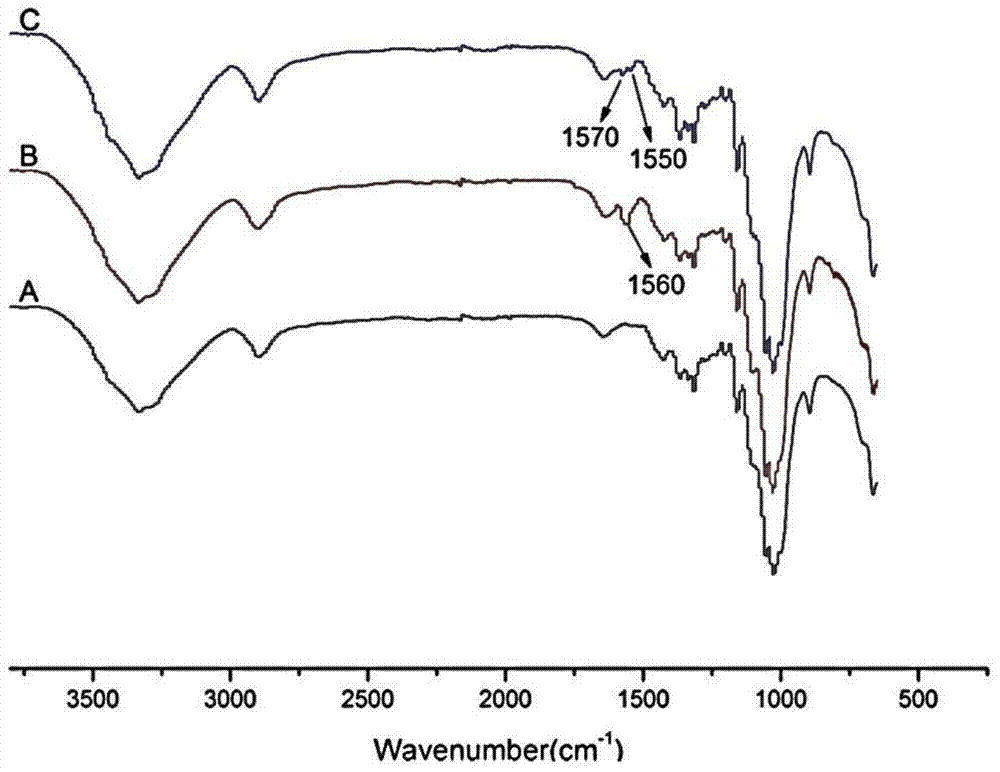

Reaction type antibacterial agent as well as synthetic method and application thereof

InactiveCN103787997AGood water solubilityImprove solubilityOrganic chemistryVegetal fibresTriclosanCyanuric fluoride

The invention discloses a reaction type antibacterial agent as well as a synthetic method and an application thereof. The antibacterial agent is of a structure shown in a formula (I). The synthetic method comprises the following steps: dropwise adding a sodium sulfanilate solution into a cyanuric chloride or cyanuric fluoride solution, reacting for 1-4 hours at the temperature of 0-5 DEG C to obtain an intermediate product, adding a triclosan solution, reacting for 2-8 hours at the temperature of 30-60 DEG C to obtain a precursor of the reaction type antibacterial agent, chlorinating the precursor to obtain a finished product of the reaction type antibacterial agent. The application process comprises the following steps: soaking fabrics into finishing liquid formed by dissolving the precursor of the reaction type antibacterial agent and a metal salt catalyst in water, adding an alkaline agent, continuing the soaking treatment, chlorinating to obtain antibacterial fabrics. The antibacterial agent disclosed by the invention has the advantages of excellent bacteriostatic and sterilizing functions, high sterilization speed, high efficiency and simplicity in synthetic process; the application process has the advantages of short reaction time, low temperature, little damage on the fabrics and no toxicity or pollution, is simple to operate and meets the processing requirements of ecological textiles.

Owner:JIANGNAN UNIV

Metallic material surface detergent

InactiveCN101368134AGood cleaning effectImprove cleanlinessInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSolventDefoaming Agents

The invention provides a cleaner for the surface of a metal material, comprising oxidizing agent, a pH regulator, surface active agent, solubilizer, defoaming agent and purified water; wherein, the weight percentage of the oxidizing agent is 0.5 percent to 5 percent, the weight percentage of the pH regulator is 3 percent to 12 percent, the weight percentage of the surface active agent is 5 percent to 15 percent, the weight percentage of the solubilizer is 1 percent to 10 percent, the weight percentage of the defoaming agent is 2 percent to 7 percent and the rest is purified water; the cleaner is an alkaline water-soluble cleaner, has good cleaning effect to pollutants remained on the surface of the metal material, has low corrosion without corrosion equipment, is not easy to damage the surface of the metal material, meets the requirements of environment protection and has reasonable formulation design, simple preparation technique and low cost; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

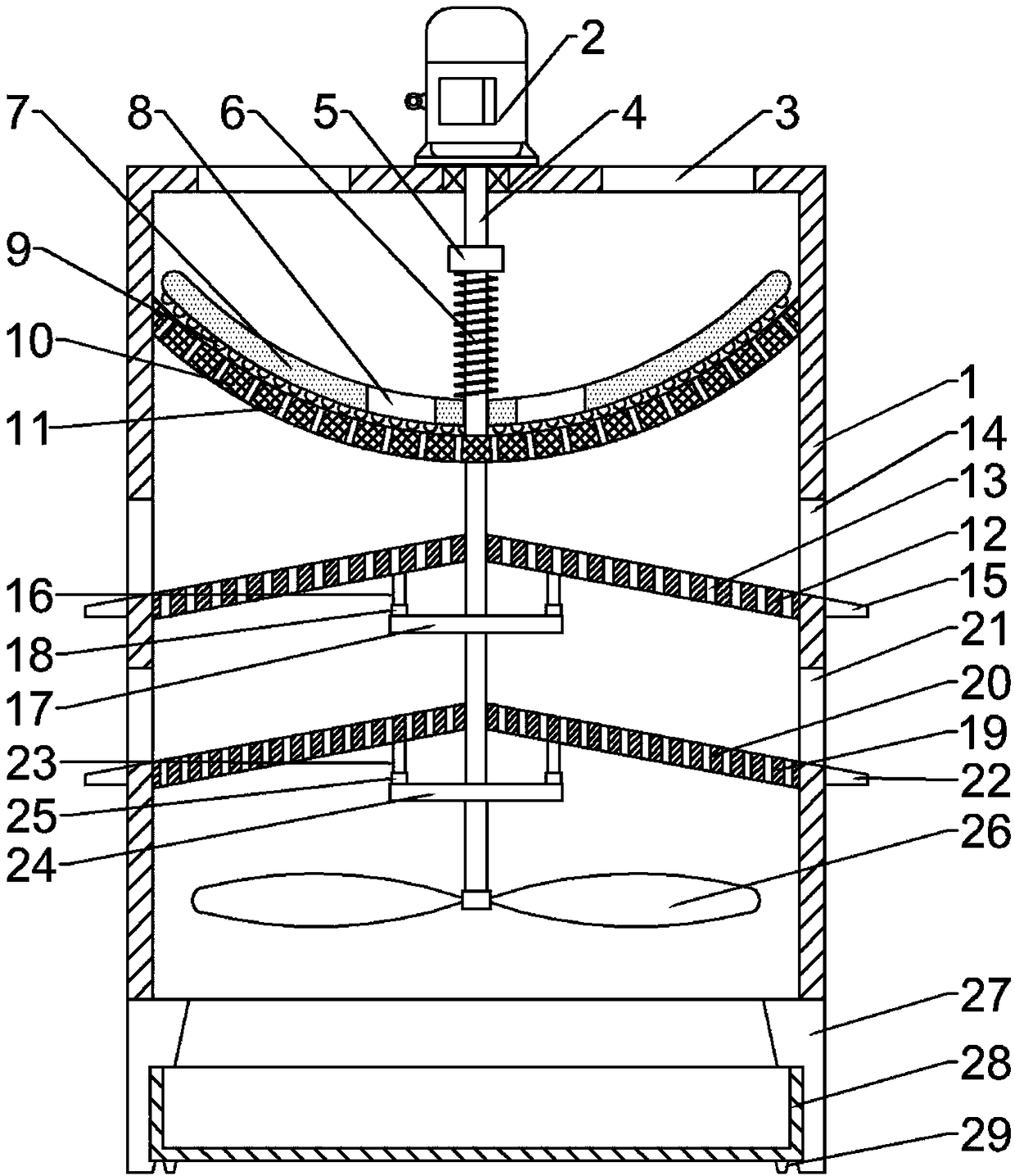

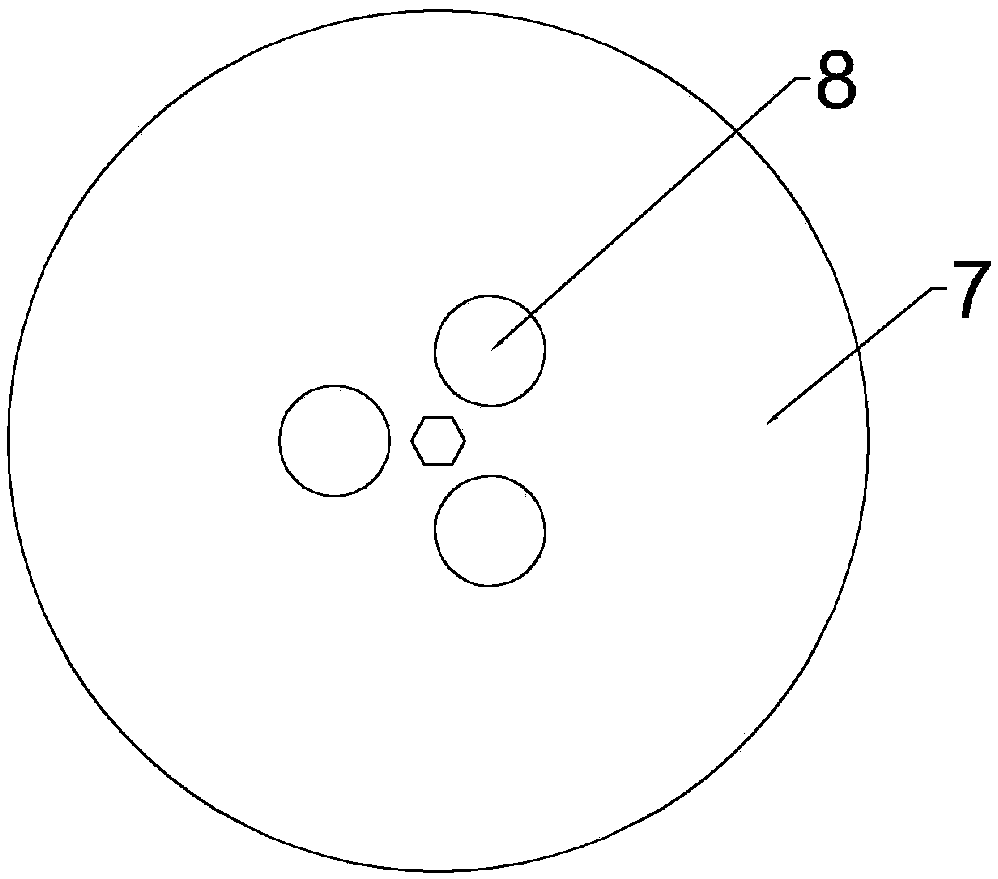

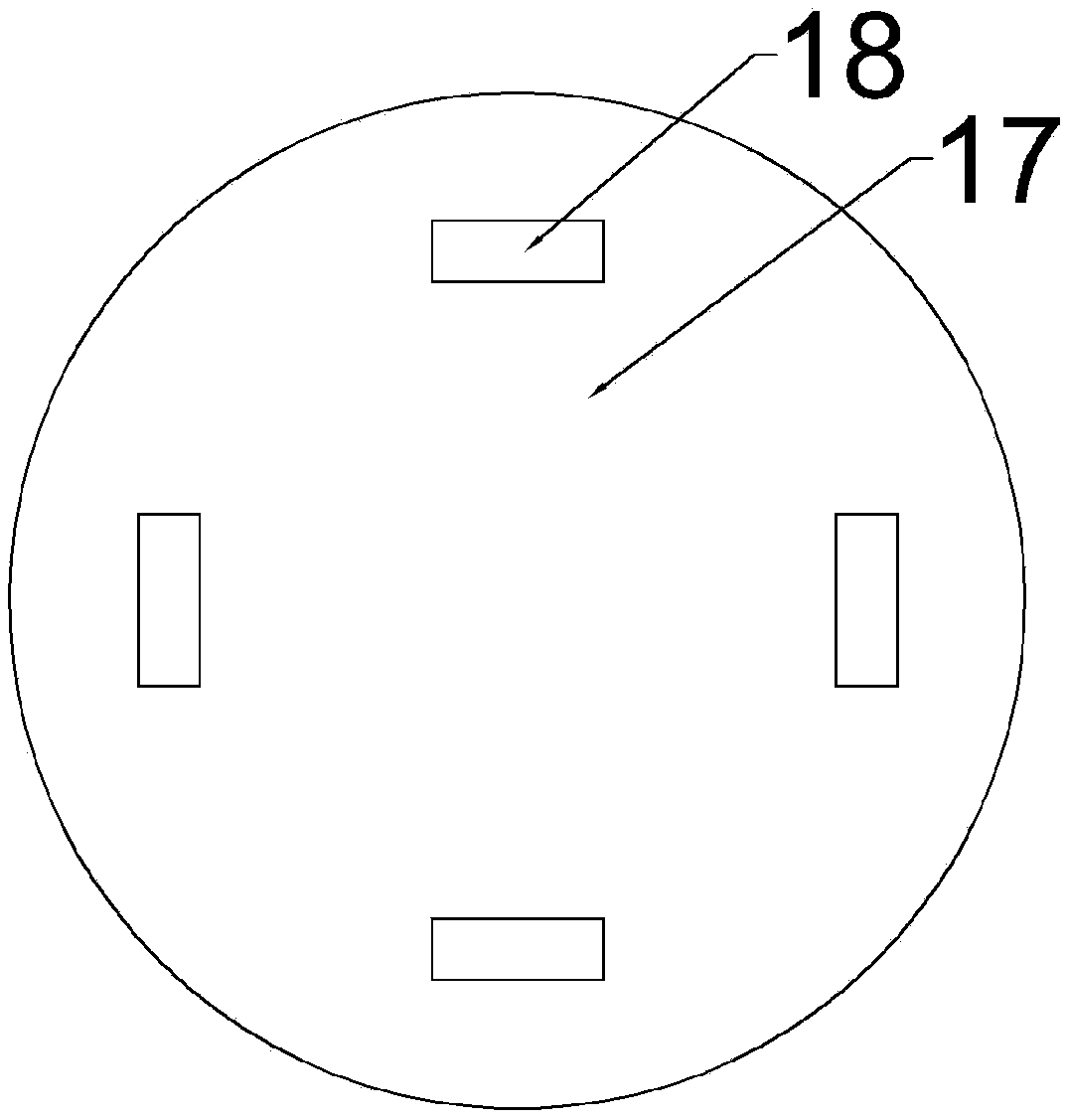

Grinding screening equipment for nanoscale carbon fiber material processing

The invention discloses grinding screening equipment for nanoscale carbon fiber material processing. The grinding screening equipment comprises a shell. The center of the top of the shell is fixedly connected with a motor, and the output end of the motor is fixedly connected with a longitudinal rotating shaft. The longitudinal rotating shaft and the shell are connected in a rotating mode. The upper side of the longitudinal rotating shaft is fixedly connected with a limiting block, and the lower side of the limiting block is fixedly connected with a spring. The spring is arranged on the outer side of the longitudinal rotating shaft in a sleeving mode. The outer side of the longitudinal rotating shaft is connected with a rotary grinding plate in a sliding mode. Discharging holes are formed in the rotary grinding plate. The rotary grinding plate is fixedly connected with the lower end of the spring. Compared with the prior art, the grinding screening equipment for nanoscale carbon fiber material processing has the beneficial effects that the structure is simple, using is made convenient, raw materials can be ground and screened in the using process, then the ground raw materials are subjected to classified screening again, and thus the effect that obtained products can meet the processing requirements is guaranteed; and in addition, the screening process can be promoted through different vibrational frequencies in the using process of the device, the screening efficiency is made higher and the grinding screening equipment is worthy of popularization.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

Dyeing and finishing method for durable press bombasine yarn dyed fabric

ActiveCN103451917ALittle strengthHigh surface finishBiochemical fibre treatmentDyeing processFiberCellulose

Belonging to the application technology field of yarn dyed fabric dyeing and finishing in the textile industry, the invention provides a dyeing and finishing method for a durable press bombasine yarn dyed fabric, and aims to solve the technical problems of easy fiber damage, undesirable antiwrinkling effect and poor washfastness, easy generation of formaldehyde residue and other ecological pollution. The method provided in the invention combines a chemical technique and a biological enzyme technique to carry out scouring and bleaching and dyeing on a bombazine fabric, that is to say, caustic soda, cellulose and catalase are taken for cotton fiber scouring and bleaching, soda ash, protease and lipase are taken for raw silk degumming and dyeing, and an active dye and laccase are employed to perform bombazine fiber dyeing and aftertreatment. Meanwhile, formaldehyde-free antiwrinkling resin is employed to perform liquid ammonia moist crosslinking on the fabric so as to improve the wrinkle resilience of the fabric. By applying the method provided in the invention to perform dyeing and finishing on the bombasine yarn dyed fabric, the fabric has a smooth surface and soft handfeel, also, the chroma of a dyeing waste liquid is reduced. When high antiwrinkling performance is acquired, the fabric strength is less reduced. The treatment process is safe and environment-friendly, thus being in line with the processing requirements of ecological textiles.

Owner:NANTONG XINLAI SILK GARMENTS

Production method of green food quick-frozen green soybean pods

InactiveCN105053166AFreeze fastGood frozen qualityFruits/vegetable preservation by freezing/coolingNutrientFlavor

The invention belongs to the technical field of deep processing of agricultural products and especially relates to a production method of green food quick-frozen green soybean pods. The production method comprises the following operation steps: checking raw materials, winnowing, selecting, grading, washing and removing detritus, blanching, cooling, draining, quick-freezing, temporarily packaging, warehousing, discharging from warehouse, packaging, detecting metal, refrigerating and the like. The production method of green food quick-frozen green soybean pods provided by the invention is simple to operate, low in cost and relatively strong in operability; neither antiseptic nor additive is added during the production process of the quick-frozen green soybean pods, so that the nutrients in the green soybean pods are preserved to the maximum; the unfrozen green soybean pods has no obvious difference in aspects such as taste, color and flavor when compared with green soybean pods which is not quickly frozen; the production method of green food quick-frozen green soybean pods satisfies processing requirements of green food and is beneficially convenient, healthy, clean, nutritious and economical. Thus, the production method of green food quick-frozen green soybean pods is a novel technology for storing and processing green soybean pods.

Owner:宁夏天瑞产业集团现代农业有限公司

Method for preparing crosslinkable polyethylene insulated cable material

InactiveCN101817949AAvoid introducingGuaranteed purityPlastic/resin/waxes insulatorsLow-density polyethyleneMaterials preparation

The invention discloses a method for preparing a crosslinkable polyethylene insulated cable material. The method comprises the following steps of: dissolving an oxidation inhibitor in a dissolved cross-linking agent to obtain a liquid compound aid; filtering the liquid compound aid to remove impurities; mixing the liquid compound aid and low density polyethylene granules at the temperature of between 60 and 80 DEG C; and diffusing the liquid compound aid into the low density polyethylene granules gradually in a temperature range of between 60 and 100 DEG C to obtain a uniformly diffused compound aid-containing crosslinkable polyethylene insulated cable material. The method has a simple preparation process and can completely avoid the heating of melt extrusion in a material preparation process, thereby avoiding possible induction of impurities caused by the heating of the melt extrusion and sufficiently ensuring the purity of the material; and the obtained product has high distribution uniformity of the compound aid and high processing stability, and meets performance requirements on a high-grade insulated cable material.

Owner:ZHEJIANG UNIV

Automatic glazing apparatus

The invention discloses an automatic glazing apparatus. The automatic glazing apparatus comprises an overturn stand, a frame, glazing modules, an overturn cylinder and a compaction device; the overturn stand comprises a bottom glazing mounting rack and a side surface glazing mounting rack, the side surface glazing mounting rack is arranged at one end of the bottom glazing mounting rack; one end of the bottom glazing mounting rack is hinged to one end of the frame; the glazing module comprises a glazing pipe and a glazing driving cylinder, the glazing modules are respectively arranged on the bottom glazing mounting rack and a central part of the side surface glazing mounting rack; the compaction device is arranged at the other end of the bottom glazing mounting rack of the overturn stand; one end of the overturn cylinder is hinged to the central part of the bottom glazing mounting rack of the overturn stand, and the other end of the overturn cylinder is fixed on the frame. The automatic glazing apparatus is used for glazing the stool blanks with different models, and can be respectively used for glazing bottom or side surface of the stool blank, so that a production process can be simplified, and production cost is reduced.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

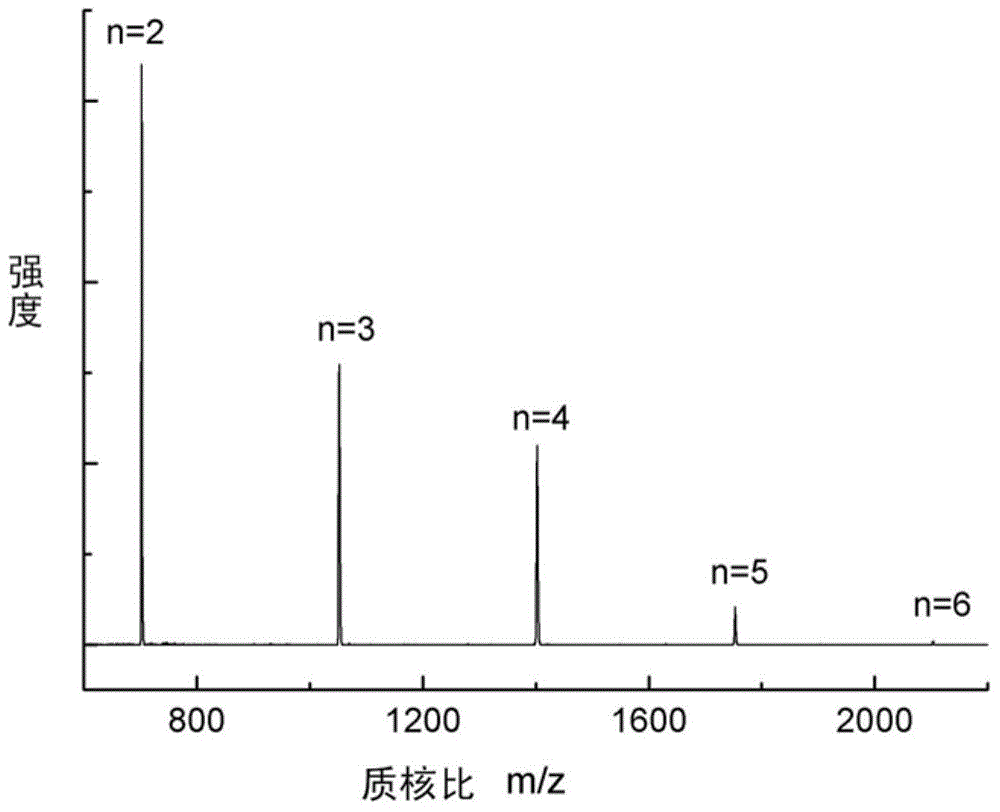

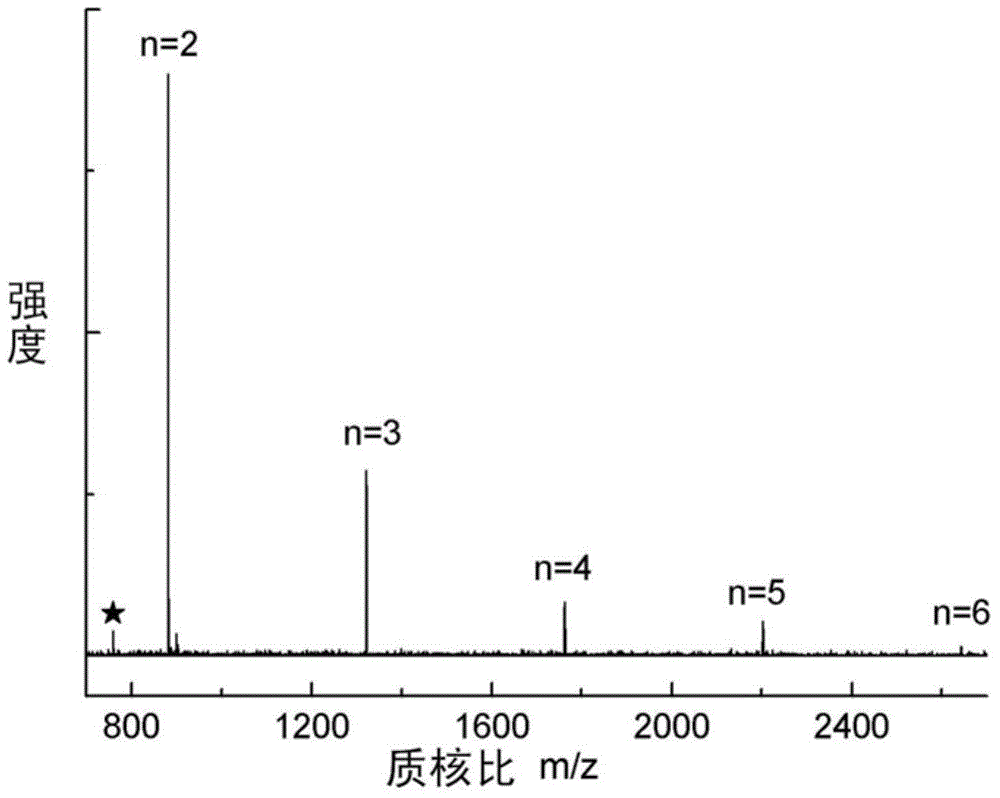

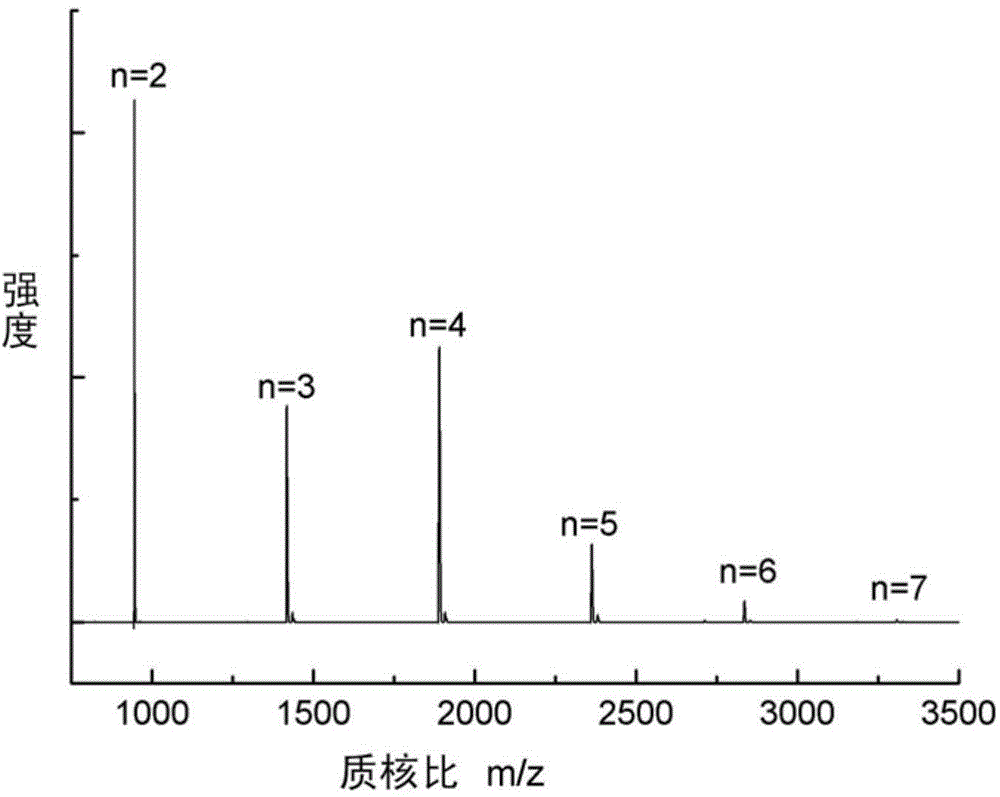

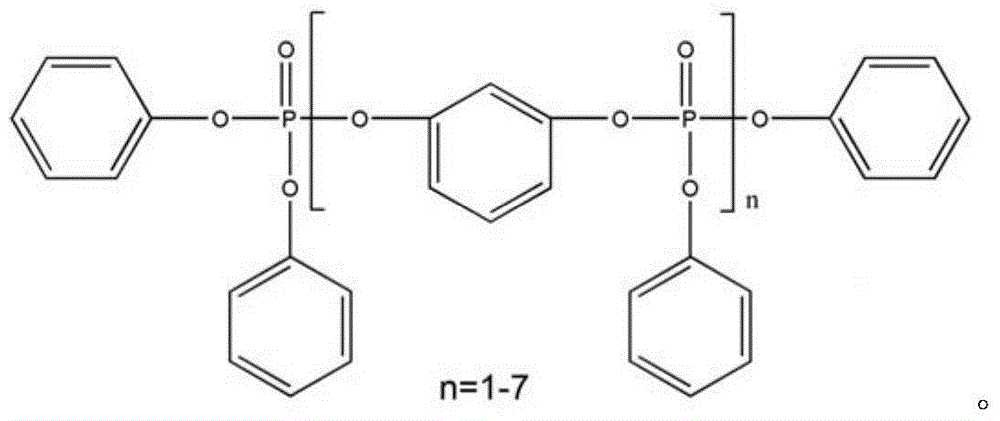

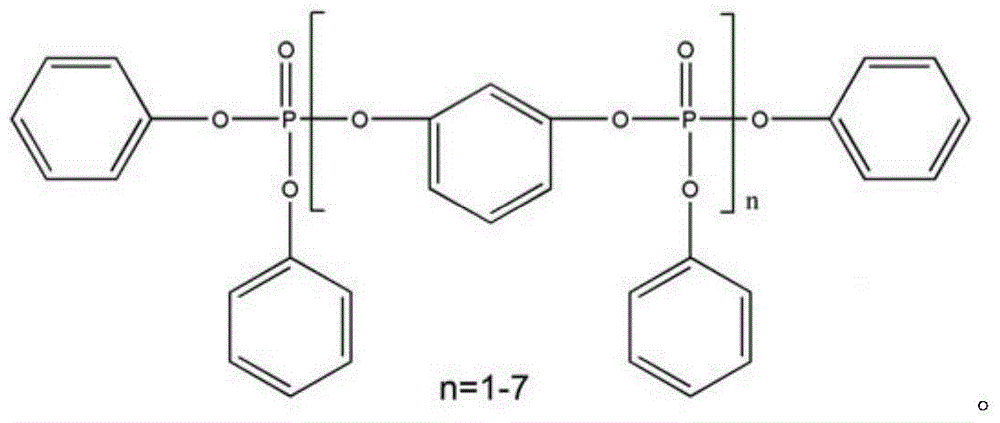

Cyclic polyphosphoester oligmer, and preparation method and application thereof

InactiveCN104629087AGood thermal stabilityImprove mechanical propertiesGroup 5/15 element organic compoundsMaterials processingPolymerization

The invention provides a cyclic polyphosphoester oligmer; the thermal stability of the cyclic polyphosphoester oligmer is good; the cyclic polyphosphoester oligmer can meet polymer material processing requirements; furthermore, after being added into a polymer material substrate, the cyclic polyphosphoester oligmer provided by the invention is capable of increasing the mechanical property of the polymer material substrate; and in addition, a series of cyclic polyphosphoester oligmers synthesized through condensation polymerization by adopting a pseudo-high dilution technology can be simple in preparation method and high in yield.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

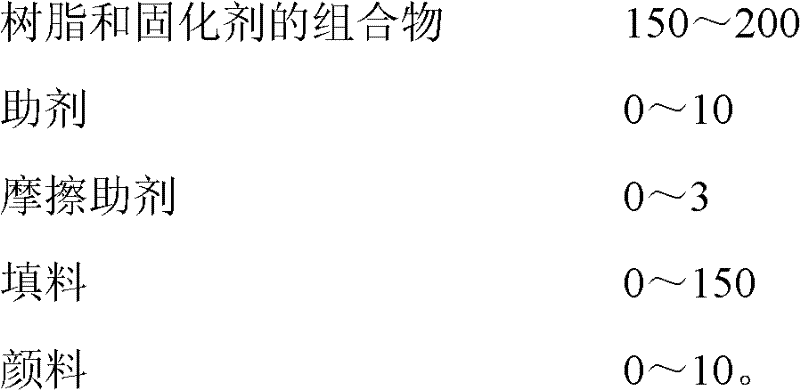

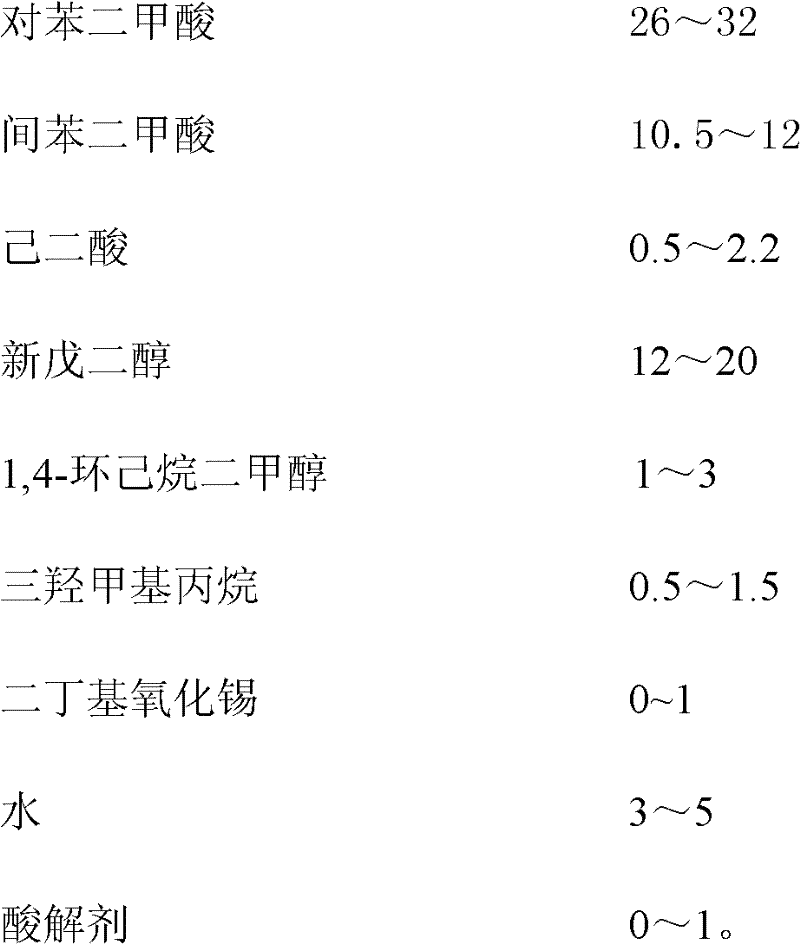

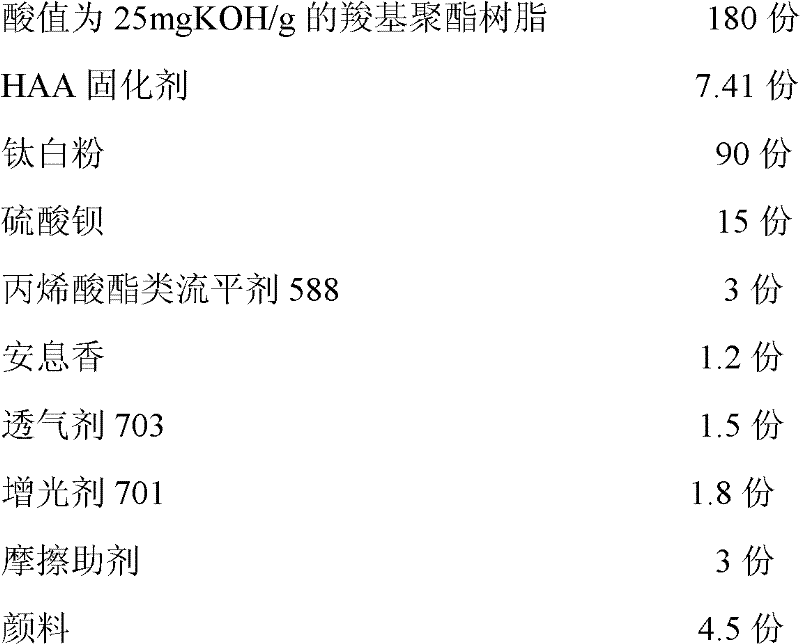

Novel environment-friendly flat coiled material pre-painting powder coating and preparation method thereof

InactiveCN102408819AReduce thicknessImprove bending resistancePolyester coatingsWear resistanceMechanical property

The invention discloses a novel environment-friendly flat coiled material pre-painting powder coating comprising the following components according to part by weight: 150-200 parts by weight of resin / curing agent composition, 0-10 parts by weight of conventional auxiliaries, 0-3 parts by weight of frictional auxiliary, 0-150 parts by weight of stuffing and 0-10 parts by weight of pigment. The invention also discloses the preparation method of the environment-friendly flat coiled material pre-painting powder coating. The powder coating provided in the invention is nontoxic and environment-friendly, good in abrasive resistance and high in electrification performance; the powder coating is capable of obviously improving the pre-painting efficiency of the flat coiled material; and the cured coating has the characteristics of excellent physical mechanical properties, chemical resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

Method for processing green tea by microwaves

ActiveCN101653175ANo loss of effective nutrientsNo pollution in the processPre-extraction tea treatmentFlavorMicrowave technology

The invention discloses a method for processing green tea by microwaves, which aims to popularize the application of microwave technology in green tea processing. Through the processes of airing, de-enzyming, first kneading, second kneading, first drying, second drying and the like, the method adopts advanced microwave technology instead of the conventional heat conduction heating mode to make the green tea, so that effective nutrients in the green tea are hardly lost, and color, flavor and taste are better than the green tea made by the conventional processing method. The whole process of processing does not require high temperature heat medium, has no dust pollution, and is in accordance with the processing requirements of green foods.

Owner:RIZHAO BAIMAN TEA

Leather antibacterial treatment agent and antibacterial treatment process for leather

InactiveCN102493173ANo formaldehyde releaseGood matchingFibre treatmentHexavalent chromiumTitanium dioxide

The invention discloses leather antibacterial treatment agent, which comprises, by weight, 20-50 parts of nano material dispersant, 3-5 parts of silver-contained object, 3-5 parts of zinc oxide whiskers, 3-5 parts of nano titanium dioxide and 50-80 parts of inorganic powder filler. The invention further discloses an antibacterial treatment process for leather, which includes an antibacterial treatment procedure added to the conventional tanning process. The leather antibacterial treatment agent is added to immerse fur, so that mould resistance of finished leather is improved. Shrink temperature of leather in industrial production can reach above 90 DEG C by the aid of the leather antibacterial treatment agent and by the antibacterial treatment process, and shoemaking requirements can be met. Detection requirements of environmental symbol products on hexavalent chromium and total chromium are met. No phosphorous pollution occurs, and no formaldehyde emits. Requirements of leather of high-grade environment-friendly uppers and shoe linings on mould resistance are met. The conventional tanning process needs no special adjustment, and the antibacterial treatment process can be well used with the existing tanning process.

Owner:成都富路其鞋业有限公司 +1

Bio-based degradable flame-retardant polylactic acid engineering material and preparation method thereof

The invention discloses a bio-based degradable flame-retardant polylactic acid engineering material and a preparation method thereof. The engineering material is prepared by fusion and mixing of polylactic acid, liquor vinasse after surface treatment and high-molecular type phosphorus-containing fire retardant. The mass percent of polylactic acid, the liquor vinasse after surface treatment and the high-molecular type phosphorus-containing fire retardant is 70:(30-5):(0-25). The engineering material has the advantages of simple formula, improved flame retardation efficiency, and excellent mechanical properties of the original material; a stable compact carbon layer is generated during combustion, and droplet phenomenon is effectively inhibited.

Owner:NANJING UNIV OF SCI & TECH

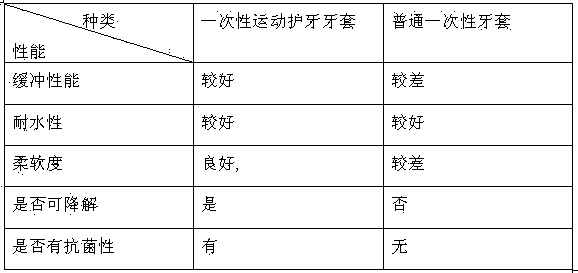

Disposable movement tooth protecting socket and preparation method thereof

The invention relates to a disposable movement tooth protecting socket and a preparation method thereof. The preparation method of the disposable movement tooth protecting socket disclosed by the invention comprises purification and modification of konjac glucomannan, preparation of compound gel, degasification, molding and drying. The konjac glucomannan is taken as a carrier and assisted by other assistants; the disposable movement tooth protecting socket has excellent film-forming property, water-tightness, antibacterial property, large tensile strength, and good toughness; the konjac glucomannan is taken as a main material of the disposable movement tooth protecting socket. Compared with the existing movement tooth protecting socket, the disposable movement tooth protecting socket is high in tensile strength, and high in acid and alkali resistance, high-temperature resistance and antibacterial effect. The product is not degraded under normal use, can be completely degraded in soil under the conditions such as water, carbon dioxide, microorganisms, temperature and the like, is short in degradation time, convenient to draw materials, low in price and simple in production technology, accords with the national environment-friendly and low-carbon policy, and accords with the processing and production requirements of the disposable product. The disposable movement tooth protecting socket also has excellent performances such as antibacterial property, water resistance, breaking resistance, softness and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

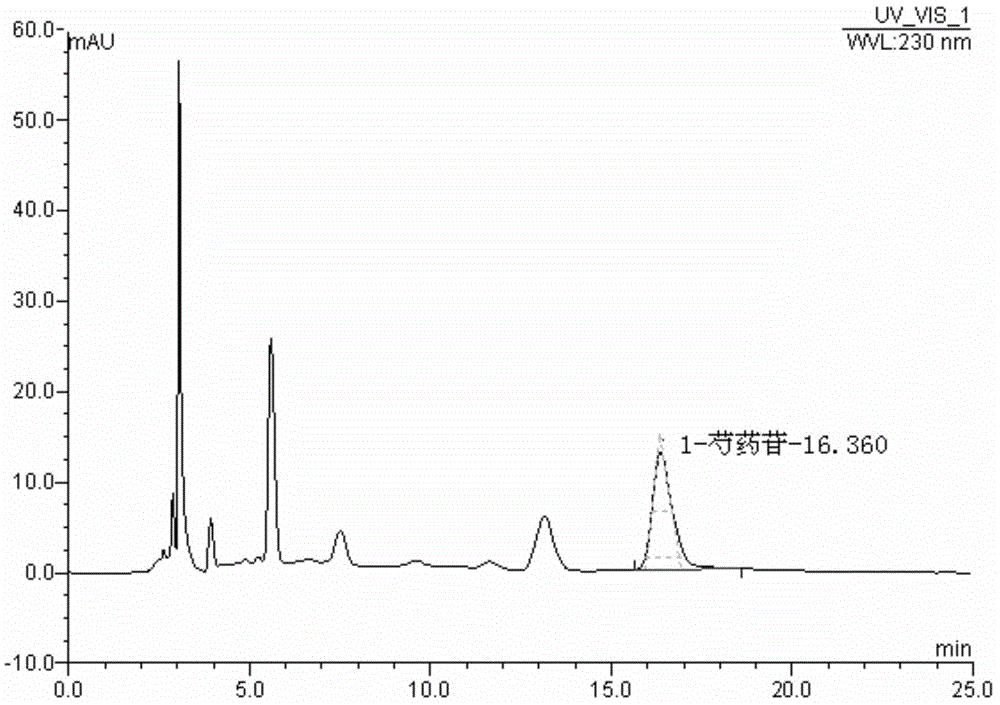

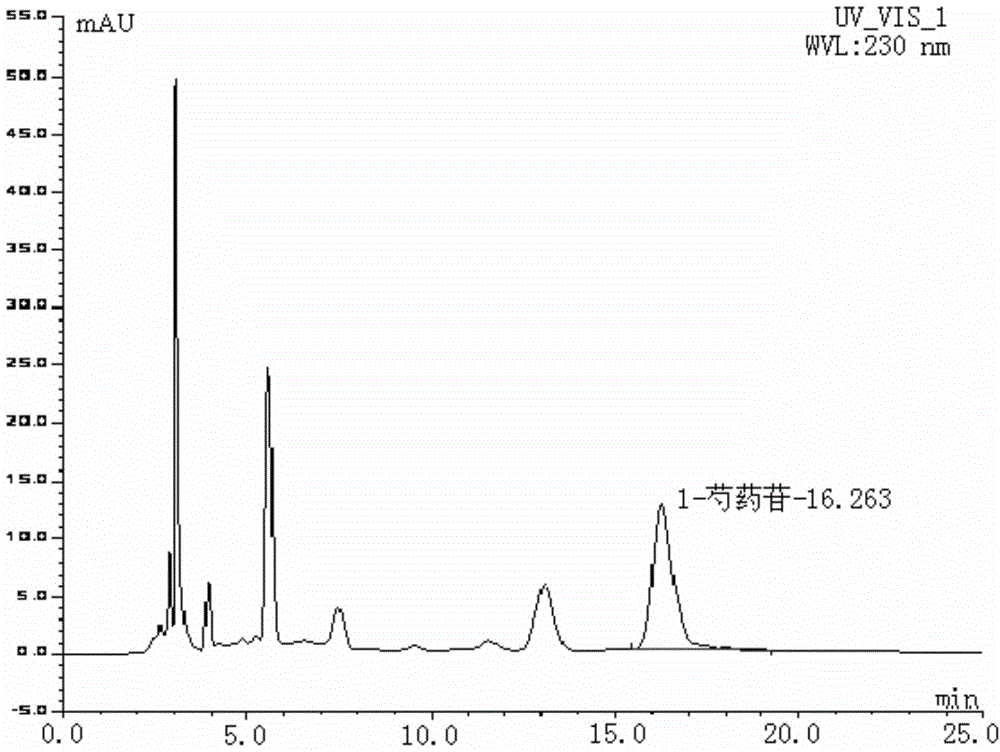

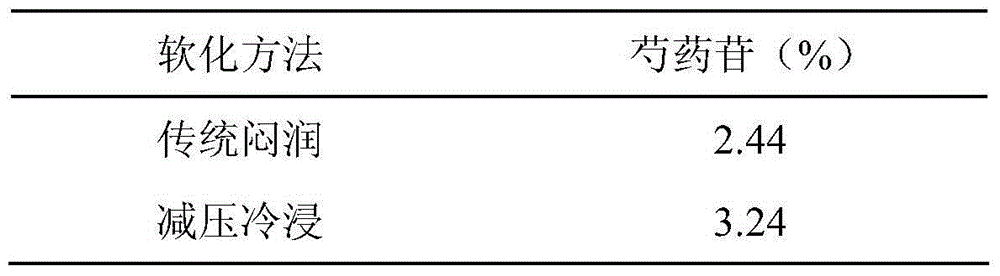

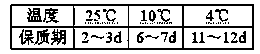

Novel processing method of paeonia sterniana medicinal slices

InactiveCN104083459AEasy to fixShorten the production cyclePlant ingredientsRoom temperaturePaeoniflorin

The invention discloses a novel processing method of paeonia sterniana medicinal slices. The method comprises the following steps: (1) impurity removing: sorting the roots of paeonia sterniana and cleaning for later use; (2) pressure-reduced cold soaking and softening: carrying out pressure-reduced cold soaking and softening treatment on the roots of paeonia sterniana; (3) slicing: taking out the roots of paeonia sterniana and cutting into slices with thickness from 1mm to 2mm; (4) drying: drying the slices which are cut well at a temperature of 55 DEG C to 60 DEG C until the content of water in the slices reaches 8% to 12%; (5) packaging: cooling the slices to a room temperature and packaging in a sealing manner. According to the method, the roots of paeonia sterniana are softened via a pressure-reduced cold soaking method, so that the softening efficiency and the softening quality are substantially improved and the production period of the paeonia sterniana medicinal slices is shortened; the softening and soaking processes are both carried out below 30 DEG C, so that the damage to the roots of paeonia sterniana, due to the heating, is avoided, i.e., the loss of paeoniflorin is substantially reduced; any materials are not added during the whole process of the method, so that the medicinal properties of the paeonia sterniana medicinal slices are not changed.

Owner:李时珍医药集团有限公司

Fried bitter gourd and production method thereof

InactiveCN102813150ACrispy tasteSolving Difficult To Swallow ProblemsFood preparationAlcoholOil temperature

The invention provides fried bitter gourd and a production method thereof. The production method includes cleaning and cutting bitter gourd, soaking the cut gourd in 10-70% edible alcoholic solution for 0.5-6 hours to remove bitterness, freezing fast for 5-120 minutes, frying for 3-40 minutes, at oil temperature of 40-70 DEG C and under vacuity of 0.08-1.00Mpa, and removing oil to obtain the gourd fried at low temperature under vacuum. Effective biological active substances in the bitter gourd cannot be damaged by high temperature, original nutrients of the fried bitter gourd are retained, and the fried bitter gourd is crispy. Especially, bitter substances, mainly charantin, are dissolved in alcohol, and accordingly the bitterness is removed greatly, the problem that the bitter gourd is unpleasant to eat is solved, and the fried bitter gourd is cooler. The fried bitter gourd can be produced mechanically and automatically on a large scale, is safe and sanitary and completely meets the processing requirements of modern agricultural products.

Owner:KUNMING JIADE AGRI PROD DEV

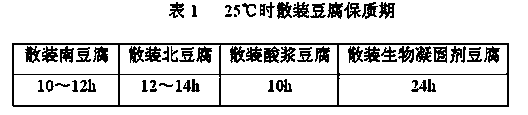

Method for prolonging expiration date of bean curd

The invention relates to a method for prolonging the expiration date of bean curd and belongs to foods and the technical field of food processing. The method is a physical preservation method harmless to the texture of the bean curd and comprises the steps of putting the prepared fresh bean curd into a sterile box, pouring yellow seriflux into the sterile box until exactly submerging the bean curd, and sealing the sterile box by utilizing a polyvinyl plastic film. The method is a preservation technique harmless to the texture of the bean curd and has the beneficial effects that no preservative is added, the requirement of people on pursuing greed foods is met, and the disadvantages that the texture of the bean curd is changed, and the taste of the bean curd is declined when the bean curd preserved by utilizing existing physical methods are overcome.

Owner:贵州智汇工匠科技有限公司

Pretreatment method for day lily buds before flue-curing barn drying

InactiveCN107019179AInhibit decay and deteriorationPromote maturityFruit and vegetables preservationFood ingredient as colourFood additivePretreatment method

The invention discloses a pretreatment method for day lily buds before flue-curing barn drying. The pretreatment method comprises the following steps: firstly utilizing cooled boiling water, natamycin and kojic acid to prepare biological preservation solution, soaking picked day lily buds in the biological preservation solution for 20 to 30 minutes, fishing out, sealing, packaging and storing for 1 to 2 days in room temperature to inhibit blooming; then utilizing the natamycin, the kojic acid, 40% ethephon aqueous solution and methyl jasmonate to prepare a chlorox; soaking the pretreated day lily buds losing blooming capacity in the chlorox for 1 to 2 hours under room temperature condition, fishing out, sealing, storing for 2 to 3 days, fading green and presenting yellow. According to the pretreatment method, biological food additives are utilized under low temperature condition, so that the problem of food security caused by chemical additives is avoided. The pretreatment method disclosed by the invention is simple, and is suitable for village farmers, small and micro enterprises and scale enterprises to use and the processing cost is low.

Owner:HUNAN AGRICULTURAL UNIV

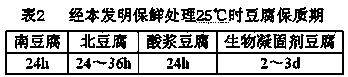

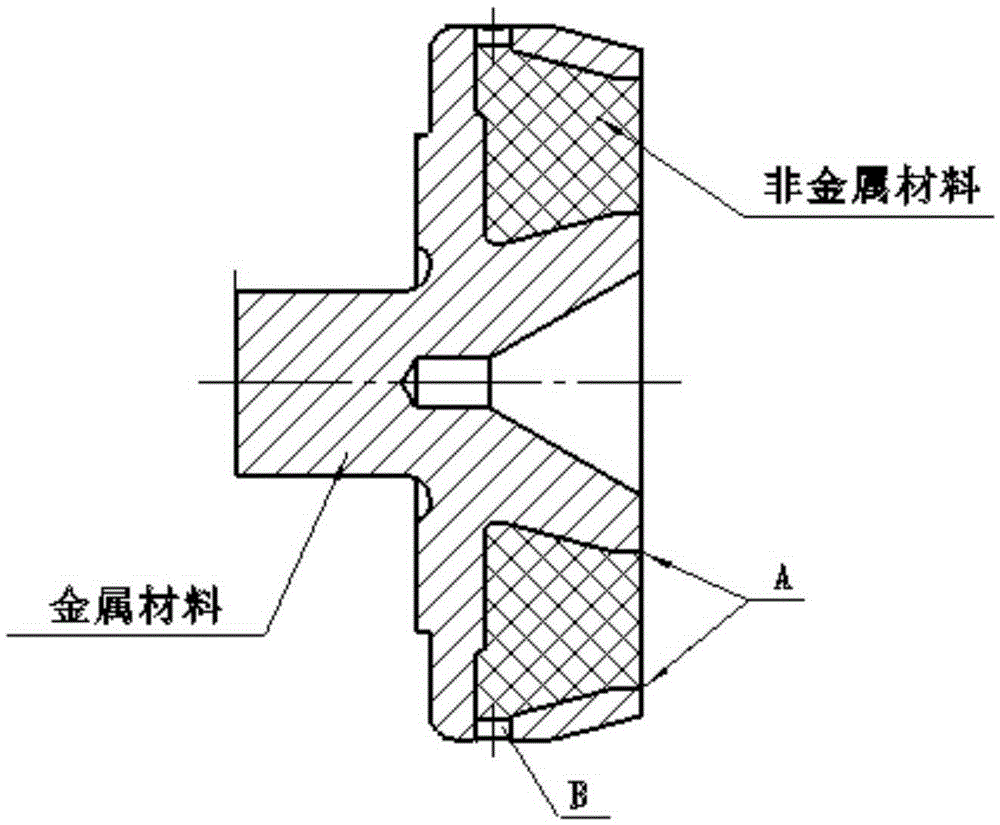

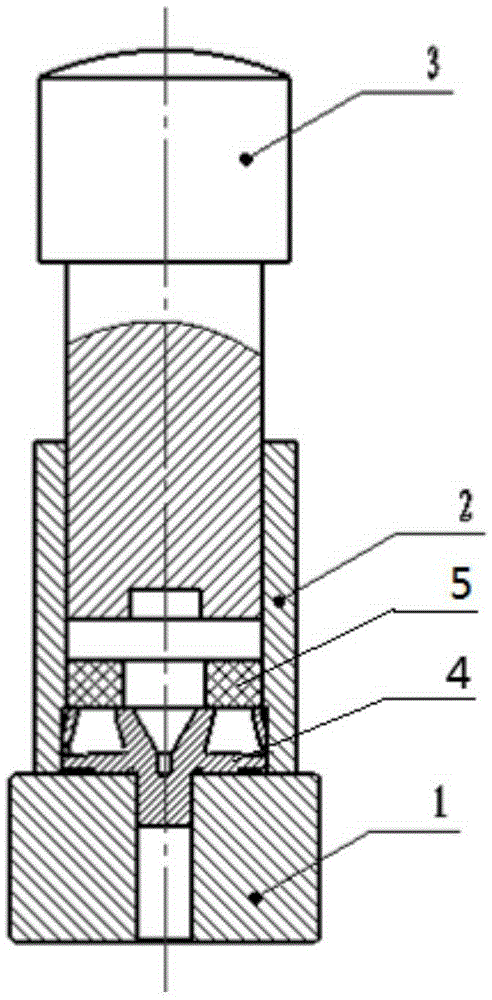

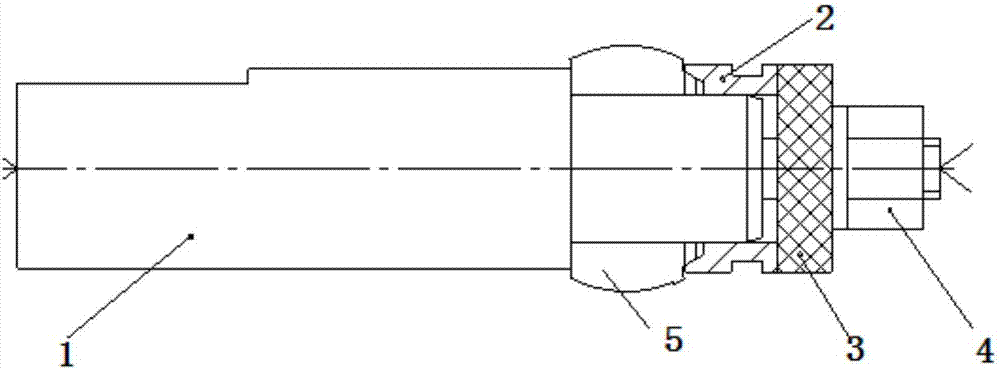

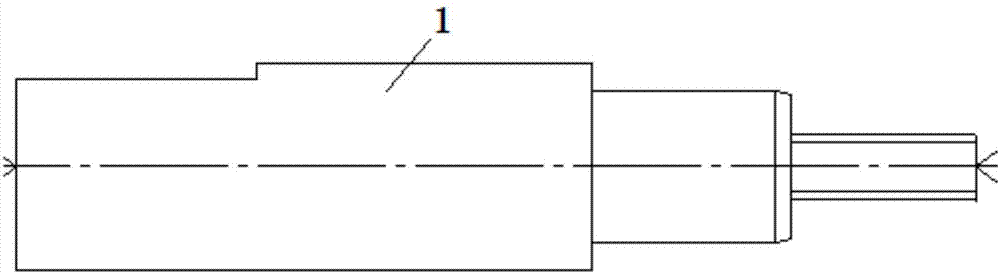

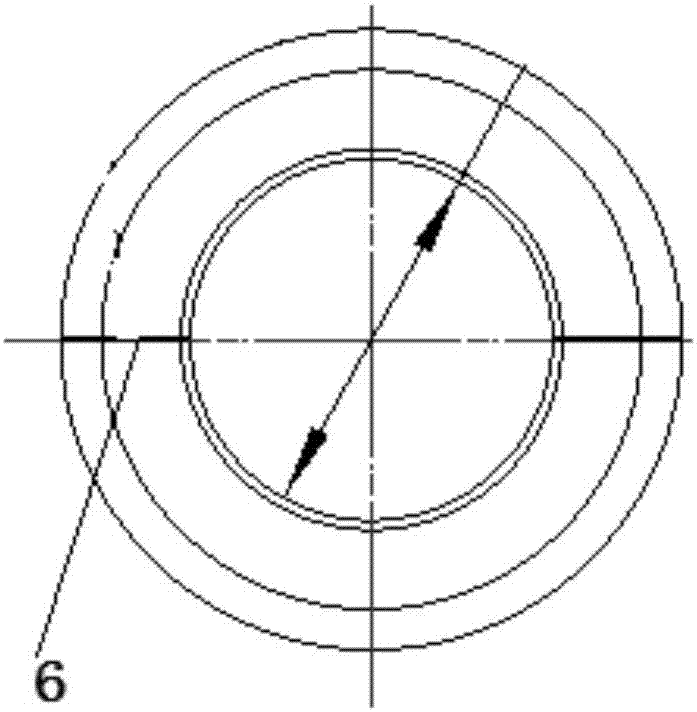

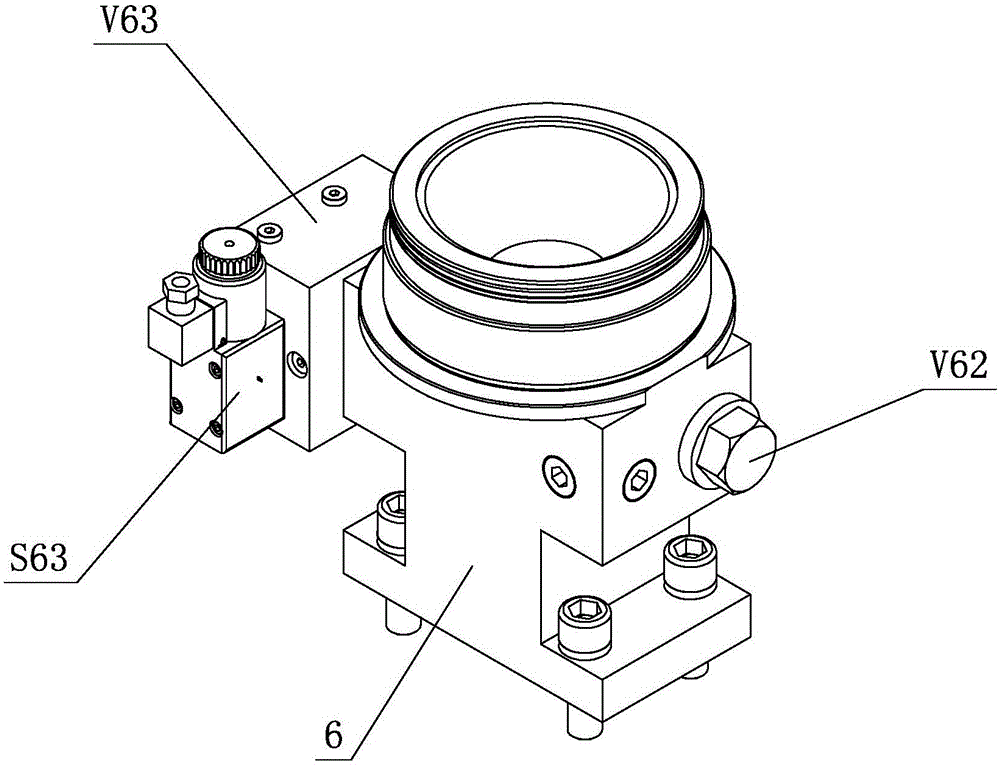

Sealing assembly assembling tool and method

InactiveCN105252481AEliminate Assembly DefectsMeet assembly requirementsMetal-working hand toolsPunchingEngineering

The invention provides a sealing assembly assembling tool and method. The tool comprises a base, a positioning sleeve arranged at the upper end of the base in a matched manner, and a punch arranged in the positioning sleeve in a sleeved manner. The base is provided with a positioning hole used for containing a small end outer cylinder face of a metal component. The large end of the positioning sleeve is used for being arranged on a large end outer cylinder face of the metal component in a sleeving manner. The small end inner diameter part and the outer diameter part of a non-metal component are matched in a sleeved manner. The punching end of the punch is a protruding annular punch. The outer diameter of the punch is the same as the outer diameter of the non-metal component. The positions of to-be-assembled components in a clamp are limited by adding the positioning sleeve, the component base and the punch of the clamp and the two to-be-assembled components are connected through the positioning sleeve in series and are kept with the center consistency. The assembling defects caused by the fact that in an original assembly clamp, positioning elements are lacked, and the assembling positions of the to-be-assembled components are not determined are eliminated. The assembling requirement can be met, the design and concept are ingenious, and the structure is compact; and the manufacturing cost is low, using is easy, and operation is convenient.

Owner:AECC AVIATION POWER CO LTD

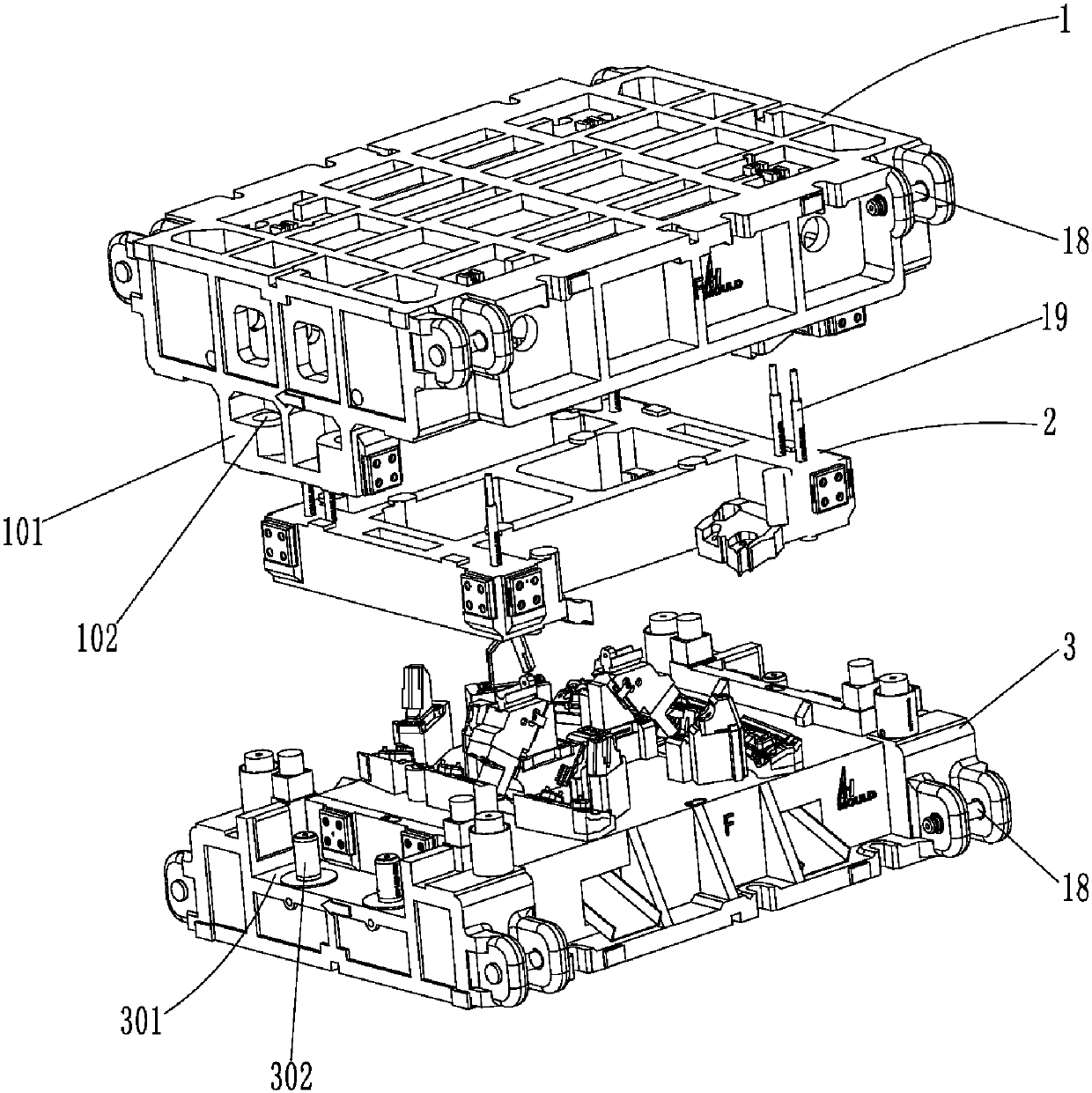

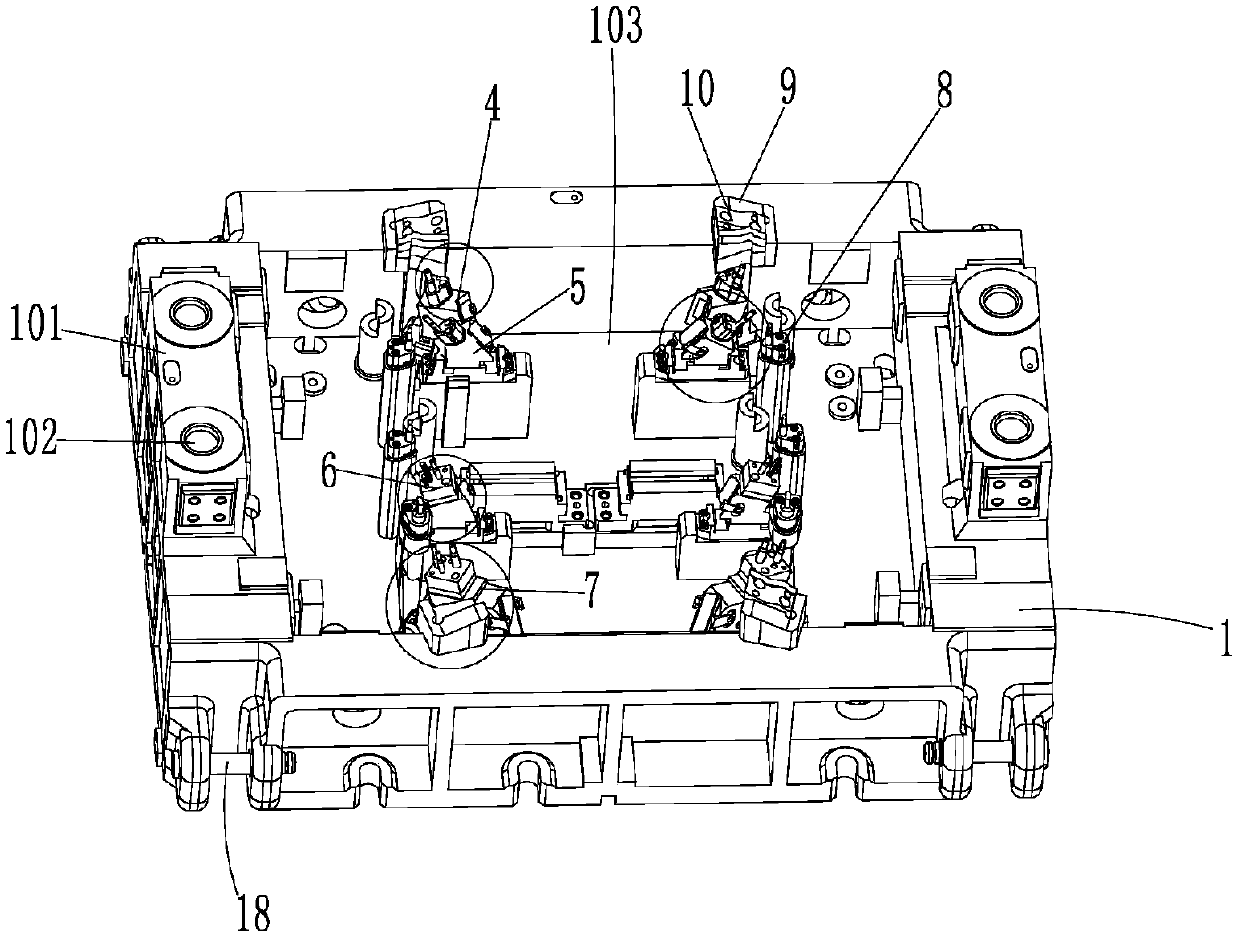

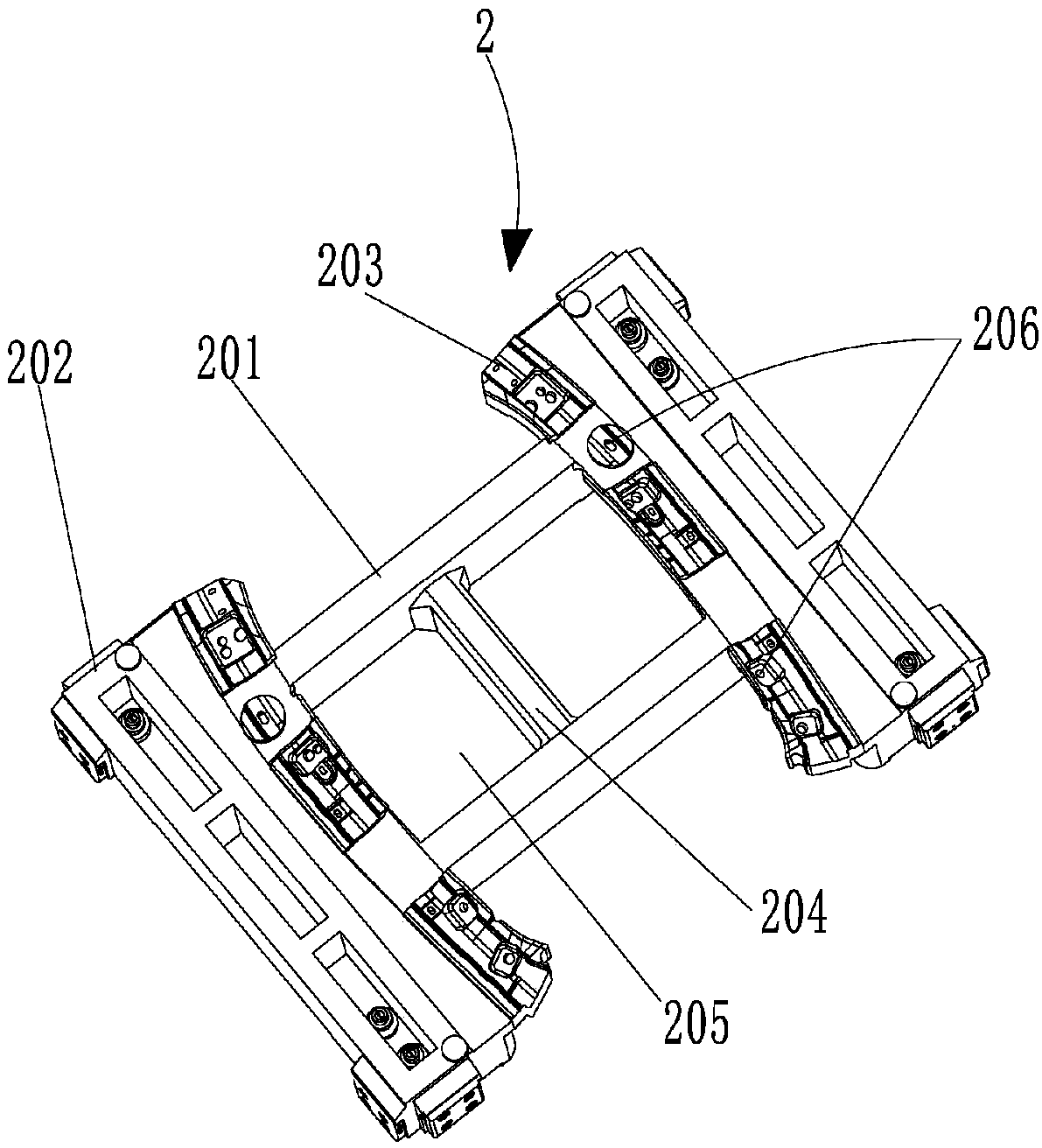

Arc plate porous machining mold

PendingCN107803425AAvoid secondary deformationAvoid multiple processingShaping toolsPerforating toolsFixed rampEngineering

The invention provides an arc plate porous machining mold. The arc plate porous machining mold comprises an upper mold, a lower mold and a material press; a mounting groove is formed in the middle part of the upper mold; two sets of inclined surface punching mechanisms are fixed in the mounting groove; three sets of plane punching modules are arranged on the outer sides of the two sets of inclinedsurface punching mechanisms; the material press comprises a rectangular frame, and mounting parts positioned at two ends of the rectangular frame; pressing blocks with arc structures are arranged attwo ends of the rectangular frame; multiple via holes matched with the inclined surface punching mechanisms and the plane punching modules are formed in the top surfaces of the pressing blocks; the mounting parts are connected to a top plate of the upper mold through multiple travel limiting rods; two sets of slide guide rails matched with the inclined surface punching mechanisms are arranged at the middle part of the upper surface of the lower mold; positioning blocks are arranged on the outer sides of the slide guide rails; and the positioning blocks are provided with punching concave moldscapable of moving through matching with punches. In the punching process, arc plates cannot move, and concave surfaces of the pressing blocks and concave surfaces of the positioning blocks can be matched with the structures of the arc plates, so that secondary deformation of the arc plates caused by the extrusion process is prevented.

Owner:重庆安亚模具制造有限公司

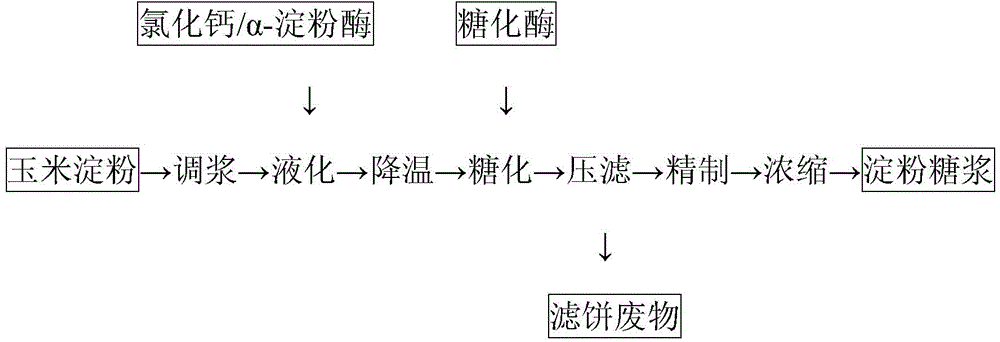

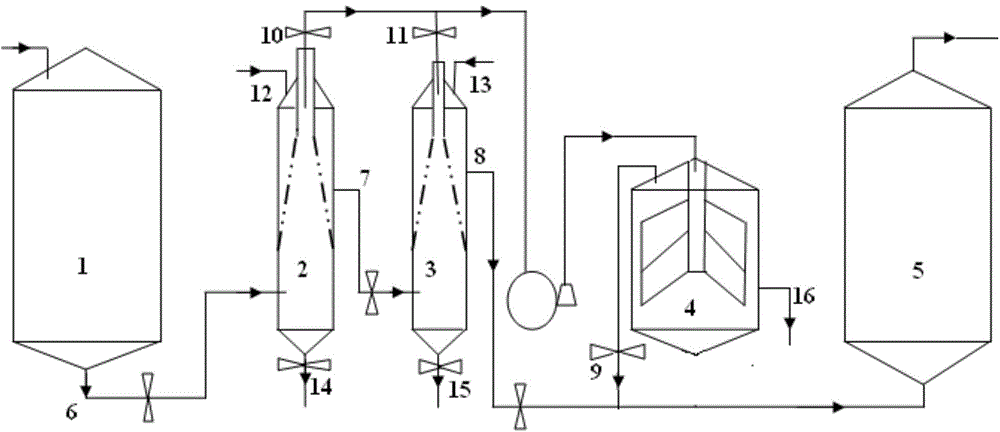

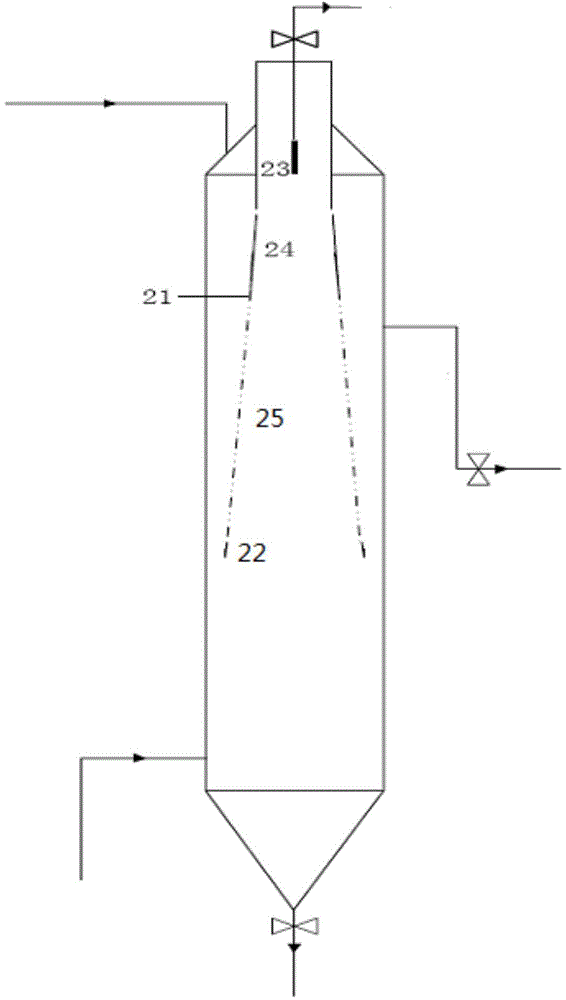

Separating device and method for enzymatic starch sugar sugar-free grains enrichment

ActiveCN104862428AEasy to filter and refineImprove efficiencyBiomass after-treatmentGlucose productionMoistureVacuum drying

The invention discloses a separating device and a separating method for enzymatic starch sugar sugar-free grains enrichment. The separating device for the enzymatic starch sugar sugar-free grains enrichment is mainly composed of a saccharifying tank, a first sugar-free grains separator, a second sugar-free grains separator, a horizontal screw type centrifugal machine and a bleaching tank, wherein the first sugar-free grains separator and the second sugar-free grains separator have same structures, are both cylindrical cavity tank bodies, the cylindrical cavity tank bodies are both provided with reverse funnel shaped filtering devices, the reverse funnel shaped filtering devices are hollow vertebral bodies with small upper ends and big lower ends, and an included angle between conical faces of the vertebral bodies and the first sugar-free grains separator or the second sugar-free grains separator are from 10 degree to 25 degree, a plurality of opening holes are formed in the middle portions of the conical faces of the vertebral bodies, and lower portion densification areas, opening holes areas and upper portion densification areas are formed in the conical faces of the vertebral bodies from the bottom up. The separating method for the enzymatic starch sugar sugar-free grains enrichment includes: using the centrifugal machine to wash sugar-free grains filter cakes, wherein the washed sugar-free grains filter cakes adsorb and mingle with little sugar, and contain no inorganic additive, sending the sugar-free grains filter cakes to a vacuum drying oven or a pneumatic dryer and drying to moisture<=10%, and then smashing, sifting out, and packing so as to obtain solid sugar-free grains products which can be used as organic albumen nitrogen sources used for fodders or fermentation.

Owner:SOUTH CHINA UNIV OF TECH +1

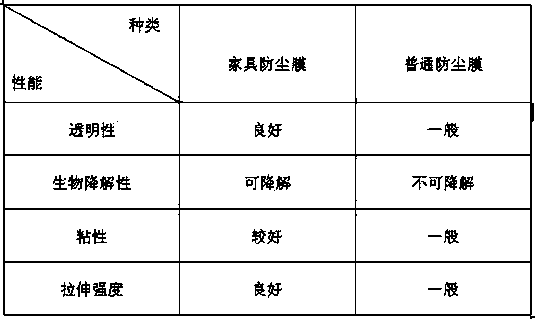

Dustproof film for furniture and preparation method thereof

The invention relates to a dustproof film for furniture and a preparation method thereof. The preparation method of the dustproof film for furniture comprises the following steps: performing subtraction modification on konjac glucomannan, blending, degassing, pouring into a plate to make the film and stripping the film. As the konjac glucomannan is used as a carrier together with other additives, the film has excellent filming property, water-tightness and antibacterial property, high tensile strength and good flexibility; as the konjac glucomannan is used as a main material of the dustproof film for furniture, compared with the conventional PVC (Polyvinyl Chloride) material film, the film is high in tensile strength, good in transparency, good in flexibility and high in antibacterial effect. The dustproof film for furniture is superior to an ordinary dustproof film in transparency, and does not damage the original color when adhered to furniture. Besides, the dustproof film for furniture is good in flexibility and is durable; as furniture is frequently touched by people and bacteria are likely to propagate on furniture, the dustproof film also has good antibacterial property, which is very important; and the film can be degraded without causing pollution.

Owner:FUJIAN AGRI & FORESTRY UNIV

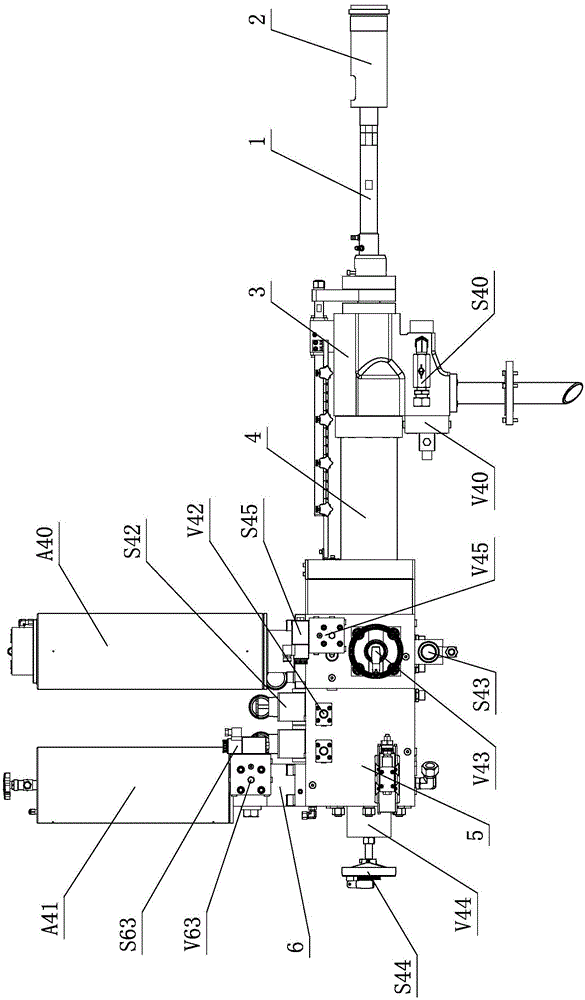

Machining device used for split-type ball bearing and machining method thereof

InactiveCN107570973AGuaranteed beatBeating meetsLarge fixed membersPositioning apparatusBall bearingGasket

The invention discloses a machining device used for a split-type ball bearing. A core shaft with one end being a stepped shaft is arranged, and a to-be-machined part, a limiting ring, a gasket and a nut are sequentially mounted on the stepped shaft of the core shaft; one end of the to-be-machined part makes contact with the end face of a shaft shoulder of the core shaft, and the other end of the to-be-machined part makes contact with one end of the limiting ring; and the other end of the limiting ring makes contact with the gasket, and the other end of the gasket makes contact with one end ofthe nut. Two to-be-machined semi-ball bearings are simultaneously clamped by the core shaft with the stepped shaft and then are closely combined through the limiting ring to ensure that jumping of theparts conforms to machining requirements. According to the machining device used for the split-type ball bearing, machining of the two semi-ball bearings in pairs is achieved, the machining device isreliable and safe in using, so that machining efficiency is doubled, and the material utilization of products is increased by one time.

Owner:AECC AVIATION POWER CO LTD

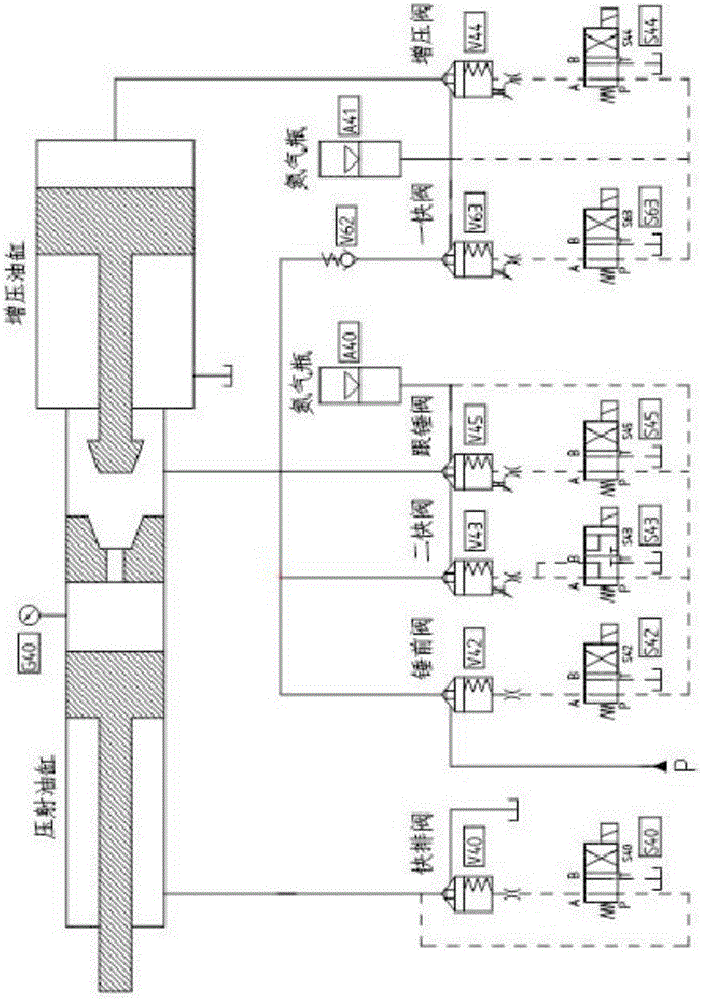

Injection pressure-boosting and speed-increasing structure of die casting machine

The invention discloses an injection pressure-boosting and speed-increasing structure of a die casting machine. The injection pressure-boosting and speed-increasing structure comprises an injection punch, wherein an injection part is arranged at one side of the injection punch; an injection oil cylinder, an injection piston rod and a pressure-boosting oil cylinder are sequentially arranged at the other side of the injection punch; a pressure-boosting cavity is formed between the injection piston rod and the pressure-boosting oil cylinder; and a primarily quick oil path block assembly and a secondarily quick oil path block assembly are arranged on the pressure-boosting oil cylinder. According to the injection pressure-boosting and speed-increasing structure, the speed of the primarily quick action and the secondarily quick action is increased by a design method and a control mode which are combined with a practical production process, so that requirements of producing thin-wall parts such as a magnesium alloy mobile phone middle plate and the like are met, and a common horizontal type cold chamber die casting machine is transformed into a special die casting machine for thin-wall parts represented by the die-cast magnesium alloy mobile phone middle plate; the modified die casting machine can realize that cast pieces are full, less in shrinkage cavities, smooth in surface, good in smoothness, free of flow marks, less in flanges, free of air bubbles and flaws and high in practicability, and meet processing requirements.

Owner:佛山联升压铸科技有限公司

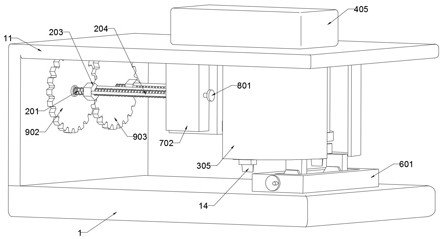

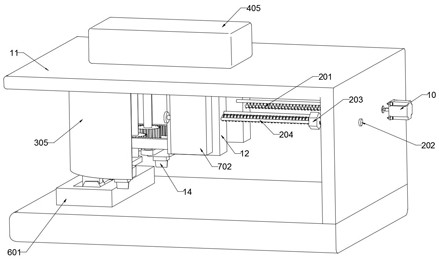

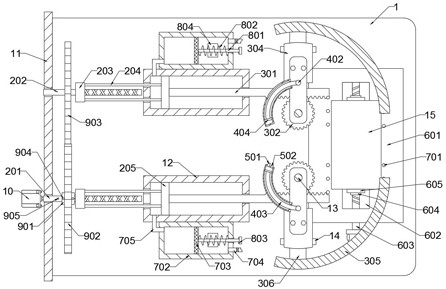

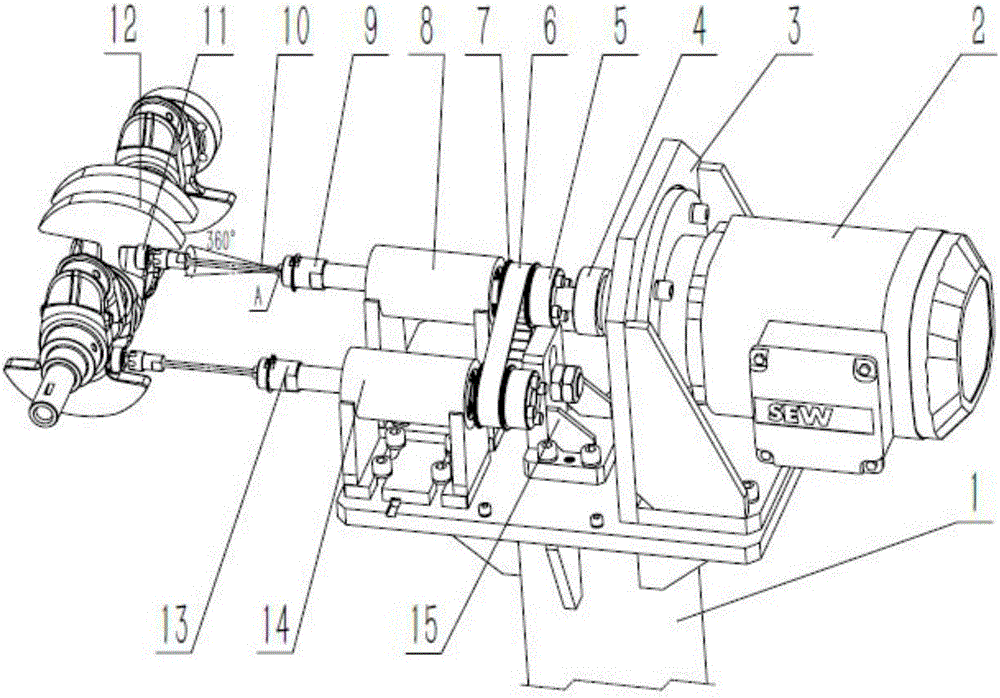

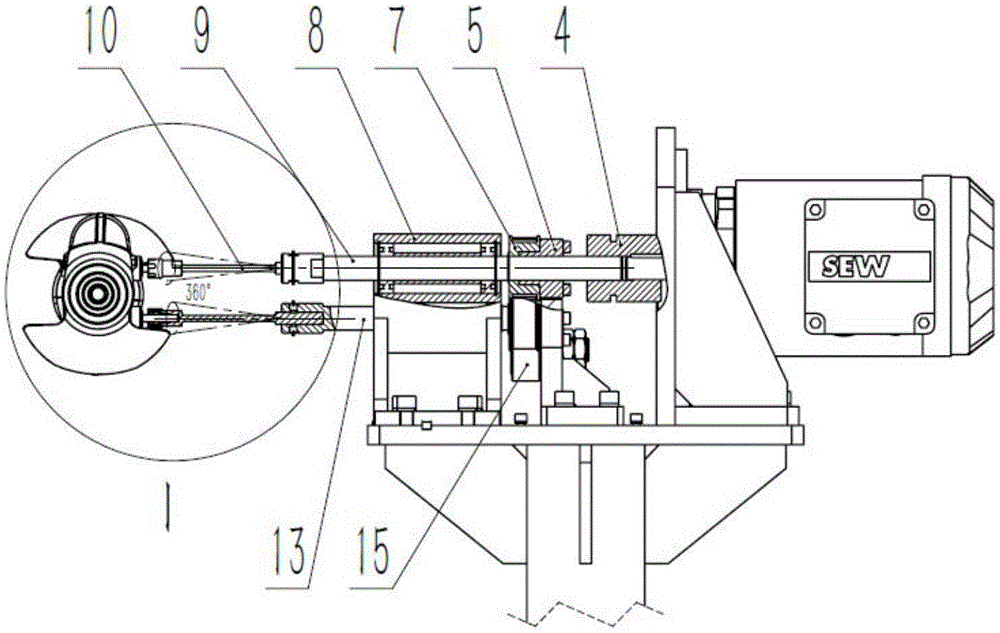

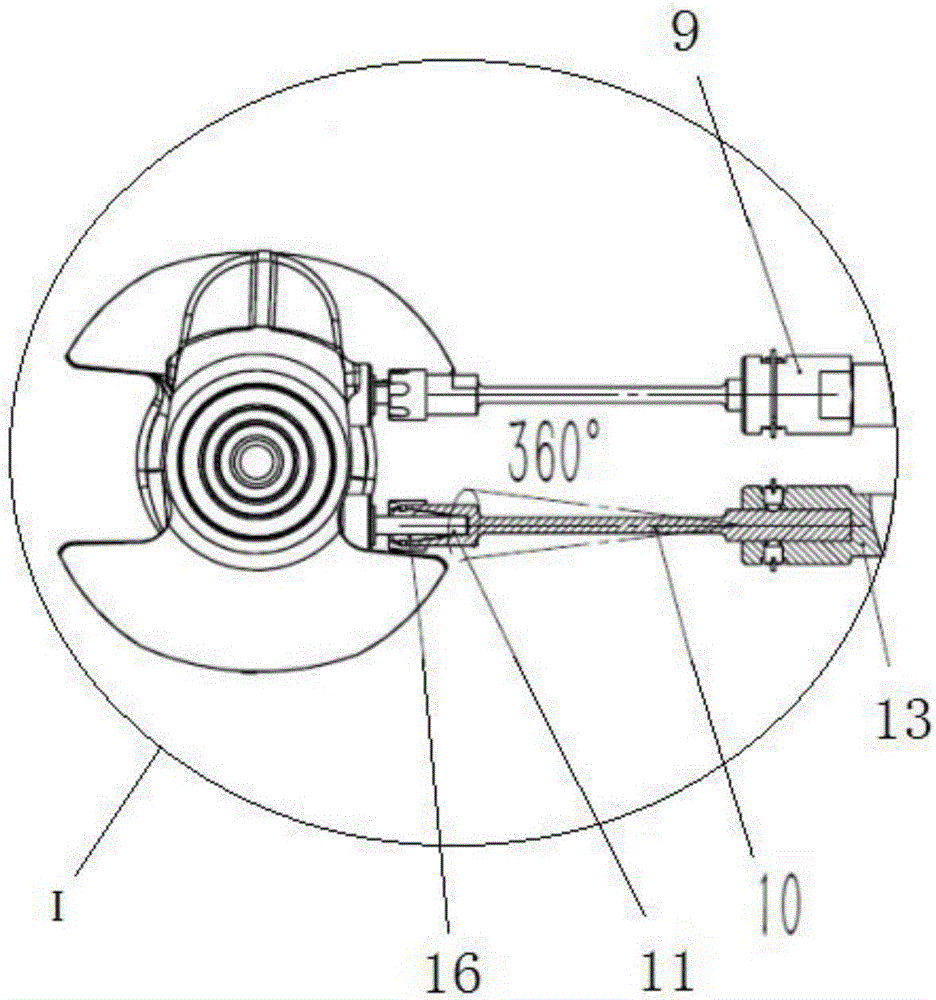

Shearing machine for lens production and processing

ActiveCN113386270AComply with processing requirementsAvoid wastingDirt cleaningWorking accessoriesGear wheelMachine

The invention discloses a shearing machine for lens production and processing. The shearing machine for lens production and processing comprises a base and a lens, a supporting plate is fixedly arranged on the base, the supporting plate is of an inverted-L-shaped structure, box bodies are symmetrically and fixedly arranged on the inner wall of the top of the supporting plate, a shearing mechanism is slidably connected to the inner walls of the box bodies in a penetrating mode, the shearing mechanism comprises a rack slidably connected to the inner walls of the box bodies, rotating rods are symmetrically and rotatably connected to the inner wall of the top of the supporting plate, gears are coaxially and fixedly arranged on the rotating rods, rotating seats are fixedly connected to the side walls of the rotating rods, supporting seats are fixedly connected to the inner walls of the rotating seats through bolts, shearing machine bodies are installed on the bottom walls of the supporting seats, arc-shaped sliding rails are symmetrically and fixedly arranged on the inner wall of the top of the supporting plate, and sliding blocks are fixedly connected to the supporting seats. According to the shearing machine for lens production and machining, the two symmetrically-arranged shearing machine bodies can synchronously carry out shearing work or independently carry out shearing, the shearing track of each shearing machine is in an arc shape, the requirement for lens machining at present is met, and the application range of the shearing machine is widened.

Owner:南通山森光学科技有限公司

Double-step floating burr removing device of crankshafts and machining method

InactiveCN106553104AAvoid rigid contactSimple structureEdge grinding machinesGrinding carriagesDrive shaftEngineering

The invention discloses a double-step floating burr removing device of crankshafts. The device comprises a speed reduction motor, a coupler, a main drive shaft, an auxiliary transmission shaft, a synchronous belt, a synchronous pulley, flexible cutter bars, brushes and the like, wherein an input end of the main drive shaft is connected to an output shaft of the speed reduction motor, one flexible cutter bar is arranged at an output end of the main drive shaft, an input end of the auxiliary transmission shaft is connected to the input end of the main drive shaft through the synchronous pulley and the synchronous belt, and the other flexible cutter bar is arranged at an output end of the auxiliary transmission shaft. Flexible chucks used for fixedly installing the brushes are arranged in ends of the flexible cutter bars. The device has the effects that the overall structure is simple; the main drive shaft and the auxiliary transmission shaft are connected through the synchronous pulley and the synchronous belt, the rotation driving force from the motor is divided into two parts so as to realize simultaneous feeding machining, and the machining efficiency is improved; and the flexible cutter bars are matched with a robot to remove burrs, rigid contact between cutters and work-pieces is prevented, and the service life of equipment is prolonged. The invention further provides a machining method of the device. The method has the advantages that the machining steps are simplified, and the qualification rate of products is high.

Owner:CHANGSHA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com